-

Tired of adverts on RWI? - Subscribe by clicking HERE and PMing Trailboss for instructions and they will magically go away!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

If you want someone done right... (Engraving content)

- Thread starter newest dude on the forum

- Start date

Very good.Haha, no doubt about it. I could see it being tedious if it's what you were doing all day. I definitely have had a lot of fun messing with the engraver (there are way too many things engraved in my house right now), but if it was my job, probably not so much.

If I may say so, the engraving on the case back style 1665 is better than the serial number on the case.

Maybe it depends on how the case has aged between the two lugs.

That has always been the weak point.

I'm fairly certain that those casebacks were stamped and not engraved.Very good.

If I may say so, the engraving on the case back style 1665 is better than the serial number on the case.

Maybe it depends on how the case has aged between the two lugs.

That has always been the weak point.

...don't challenge me to adopt a new hobby!

I've been engraving! Huge thanks to the members who reached out to have me engrave their cases. Your trust is appreciated. I haven't posted pics of anyone else's watches because I'm not sure if people would be ok with their chosen serial numbers being out there. Here's two of my personal watches that I've recently engraved.

I might know a guy who needs a few cases engraved

Keep up the good work

Keep up the good work

OI812

Active Member

- 17/3/06

- 210

- 177

- 43

- 14/3/18

- 427

- 177

- 43

Just had a case engraved by @newest dude on the forum . Fine work, thx for that

Well done....You are now "our engraver guy"

prepared to get slammed with DMs lol

looks great.

prepared to get slammed with DMs lol

looks great.

Amazing job

Looks very accurate - perfect what you are doing.

I will contact you - if I am allowed to?

Looks very accurate - perfect what you are doing.

I will contact you - if I am allowed to?

Any time!Amazing job

Looks very accurate - perfect what you are doing.

I will contact you - if I am allowed to?

Hello! I've been following this thread for a while (long enough that I convinced myself to buy one, lol). So I'm posting to contribute what I've managed to learn along the way, as reference.

The New Hermes engravers seem to pop up here and there, but there's almost always one for sale on Ebay, Craigslist, or Facebook Marketplace (for us in CONUS, there are European equivalents to Craigslist that I'm unfamiliar with, but the idea is the same). They sell for anywhere from $100-1000 or so, depending on what's included.

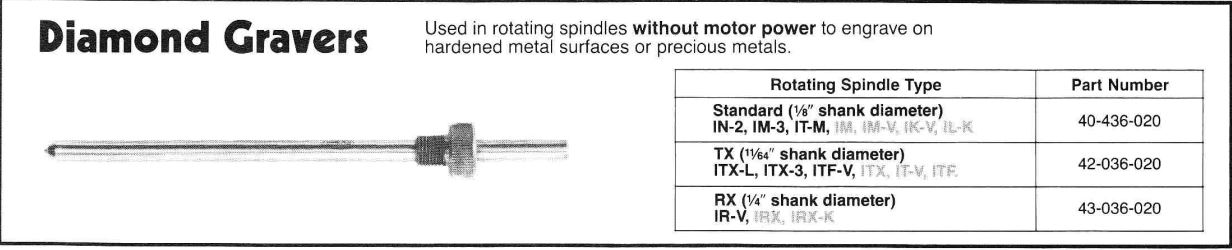

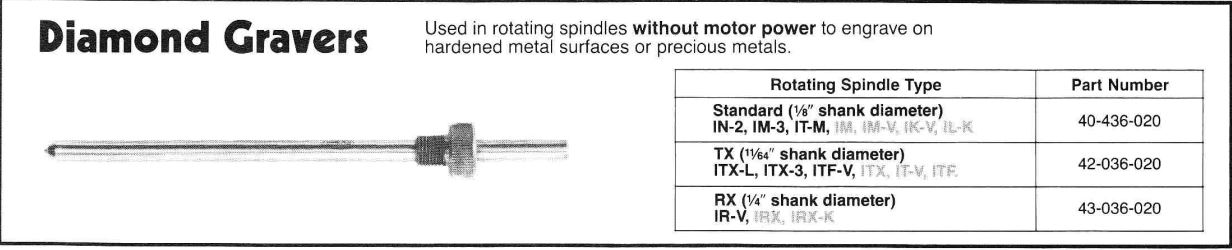

There are two general types, and several models within the two basic types. Drag Engravers, which are completely manually operated, and Rotating Engravers, which use an electric motor on a belt to spin a bit to engrave. Rolex seems to have used drag engravers. If you find a deal on a rotating engraver, you can use a bit that's designed for drag engraving in it...assuming you can find one. This is the part you need:

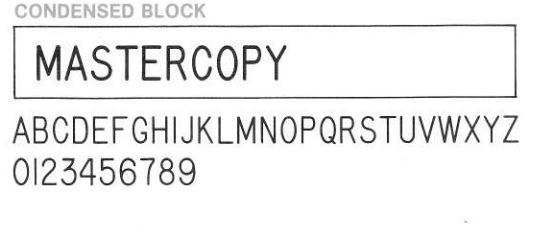

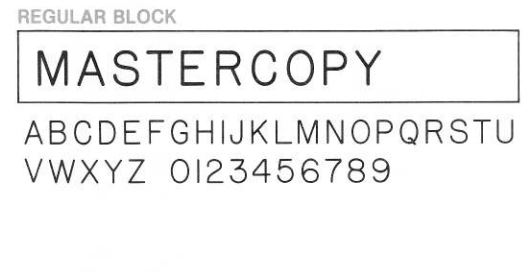

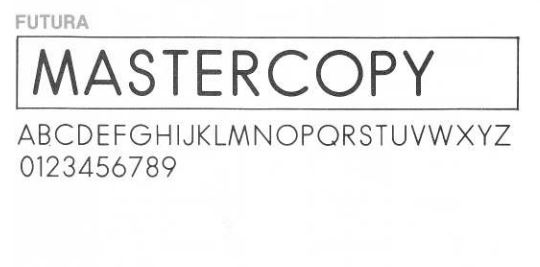

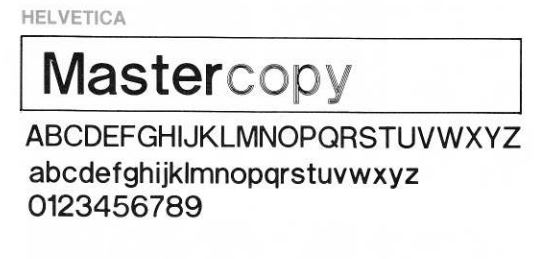

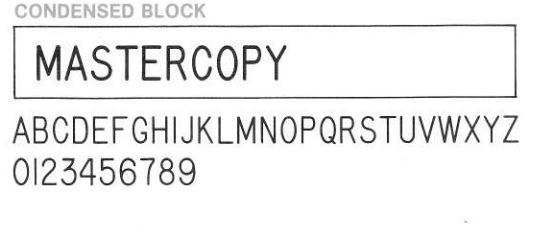

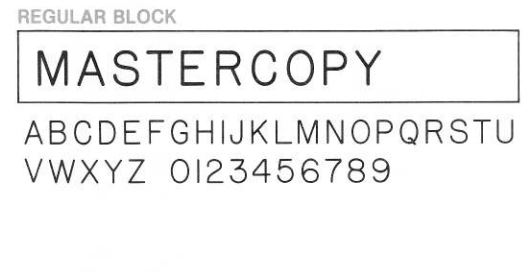

New Hermes offered several different kinds of fonts. The correct font set is a little hard to nail down. To my eye, it appears to be either "Regular Block" or "Condensed Block," which were the most common fonts they offered. That said, letters from those sets look right, but the numbers from those sets don't appear to match the ones Rolex used, so it's possible that Rolex used a custom set, or a mix of fonts from different sets.

These are what the Rolex fonts look like (from this excellent post):

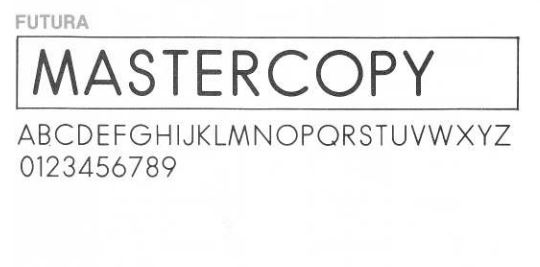

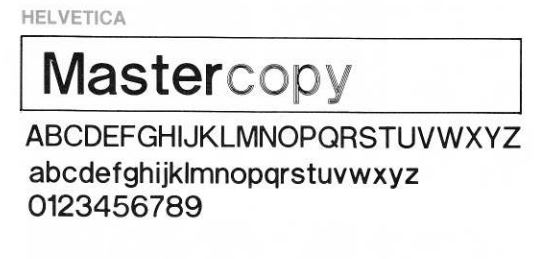

And these are the New Hermes fonts:

The letters look very good (although I can't decide if Regular or Condensed is correct...it's difficult to say, since the engraver is designed to write on a flat plane, and the case itself is curved, so the letters would be compressed as you get farther from the center.

For the numbers, Rolex used more than one font. At least 2, up to 5, if you count service center engraving. Regular and Condensed Block are very close, but to my eye, Helvicta and Futura have better a better number 1.

That said, we're talking about writing that's shallow, often nearly worn off, and covered by the end links or band, so infinitely parsing the serifs on specific characters is maybe a bit of overkill. On my gens, most of the time the number is barely legible after a few years, and the case has to be manipulated under a strong light, at just the right angle, to even see that they're there.

As far as how big the font is, it's a bit tricky to nail down. New Hermes offered fonts in different sizes, and the engraving machines can reduce those sizes from 1:1 to 1:8. So if you have a set of 1" fonts, you can reduce it down to 1/8" If you have a 1/2" set, you can go down to 1/16". Pretty much any set over an inch is useless for engraving between the lugs, so you're stuck with either 5/16", 1/2", 5/8" or 3/4". I have yet to take a caliper to the numbers, but if anyone knows the EXACT size, I'd love to know it.

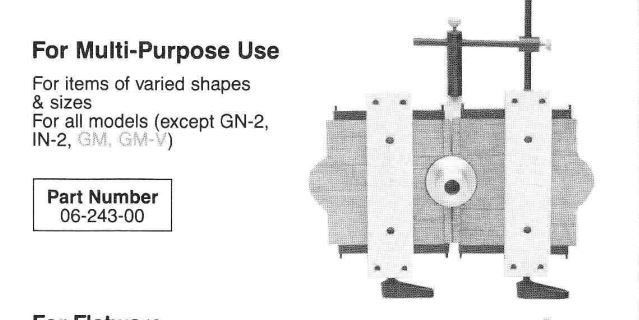

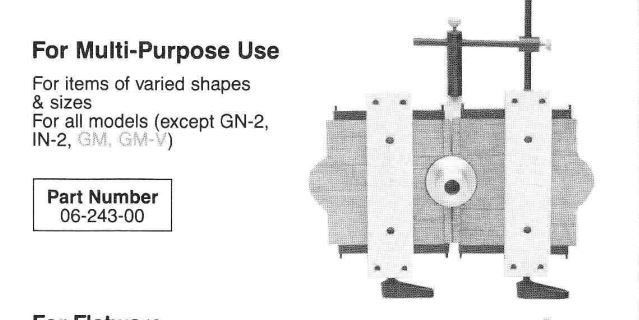

Other options they offered that would be of value to a watch modder would be a vice and jig designed for holding watch cases (although this holds the watch on the wrong plane, it's more for engraving case backs):

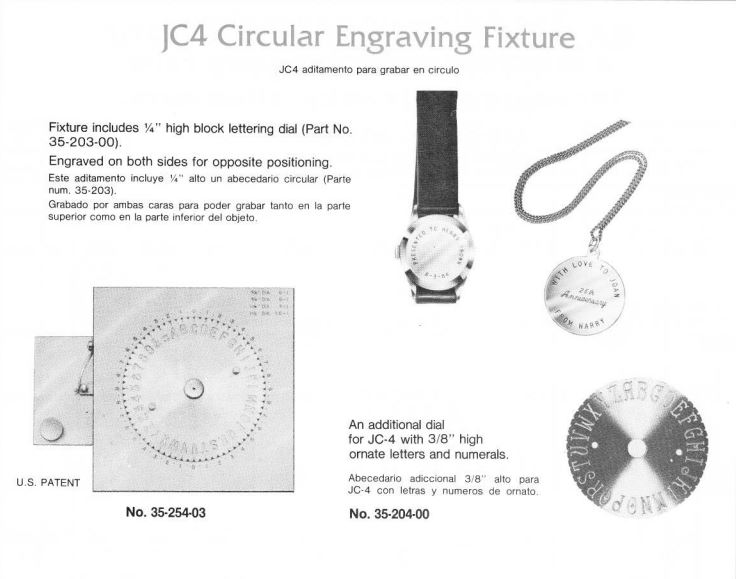

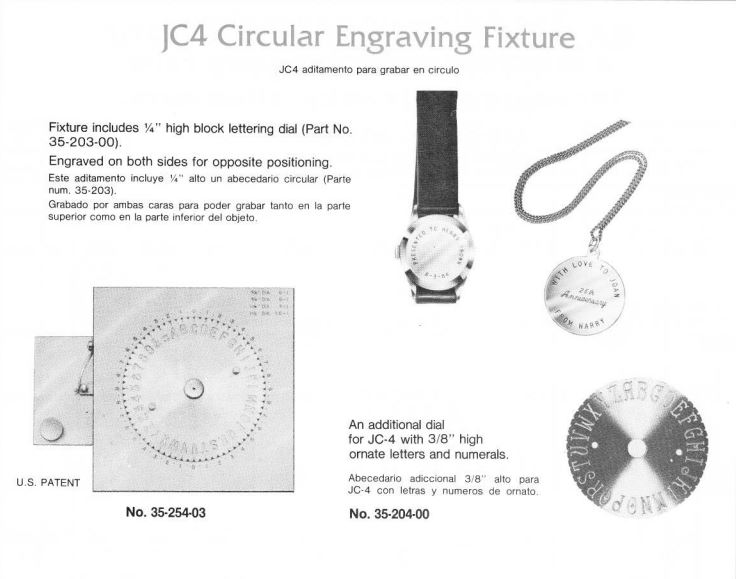

And a cool jig for rotating in a circle (like on the case back of a Tudor or Seadweller, or some of the writing inside the case back):

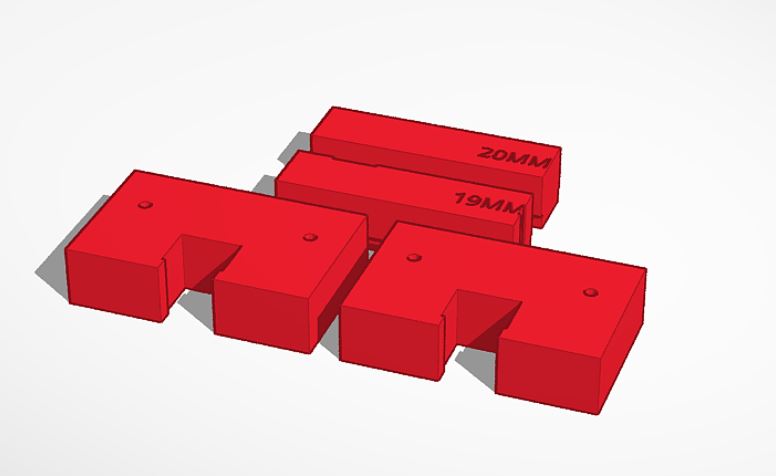

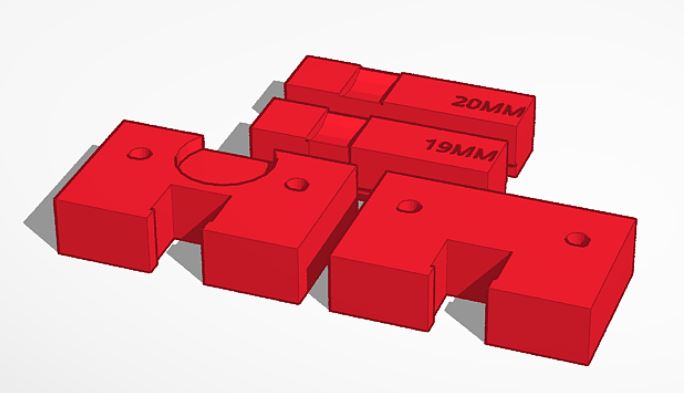

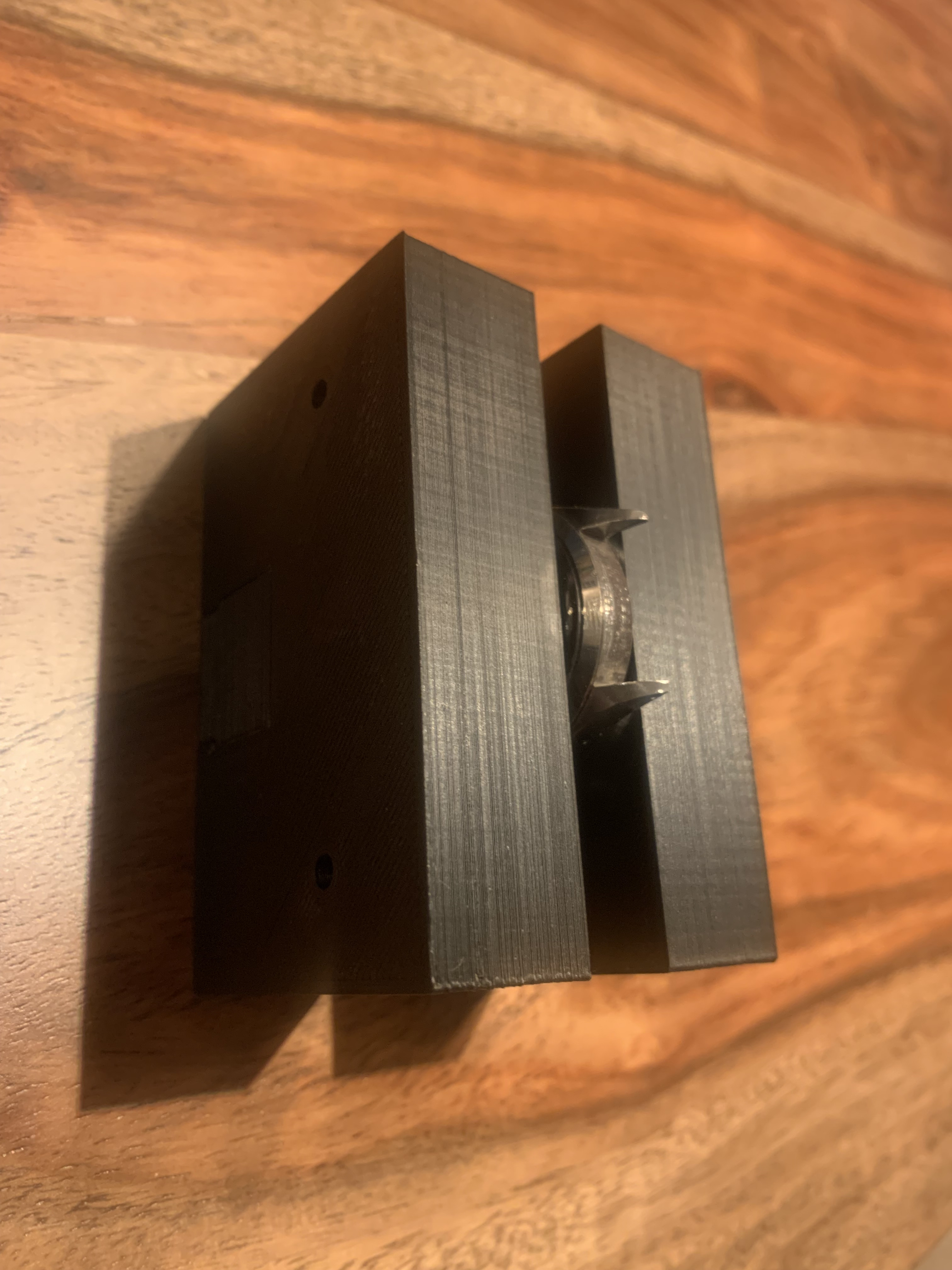

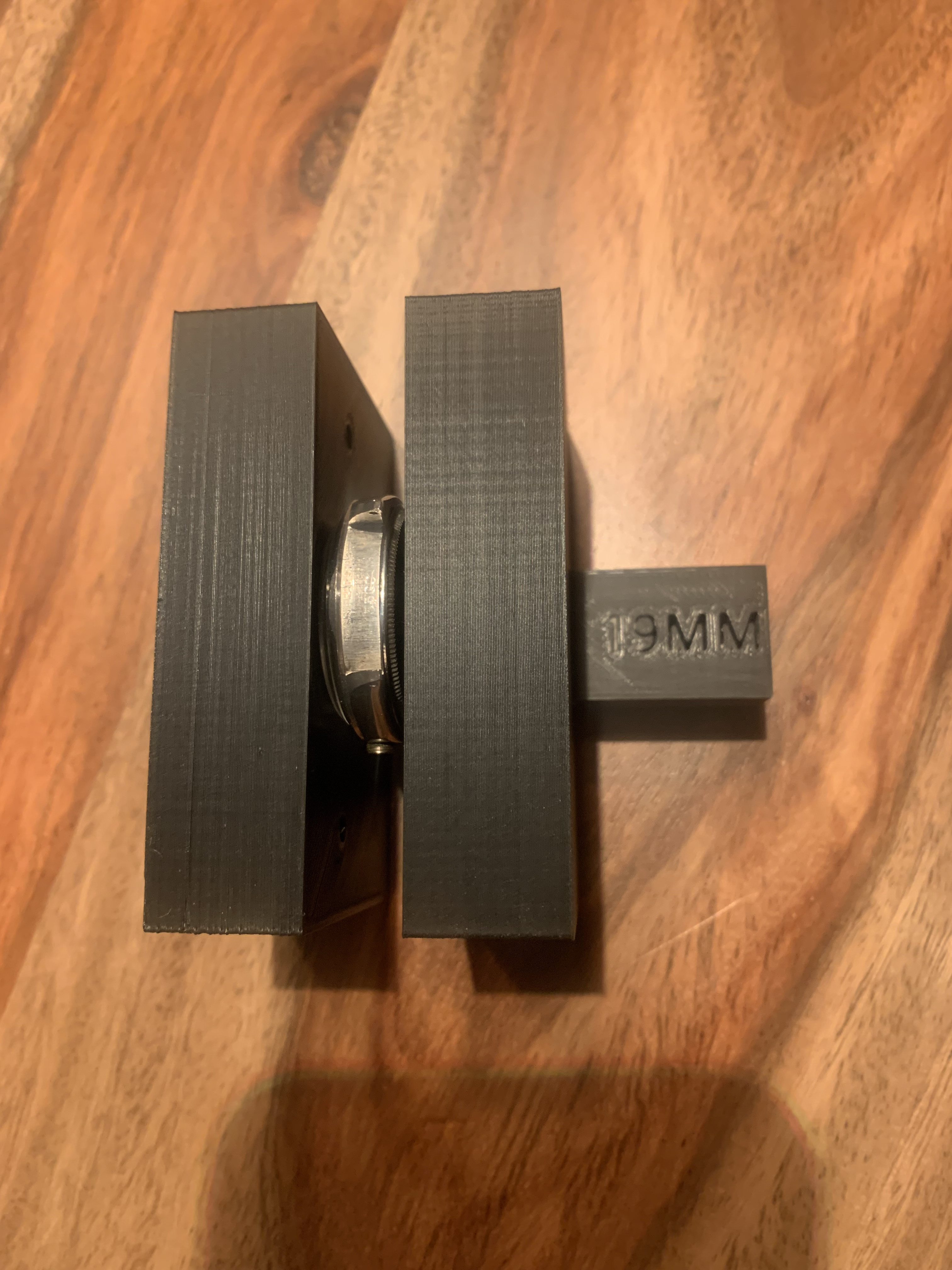

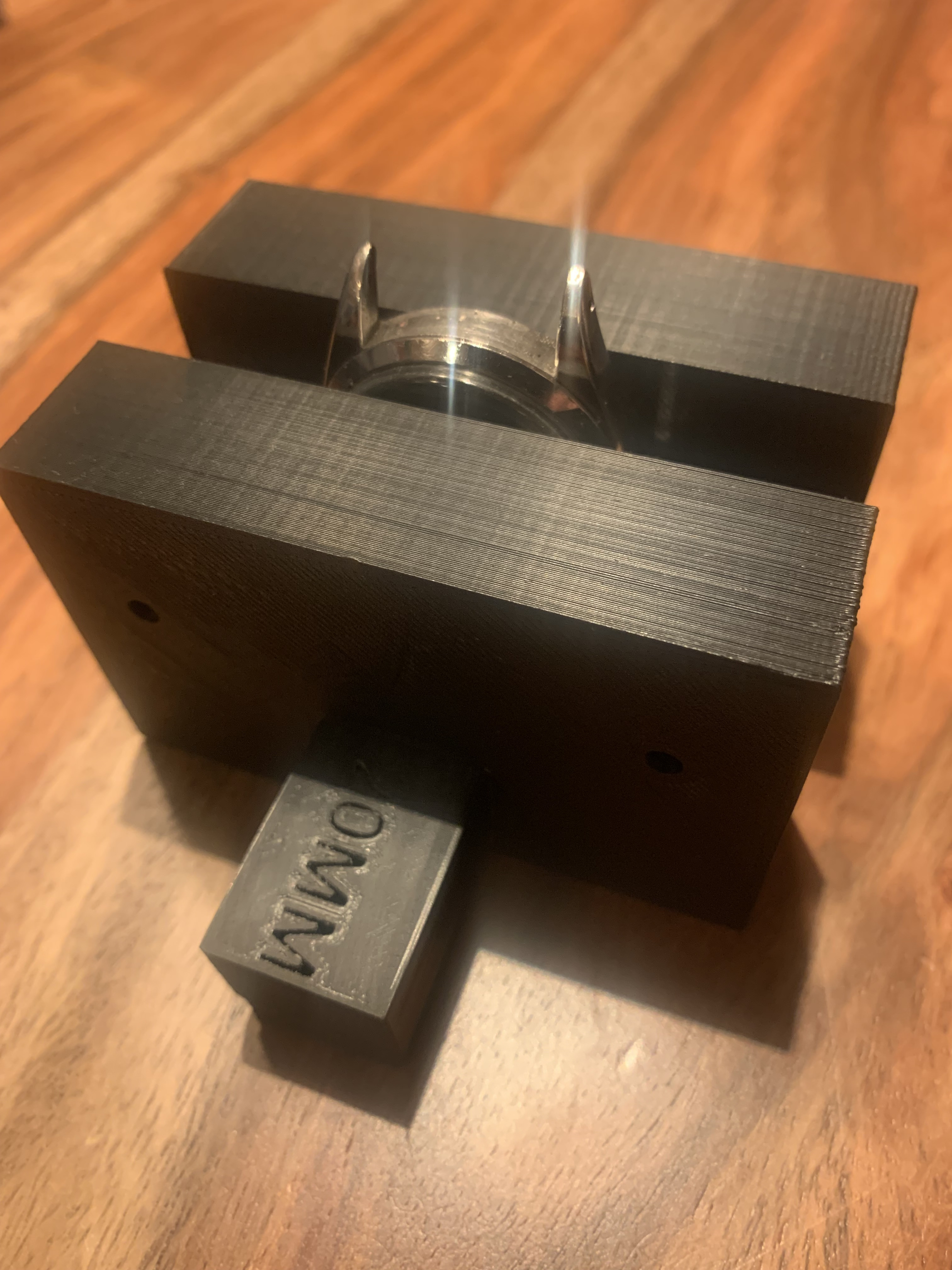

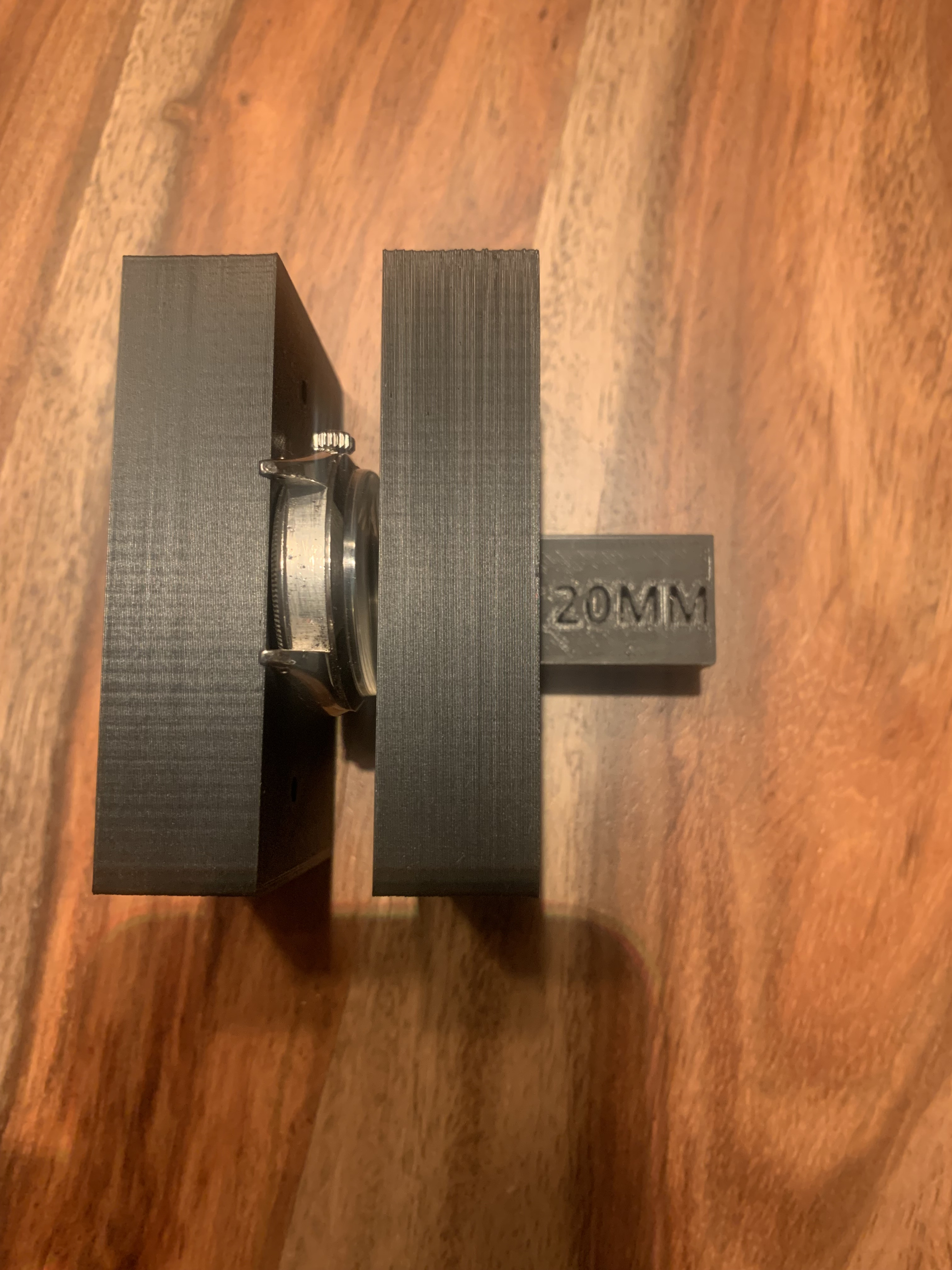

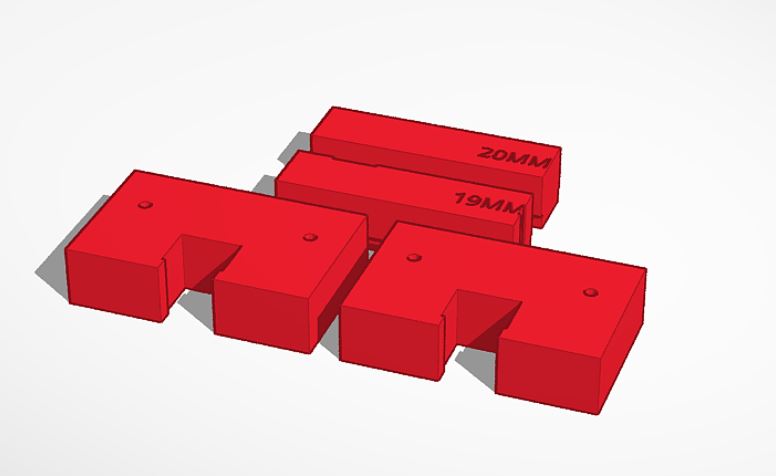

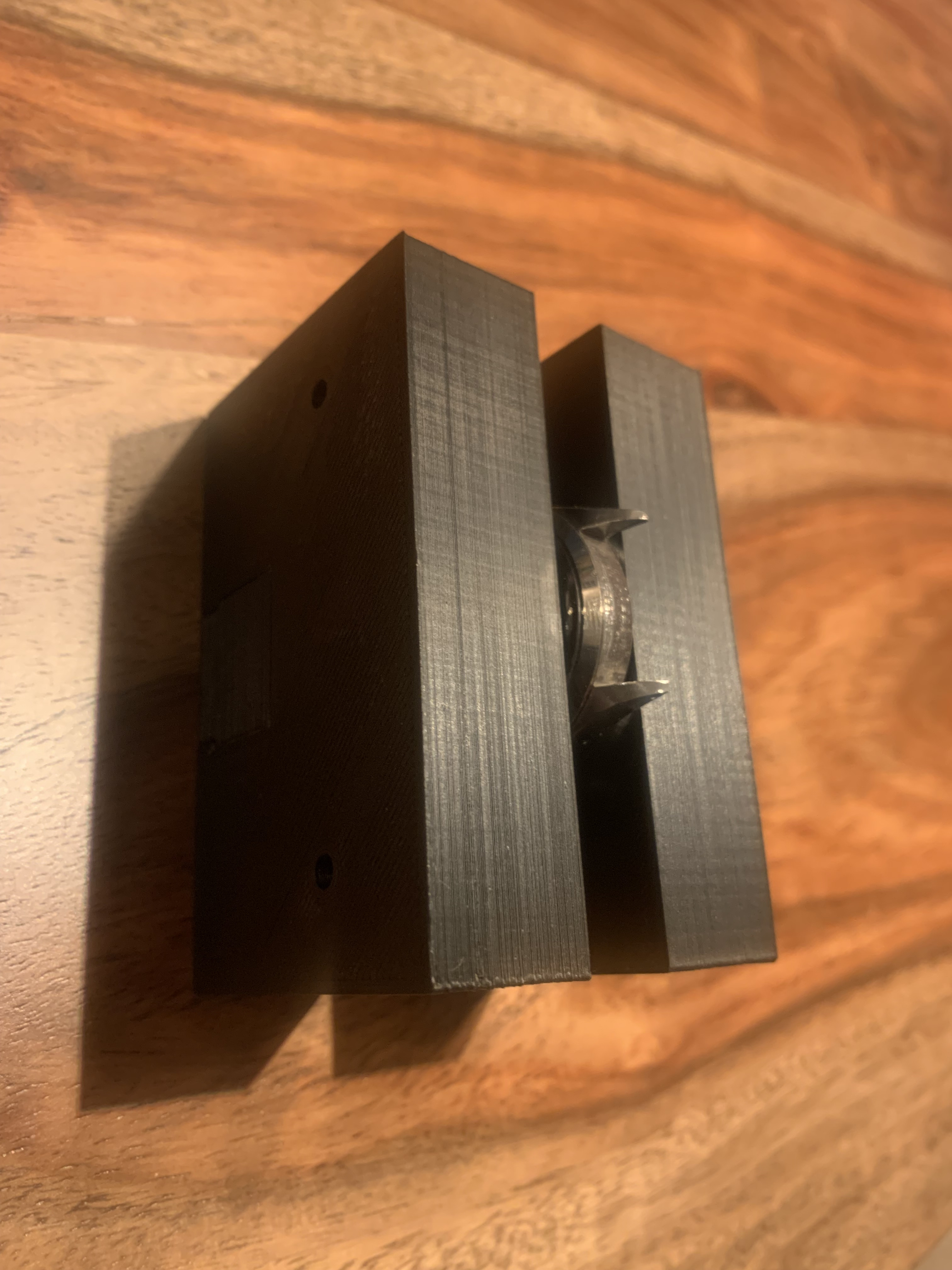

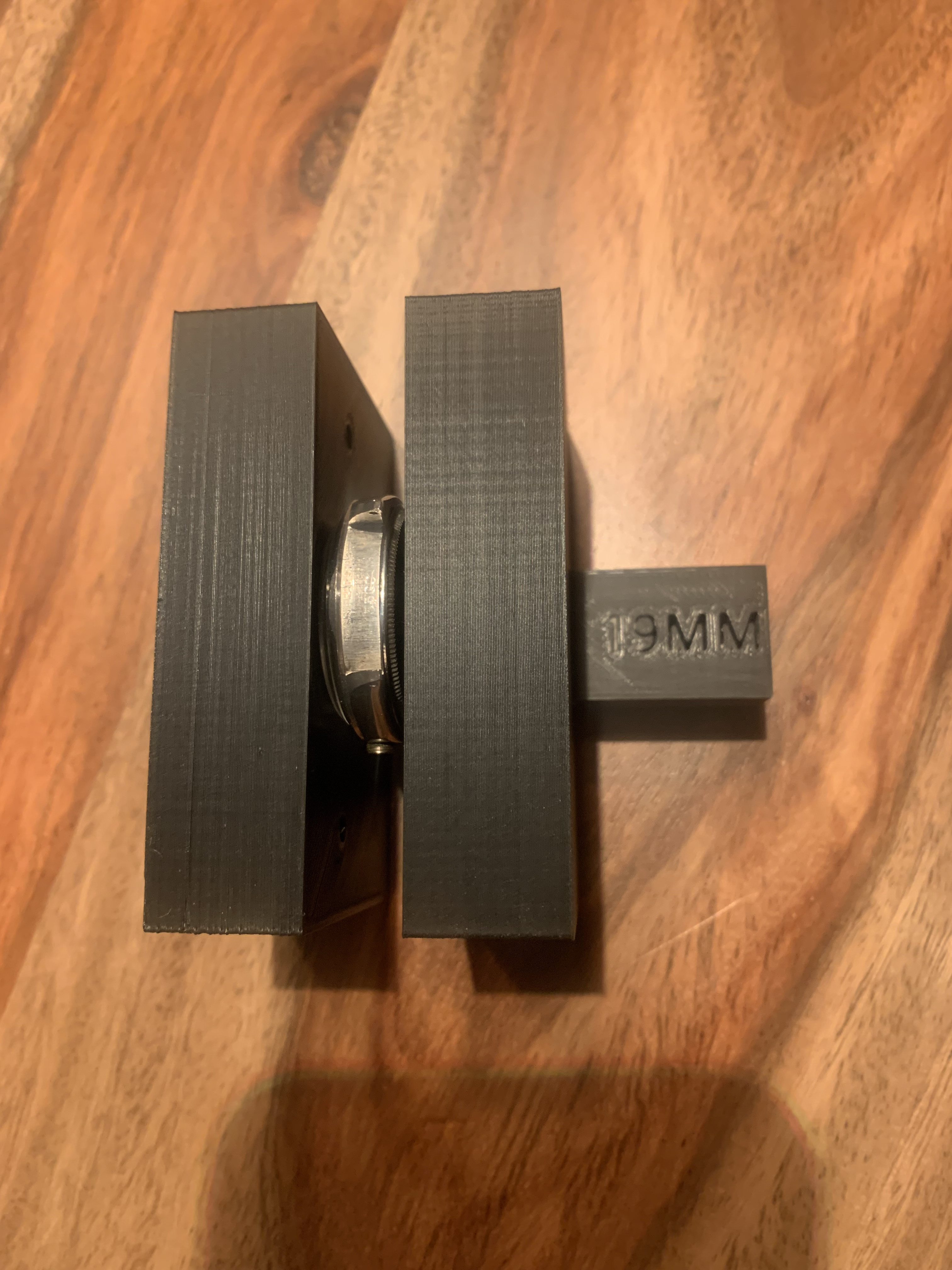

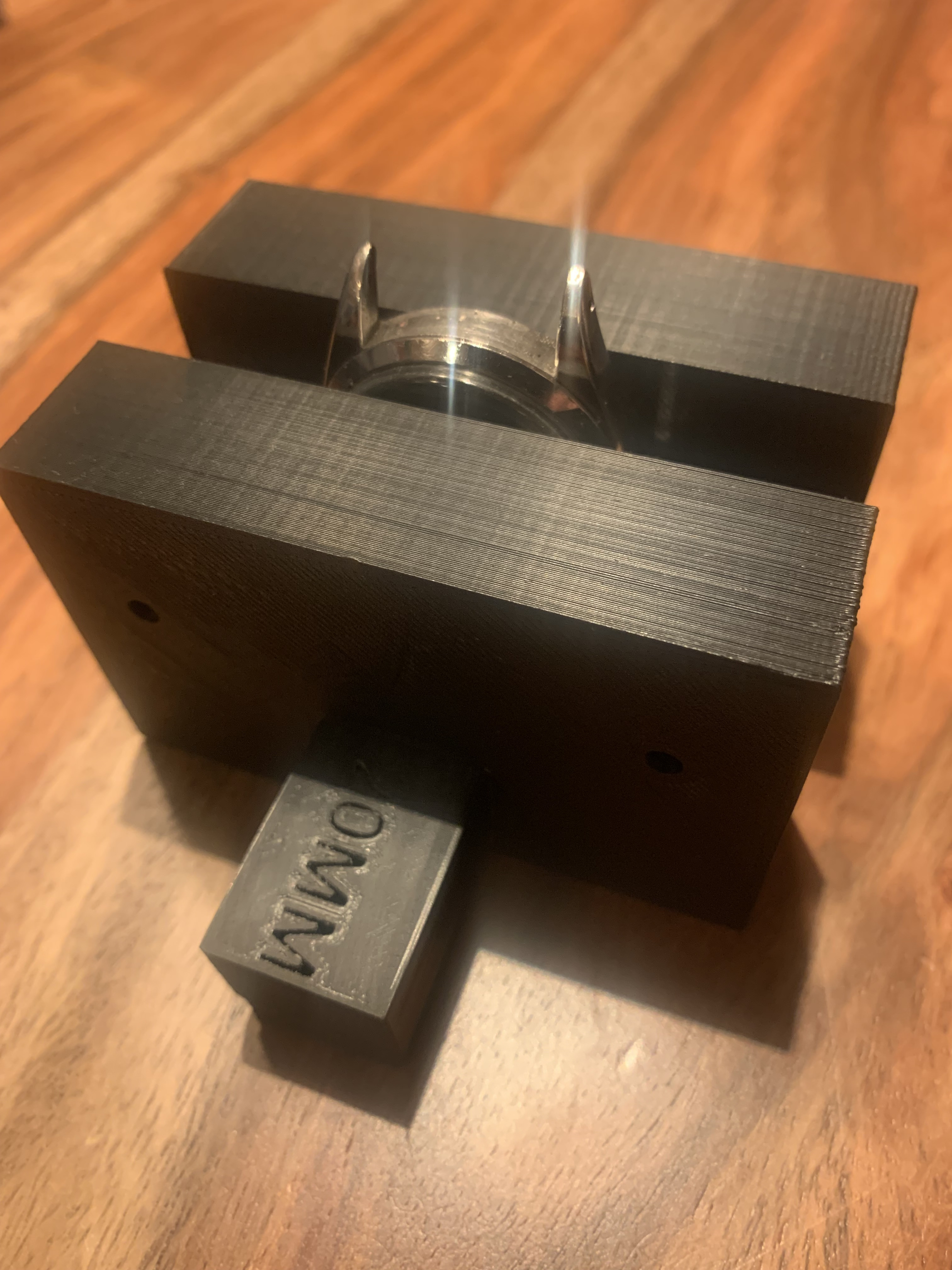

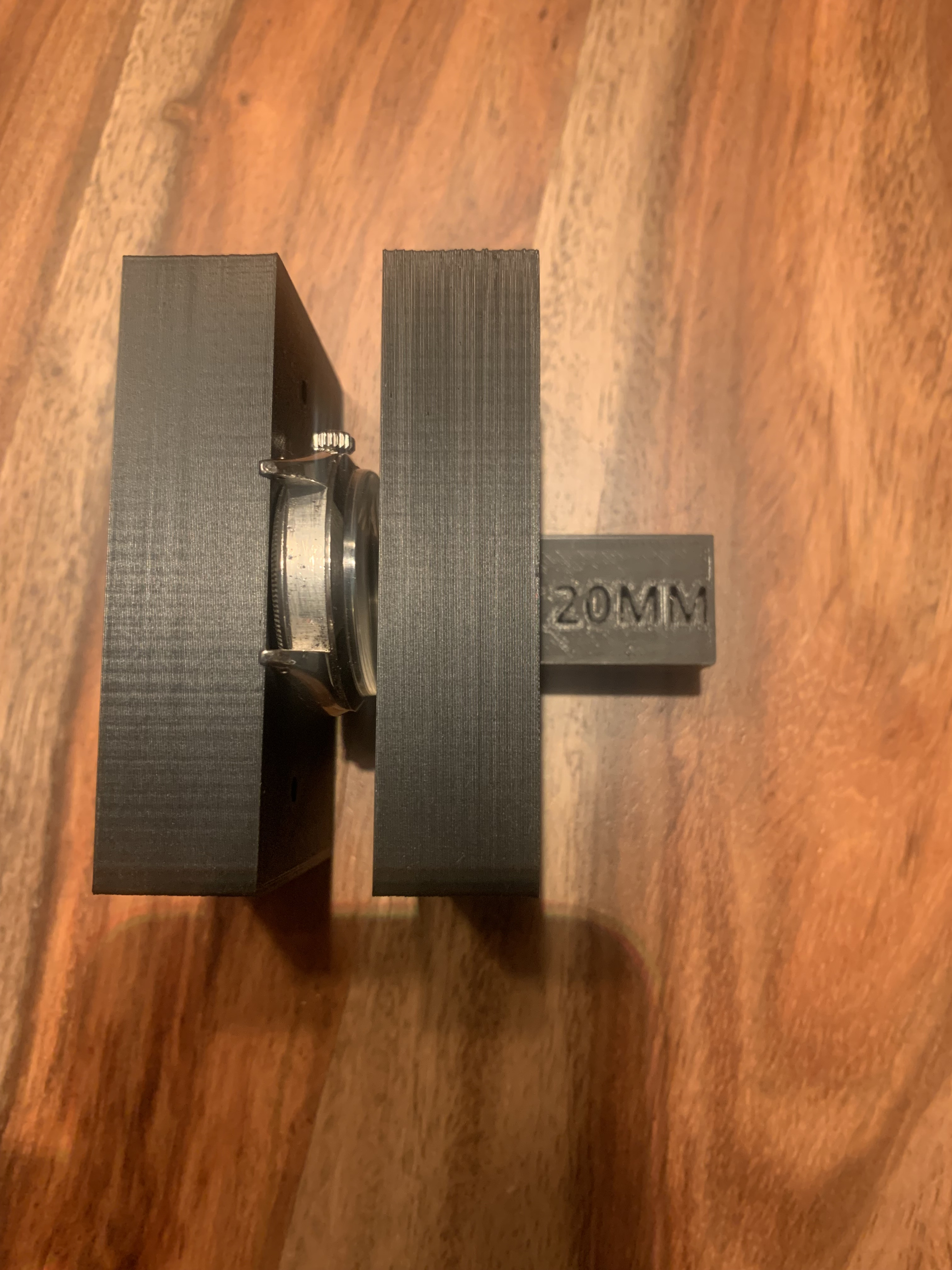

As far as holding the watch still for engraving, I'm still working the bugs out, but I did start a rough jig and 3D printed it to hold the cases. It's a little stiff out of the box, so the flat sides benefit from a little sanding to smooth it up, but it's rock solid. There are holes in the sliding pieces for a bolt to go through, so it can be clamped with wing nuts. I made it 1/4", but the holes can be opened for a bigger bolt...I just didn't want to allow enough clamping force to damage the watch or the jig.

I'm making improvements in real time, so what you see is likely not what you would download, but if you do get a mind to printing this up, go with whatever is the latest version. It will hold cases with 19mm and 20mm lugs. The first link will be the last known working copy, and the "beta" will include untested improvements that may or may not work, lol. Future improvements will probably include relief cuts for the watch case, to increase the contact area and make it more solid, a system to mount it to the engraver base (where the vice/jig is), and possibly some other tweaks. I'd also recommend something like foam or rubber tape on the surfaces that make contact with the watch, to protect the surface and to hold it more securely.

Watch Jig for Engraving 3D Print file (working copy)

Watch Jig for Engraving 3D Print file BETA (with most recent upgrades, some of which might not be better, lol)

The rough idea and some photos of it in practice:

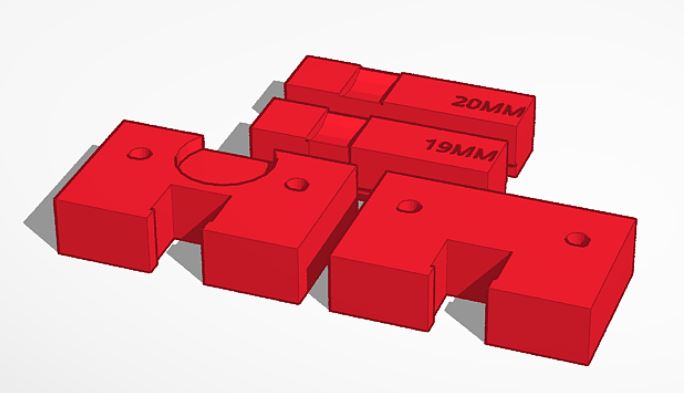

And the Beta version I'm trying to improve. Upgrades at the moment are bigger holes for threaded bolts, a relief cut for the crystal (size and diameter probably need tweaking, it's a rough guess based on the watch I'm wearing), and a curved cutout to support the bottom of the case between the lugs.

Finally, some links to New Hermes catalogs, which show some of the machines, fonts, and accessories, and explain how some of it works.

The New Hermes engravers seem to pop up here and there, but there's almost always one for sale on Ebay, Craigslist, or Facebook Marketplace (for us in CONUS, there are European equivalents to Craigslist that I'm unfamiliar with, but the idea is the same). They sell for anywhere from $100-1000 or so, depending on what's included.

There are two general types, and several models within the two basic types. Drag Engravers, which are completely manually operated, and Rotating Engravers, which use an electric motor on a belt to spin a bit to engrave. Rolex seems to have used drag engravers. If you find a deal on a rotating engraver, you can use a bit that's designed for drag engraving in it...assuming you can find one. This is the part you need:

New Hermes offered several different kinds of fonts. The correct font set is a little hard to nail down. To my eye, it appears to be either "Regular Block" or "Condensed Block," which were the most common fonts they offered. That said, letters from those sets look right, but the numbers from those sets don't appear to match the ones Rolex used, so it's possible that Rolex used a custom set, or a mix of fonts from different sets.

These are what the Rolex fonts look like (from this excellent post):

And these are the New Hermes fonts:

The letters look very good (although I can't decide if Regular or Condensed is correct...it's difficult to say, since the engraver is designed to write on a flat plane, and the case itself is curved, so the letters would be compressed as you get farther from the center.

For the numbers, Rolex used more than one font. At least 2, up to 5, if you count service center engraving. Regular and Condensed Block are very close, but to my eye, Helvicta and Futura have better a better number 1.

That said, we're talking about writing that's shallow, often nearly worn off, and covered by the end links or band, so infinitely parsing the serifs on specific characters is maybe a bit of overkill. On my gens, most of the time the number is barely legible after a few years, and the case has to be manipulated under a strong light, at just the right angle, to even see that they're there.

As far as how big the font is, it's a bit tricky to nail down. New Hermes offered fonts in different sizes, and the engraving machines can reduce those sizes from 1:1 to 1:8. So if you have a set of 1" fonts, you can reduce it down to 1/8" If you have a 1/2" set, you can go down to 1/16". Pretty much any set over an inch is useless for engraving between the lugs, so you're stuck with either 5/16", 1/2", 5/8" or 3/4". I have yet to take a caliper to the numbers, but if anyone knows the EXACT size, I'd love to know it.

Other options they offered that would be of value to a watch modder would be a vice and jig designed for holding watch cases (although this holds the watch on the wrong plane, it's more for engraving case backs):

And a cool jig for rotating in a circle (like on the case back of a Tudor or Seadweller, or some of the writing inside the case back):

As far as holding the watch still for engraving, I'm still working the bugs out, but I did start a rough jig and 3D printed it to hold the cases. It's a little stiff out of the box, so the flat sides benefit from a little sanding to smooth it up, but it's rock solid. There are holes in the sliding pieces for a bolt to go through, so it can be clamped with wing nuts. I made it 1/4", but the holes can be opened for a bigger bolt...I just didn't want to allow enough clamping force to damage the watch or the jig.

I'm making improvements in real time, so what you see is likely not what you would download, but if you do get a mind to printing this up, go with whatever is the latest version. It will hold cases with 19mm and 20mm lugs. The first link will be the last known working copy, and the "beta" will include untested improvements that may or may not work, lol. Future improvements will probably include relief cuts for the watch case, to increase the contact area and make it more solid, a system to mount it to the engraver base (where the vice/jig is), and possibly some other tweaks. I'd also recommend something like foam or rubber tape on the surfaces that make contact with the watch, to protect the surface and to hold it more securely.

Watch Jig for Engraving 3D Print file (working copy)

Watch Jig for Engraving 3D Print file BETA (with most recent upgrades, some of which might not be better, lol)

The rough idea and some photos of it in practice:

And the Beta version I'm trying to improve. Upgrades at the moment are bigger holes for threaded bolts, a relief cut for the crystal (size and diameter probably need tweaking, it's a rough guess based on the watch I'm wearing), and a curved cutout to support the bottom of the case between the lugs.

Finally, some links to New Hermes catalogs, which show some of the machines, fonts, and accessories, and explain how some of it works.

Last edited:

Superb!!!

This is an incredible feature, now Milk case could have it!

This is an incredible feature, now Milk case could have it!

I'm searching for the correct fonts quite a while... which ones you took?here's the teaser

To my eye, it looks like Rolex used more than one font over the years, perhaps a combination of fonts. My guess is when they were a relatively small operation, they bought some engraving machines and fonts, but over the years, as parts wore out and were replaced, and production increased, some of the block letters, or even complete sets, were replaced by different font sets, or even the same fonts made from different production runs, as the photos posted here a page or so back show. It's also possible that as a smaller operation grew into a larger one, they had to use different machines, made at later dates, to keep up with prodution. So a half dozen manual engravers was likely enough to keep up with a few thousand watches a year, many more, possibly automated, machines replaced them when production increased 10 or 100 fold.I'm searching for the correct fonts quite a while... which ones you took?

Condensed and Regular Block seem to be where they started, and as production went on, some of the letters seemed to change, to either Helvicta or Futura. It's also possible that service cases were sent without engraving, and it was added at a local level by service centers, who may have used the "incorrect" font.

We study these things after the fact, scrutinizing details as if there were a strict adherence to every minor detail, but sometimes we forget that Rolex was once a small watchmaker, struggling to grow their business and keep up with demand. The "wrong" font is a deal breaker for us today, but 50-100 years ago, "good enough" was probably used quite frequently.

First attempt worked out pretty fine... Hope to bring it that way down on the case... What a hell of a ride in a rabbit hole, I never wanted to go down!!!To my eye, it looks like Rolex used more than one font over the years, perhaps a combination of fonts. My guess is when they were a relatively small operation, they bought some engraving machines and fonts, but over the years, as parts wore out and were replaced, and production increased, some of the block letters, or even complete sets, were replaced by different font sets, or even the same fonts made from different production runs, as the photos posted here a page or so back show. It's also possible that as a smaller operation grew into a larger one, they had to use different machines, made at later dates, to keep up with prodution. So a half dozen manual engravers was likely enough to keep up with a few thousand watches a year, many more, possibly automated, machines replaced them when production increased 10 or 100 fold.

Condensed and Regular Block seem to be where they started, and as production went on, some of the letters seemed to change, to either Helvicta or Futura. It's also possible that service cases were sent without engraving, and it was added at a local level by service centers, who may have used the "incorrect" font.

We study these things after the fact, scrutinizing details as if there were a strict adherence to every minor detail, but sometimes we forget that Rolex was once a small watchmaker, struggling to grow their business and keep up with demand. The "wrong" font is a deal breaker for us today, but 50-100 years ago, "good enough" was probably used quite frequently.