chubbychaser911

Active Member

- 31/10/19

- 405

- 112

- 43

So this week, in "slow progress" news, I have done the following:

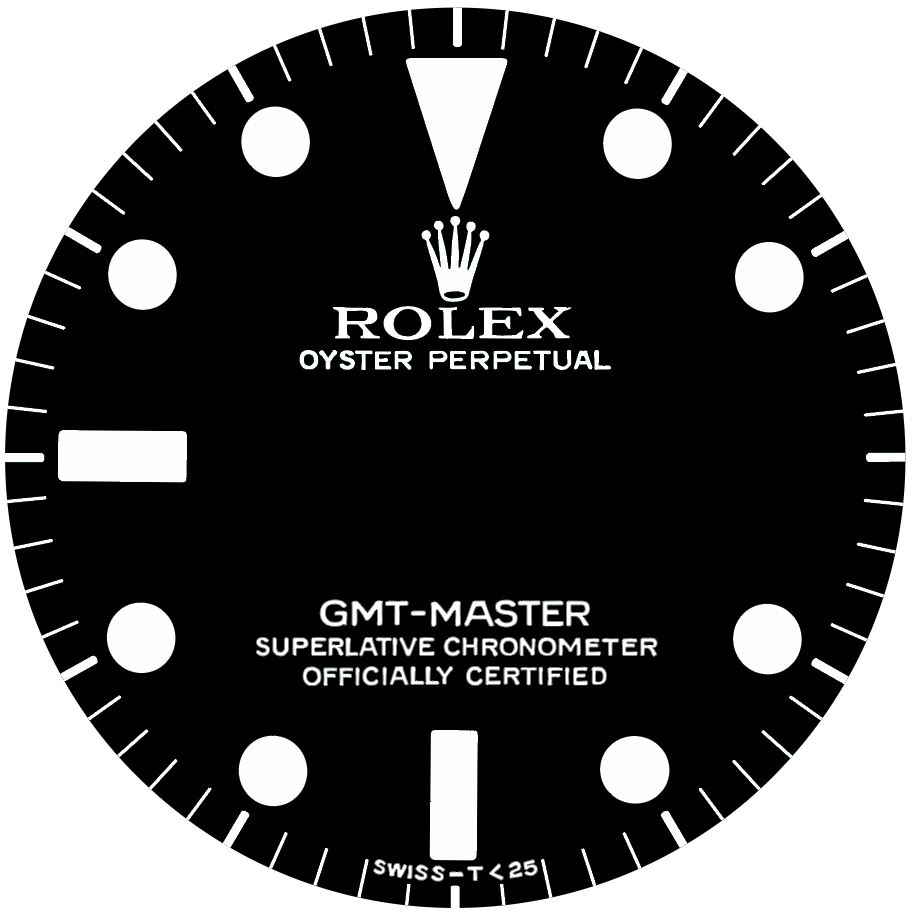

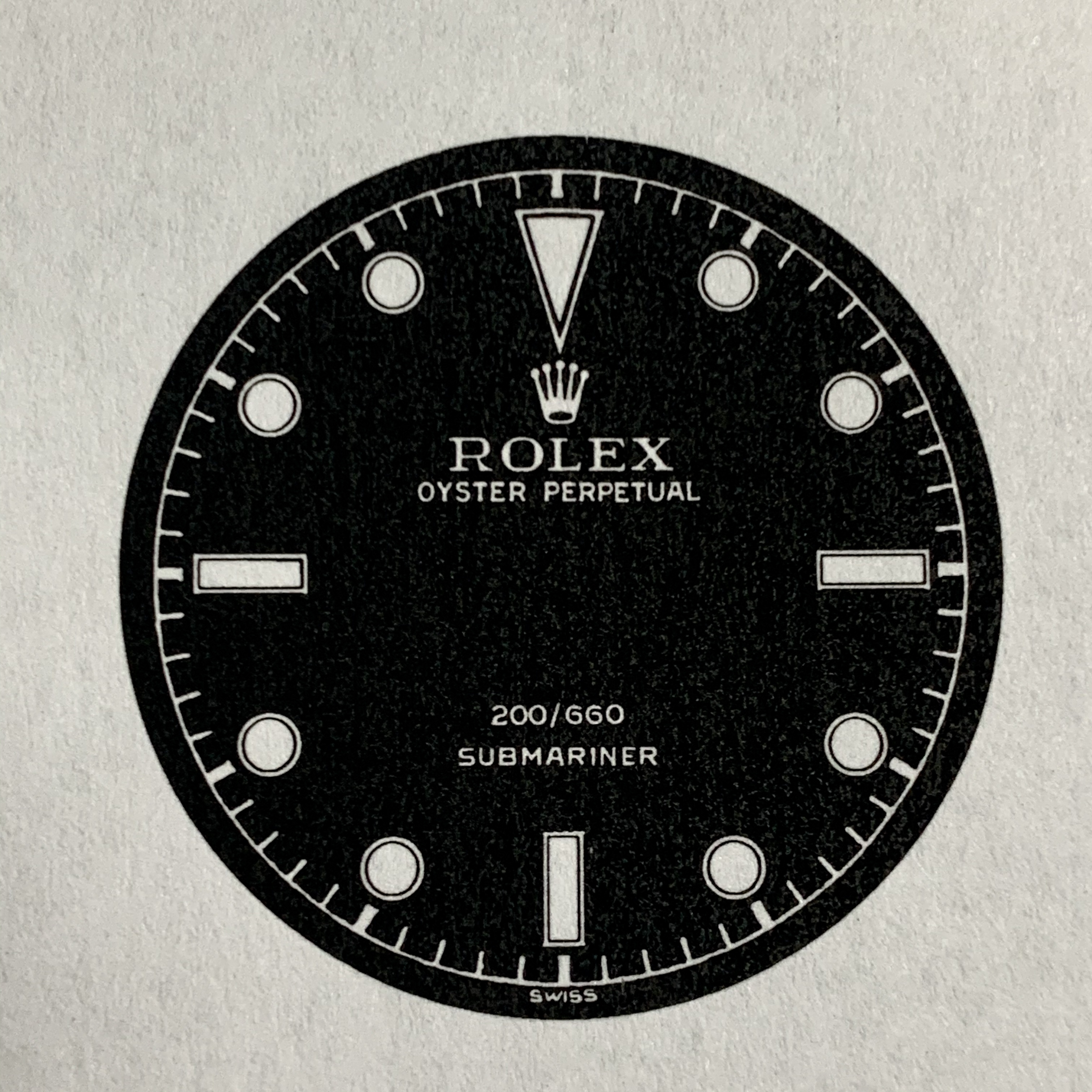

Here's the first Sub dial test print - I'm really happy with how the detail is reproduced. Note that this print was just on plain cheap paper, which is why it looks "textured". Plus the level of black isn't as good as it will be on smooth decal film. Oh, and the design will be different for the GMT...

- Decided to shelve the idea of making one good ETA from two broken ETAs (given my almost complete lack of watchsmitherying skillz), and am waiting for an HZ6460 (2836-2 GMT clone) I also ordered to arrive from the eBay seller.

- Saw a nice leather strap on a GMT that someone was selling here and inspired by its simple good looks, I've bought some tools and waxed thread (I already had some leather), and started making my first leather strap.

- Resurrected my dial printing efforts, and to that end found a mono A4 laser printer that prints to 1200 x 1200 dpi. Test printing one of my Sub dial designs, it looks really promising, amazing for a printer that cost the same as a bad Gate rep..!

I'll post pics of the strap(s) as I work on the project. I'm planning to make a two-piece conventional strap, and also a leather NATO.Yay! Love the DIY strap project, I am very curious how it will look. And the test dial is very promising indeed! Where do you source your blanks? Will you gold plate or use brass gilt?

Has anyone successfully sanded their insert to fit their bezel? I'm very close to getting it to fit. Just wondering if there is a particular angle I need to sand at so that it pops into the bezel and snaps in. I'm okay with adhesive if necessary but would prefer a snap in assembly.

i have sanded a gen insert actually on my 1675, Just have to go very slowly evenly all around and it fits perfectly

That’s an interesting thought cc911... It would be great if someone else could confirm whether or not this is correct. Should we shave the diameter or thickness on the insert to get it to fit?I think instead of sanding down the diameter, one should sand down the thickness to get it to snap in.

For the milk bezel and milk bezel insert I have the diameter just right but I think the insert is a little too thick and can't catch under the lip of the bezel. I could be wrong. I had it basically snapping in but wouldn't hold because it was above the lip of the bezel. So like a dumbass I sanded it some more. Now I have an insert that is exactly the same size as the bezel and almost snaps because it is a nanometer bigger than the bezel but it isn't just enough to snap. I believe my error was not sanding away thickness. In short, I think that for the milk bezel it is necessary to sand for thickness once you get the diameter almost right. In fact, I think maybe starting the sanding process to address thickness is better than starting the sanding process to address diameter.

For now I will use an adhesive ring and buy another bezel insert to test my theory.

On the positive side I'm super happy with my crown guards.

I'll post pics of the strap(s) as I work on the project. I'm planning to make a two-piece conventional strap, and also a leather NATO.

I was gifted a scrap GMT dial by another member which I'll be using - there being no ready source for blanks, at least according to Bart Cordell's lengthy "Decal Printed Dial" thread. You simply sand the donor scrap dial back to the brass.

I've done test runs on a 29mm big crown dial with the design above, using waterslide decal film, and it looks great. But currently I'm waiting on a pack of film free decal paper and glue from "Sunnyscopa", which should give the best possible results. It can be tricky to transfer the image and remove the film successfully though, so we'll see..! There's always the waterslide method to fall back on.

YES! I definitely will!Dude make a bund strap also. Would look sick.

Very sound and logical analysis there cc911, which is the sort of thing that keeps me focused, so thanks!Thinking further on this. So the bezel insert from milk has an outer diameter that is too wide for the bezel. I’d take an edge of your insert and see if it has a chance at snapping into the lip. If so then start on the diameter. If not then start on thickness. And I’d go back and forth between diameter and thickness depending on what you’re seeing with each test fit. Because either or both of those dimensions may be the issue. Imagine that you Take off some diameter and then you’re at a thicker part of the insert. Now you need to take off thickness. I think the key is to remember that both of those dimensions matter. And that they can have interplay.