If I can manage to find a couple if things, then I'd continue with my own dial print projects. Note that I'm not talking about pad-printed in the traditional way, but rather by using a water-slide transfer to layer the dial print over a brass blank. See this thread:

https://forum.replica-watch.info/for...l-printed-dial

However, what I still need to source are:

1) a printer (laser preferably) that will print at 1200 dpi or better

2) a film that will dry and adhere without wrinkling (which has been the problem to date).

I bought a B&W laser that was advertised as being able to print up to the target res - but then found the terrible driver software meant it was impossible to achieve this. And I have also found that my water slide film wrinkles as it dries (but this could be down to my defective workflow/application attempts!).

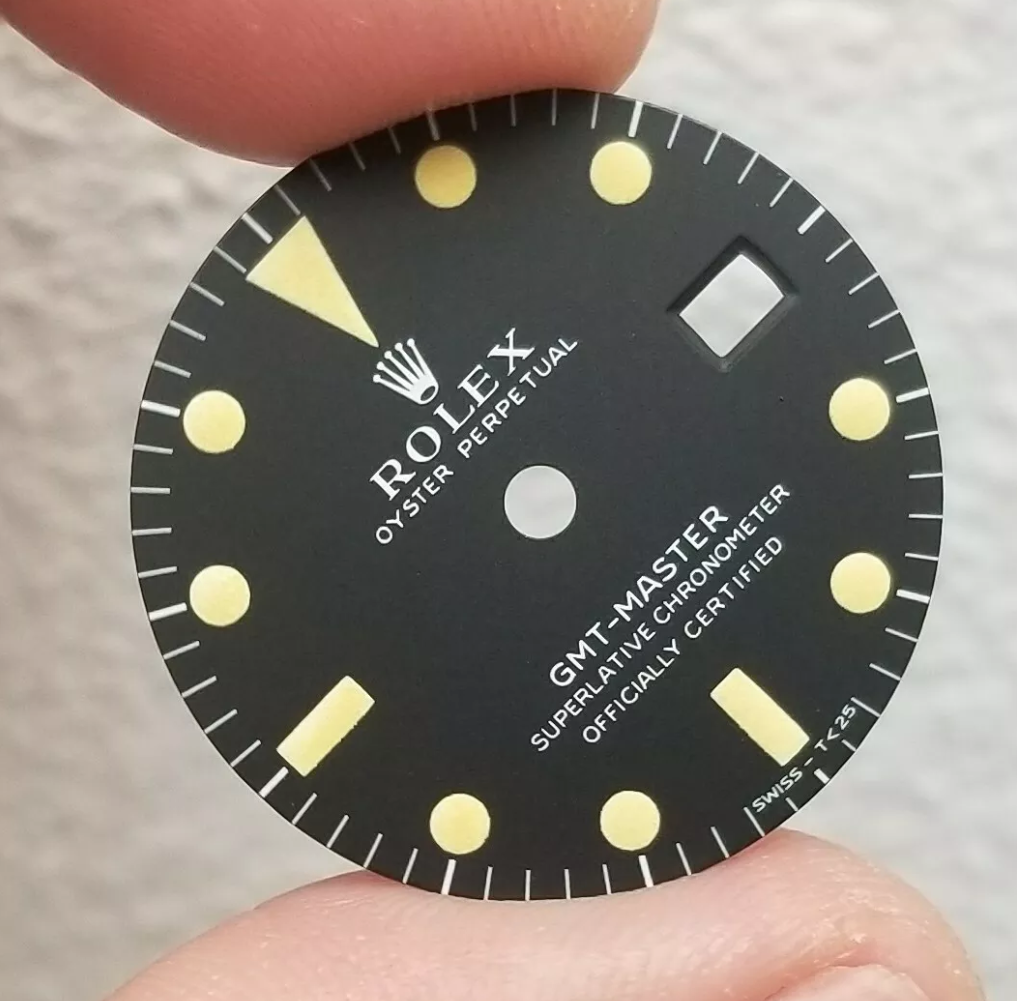

The closest I've come to success is this:

This is with a Canon inkjet printer that does 1200dpi. But this print lifted a little at the edges, so I damped it down to flatten it - and it wrinkled! In retrospect I probably didn't need to worry about the edges having lifted slightly as they'd have been flattened by the dial against the inside of the case.

But I also think the print resolution is below the standard I'd like. I'll need to experiment with the MQ dial details, and see how it goes.

Just to double-check here, the dial diameter I need to work with is 27.3mm - correct? (I haven't actually checked with anyone yet to find out what dial/movement combo fits the milk case lol! I just assumed it was 27.3 and an Asian/ETA 2836 GMT movement...)