- 7/8/16

- 2,597

- 800

- 113

Top is noob in both pics. Bottom is gen.Pictures of the black hole effect please

Noob v7 latest batch. Some call it v8.

Sent from the RWI App

Top is noob in both pics. Bottom is gen.Pictures of the black hole effect please

The latest batch of noob have a black hole effect. Not as obvious as gen but it is there for sure.

I made some macro shots of the v7 datewheel. The text is glossy and raised. I don't think a gen would make much of a difference.

You can just mod the insert of a nodate and be done. Cheers

Sent from the RWI App

The noob insert gets grayish after a while o usage, this is a well known issue. I am wondering about whey this happened, so i made some exam.

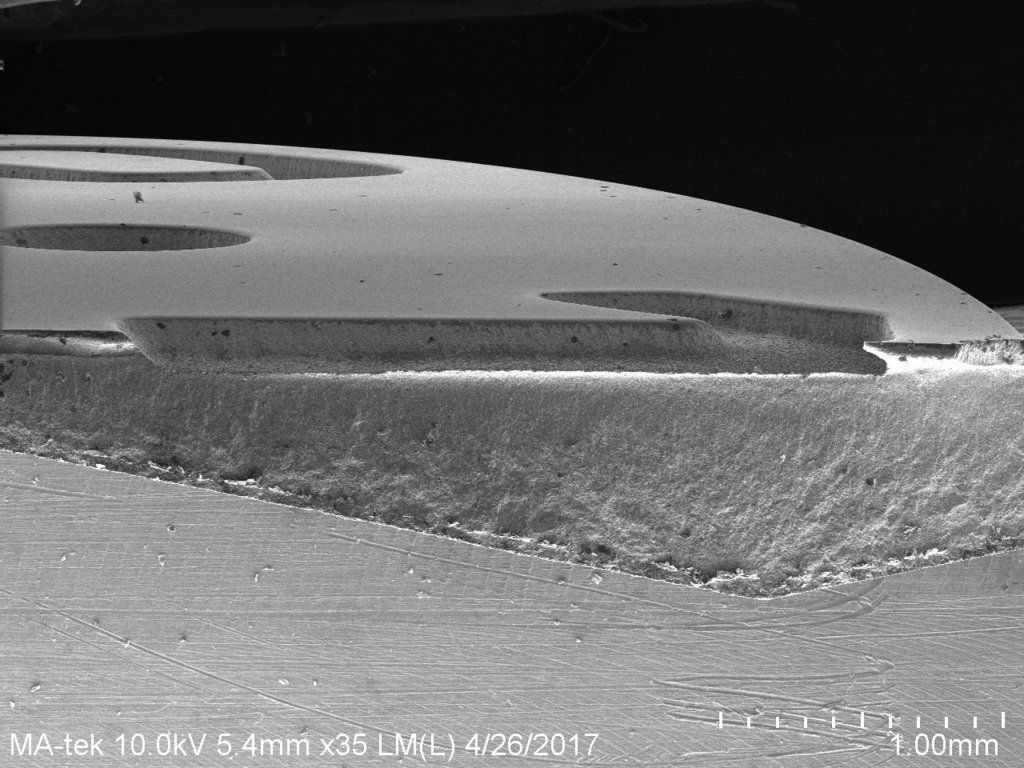

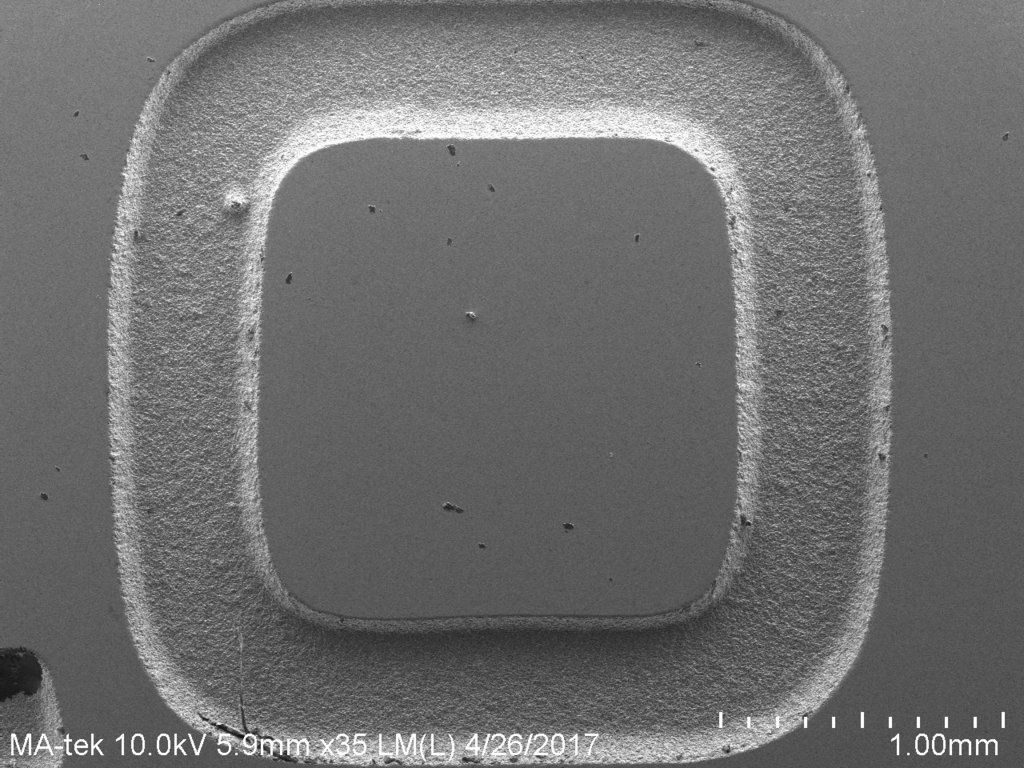

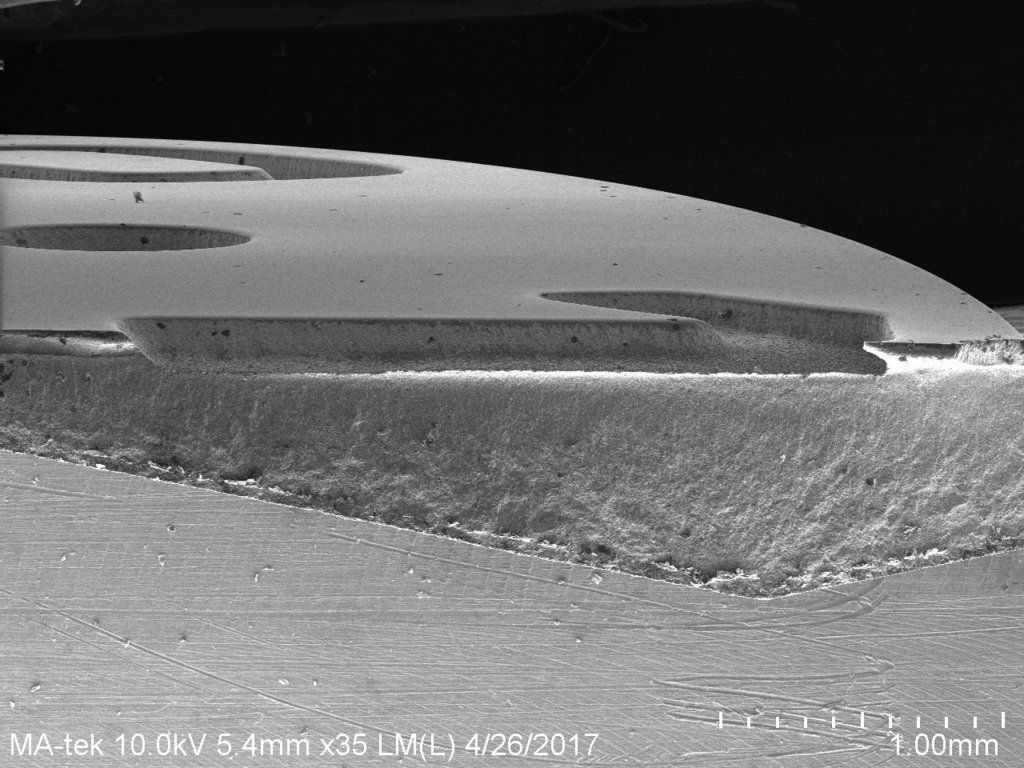

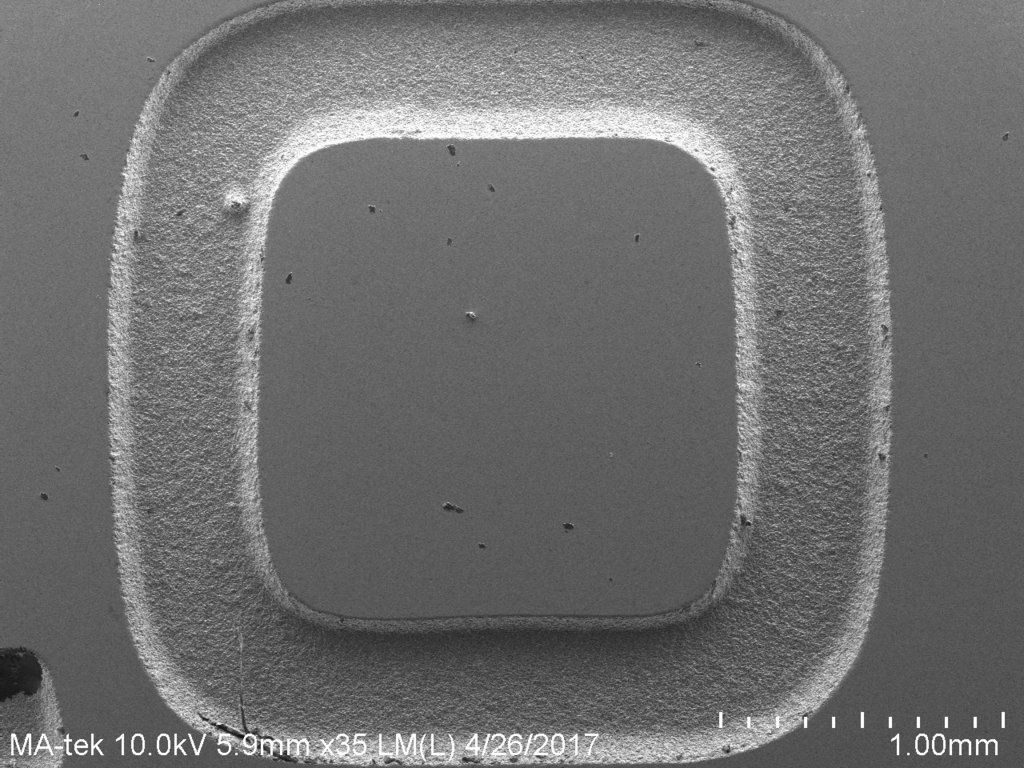

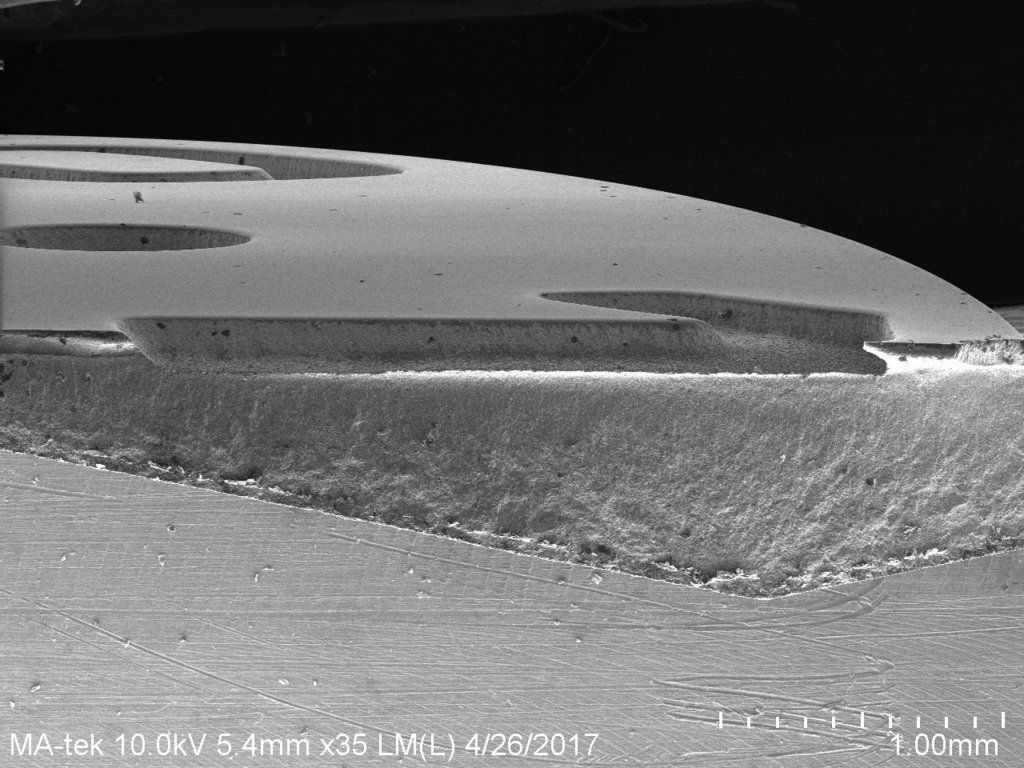

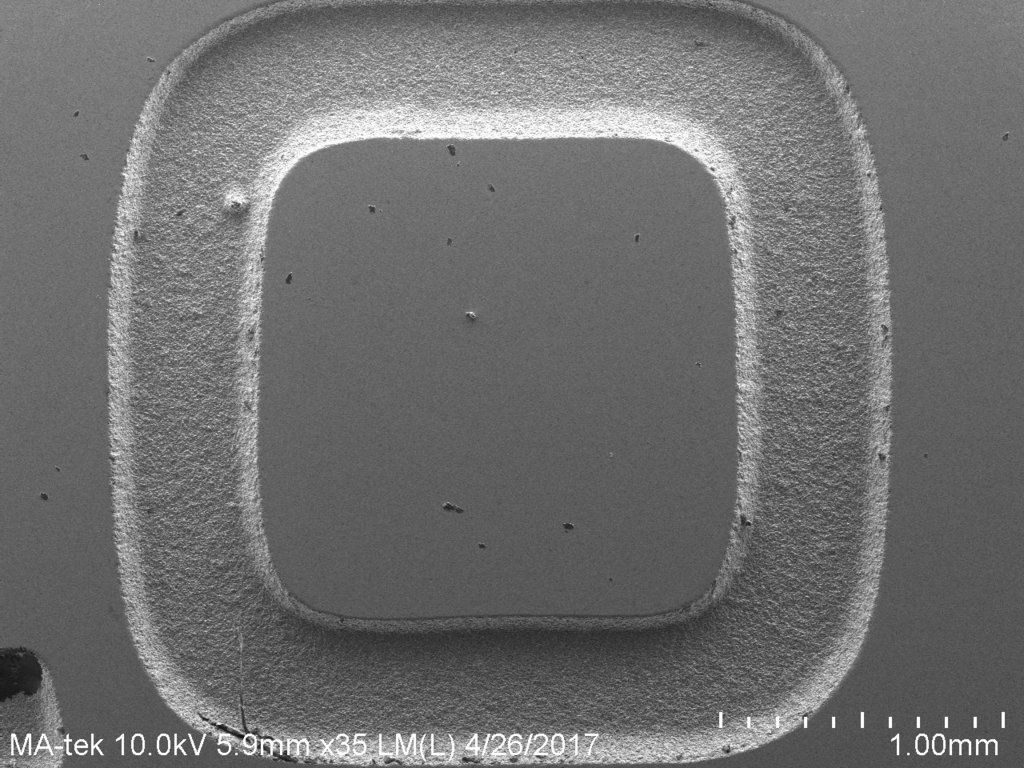

These are the macro shot of the sample i examed, a insert was crashed into small pieces and loaded into the the SEM(Secondary Electron Microscope) for the inspection. The machine is capable of observing the micro or nano scale structure and also able to analysis the composition of the object(EDX function).

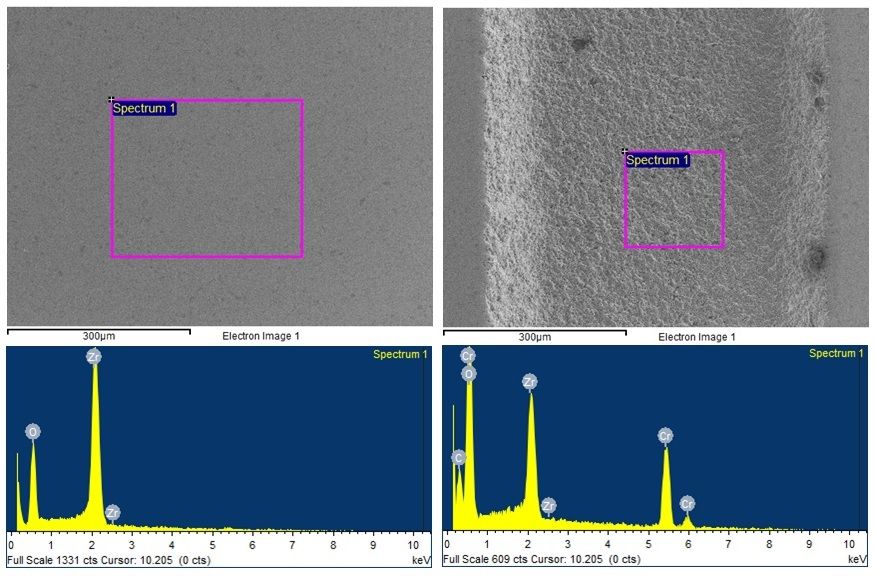

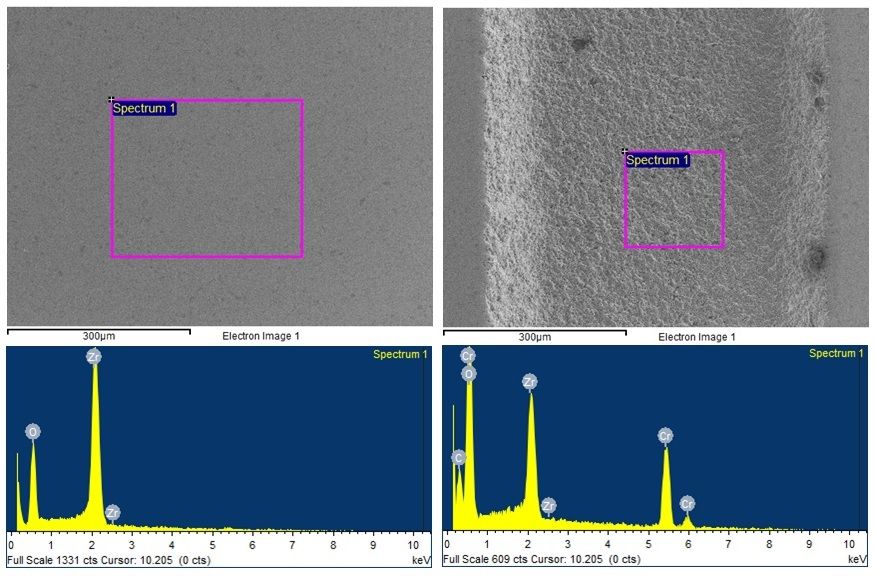

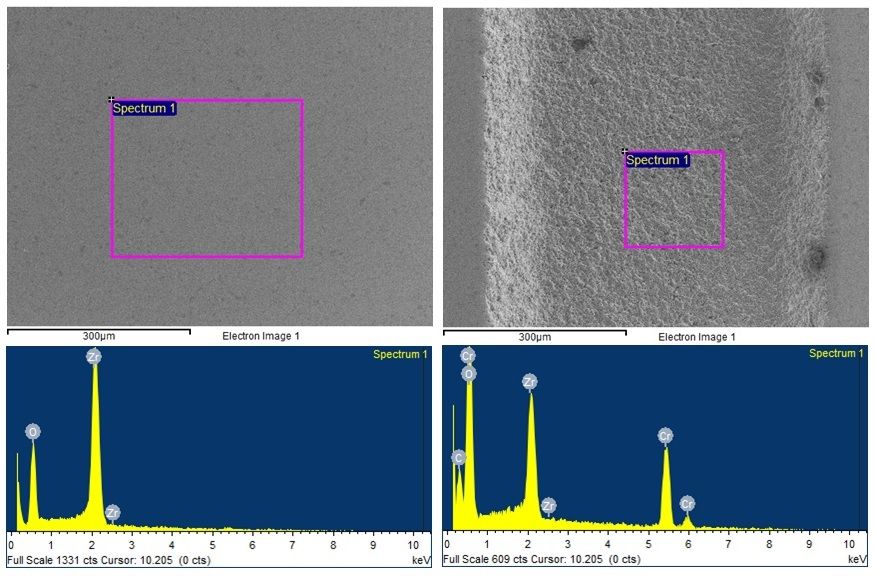

The following 2 photos are the EDX result:

The photo on the left is the signal from the center of the "0". (The black color region with polished finish)

The photo on the right is taken from the groove. (The stock paint)

After these 2 photos, i realized that this insert is made by zirconium oxide and this is a very common ceramic which was widely used in many applications. And the material in the groove is not any kind of paint, it is a chromium based metal layer, this is a very durable material, also not easy to deal with. Most of the chemicals are not able to remove this layer or corrode it with very slow etch rate. A feature of this material is that it becomes yellowish or grayish after a while of usage.

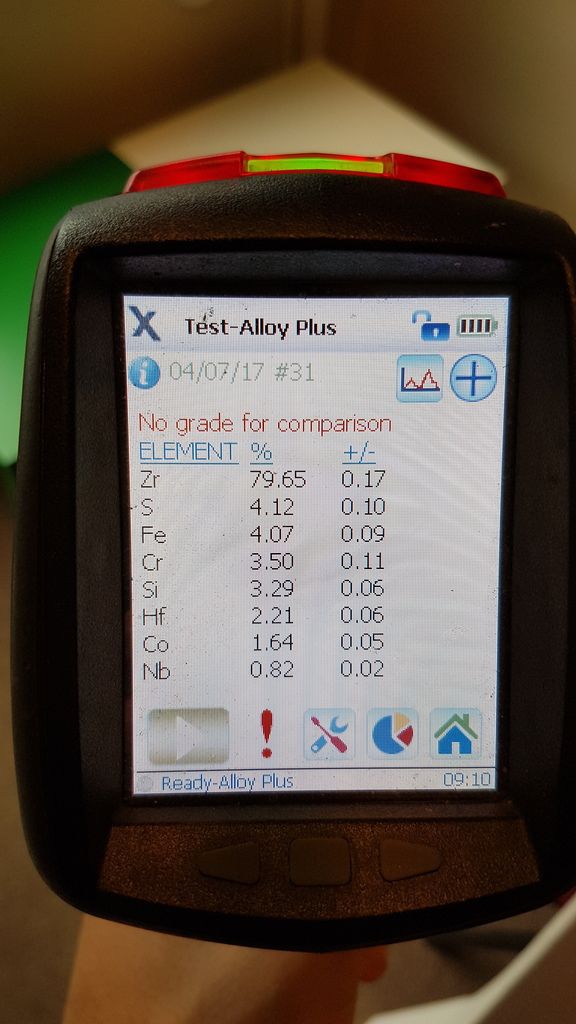

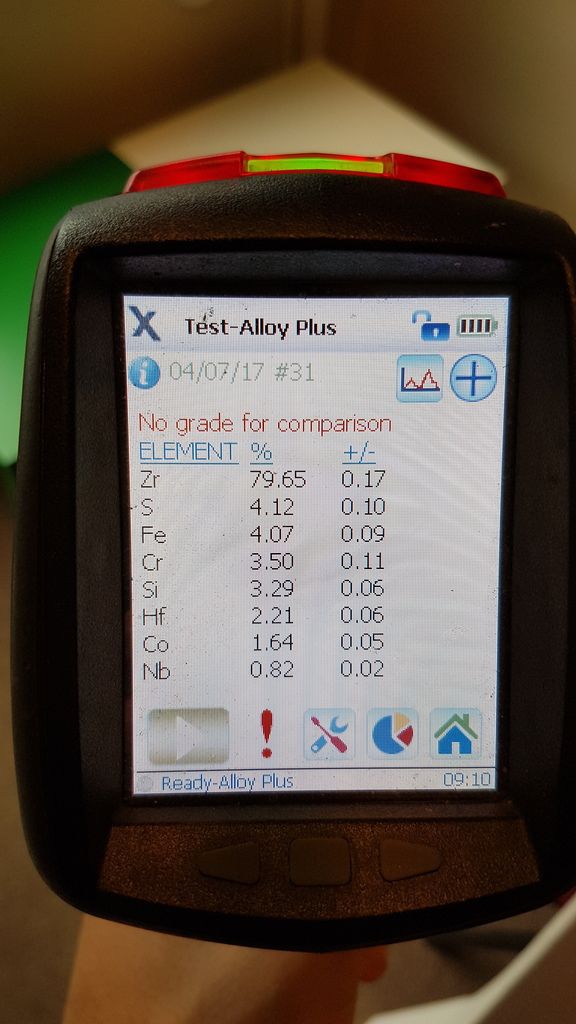

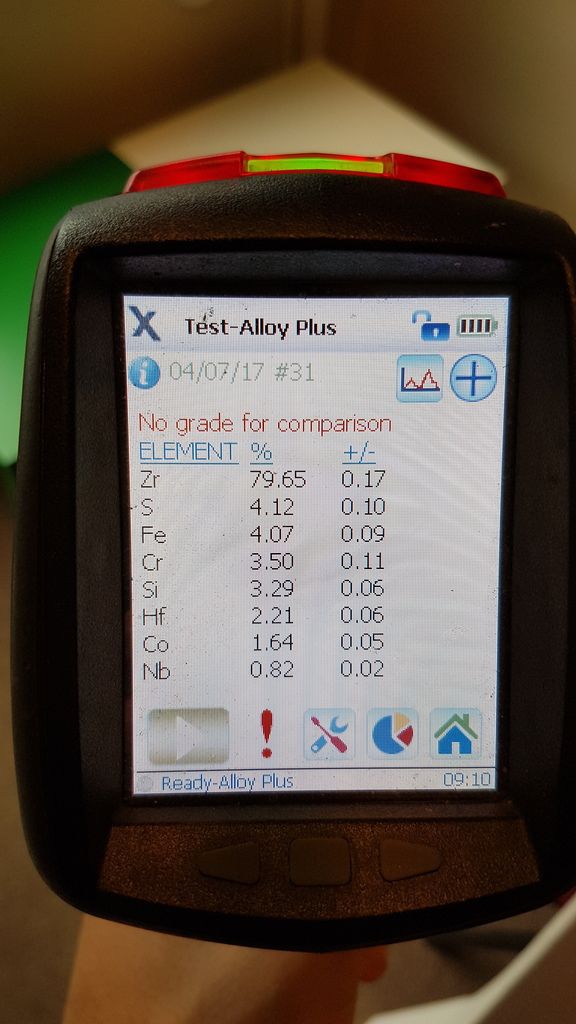

The following photo is the XFA result(X-ray Fluorescence Analysis) which was provided by @andrei01, thanks for the help!!

The analysis shows highly amount of zirconium and some chromium signal, both elements also exist in my result.

Sorry my bad English sometimes doesn't help me to understand! You mean that V7 has been improved lately and now the cyclop is very close to the original (stock cyclop) or did you just modify it? Where can I get this new Noob V7?Top is noob in both pics. Bottom is gen.

Noob v7 latest batch. Some call it v8.

Sent from the RWI App

This is stock noob crystal. I bought the watch from chazing time. I mentuoned to them i want the latest batch. The crystal is very close to the gen yes. At least in my opinion.Sorry my bad English sometimes doesn't help me to understand! You mean that V7 has been improved lately and now the cyclop is very close to the original (stock cyclop) or did you just modify it? Where can I get this new Noob V7?

This is stock noob crystal. I bought the watch from chazing time. I mentuoned to them i want the latest batch. The crystal is very close to the gen yes. At least in my opinion.

Let's keep this thread about the insert mod which is freaking amazing.

Sent from my SM-G930F using RWI mobile app

Nocrystal close to the gen??? it's a joke?

Envoyé de mon iPhone en utilisant Tapatalk

I'm not gonna argue with you. The discussion is offtopic anyway.lol ... look men .... When I put gen crystal, it's night and day. And the cyclop suck ...

Envoyé de mon iPhone en utilisant Tapatalk

lol ... look men .... When I put gen crystal, it's night and day. And the cyclop suck ...

Envoyé de mon iPhone en utilisant Tapatalk

The noob insert gets grayish after a while o usage, this is a well known issue. I am wondering about whey this happened, so i made some exam.

These are the macro shot of the sample i examed, a insert was crashed into small pieces and loaded into the the SEM(Secondary Electron Microscope) for the inspection. The machine is capable of observing the micro or nano scale structure and also able to analysis the composition of the object(EDX function).

The following 2 photos are the EDX result:

The photo on the left is the signal from the center of the "0". (The black color region with polished finish)

The photo on the right is taken from the groove. (The stock paint)

After these 2 photos, i realized that this insert is made by zirconium oxide and this is a very common ceramic which was widely used in many applications. And the material in the groove is not any kind of paint, it is a chromium based metal layer, this is a very durable material, also not easy to deal with. Most of the chemicals are not able to remove this layer or corrode it with very slow etch rate. A feature of this material is that it becomes yellowish or grayish after a while of usage.

The following photo is the XFA result(X-ray Fluorescence Analysis) which was provided by @andrei01, thanks for the help!!

The analysis shows highly amount of zirconium and some chromium signal, both elements also exist in my result.

SEM?! You are a serious scientist , @d09624008. Love your work. So the chromium based metal layer is hard to deal with...does that have implications for your platinum mod?