So after struggling to find a watchsmith in Vancouver that would service reps, I decided that I'd try to learn how to do it myself. I enrolled in Mark Lovick's online course and studied my way through the first two levels of the course before being brave enough to try to disassemble a movement. I'd ordered a Unitas 6497 (the movement used in the course) from AliExpress, but it has been stuck in customs for the last two weeks, and I was getting impatient. So rather than continue to wait, I elected to try "servicing" the VR3235 out of my CF DJ41. Note: I put the word "servicing" in scare quotes here because I'm pretty sure that since this is my first attempt, I'm going to leave the movement in worse shape than it was when it left China. Regardless, onwards... Here are some pics and some things that I found harder and easier than I expected.

Things that were easier than I expected:

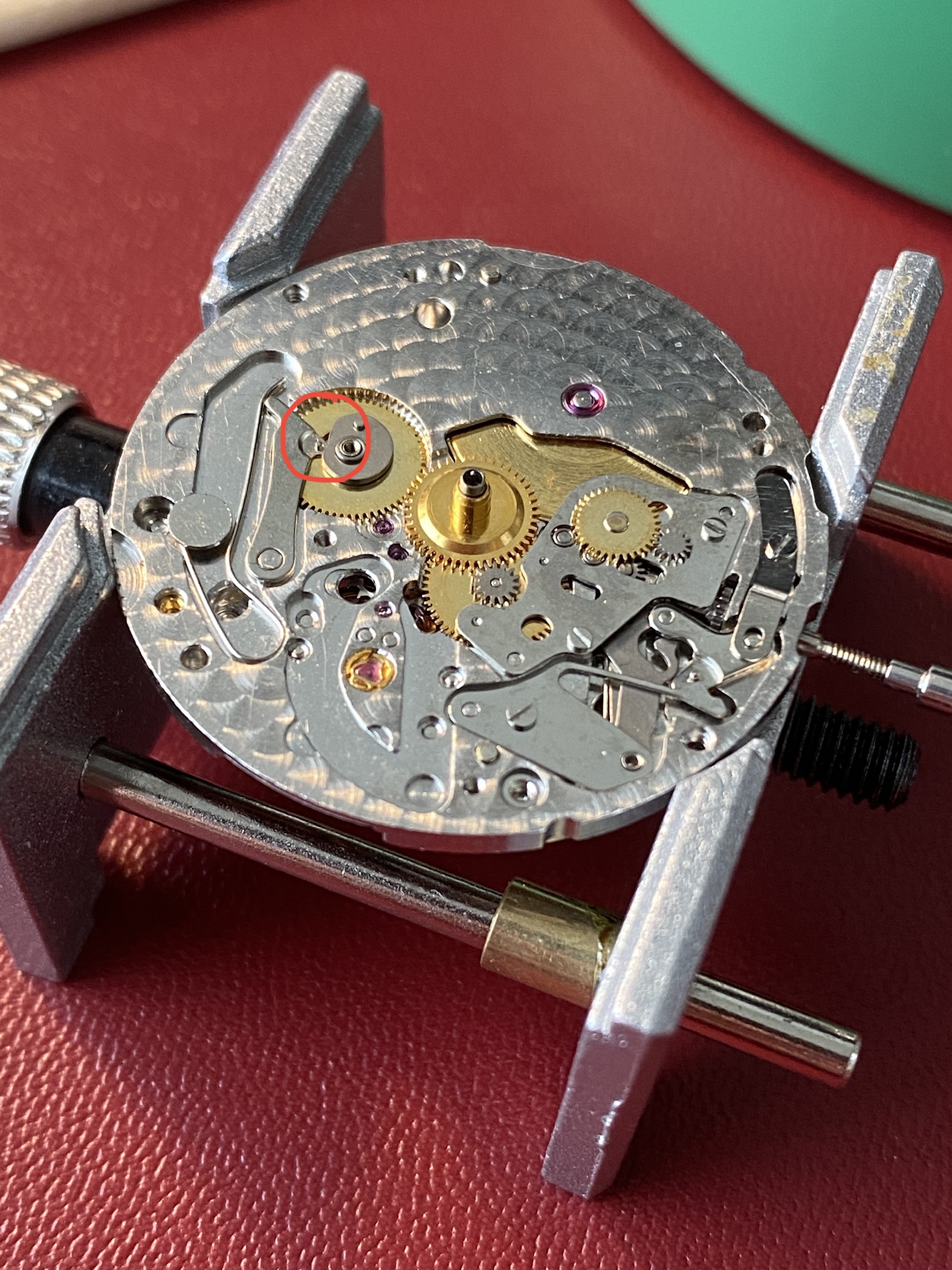

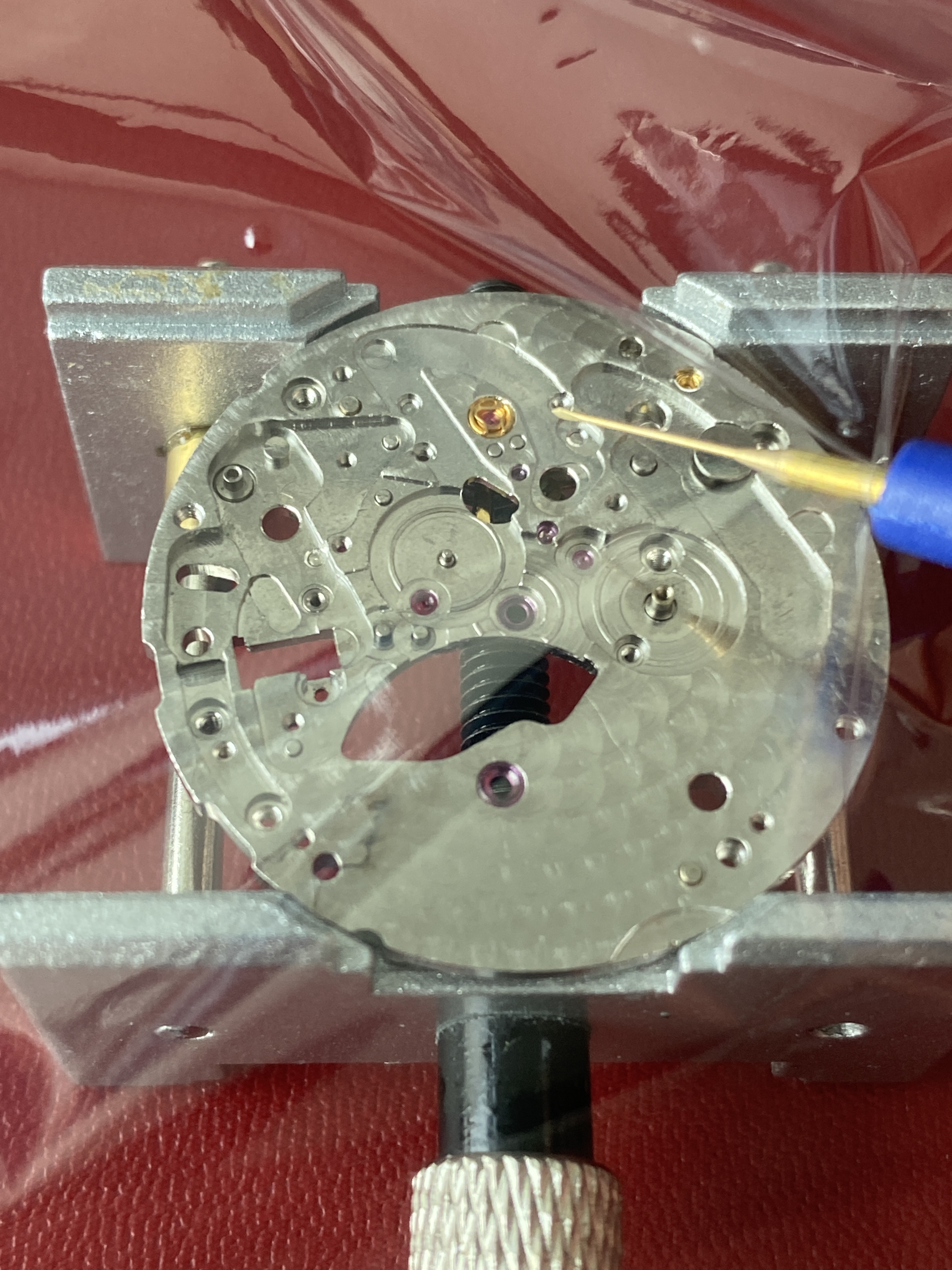

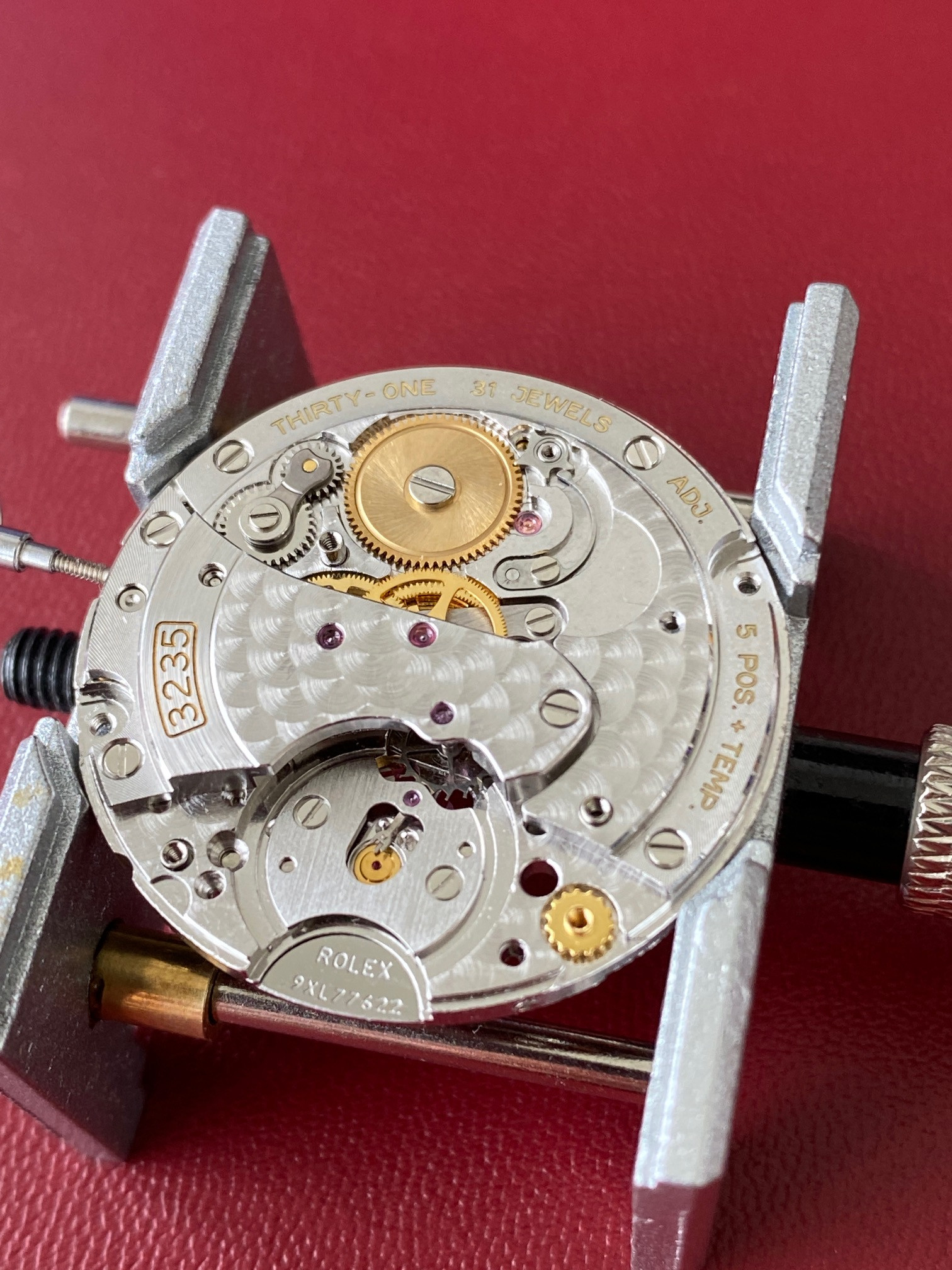

The parts:

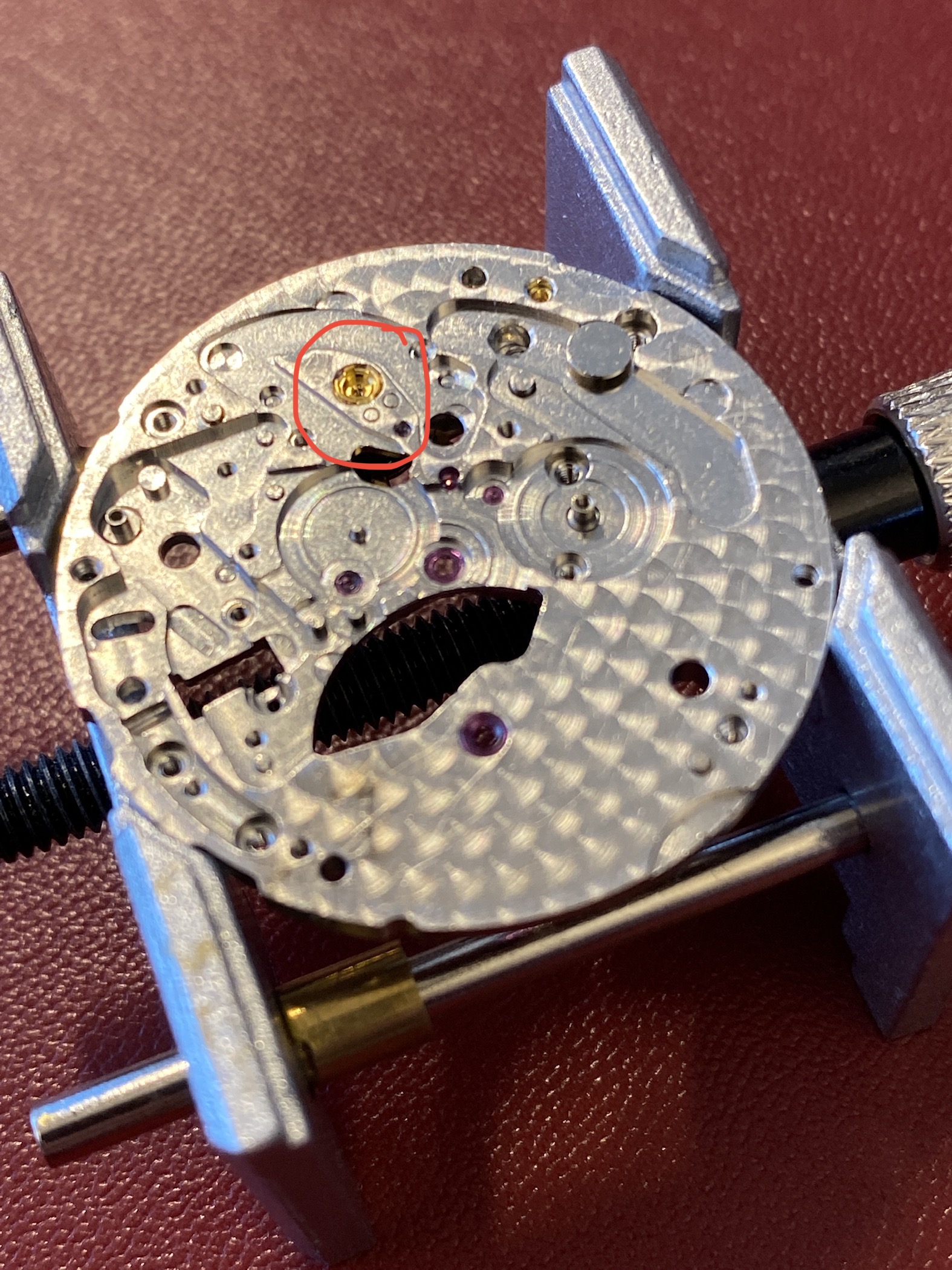

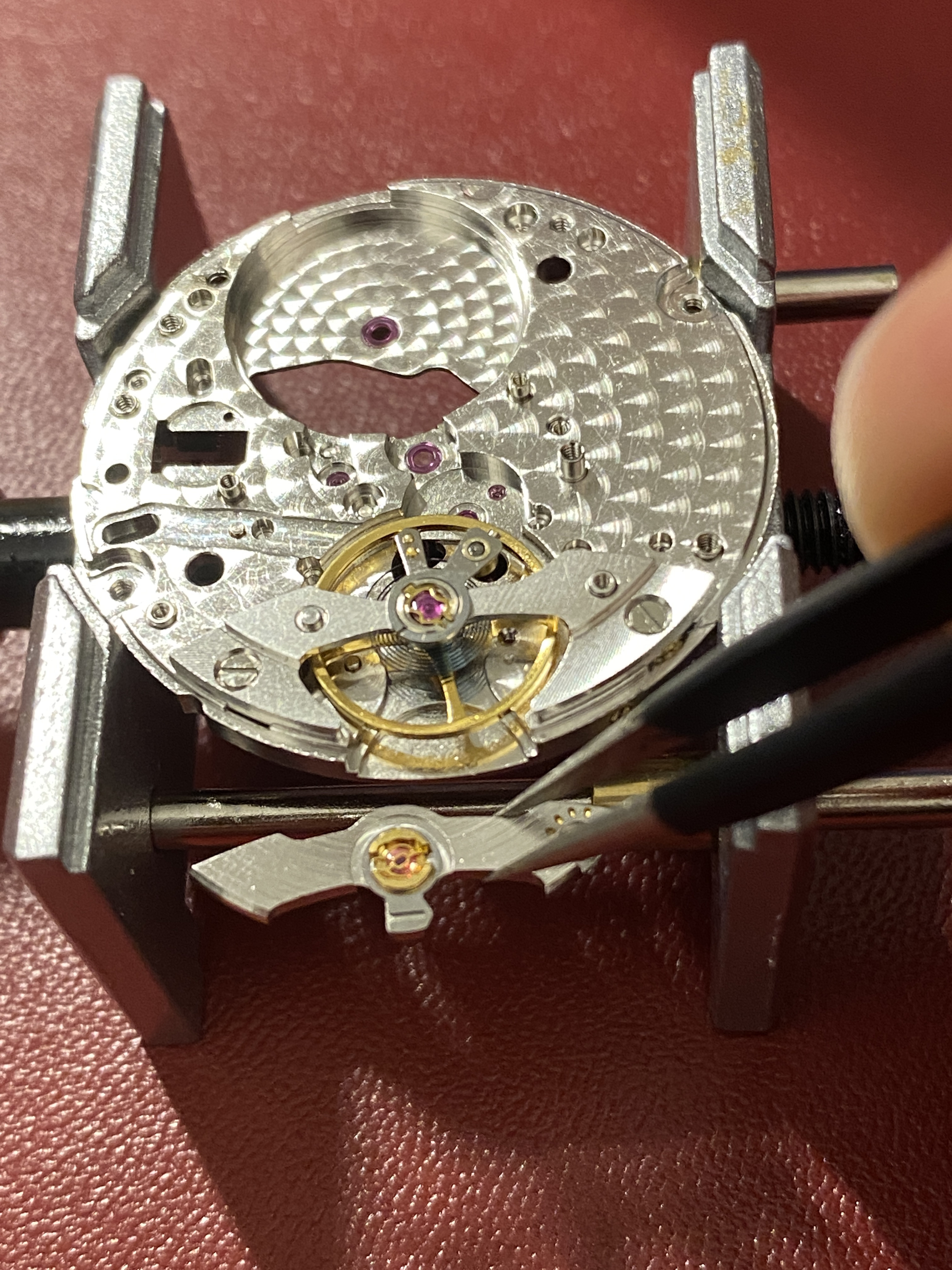

The semi re-assembled movement. Note the missing 3135-5115 screw that should be holding the click down.

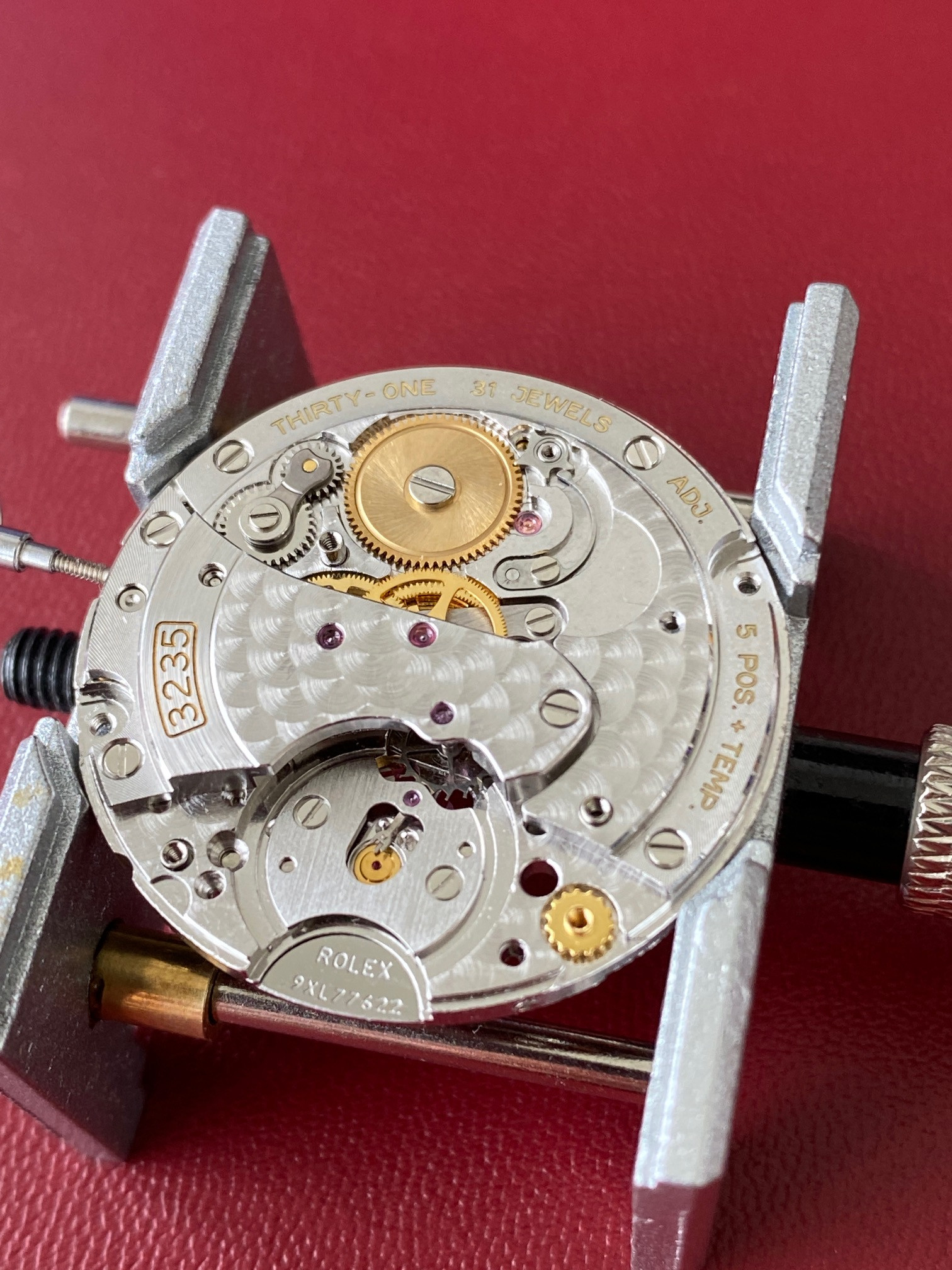

The balance back in and swinging.

My attempt to trap the missing screw by adding a magnetic trap to my vacuum.

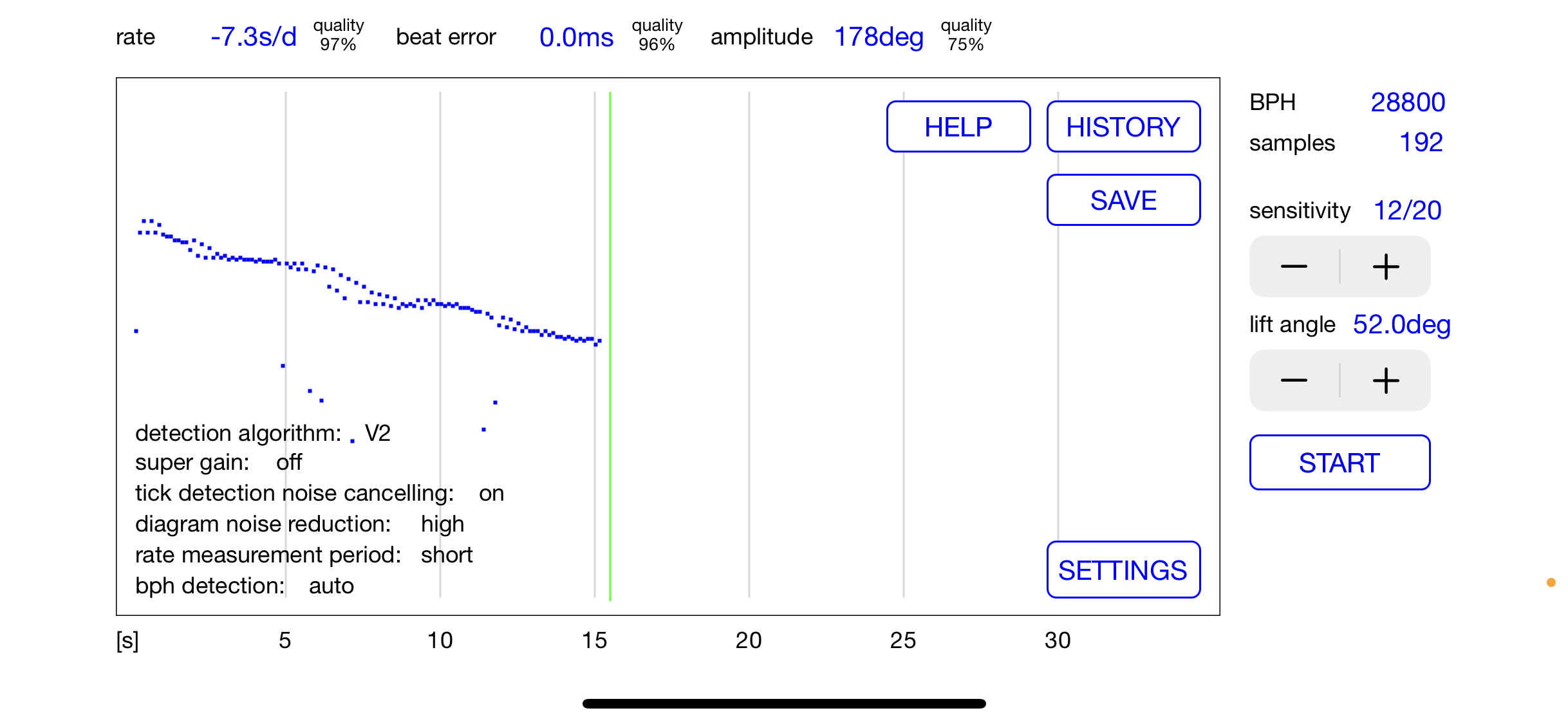

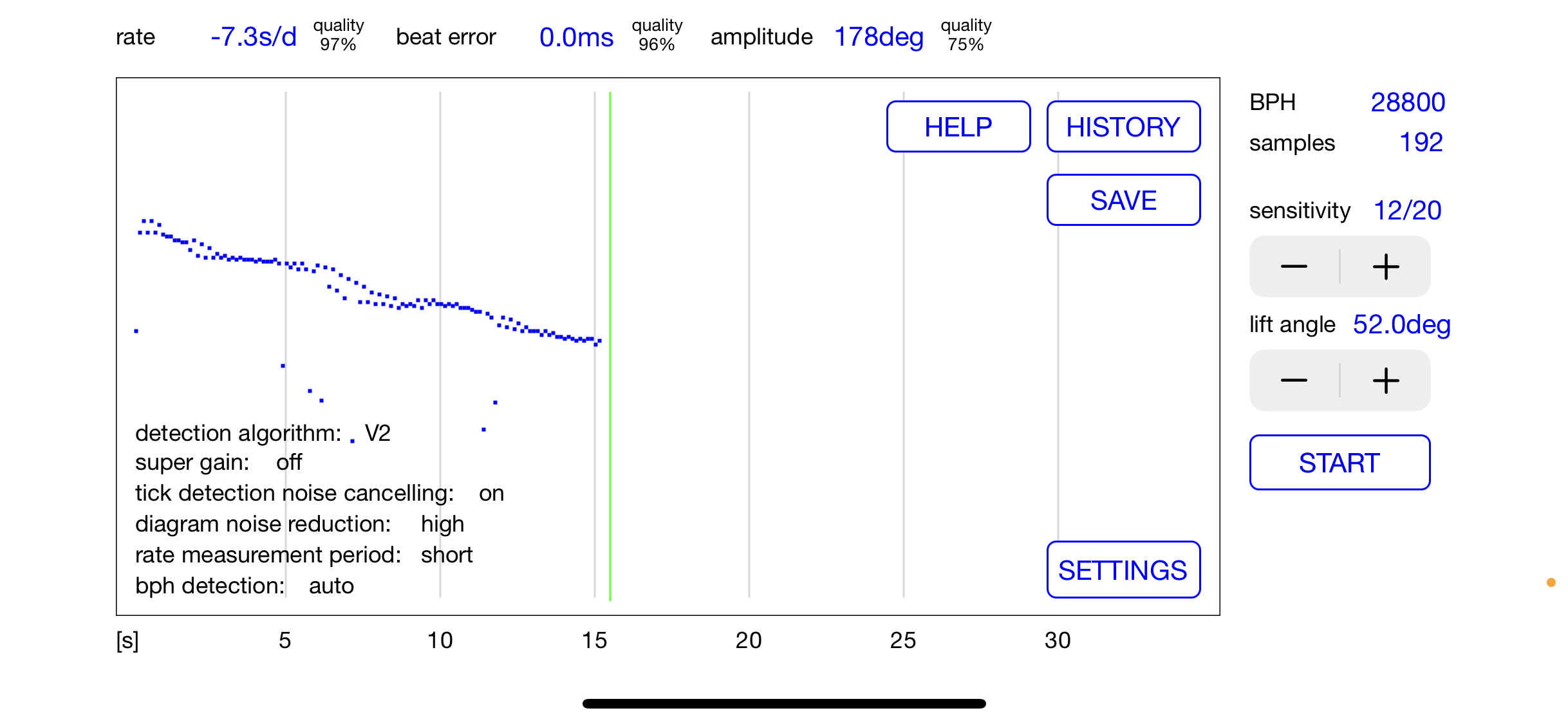

My first attempt at regulating the movement. When it was first re-assembled it was +25s/d, so I'd say getting it to here is technically a step in the right direction. Yes, amplitude is trash, but I'm pretty sure that's because it's not fully wound. I'm waiting for my spare screw to come in to finish the re-assembly, at which point I'll regulate properly.

Things that were easier than I expected:

- Removing the watch hands was pretty easy. I bough one of those cheap presto tools for hand removal from amazon, and with a layer of plastic to protect the dial, it worked like a charm. I thought this would be way harder.

- The disassembly and re-assembly process were actually pretty easy to follow. PsychoTee16 gave me access to some a rolex 3135 movement service manual that he had. And while the VR3235 is pretty different on the balance side, on the dial side and in the keyless works, it's very much like a 3135, so that was really helpful.

- Removing the dial from the movement was less intuitive than I expected. I loosened the dial screws on the movement, but the dial didn't come free. There were some places that looked like they'd been put there to insert a screwdriver to pry, but these didn't help (it turns out those slots were to help remove the date plate). I eventually got it when I realized the dial was thinner than I'd expected and that I was trying to pry off too much (i.e. the date plate AND the dial).

- Manipulating tiny screws with tweezers is HARD. I managed to launch a 3135-5115 screw (the tiny ones) somewhere into my office when my tweezers slipped and closed. I saw which direction it flew off in, but I was never able to find it. My office is only about 4 square meters and has a hardwood floor, so there aren't many places to hind. But despite an hour on my hands and knees with a low angle light, I couldn't find it. I even tried putting some powerful magnets onto the bottom of my vacuum's cyclone and vacuuming the area and all the nooks and crannies. Still no luck. I had to order a replacement box of screws from Perrin for $100... I figured this was better value than just buying a single replacement screw for $5, since I'd be this isn't gonna be the last tiny screw that I launch across the room.

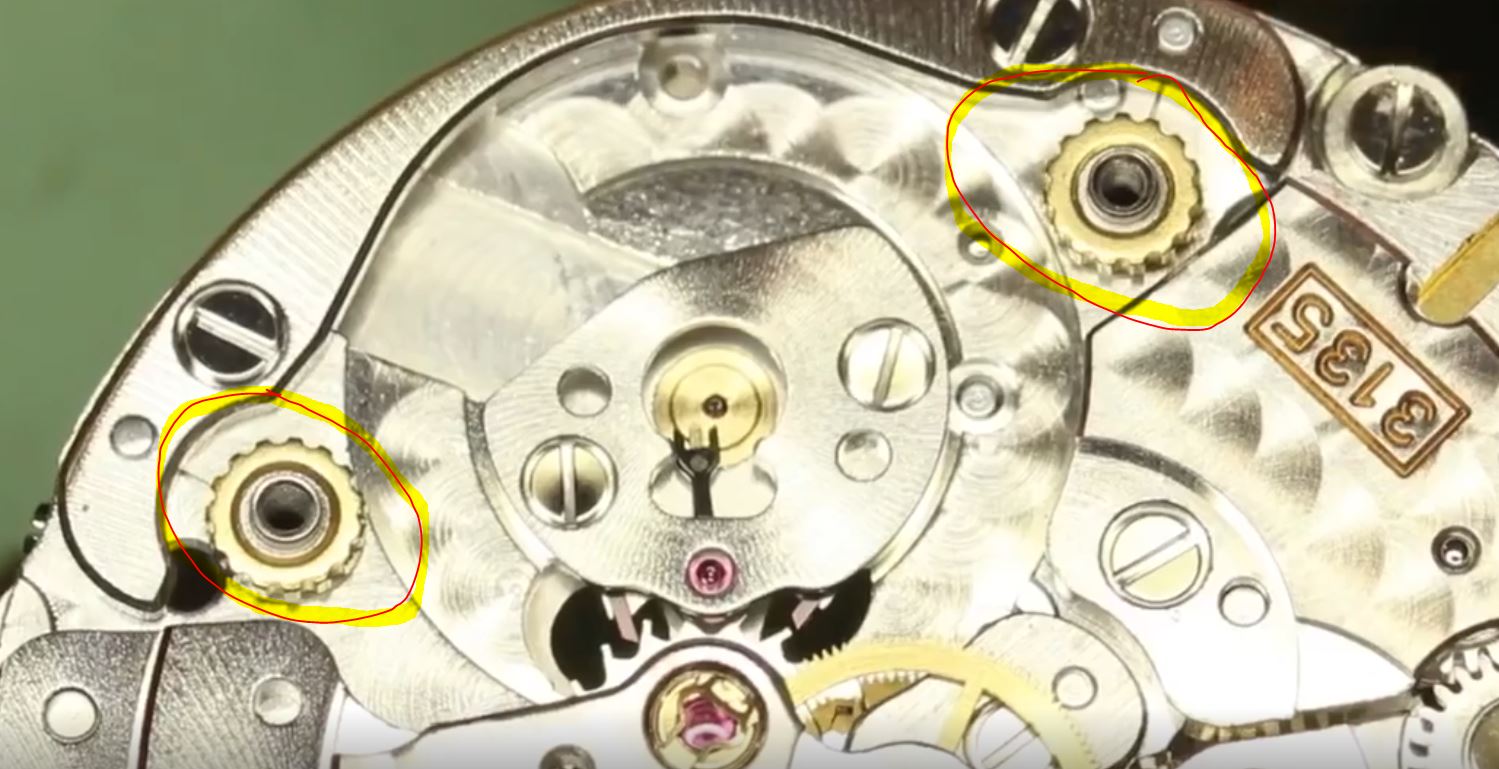

- Getting the yoke spring into place against the yoke, while keeping the yoke in the right place on the sliding pinion. I messed this up the first time and didn't realize it until I was a few more steps down the garden path re-assembling the winding works... I had to disassemble everything and start again.

- Screwing in tiny screws... I take an ADHD medication which allows me to concentrate, but gives my hands a bit of shake (think the hand tremors you'd get about a triple espresso). And so it was pretty hard to get screws to start threading because invariably my screwdriver tip was trembling. I kinda got better at this by using two hands and resting both forearms on the desk to steady them.

- A set of +2.0 reading glasses... I'm still young enough that I don't need reading glasses, but I bought a pair of +2.0 glasses from the drugstore on the off chance that I'd want something less powerful than my x10 loupes. And, yeah, WOW, these things are amazing. I might go back and get a set of +3.5 glasses now.

- Rodico is amazing stuff, and I've been using it way more than I though just to pick up little things and move them around rather than trying to do everything with tweezers (see the point above about accidentally launching a 3135-5115 screw into orbit)

The parts:

The semi re-assembled movement. Note the missing 3135-5115 screw that should be holding the click down.

The balance back in and swinging.

My attempt to trap the missing screw by adding a magnetic trap to my vacuum.

My first attempt at regulating the movement. When it was first re-assembled it was +25s/d, so I'd say getting it to here is technically a step in the right direction. Yes, amplitude is trash, but I'm pretty sure that's because it's not fully wound. I'm waiting for my spare screw to come in to finish the re-assembly, at which point I'll regulate properly.