Hopefully one of you will know this. If standard watch dials are .4mm thick and I am using right now brass discs that are .5mm will that be an issue when using the usual movements? I don’t know how much space is between the dial and the hand stack and Lume plots.

-

Tired of adverts on RWI? - Subscribe by clicking HERE and PMing Trailboss for instructions and they will magically go away!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

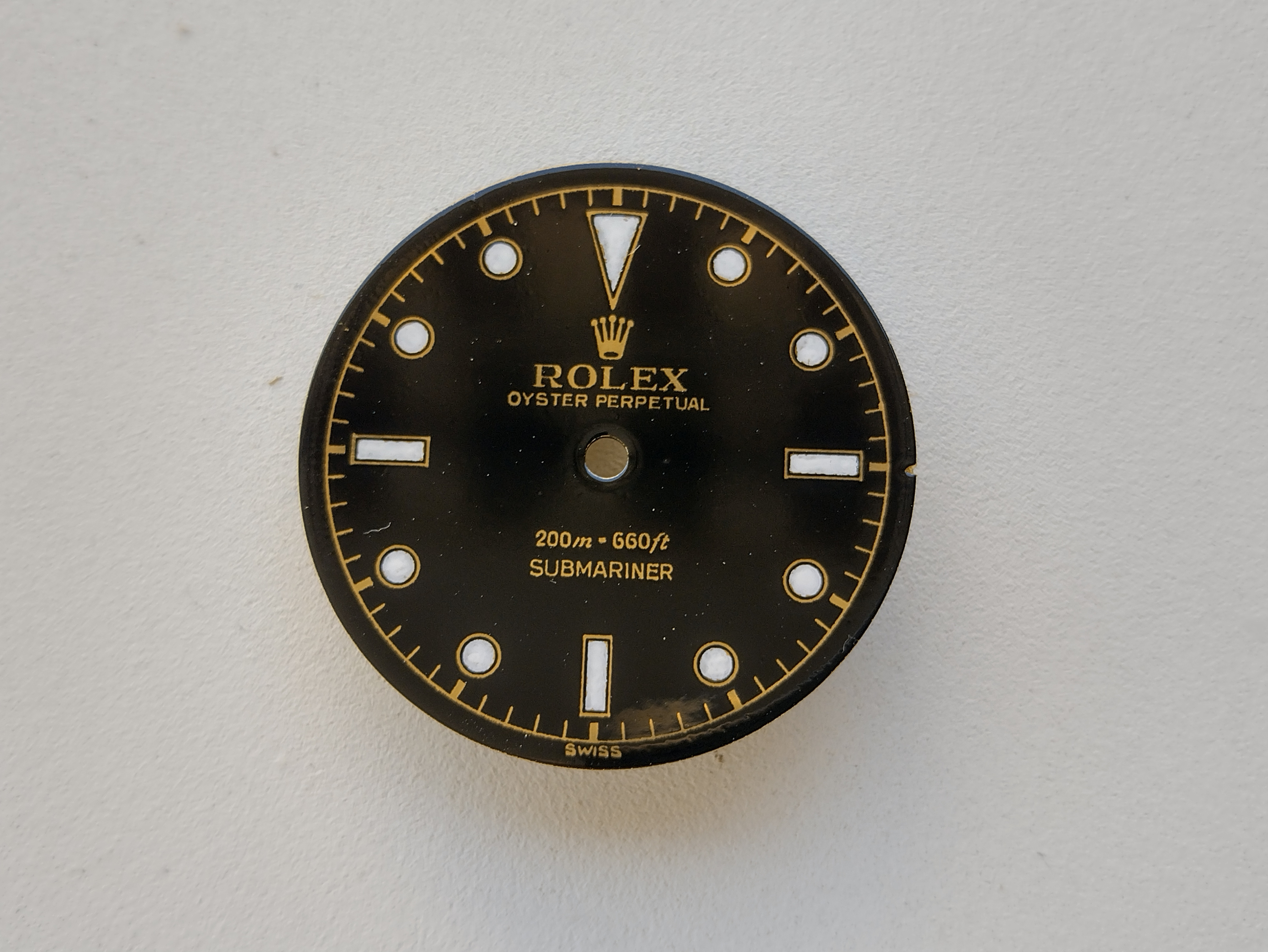

Making a gilt dial (not decal)

- Thread starter chrome72

- Start date

Motorhead13

Getting To Know The Place

- 11/10/21

- 23

- 30

- 13

I wouldn’t think so. I just measured my brass discs at 0.45mm and I haven’t had any problems. I usually sand them though. BTW your dials looks great! Are you going to sell them later on? I’d be interested….

I wouldn’t think so. I just measured my brass discs at 0.45mm and I haven’t had any problems. I usually sand them though. BTW your dials looks great! Are you going to sell them later on? I’d be interested….

How would you sand these down? Like how would you go about doing it. I used duct tape and taped it to a piece of wood and started sanding against a piece of sandpaper but I’m sure there are better ways to do that.

Eventually sell some to recoup R&D costs and then tell the word how to make them. Hopefully I can get to 98% of the Vietnam dials for a lot cheaper. I think I cracked the masking technique prior to plating today. Got a perfect mask without using a pad printer on the first try or slightly altering my technique.

Motorhead13

Getting To Know The Place

- 11/10/21

- 23

- 30

- 13

I just glue a piece of sandpaper to a thick piece of glass and then put the dial face down, two fingers on the back of the dial and rub in a circular motion (sort of what you do to a member of the opposite sex….)

I use a fairly rough grit for the gilt glue to stick. If you’re just using the brass plate and no gold leaf, I would use up to 2000 paper and then metal polish to get the shine up.

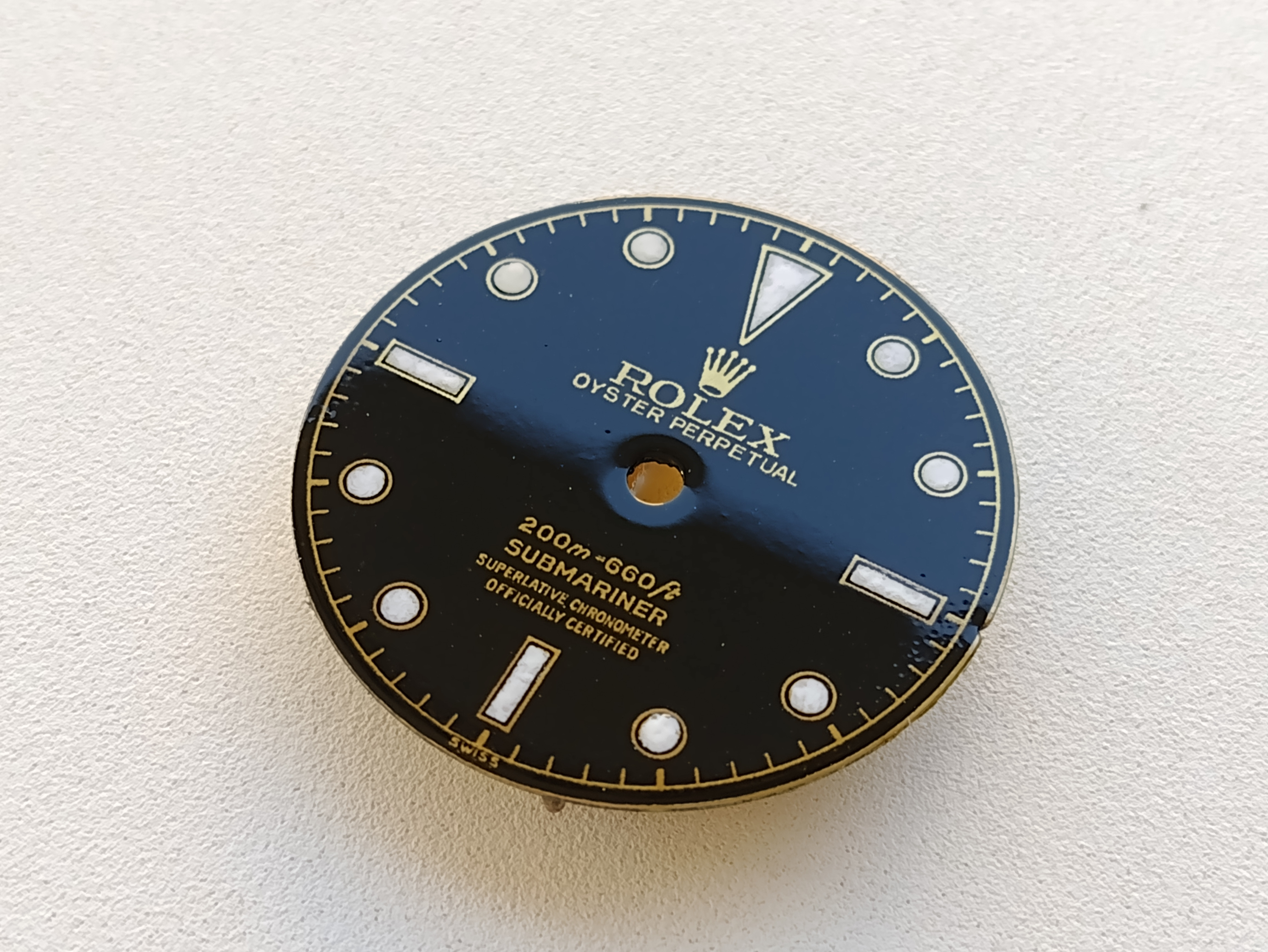

keep up the good work. Love the tropic effect you got going….

I use a fairly rough grit for the gilt glue to stick. If you’re just using the brass plate and no gold leaf, I would use up to 2000 paper and then metal polish to get the shine up.

keep up the good work. Love the tropic effect you got going….

If you routinely rub a member of the opposite sex onto a sheet of sandpaper in a circular motion, then it's small wonder you have so much time for watch modding.(sort of what you do to a member of the opposite sex….)

chrome72 I'll get you the updated dial artworks today, I promise!

Motorhead13

Getting To Know The Place

- 11/10/21

- 23

- 30

- 13

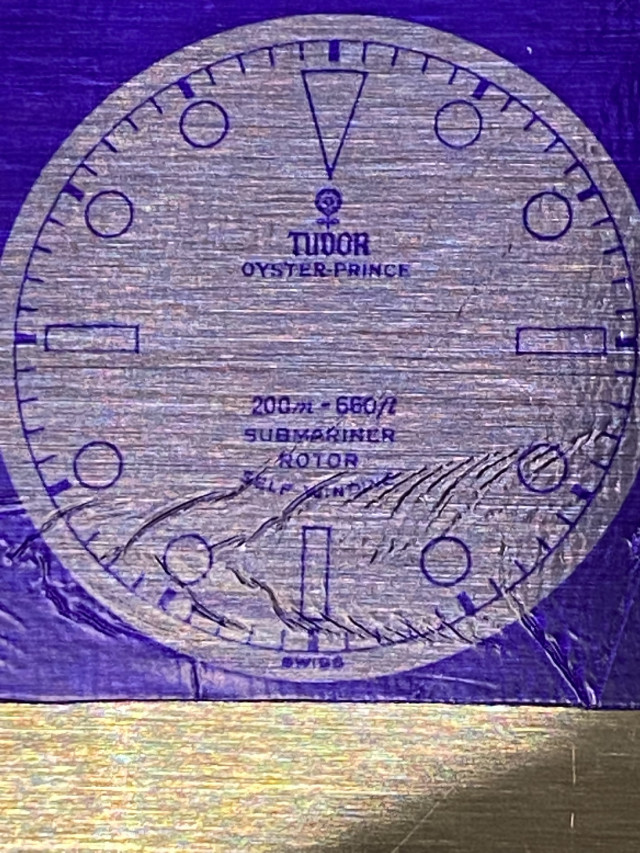

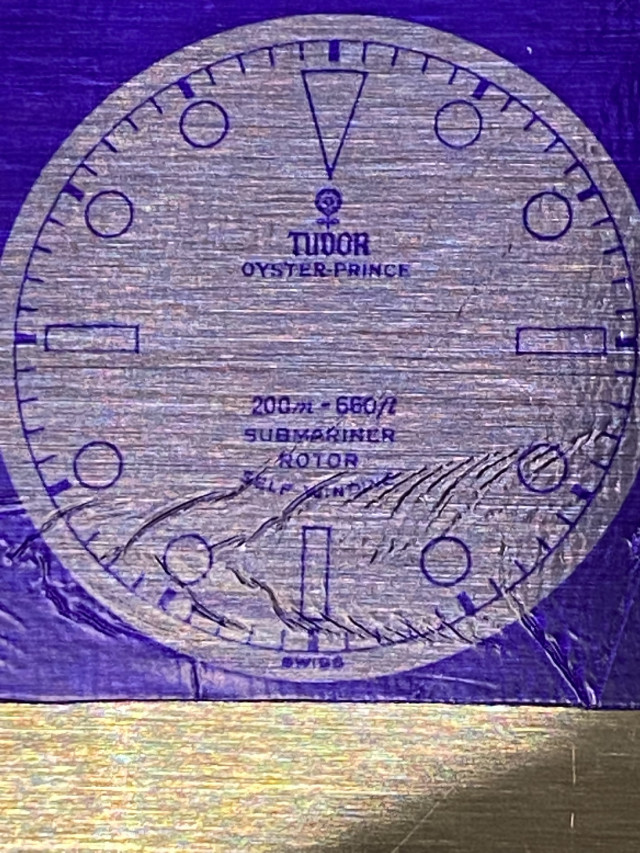

Always tinkering. Been doing the photoresist method since I get better alignment with it. Tried to approach it more scientifically and after 3 attempts with appropriate light, distance and time I think I got my magic formula for a mask prior to plating. This one was still just testing method. My laminator crinkled the photoresist film a bit. Will try it on a dial next time I have time to tinker.

I have a laser engraving manufacturer running a test to see if it can do .4mm text and have it be readable. If it is I might switch to using a laser cutter to make electroresist masks as it should be more consistent.

I have a laser engraving manufacturer running a test to see if it can do .4mm text and have it be readable. If it is I might switch to using a laser cutter to make electroresist masks as it should be more consistent.

Last edited:

Phaedros

Getting To Know The Place

- 5/8/20

- 36

- 18

- 8

Long time lurker - Just stumbled upon this. What a great read!

I‘m on the chemical/ galvanic side for blackening the brass. The process is a lot more controllable in larger batches and imho correlates better with the fading of the tropical dials.

There’s a publication ftom the german „copper institute“ on the chemical processes used.

Page 28 has the info on blackening brass. They also show that shorter time spent in the solution leads to brown gradients. It seems logical to me, that with time and deterioration of the surface oxides this would be reversed from black to brown.

In short they use 200g of copper (II) carbonate in 1000ml of 25% ammonia which leads to a (over-) saturated solution.

Soaking time in a cold (and very stinky) solution - depending on room temperature - up to five minutes for a jet black.

The oxides are resistant to solvents, so releasing any masking lacquers wouldn’t have been a hassle.

Bests, P.

I‘m on the chemical/ galvanic side for blackening the brass. The process is a lot more controllable in larger batches and imho correlates better with the fading of the tropical dials.

There’s a publication ftom the german „copper institute“ on the chemical processes used.

Page 28 has the info on blackening brass. They also show that shorter time spent in the solution leads to brown gradients. It seems logical to me, that with time and deterioration of the surface oxides this would be reversed from black to brown.

In short they use 200g of copper (II) carbonate in 1000ml of 25% ammonia which leads to a (over-) saturated solution.

Soaking time in a cold (and very stinky) solution - depending on room temperature - up to five minutes for a jet black.

The oxides are resistant to solvents, so releasing any masking lacquers wouldn’t have been a hassle.

Bests, P.

Last edited:

Thanks. One of my earlier attempts was with Birchwood Casey's Brass Black. It looked ok and would suffice if its all you had. There might be other options out there that blacken the brass to a deep black hue like gun bluing. The black nickel plating gives the dial that deep black hue.Long time lurker - Just stumbled upon this. What a great read!

I‘m on the chemical/ galvanic side for blackening the brass. The process is a lot more controllable in larger batches and imho correlates better with the fading of the tropical dials.

There’s a publication ftom the german „copper institute“ on the chemical processes used.

Page 28 has the info on blackening brass. They also show that shorter time spent in the solution leads to brown gradients. It seems logical to me, that with time and deterioration of the surface oxides this would be reversed from black to brown.

In short they use 200g of copper (II) carbonate in 1000ml of 25% ammonia which leads to a (over-) saturated solution.

Soaking time in a cold (and very stinky) solution - depending on room temperature - up to five minutes for a jet black.

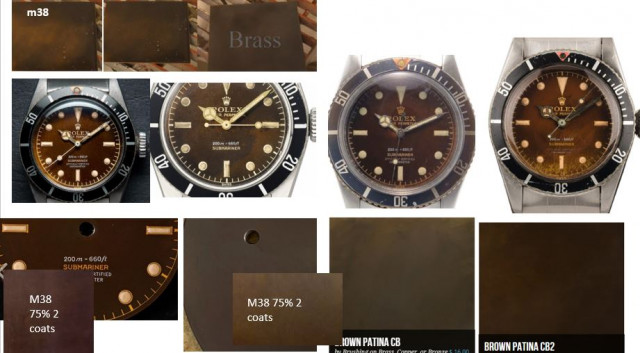

In terms of turning brass brown to a good looking "tropical" color, you can do that with some oxidizing agents and get some good results. Some of my earlier photos were using such agents. Below is my cheat sheet of some of the tropical colors I am hoping to achieve and some of the oxidizing agents out there that can get those browns and maroons. I have already achieved a homogenous chocolatey brown dial and some of the lighter browns but splotchy dials (which still looks cool). This however will take more tinkering as they are fast acting and sensitive to humidity, temp of the metal, temp of the air, how quickly the agent dries on metal.

Forcing black nickel plating to tropicalize is another beast. I have gotten 1 to do it so far but its not something that appears to be super repeatable consistently.

lastly, i bought a laser printer with high resolution printing so I will be back up and running soon.

Phaedros

Getting To Know The Place

- 5/8/20

- 36

- 18

- 8

@chrome72 interesting! I tried cold blueing agents as well but found the resulting oxyde layers to be too fragile. That was for artificial ageing of brass parts that would be handled afterwards. My favourite solution there was 5g liver of sulphur in 1000ml destilled water with a dash of ammonia (also pretty stinky) - this would give off a nice greenish brown.

Thinking of which dials would "tropicalize" another Rolex-Affiliate comes to mind - some vintage Panerai have wonderfully faded dials and they are as well blackened with oxydes. Albeit anodized but not in the modern way by opening the surface and embedding a coloring agent but by etching and electrolysis.

Some very nice examples/ also rolex to look at:

perezcope.com

perezcope.com

It is mostly assumed that the massive amounnt of radium lume was the main force in fading the panerai dials but wouldn´t the rolex dials have halo-like effects around the lume dots and markers if that was the case?

Thinking of which dials would "tropicalize" another Rolex-Affiliate comes to mind - some vintage Panerai have wonderfully faded dials and they are as well blackened with oxydes. Albeit anodized but not in the modern way by opening the surface and embedding a coloring agent but by etching and electrolysis.

Some very nice examples/ also rolex to look at:

Dials

The value of a historic watch depends to a very large extent on the condition of its dial, the “face” of a watch, and also whether the dial is original to the watch or not. Historic Pan…

It is mostly assumed that the massive amounnt of radium lume was the main force in fading the panerai dials but wouldn´t the rolex dials have halo-like effects around the lume dots and markers if that was the case?

- 13/10/16

- 4,048

- 2,742

- 113

Is that your film free method? Nice job if so.5512 4 lines ...

6538 2 lines ...

- 13/10/16

- 4,048

- 2,742

- 113

Is that your film free method? Nice job if so.

Yes Sir

Pseudo related. Got an refillable air freshener for my car. It was anodized black originally. Been sitting in my car parked outside for 3 years or so. The black has tropicalized to various shades of brown depending on how much sun got it.

If someone replicates what I do but goes the route of anodizing (can’t anodize brass) and fills in the negative space with electroplated brass or gold leaf you can tropicalize the anodized black just by leaving it in the sun.

If someone replicates what I do but goes the route of anodizing (can’t anodize brass) and fills in the negative space with electroplated brass or gold leaf you can tropicalize the anodized black just by leaving it in the sun.

After a lot of learning and mastering different parts of the process at different rates depending on materials/printer/heat source used…with my new laser printer I think I now have 1) perfect impression 2) perfect centering.

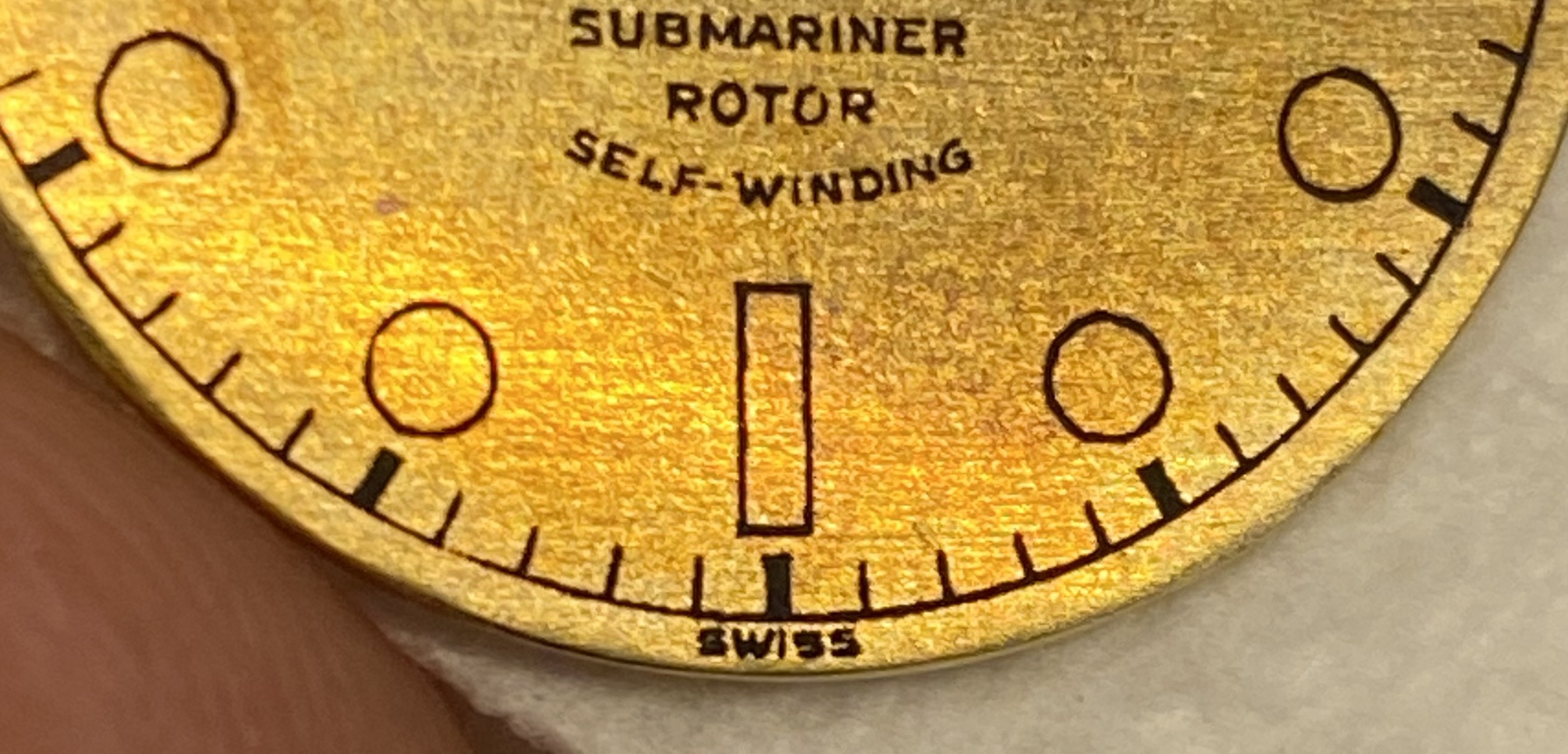

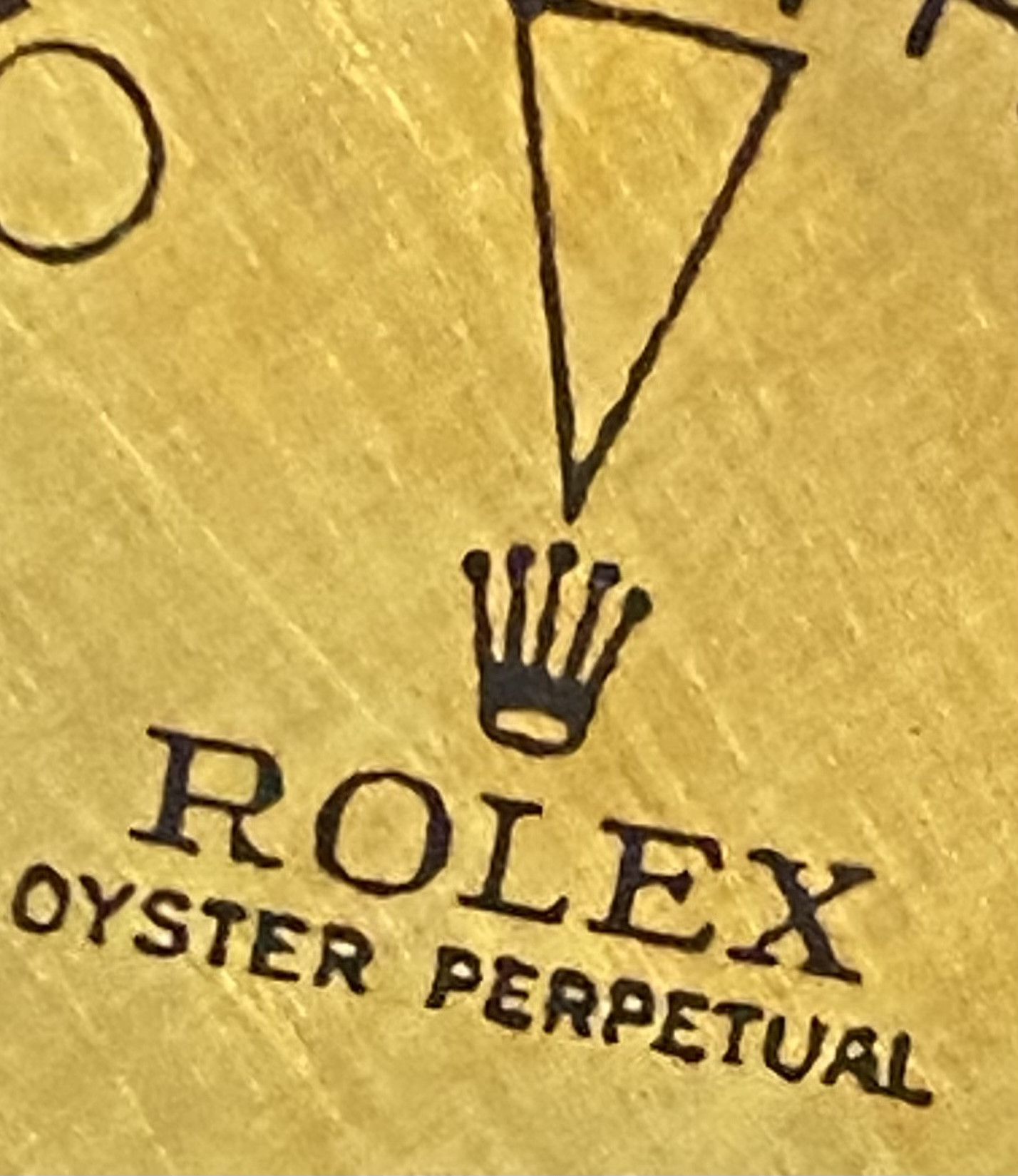

Here is a zoom in of a perfect impression that is centered right where it needs to be.

Looking forward to plating, tropicalizing, and lacquering as many as my heart wants.

Also discovered a process to get white text on the dial without having a pad printer. More on that later once I get to that method.

Here is a zoom in of a perfect impression that is centered right where it needs to be.

Looking forward to plating, tropicalizing, and lacquering as many as my heart wants.

Also discovered a process to get white text on the dial without having a pad printer. More on that later once I get to that method.

Samsung 2525. You have to make sure you have glossy paper setting. Do max density of toner setting too. select the 1200 dpi setting which can sometimes the “best” quality option instead of “standard”.What printer are using? I’m using a printer from work that claims to print 1200x1200, but I can never get anything as clear

You can use glossy magazine paper as paper.

If you are US based I found the UPS store’s printer worked perfectly. High chance of gumming up their printer and being banned from using that paper though. You will have to tape it down to a plain sheet before it gets fed into the paper tray. They should have the same printer across all locations is my guess. Some big industrial laser printer. No need to adjust settings. It just worked well.