Jayalvin777

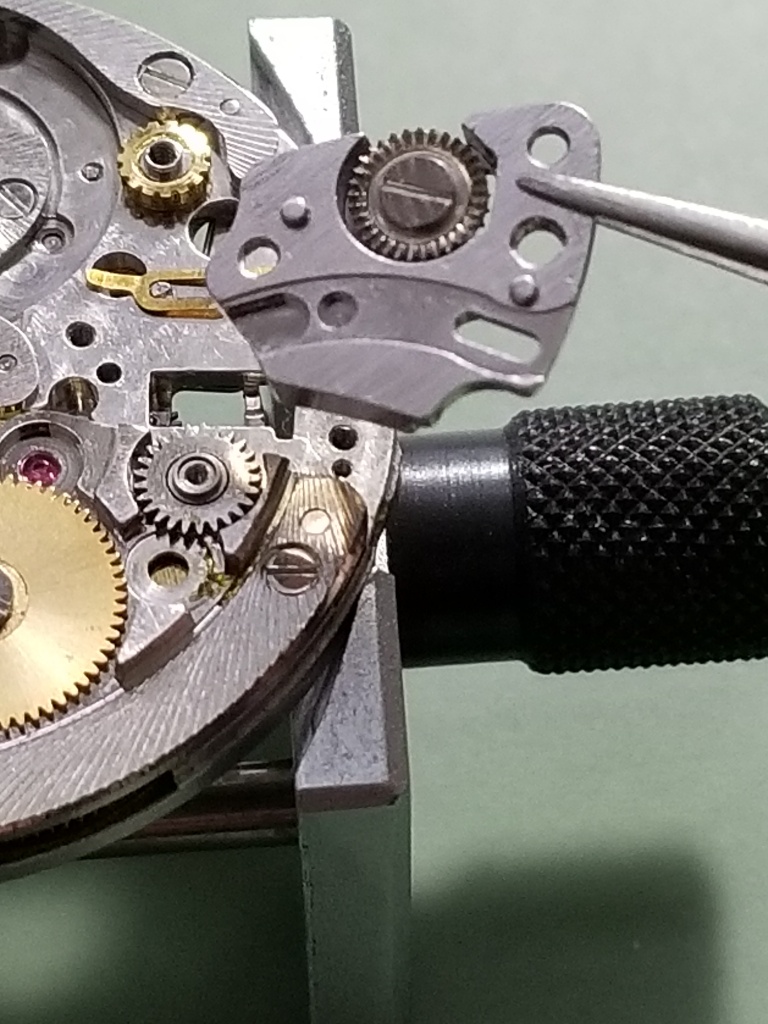

I found out the cause of the winding issue on the VS3235 and it's not the yoke for sliding gear. While working on mine, the yoke quit engaging and I noticed a post was popping up through the train bridge nearby.

3235

This post contains the crown wheel and on the VS3235 (probably gen also) the post has a very thin washer built in on it that has a curved bend in it like a dial washer. It appears this washer is meant to push down on the post, driving it away from the underside of the train bridge. When it fails to do this, the crown wheel disengages from the intermediate crown wheel (right under the yoke for sliding gear) and this is what interrupts the manual winding capability.

3235

3235

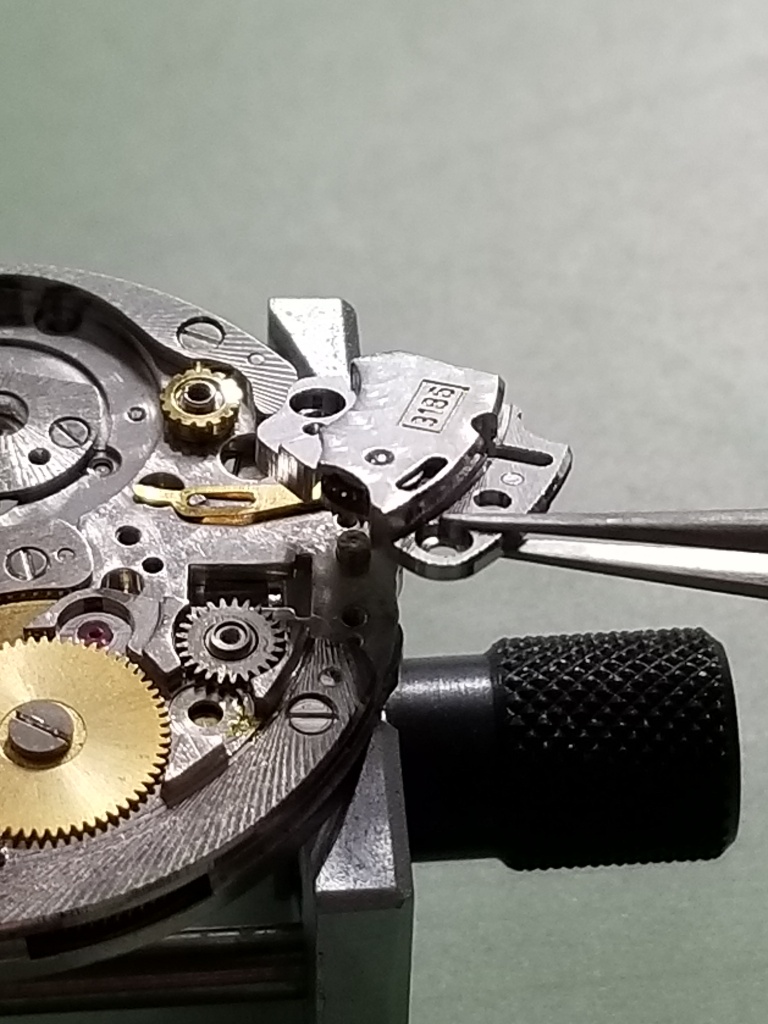

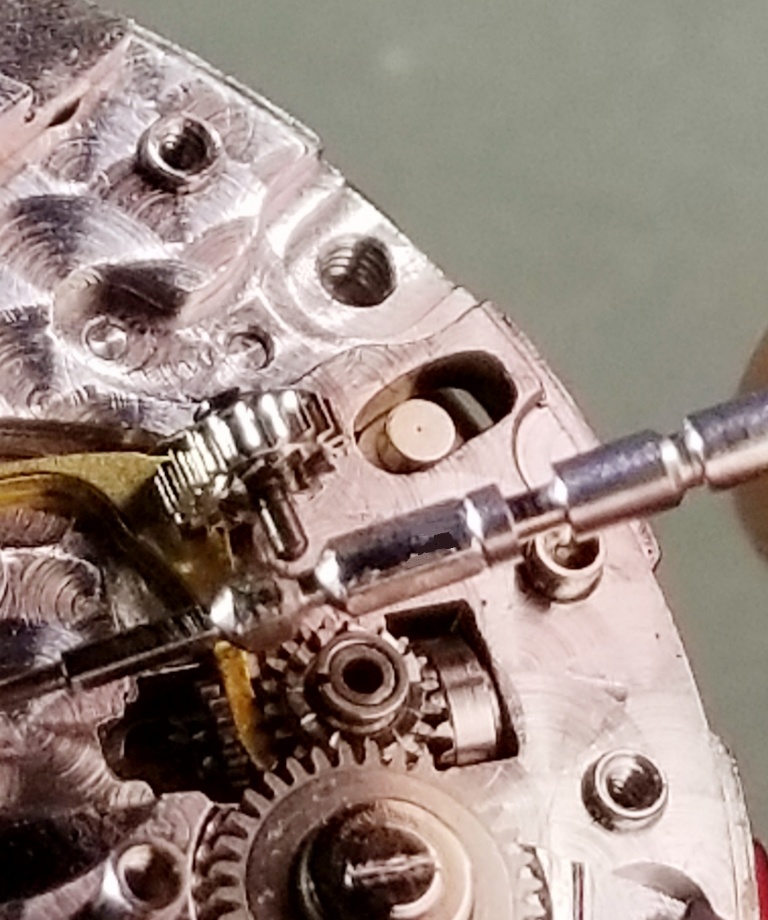

The 3135 is designed differently. It has a separate winding bridge from the train bridge, and the crown wheel is screwed directly into the underside of the winding bridge. IDK why the 3235 crown wheel isn't fixed in height - I can see no reason for it not to be, the 3135 crown wheel is fixed in height with a solid spacer called the crown wheel core. They probably just copied the gen design but that rep washer is crazy thin and cheap - worthless and causing these winding issues.

3135

3135

As a proof of concept, I inserted a 27 guage wire "clip" (0.361mm) onto the 3235 crown wheel post under the thin curved washer and the issue is resolved. I needed to be able to wind the movement to work on it, so I'm leaving it in for now. I'll replace that clip with a similar height spacer of some kind, maybe a nylon or SS washer with a cutout to allow for placement around the post.

Reps are so much fun to fix, ha.

Edit: Thinking about this some more, there is undoubtedly a reason for the crown wheel to be able to disengage from the intermediate crown wheel on the gen or it wouldn't have been made that way. Some kind of safety measure in the event of some other conditions. It wouldn't be to prevent over-winding I believe, or we all would have noticed the difference between winding a fully wound spring and not engaging the ratchet wheel at all. In any case, on the rep once that cheap washer starts to fail at its task there really isn't a better solution than to add a spacer and fix the crown wheel in place.