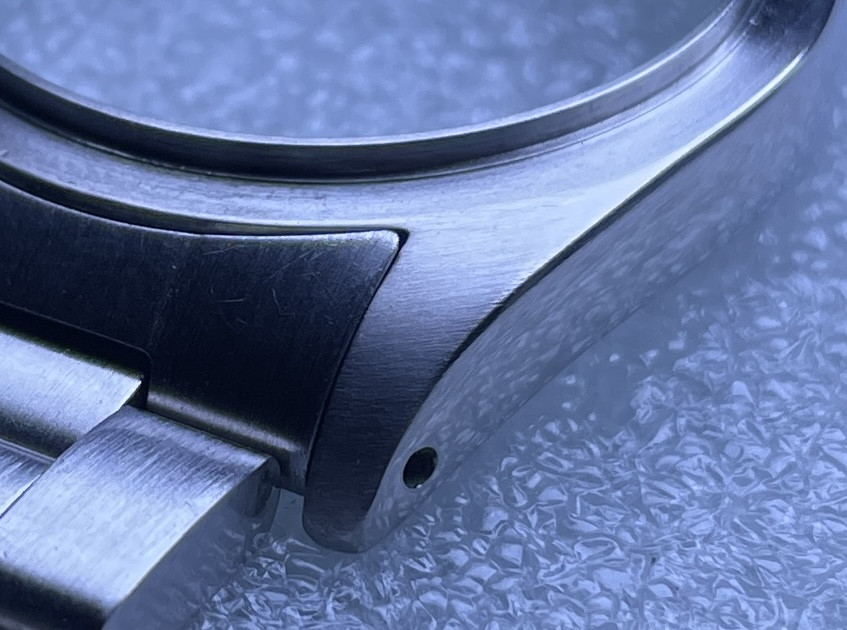

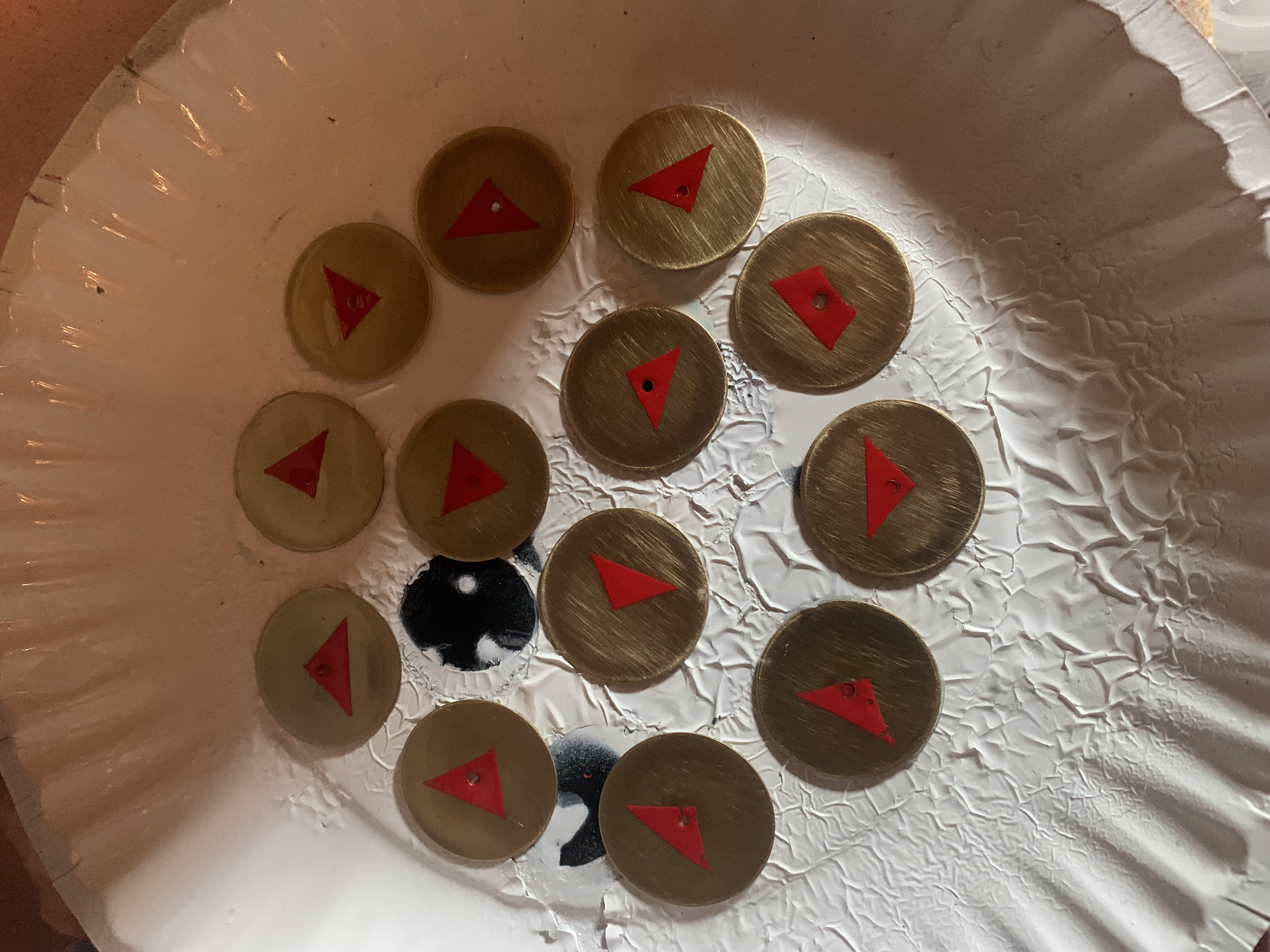

Completed case work on the 6610 and did a temporary dial-ageing mock up while I wait for the TC hands… I expect I will be able to strip and redo the dial and fit the hands next week.

I’ll probably spend the spring deciding which one sings to my heart, and move the other two to help fund a 1675 build

I’ll probably spend the spring deciding which one sings to my heart, and move the other two to help fund a 1675 build