Here are some of the methods I have been trying if anyone wants to attempt this:

Toner Transfer (Cold Process):

Here is an overview

1) Print image mirror imaged and inverted colors. I found just regular glossy magazine paper works. Must use laser printer!

2) mix 3 parts acetone to 8 parts isopropyl alcohol (try to get 100% of each or you will need to tinker with ratio)

3) clean brass disc, flood with mixture from above

4) lay image on brass disc, lightly press briefly to ensure everything is touching the mixture/board. Let sit 15 secs.

5) apply even pressure for 2 minutes

6) remove pressure from dial and let air dry till the smell of the mixture is completely gone

7) place dial in water and let the paper float off.

8) clean/degrease and plate.

Toner Transfer (Hot method)

1) Print image mirror imaged and inverted colors. I found transfer paper works. Must use laser printer!

2) Place image down on brass disc.

3) I used my wifes hair straightener set to 270 F and pressed down for about 15 seconds, moved the dial around and repeated. Did this for 4 minutes. I place a folded up paper towel on the bottom of the hair straightener and then the dial and then the image. It provides a bit of filler between the gaps of the heating plates so allow for more pressure to be applied.

4) Place dial in water and let paper float off or to where you can easily peel it off

Toner Transfer Hot Method Option 2 (

video)

1) Print image mirror imaged and inverted colors. I found transfer paper works. Must use laser printer!

2) Place image down on brass disc.

3) Feed dial through a laminator set on hot. You are looking for around 270ish degrees as the sweet spot. If you don't hack your machine to play with the roller speed, you will need to feed it through quite a few times. I do 12.

4) Place dial in water and let paper float off or to where you can easily peel it off

Toner Transfer Combo Method

I found my best results so far doing this by moving the straightener around briefly to set the image on then rolling it through the laminator.

Photo Resist: video

1) Depending on whether or not you are using positive or negative film will determine how you print your image. Will need to print mirror imaged (more later)

2) Print your image onto transparency paper (like over head film from way back when)

3) Stack 2 images ontop of each other so you have a super dark template

4) apply dry photoresistant film to your brass disc, either feed it through the laminator or use a hair dryer to make it smooth/tight.

5) Apply template from step 2 onto your covered dial. (you want the actual printed side down so there isnt even a micro gap between the dial and the transparency. This is why you print mirror imaged)

6) Place dial/template between 2 glass plates and use clamps or grips to make sure everything is tight.

7) Apply UV light to the board. There is a lot of figuring this step out unless you can control light source and time. I have used sun light, a uv nail lamp, and a regular light bulb. My best results appear to be bright sunlight for somewhere less than 3 minutes. You will be left with the image "baked" onto the dial.

8) Remove dial from UV light, remove top layer of film and place in a bath of washing soda and water. This will "wash" away the non baked on portions revealing your mask.

9) Clean/degrease and plate.

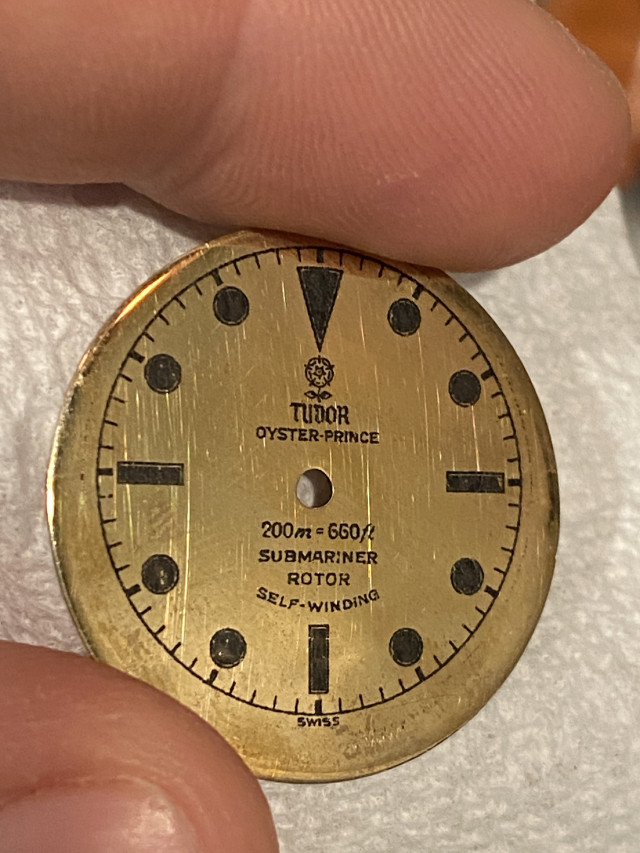

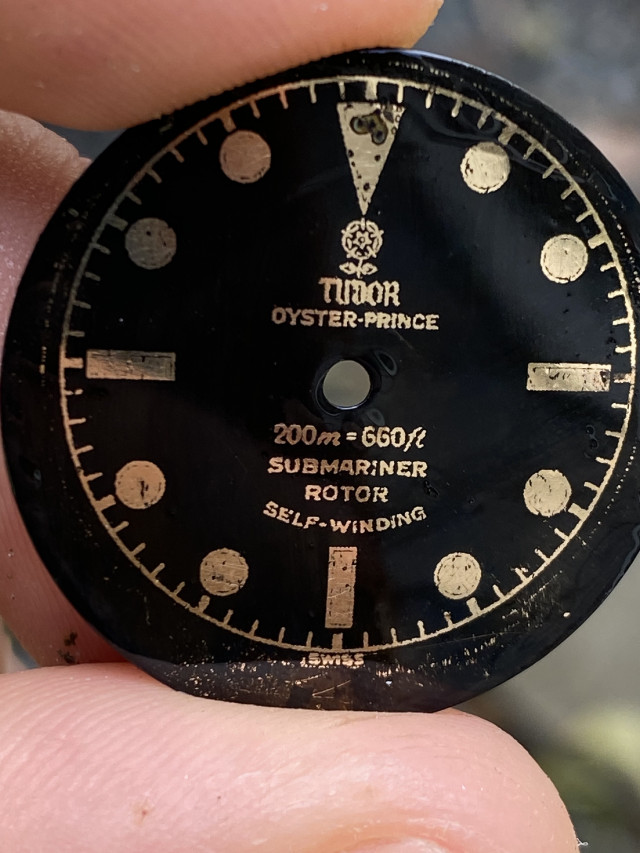

My Learnings

-you can print toner transfer very cheaply. I print an entire sheet of dials out at the USPS for $.15 a sheet. You can mess up and tinker for cheap and quickly.

-I have had about 98% accurate transfer results with the cold method. I am sure i can tinker around more and get better results.

-Using my wifes hair straightener i have also gotten about 98% accuracy. I could increase heat a bit and see how that goes.

-Photoresist appears to give pretty sharp results but there is quite a learning curve. As stated above trying to get the "SWISS" legible and that is just an issue of time and UV exposure. There is a lot more that needs to be controlled this way.

-Using any of these methods, you could make a mask for plating pretty cheaply, with toner transfer costing you pennies.

There are 3 other options I have not tried.

1)

Pad Printing: This is the most expensive method with a decent machine costing hundreds of dollars and then got to make a cliche for every design. So it adds up.

jamiex I am looking at your to be my guinea pig. This method is going to be the only way to get color on your dial other than black and gilt.

2)

Screen printing: You will need to figure out a good "ink" that can easily be washed away post plating and not too sticky enough where it wont show the small fonts/details.

3)

Hacking a printer to print onto your dial. You would get super accurate results with this and can print whatever you want.

Now that I have shared my learnings and successes, you guys need to get busy tinkering!