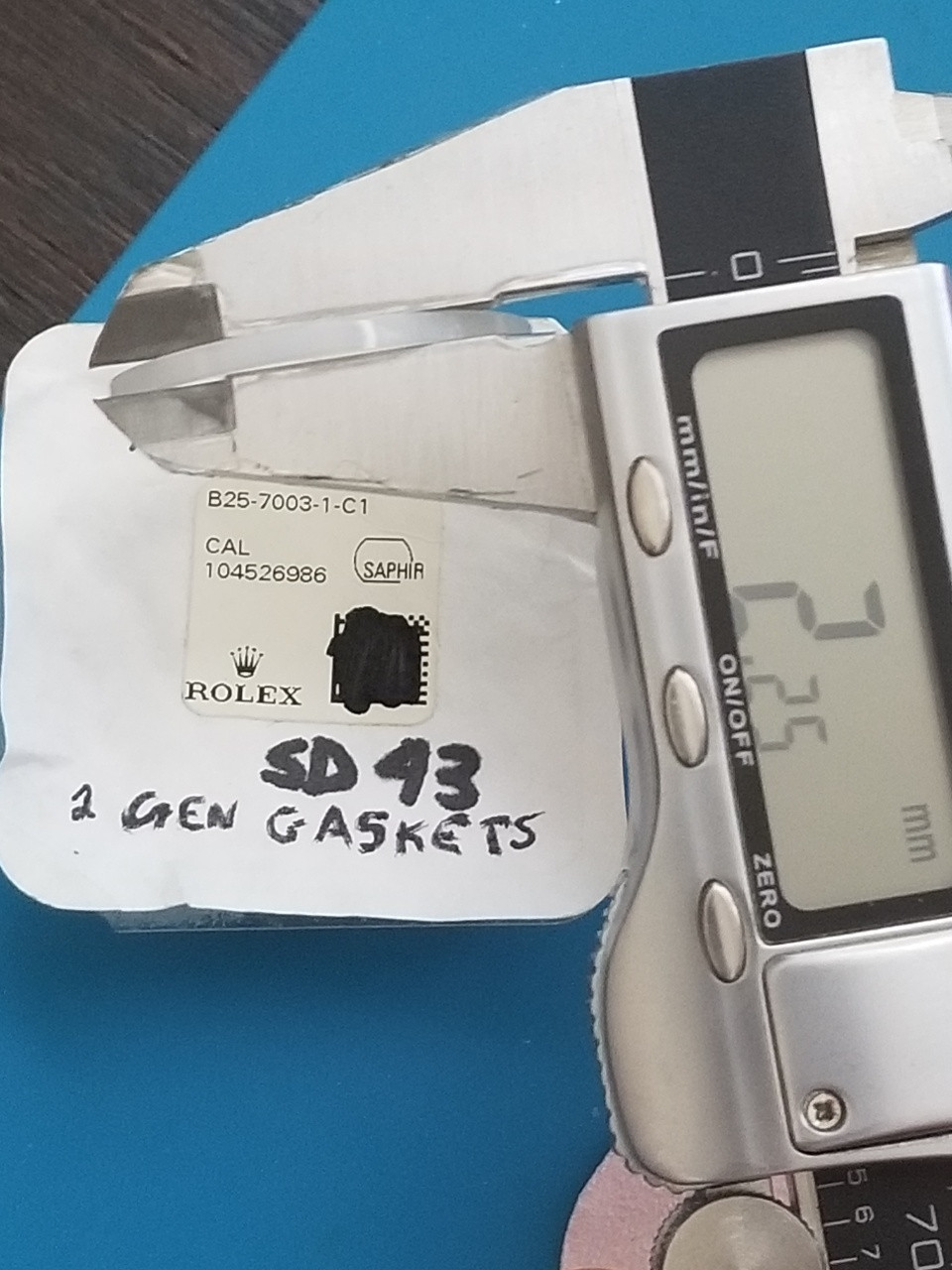

Hi, I was about to replace the crystal in my Clean Rolex 126600 Sea-Dweller with a genuine crystal and gasket.

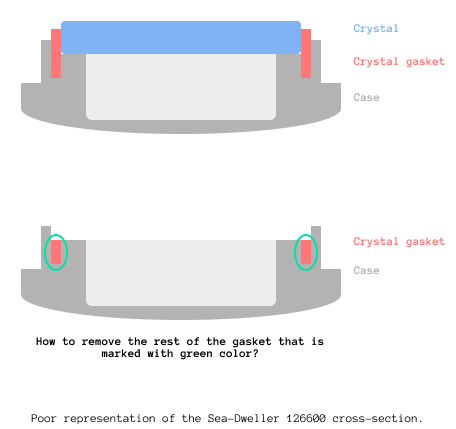

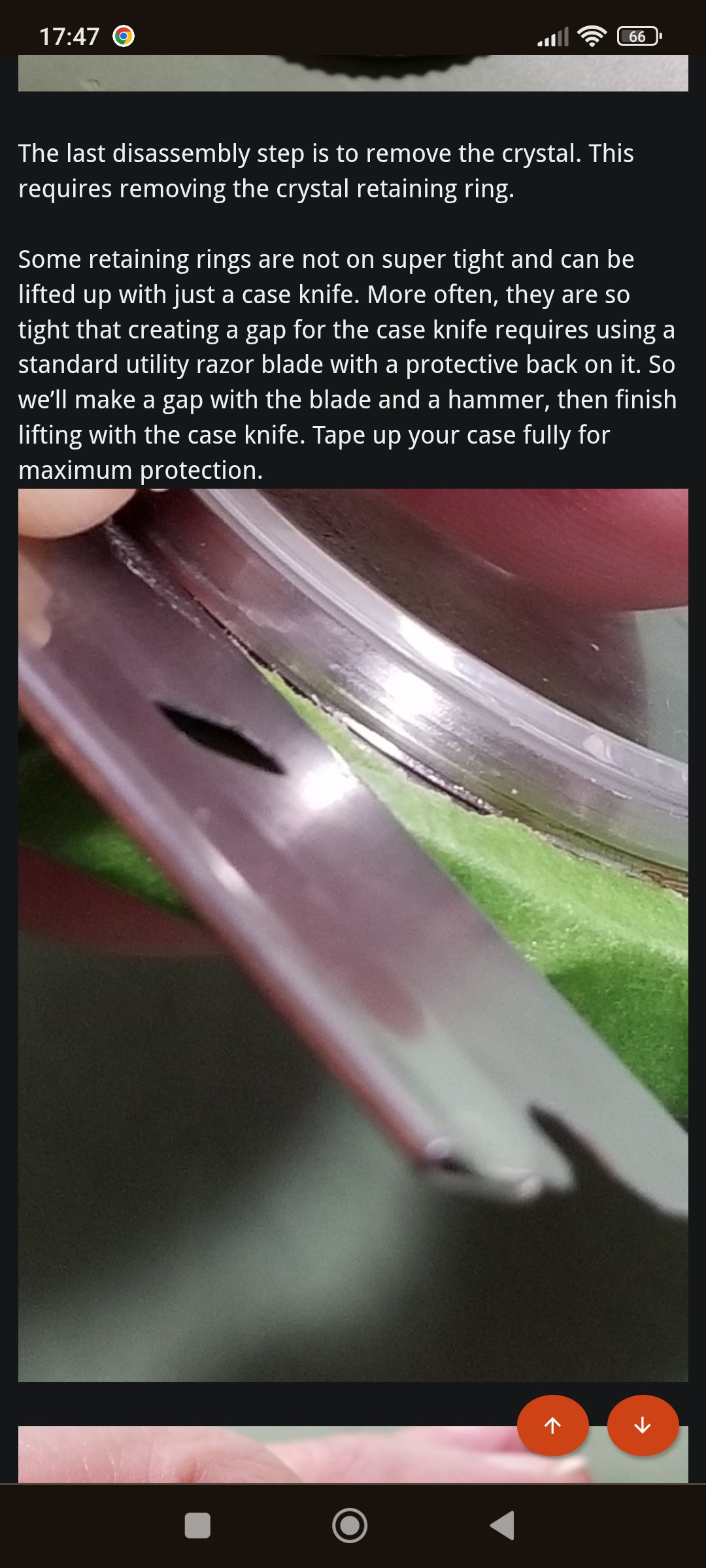

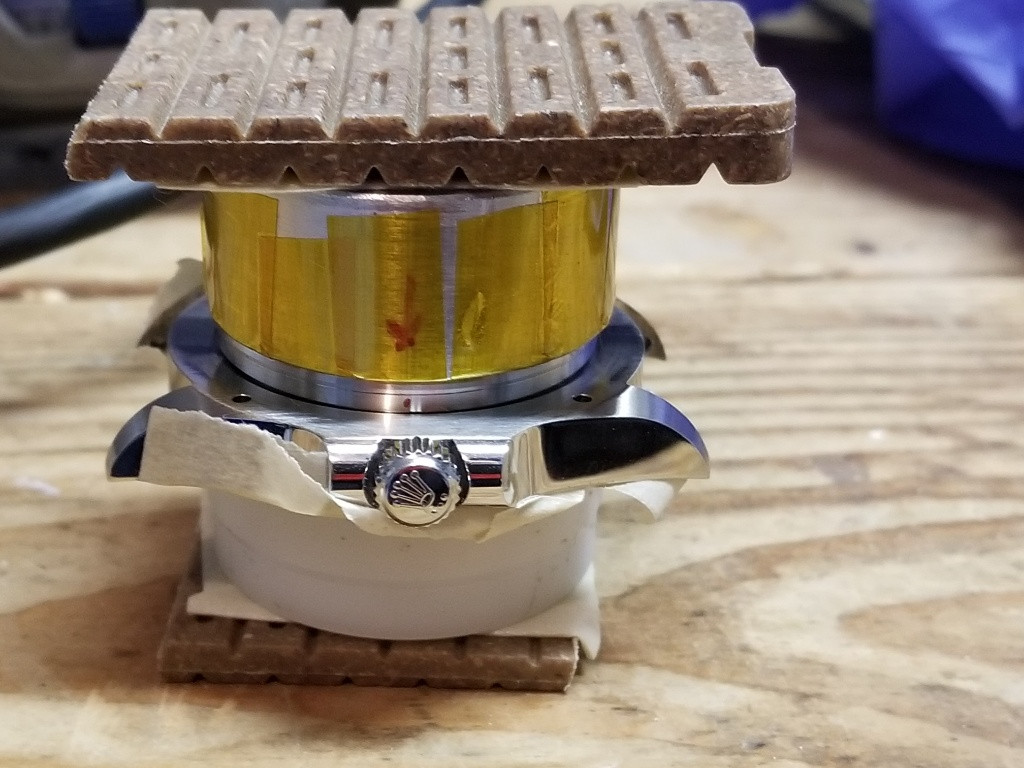

It wasn’t possible to easily remove the gasket — it’s pressed in so tightly that I ended up cutting it out piece by piece. When I started, I didn’t realize how deeply it was seated in the watch case. I’ve stopped at the point where the upper half of the gasket has been removed, but the remaining part is still stuck in the groove in the case. From what I know, the gasket is made of PTFE or a similar material.

Do you have any ideas on how to remove the remaining part of the gasket from a groove that's about 0.4mm wide? I’ve tried using a very thin screwdriver, but it’s completely unsuitable for the task. I also tried a soldering iron with a thin 0.4mm copper wire attached, heated to 200/300/400°C — the gasket started to melt slightly, but it was very ineffective and I gave up on that method. That’s why I’m now looking for other solutions.

I’ll add that I have a 3D printer and the ability to design my own tools. I was considering something like a hole saw with sandpaper or an abrasive edge that could grind down the gasket. But maybe there are better and more effective solutions?

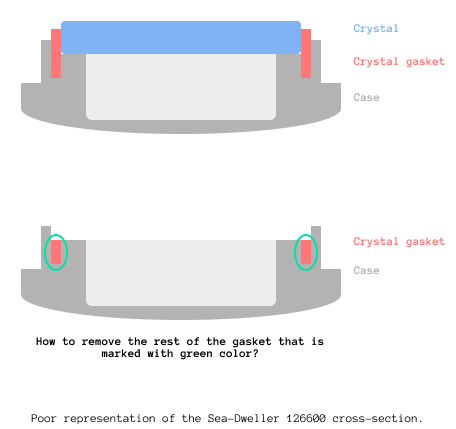

Here photo and visualization of the situation:

It wasn’t possible to easily remove the gasket — it’s pressed in so tightly that I ended up cutting it out piece by piece. When I started, I didn’t realize how deeply it was seated in the watch case. I’ve stopped at the point where the upper half of the gasket has been removed, but the remaining part is still stuck in the groove in the case. From what I know, the gasket is made of PTFE or a similar material.

Do you have any ideas on how to remove the remaining part of the gasket from a groove that's about 0.4mm wide? I’ve tried using a very thin screwdriver, but it’s completely unsuitable for the task. I also tried a soldering iron with a thin 0.4mm copper wire attached, heated to 200/300/400°C — the gasket started to melt slightly, but it was very ineffective and I gave up on that method. That’s why I’m now looking for other solutions.

I’ll add that I have a 3D printer and the ability to design my own tools. I was considering something like a hole saw with sandpaper or an abrasive edge that could grind down the gasket. But maybe there are better and more effective solutions?

Here photo and visualization of the situation: