It actually looks like 904 is softer than 316

316L VS 904L Stainless Steel in Watches

ShareTweet

The FAQs

[h=1]All About 316L VS 904L Stainless Steel in Watches[/h]

With watch brands

like Ball starting to use 904L stainless steel, taking the bragging rights away from Rolex, we thought now is the perfect time to explore the

differences between 316L and 904L – at least when it comes to watches.

The industry standard stainless steel is 316L. In addition to watches, this alloy is also commonly used in the food industry, the medical field, and a wide variety of water and marine applications. You may see some watch brands refer to 316L as

surgical grade steel or marine grade steel. Its popularity in these areas comes from the properties which make it resistant to rust and corrosion. 904L takes the resistance to corrosion up a notch.

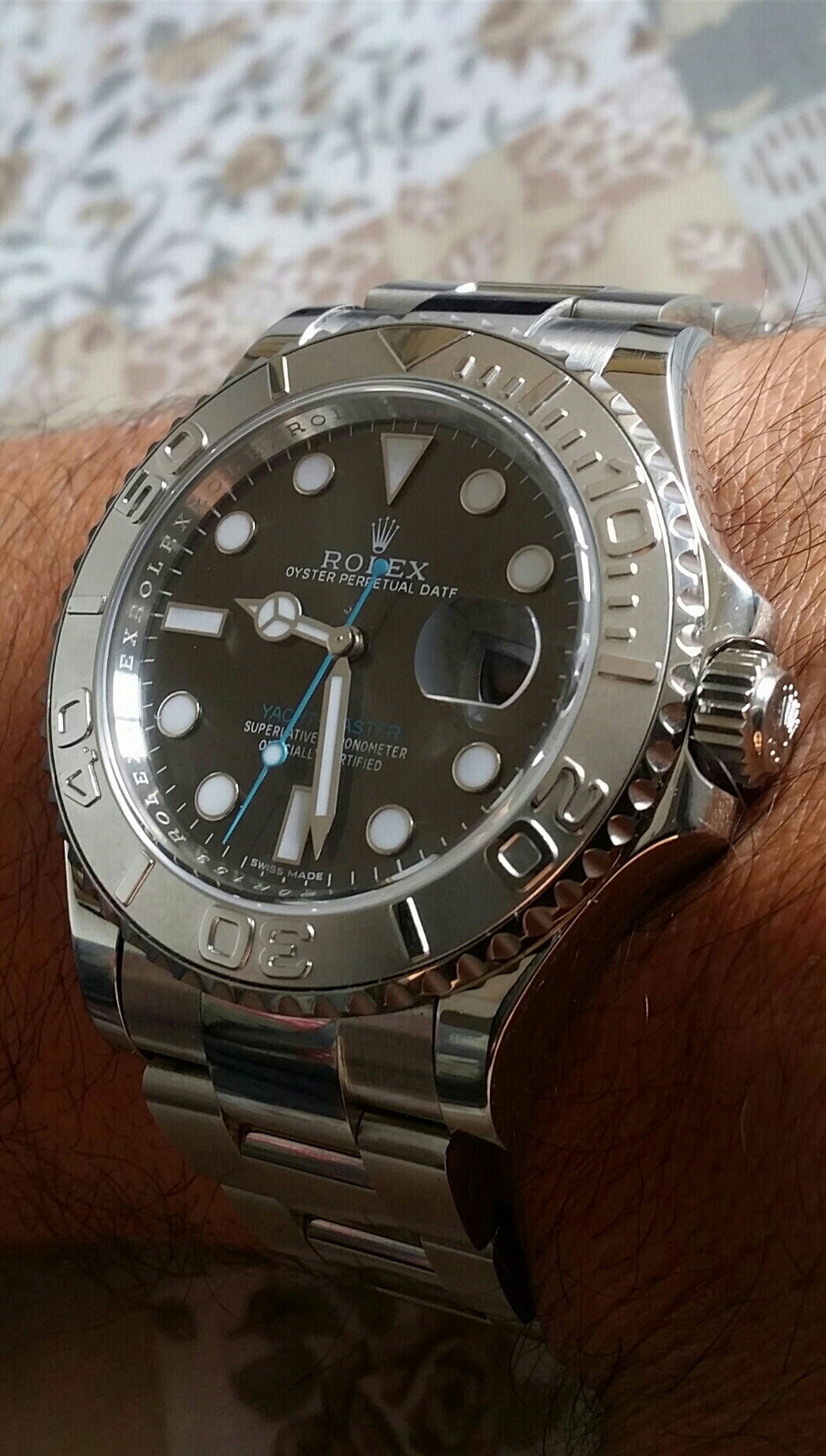

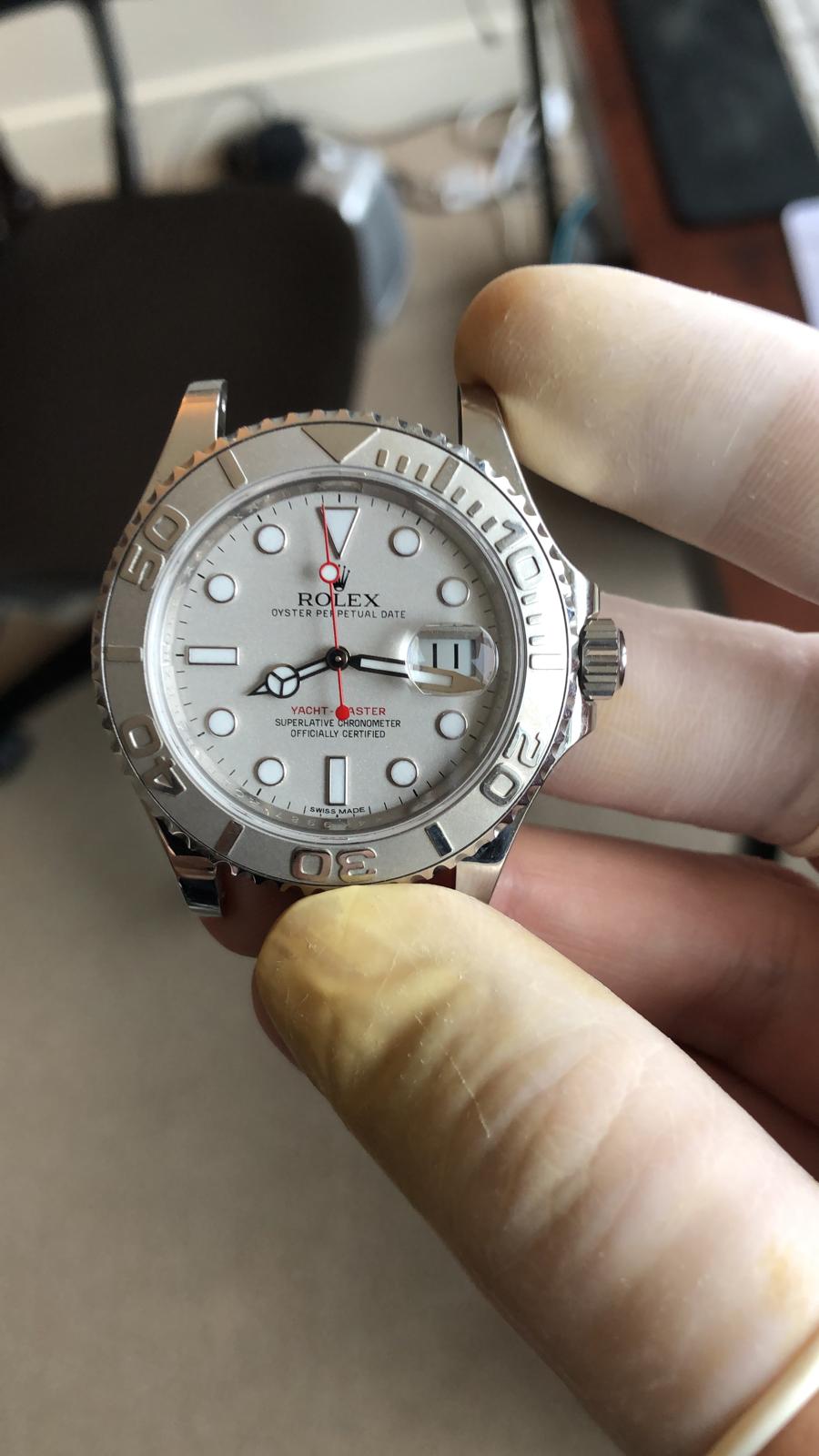

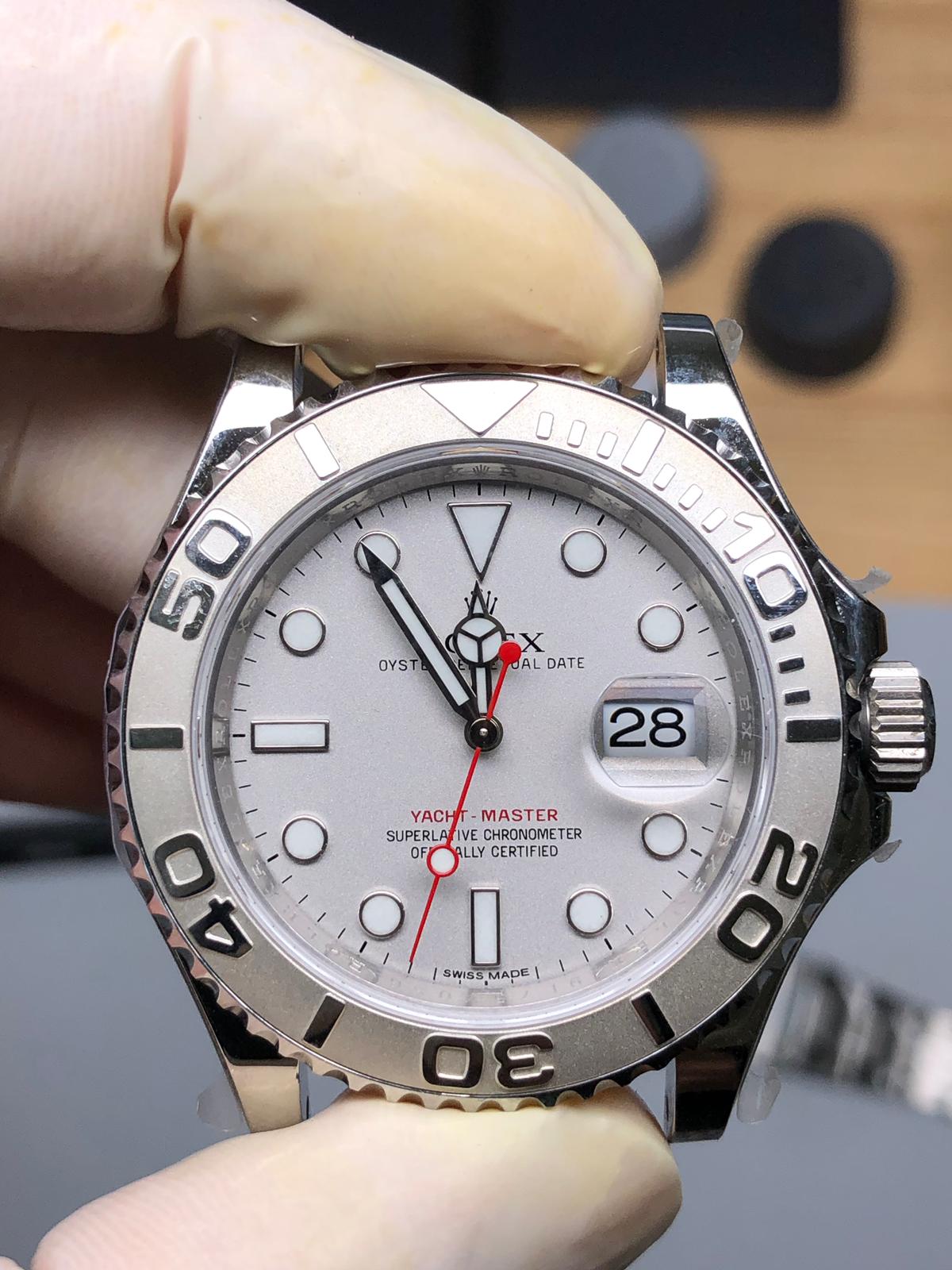

[h=3]Rolex 904L[/h] To say Rolex is serious about their 904L steel is an understatement. Their advertisements have go as far as calling it a precious metal.

Even the

Wikipedia entry for 904L has been edited to include a Rolex mention (well done, Rolex!):

In 1985 Rolex became the first wristwatch manufacturer to utilize 904L grade steel in its watches. Rolex chose to use this variety of steel because it takes a higher polish than other grades of steel and provides greater corrosion resistance, though it does not machine as well and requires specialized equipment to be properly modified into the required shapes.

Rolex does deserve credit for being recognized as the first brand to make cases out of 904L steel, and this has lead many to think that 904L was a Rolex invention or a material exclusive to Rolex. This could be due to the verbiage around the term Oystersteel, which Rolex defines as:

“…a steel alloy specific to the brand. Oystersteel belongs to the 904L steel family, which is particularly resistant to corrosion and acquires an exceptional sheen when polished.” –

source

Rolex and their use of 904L steel has largely gone unchallenged in the watch industry for decades. Now, as brands scramble find any competitive edge in a saturated market, we’re seeing other watch companies start to jump on the 904L train. But is 904L really that much better?

[h=3]316L VS 904L Composition[/h]

| | 316L | 904L |

| Carbon | 0.035% max | 0.2% max |

| Chromium | 16-18% | 19-23% |

| Copper | 0 | 1-2% |

| Iron | Balance | Balance |

| Molybdenum | 2-3% | 4-5% |

| Manganese | 2% max | 2% max |

| Nickel | 10-12% | 23-28% |

| Phosphorus | 0.45% | 0.03% max |

| Silicone | .75% max | 1% max |

| Hardness (Rockwell) | 95 | 70-90 |

| Hardness (Brinell) | 217 | 150 |