The noob insert gets grayish after a while o usage, this is a well known issue. I am wondering about whey this happened, so i made some exam.

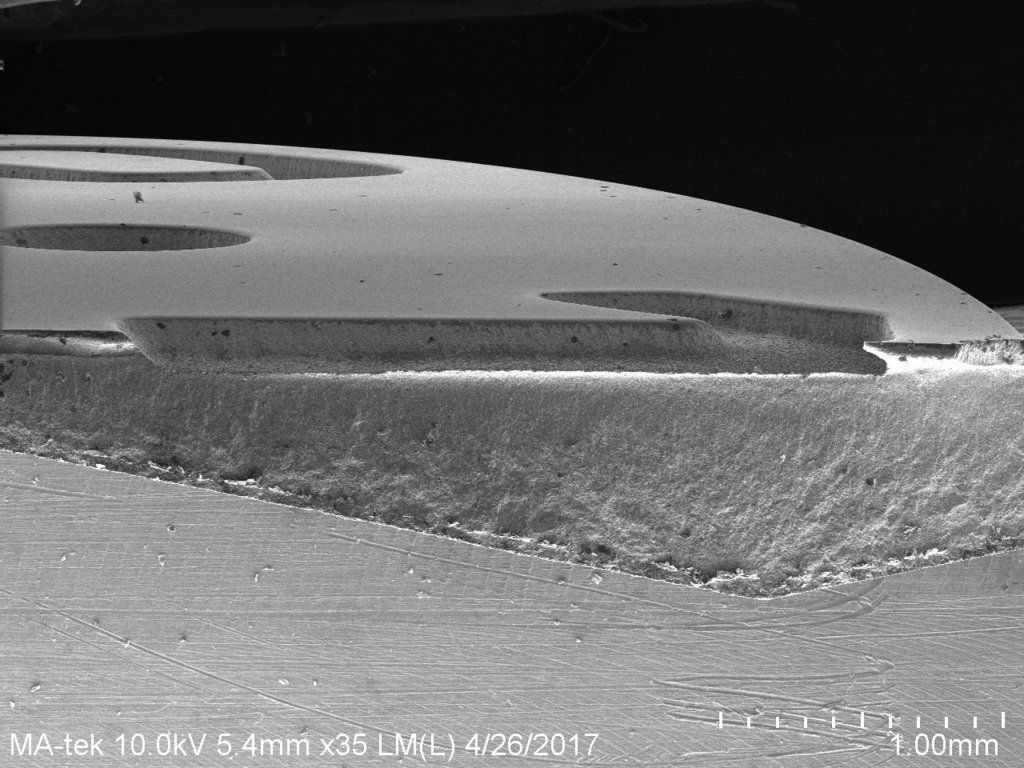

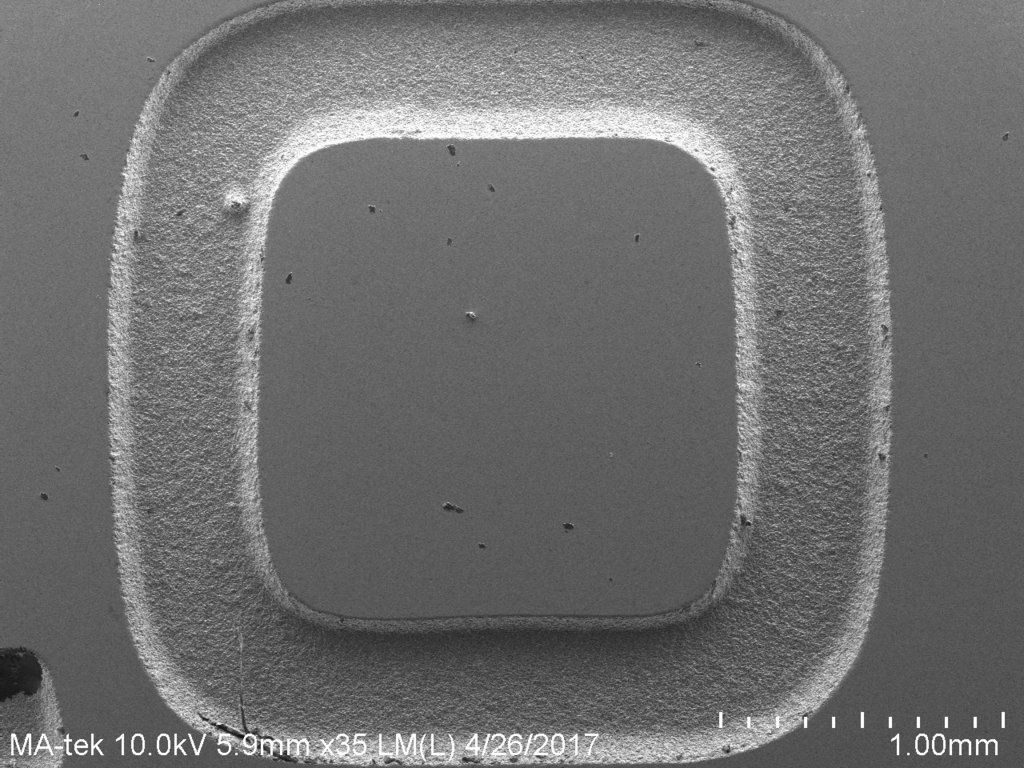

These are the macro shot of the sample i examed, a insert was crashed into small pieces and loaded into the the SEM(Secondary Electron Microscope) for the inspection. The machine is capable of observing the micro or nano scale structure and also able to analysis the composition of the object(EDX function).

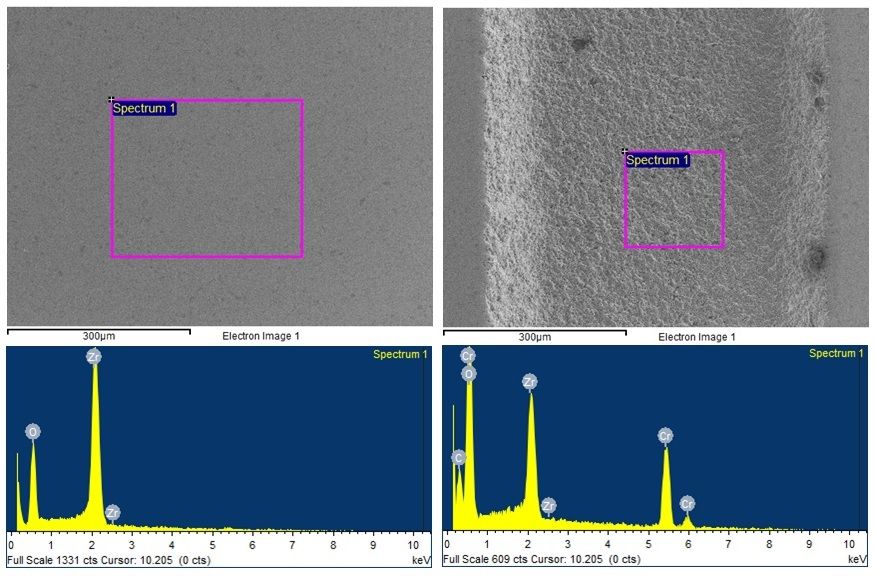

The following 2 photos are the EDX result:

The photo on the left is the signal from the center of the "0". (The black color region with polished finish)

The photo on the right is taken from the groove. (The stock paint)

After these 2 photos, i realized that this insert is made by zirconium oxide and this is a very common ceramic which was widely used in many applications. And the material in the groove is not any kind of paint, it is a chromium based metal layer, this is a very durable material, also not easy to deal with. Most of the chemicals are not able to remove this layer or corrode it with very slow etch rate. A feature of this material is that it becomes yellowish or grayish after a while of usage.

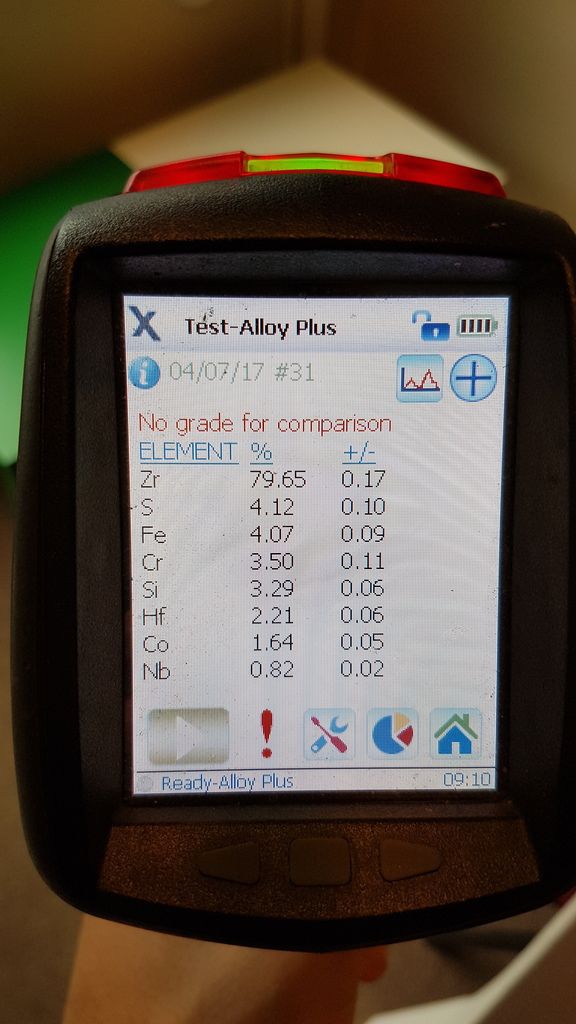

The following photo is the XFA result(X-ray Fluorescence Analysis) which was provided by

@andrei01, thanks for the help!!

The analysis shows highly amount of zirconium and some chromium signal, both elements also exist in my result.