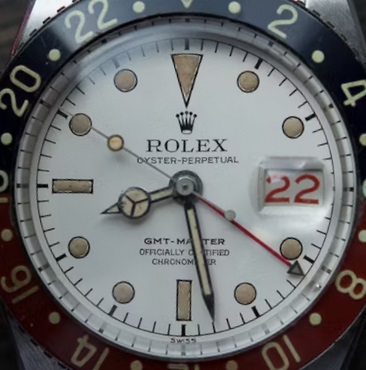

Again, thanks to everyone for the feedback! My last dial transfer was a disappointment for sure, but I tossed it a case for motivation anyway. No date wheel, no sweep hand... just needed some an extra push to stay on track. The feedback is helpful there too. Gave me a few more ideas to try out and needed the reminder to keep heat/pressure higher up on the list with toner transfer. And finally, to remind myself that a shit lume job at the start, will stay as a shit lume all the way through.

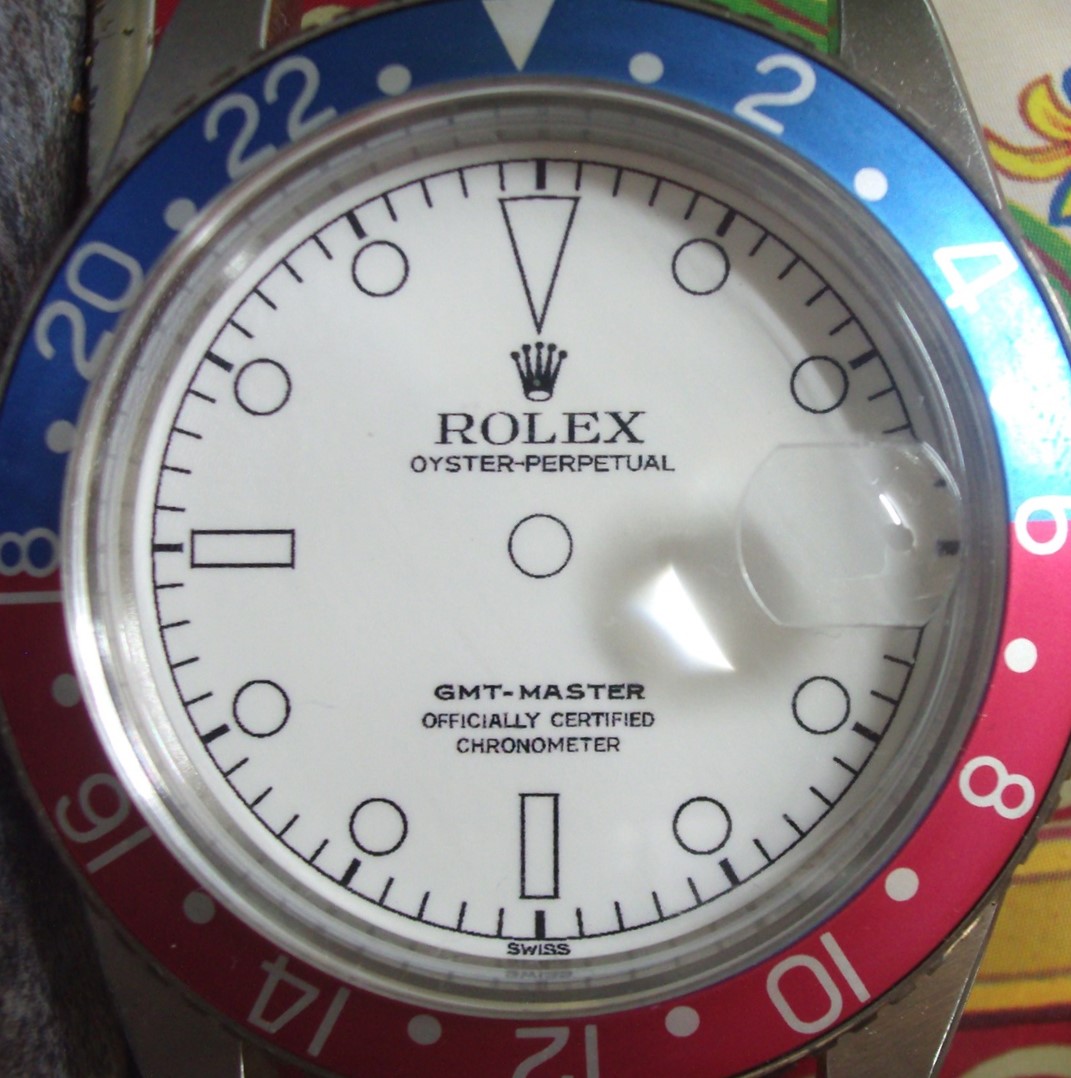

Here's a picture for everyone's amusement, but I still think it's another success for finding out what doesn't work!

Here's a picture for everyone's amusement, but I still think it's another success for finding out what doesn't work!