-

Tired of adverts on RWI? - Subscribe by clicking HERE and PMing Trailboss for instructions and they will magically go away!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

GMF Day-Date 40mm Tungsten Heavy Version

- Thread starter Theodizee

- Start date

- 12/3/18

- 37,544

- 80,336

- 113

I think the case is made of tungsten so it will still feel light. The ultimate dream will be if the bracelet feels also heavy like gen.

Jtime's description

Case Material Solid 904 stainless steel bracelet (with tungsten in steel to increase the weight) Strap Solid 904 stainless steel bracelet (with tungsten in steel to increase the weight)

didjital7

Renowned Member

- 30/1/21

- 567

- 406

- 63

AndroidNut

Known Member

- 4/5/20

- 110

- 39

- 28

This should be done for two tone watches (smaller weight delta between gen/rep).

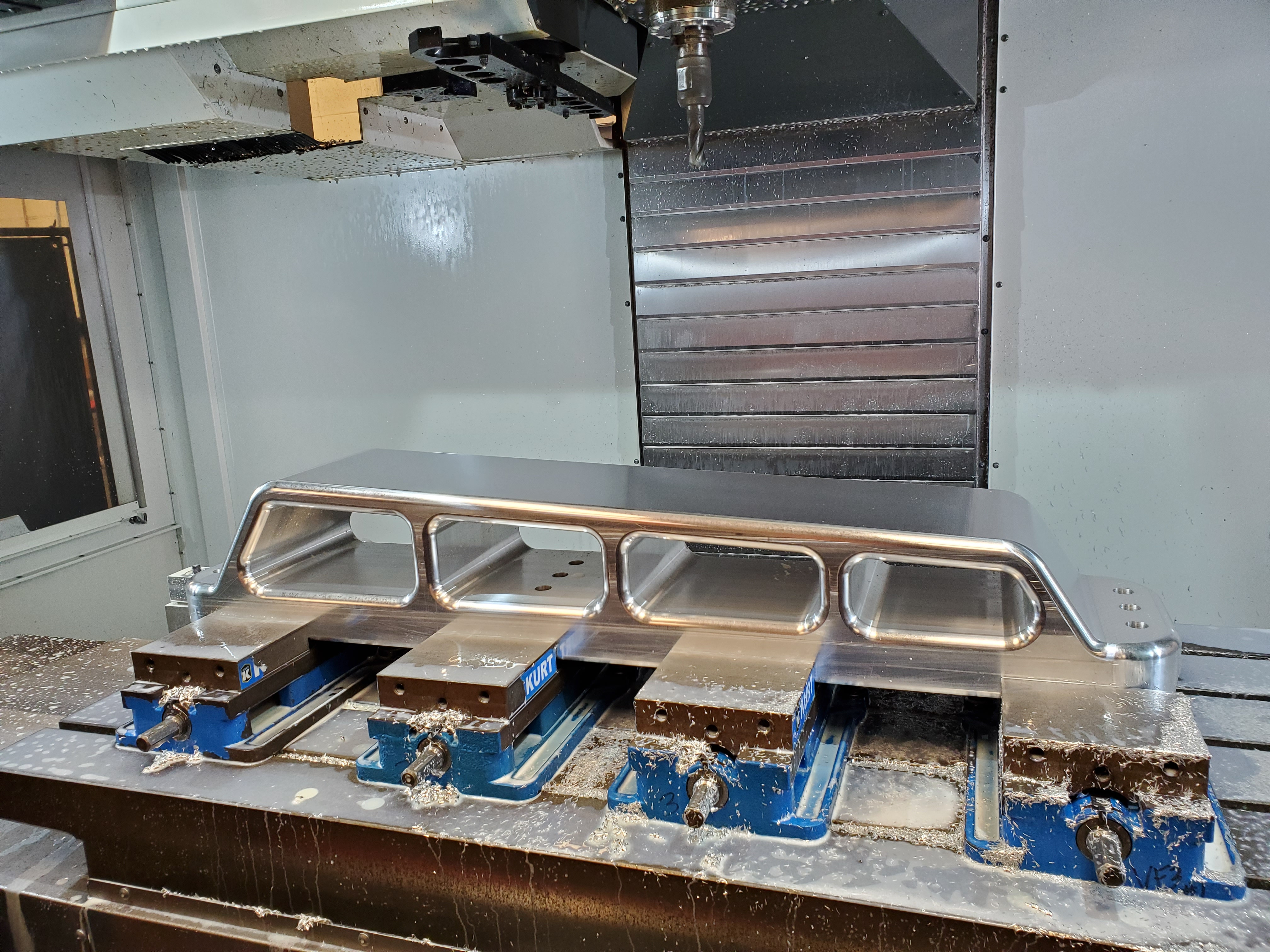

If it’s just a weight hidden somewhere eg inside a thicker caseback, then it’s probably just a simple tungsten slug. But if it’s actual watch parts (case, clasp, bracelet links) then they’re almost certainly made out of Tungsten-Copper (W80-Cu20) alloy which is much easier to machine than 100% tungsten. W-Cu machines about the same as cast iron — not easy, but certainly not hard.

nom_deplume

Known Member

A Tungsten slug ... hidden somewhere in the watch. Interesting concept. I imagine difficult to hide anything in a watch.

A Tungsten slug ... hidden somewhere in the watch. Interesting concept. I imagine difficult to hide anything in a watch.

Agreed. Assuming we’re swapping out steel or brass parts that are easy to machine for tungsten versions of the same part. This watch weighs ~40g more than the SS version. The density of tungsten in 19.3g/cm3. And we’d be displacing steel (7.8g/cm3) or brass (8.7g/cm3) we have to swap out approximately 3.5 cm3 of steel or brass parts for tungsten parts to add 40g.

- an easy place to hide a tungsten slug might be the dial blank. Instead of brass for the blank, use tungsten. I don’t know exactly how big the day date dial is but let’s assume 30mm diameter and 1mm thick. That’s a volume of 0.7cm3… but that’ll only add 8g. That’s a start, but we’ll have to do better.

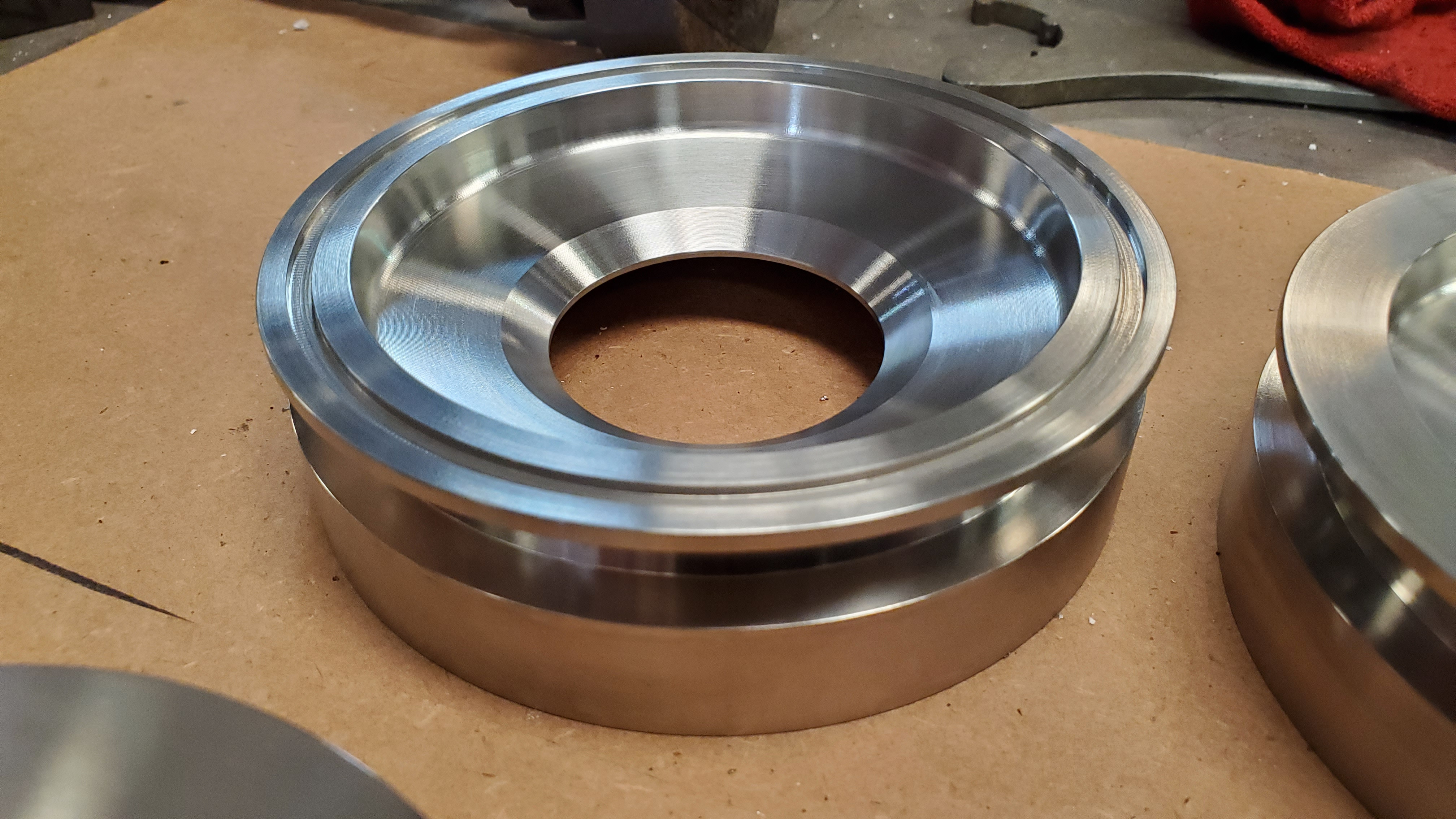

- the screw down caseback is 11.3g and is made of stainless steel. The same caseback made of tungsten would weigh 28g. That’s a gain of 16.7g… pretty good, but still a long way from 40g.

- There is a movement spacer / cradle ring between the movement and the case on this model; maybe that’s made of tungsten? This spacer ring could be ~3mm wide, ~7mm deep and around ~26mm in diameter (I’m guessing here). If we made that part out of tungsten it would weigh ~ 82g vs ~33g if it were made of steel. So that’s +50g.

I don’t have the exact dimensions of the movement cradle that holders the Asian ETA clobe movement that’s used in these GMF dayDates, but my guess is that the metal ring that secures the movement inside the case is the part that’s been swapped out for tungsten to add 40g to the watch. The movement ring is relatively easy to machine and doesn’t require precise finishing or geometry. And it means swapping one part in the assembly process to get a rep that’s a lot closer to the gen weight. But obviously not the gen weight distribution.

nom_deplume

Known Member

Regardless of what % of Tungsten may be 'hidden' ... even if it's 50% it will still be .. MOAR ... so chill get it or not. move on. Hidden. You think the geniuses building this rep think how they can hide an extra 10% of Tungsten. C'mon

- 13/7/14

- 412

- 338

- 63

^ This. No point in having a heavy case and a light bracelet. The weight will be completely disproportional and wear ridiculously.I think the case is made of tungsten so it will still feel light. The ultimate dream will be if the bracelet feels also heavy like gen.

newest dude on the forum

Some Guy

Dude, make 1:1 5 digit cases!

didjital7

Renowned Member

- 30/1/21

- 567

- 406

- 63

I asked people about thos before. I would need a sample to reverse engineer...

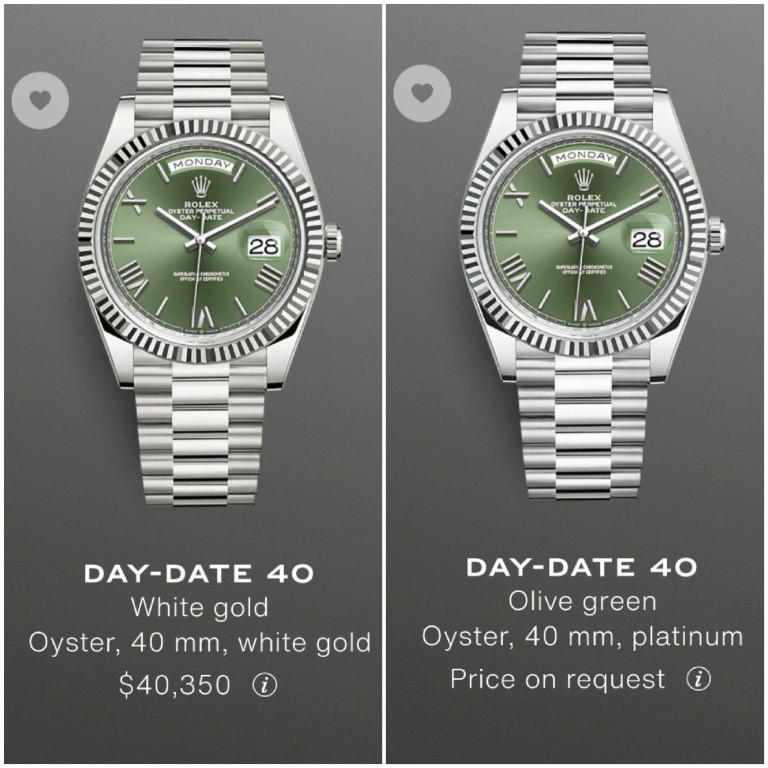

The link shows a model that's made from Platinum as far as I know.Gold 19.30 g/cm^3

Tungsten 19.25 g/cm^3

- 12/3/18

- 37,544

- 80,336

- 113

Only way you could tell for sure is with an Ice Blue dial, available only in PT.The link shows a model that's made from Platinum as far as I know.

Green, white and blue Roman dials are available in both WG and PT

Last edited:

I sold my GMF 40mm DD because it felt too light

but 40 grams ? IDK if that will make a difference ?

IF Gmf would make a 36mm DD that weighs 160 grams that would be ideal! would be same as the 18038 gen rolex I had !

but 40 grams ? IDK if that will make a difference ?

IF Gmf would make a 36mm DD that weighs 160 grams that would be ideal! would be same as the 18038 gen rolex I had !

Probably just the larger parts have a tungsten core, as its notoriously difficult to machine. Its all for nothing though if the 'gold' plating is shit - which it probably will be.

Right ... but at least for the WG / PT models it would be good ... although, hm, around 40g extra through tungsten ... and in case of the YG DD still 60g(!) more to go ... that's, huh ... well, at least a little bit improvement.

I look at this whole rep vs. gen weight difference issue differently / more seriously since my friend presented me his new gen DD Platin (same like this one: https://www.chronext.de/rolex/day-date/228206/V00100343) ... and it was CRAZY heavy! I totally didn't expect that ... and was kind of "happy" with my superlight blue Noob Daytona ... much more "comfortable" on the wrist, lol!

Only way you could tell for sure is with an Ice Blue dial, available only in PT.

Green, white and blue Roman dials are available in both WG and PT

Yeah, kinda right ... I was at the same point like you ... and then saw, that even in their renderings they make a tiny little color distinction between WG and PT:

... as in real life (I guess?!), the WG is a little more yellow than the PT.

... I used old school GIF animation to show