link?I am starting to think about making a Railmaster. Any ideas to get me started?

I found a listing on DHGate but it's probably going to be a shitter watch

I remember I saw a dial listed somewhere but I can't remember where

-

Tired of adverts on RWI? - Subscribe by clicking HERE and PMing Trailboss for instructions and they will magically go away!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The 1016: The Under Appreciated Thread

- Thread starter ebzen02

- Start date

i am embarrassed to put this here, but oklink?

I have not asked for pics yet

It's a beauti am embarrassed to put this here, but ok

I have not asked for pics yet

Not that one but I bought a Seamaster 300 heritage from there and it was shit as well lolyou bought the DHGate watch before?

I just know where to dig for pictures^^

I just want a case and a dial to get started.Not that one but I bought a Seamaster 300 heritage from there and it was shit as well lol

I just know where to dig for pictures^^

I don't really care that much about quality, as I will age the thing into oblivion anyway

- 16/10/23

- 197

- 130

- 43

As expected, the problem was that there was too much solvent.. I'll follow your process step by step.I use 3% Hydrogen Peroxide and it works just fine

a teaspoon of 3%

a teaspoon of vinigar

a pinch of baking soda

a pinch of salt.

when the bubble start to die down add another pinch of soda .

Nothing happens then it all happens at once.

Ive had hands nearly dissolve in the solution if left long enough become very soft.

If left long enough you could get a turquoise buildup on the hands I would say that it too far for your example but for a water damaged sub it would be cool .

If you just want the case and bracelet then yah not bad....hard to beat it at that price.I just want a case and a dial to get started.

I don't really care that much about quality, as I will age the thing into oblivion anyway

I prefer the vintage 2914 or even the special reedition version There used to be dials available a number of years ago...no idea where now.

solvet? you mean vinegar? almost any mix of those ingredients should provide corrosion effectsAs expected, the problem was that there was too much solvent.. I'll follow your process step by step.

this is going in the backlog of things to try later. I still have a few things to finish first.If you just want the case and bracelet then yah not bad....hard to beat it at that price.

I prefer the vintage 2914 or even the special reedition version There used to be dials available a number of years ago...no idea where now.

Yeah the 38mm 2914 was the one I was thinking of when you said you wanted to do a build @Karbon74If you just want the case and bracelet then yah not bad....hard to beat it at that price.

I prefer the vintage 2914 or even the special reedition version There used to be dials available a number of years ago...no idea where now.

I was trawling through AliX earlier for some suitable cases and it looks like Escapement Time has some watches in the 38mm with enough meat on the bones so that they could be used as a base for it. Albeit with a looot of casework to the lugs, polish the rehaut, machining of the bezel etc.

- 16/10/23

- 197

- 130

- 43

Vinegar and hydrogen peroxide. I put too much in compared to the solute, and I think it failed because the soda or salt didn't make much contact with the hands.solvet? you mean vinegar? almost any mix of those ingredients should provide corrosion effects

I put in about 50mm, but I think I only need to use 5mm according to the thread's advice.

this oneIf you just want the case and bracelet then yah not bad....hard to beat it at that price.

I prefer the vintage 2914 or even the special reedition version There used to be dials available a number of years ago...no idea where now.

Omega Aqua Terra Railmaster 2504.52

Review of the Omega Aqua Terra Railmaster 2504.52 and 2804.52. Constains price information and serials of recently seen watches.

36 or 49mm??this one

Omega Aqua Terra Railmaster 2504.52

Review of the Omega Aqua Terra Railmaster 2504.52 and 2804.52. Constains price information and serials of recently seen watches.ghostofgeraldgenta.com

- 4/10/22

- 526

- 908

- 93

The case could be the only problem, i ve found the dial alreadyYeah the 38mm 2914 was the one I was thinking of when you said you wanted to do a build @Karbon74

I was trawling through AliX earlier for some suitable cases and it looks like Escapement Time has some watches in the 38mm with enough meat on the bones so that they could be used as a base for it. Albeit with a looot of casework to the lugs, polish the rehaut, machining of the bezel etc.

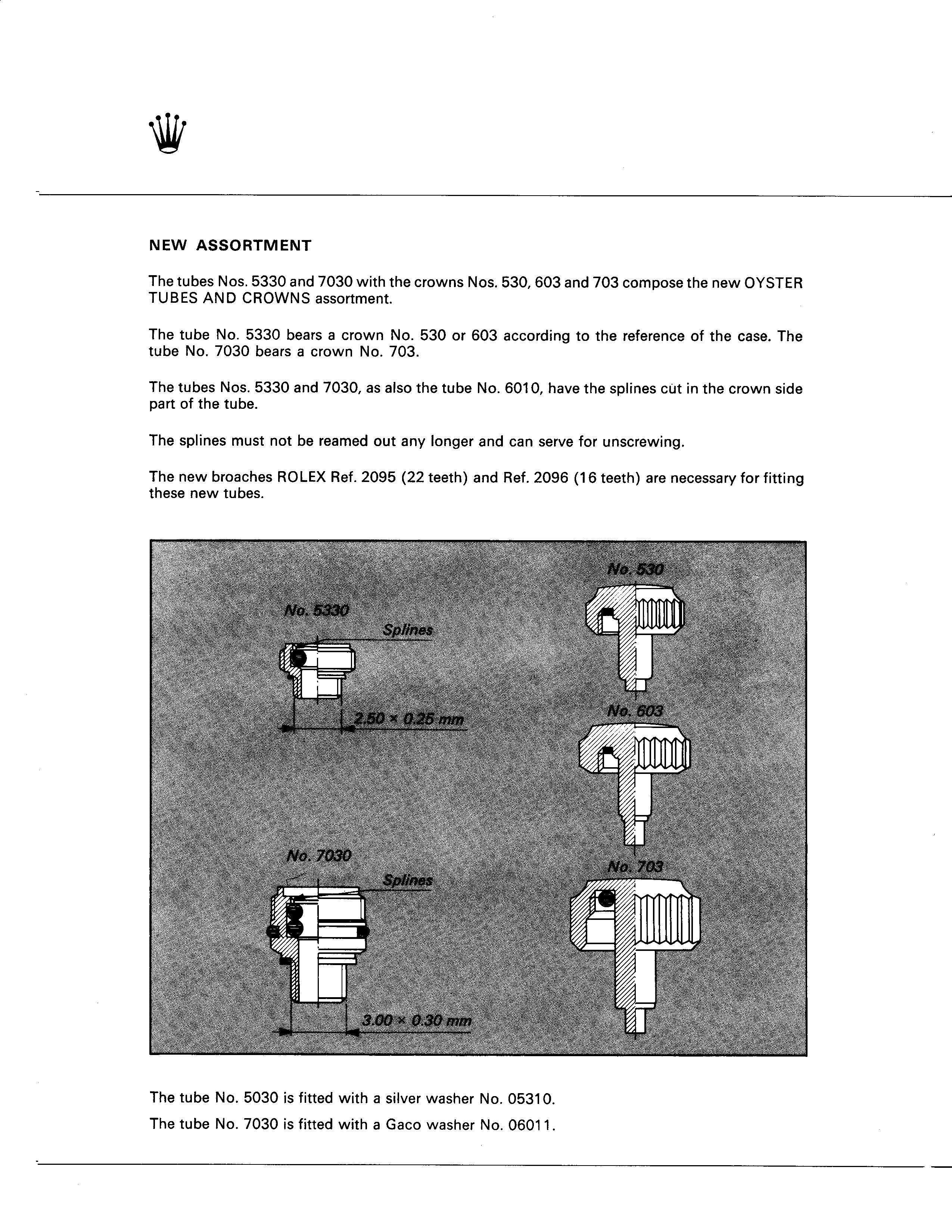

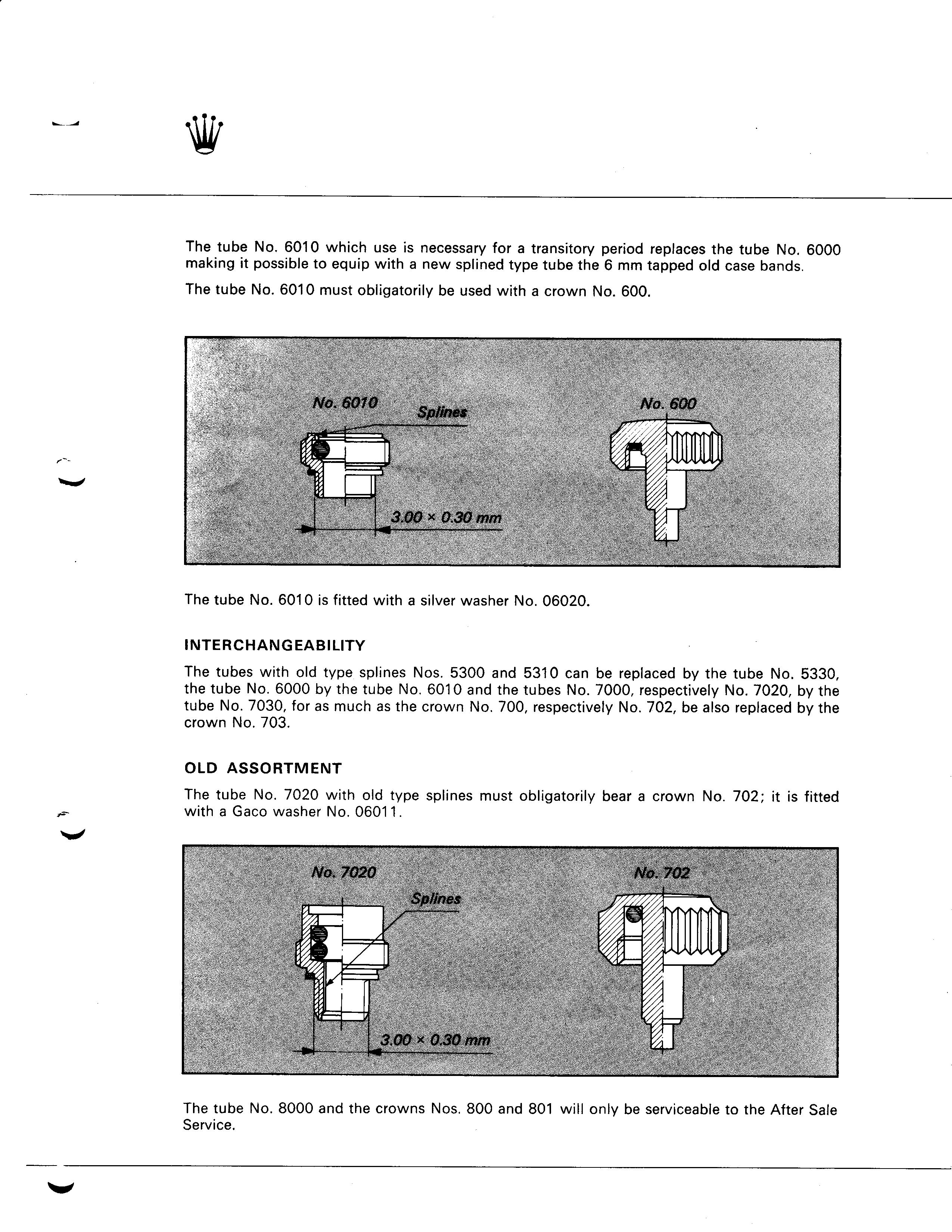

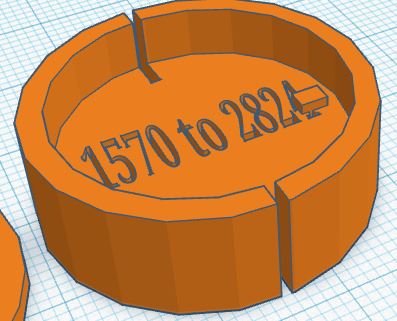

Not sure if this will work or not, but did a little research on using gen dials with ETA movements WITHOUT cutting the dial feet. It's possible, it just takes a very precise modification of the 28XX main plate. Here are a couple threads discussing the process:

forum.replica-watch.info

forum.replica-watch.info

Essentially, since gen Rolex dials have feet at 30 and 57 minutes, one has to either drill or notch the main plate at 57 minutes and 30 minutes and the gen dial will work. There is almost no margin for error, however.

That said, I always liked a challenge, so playing around with CAD software, I came up with this. It's a jig designed to hold a 2824 main plate snugly (as in, you might need to sand a little bit of the inside diameter so it will fit), and notches that are 1mm wide at exactly 30 minutes and 57 minutes.

You would then either drill or file/cut within the notch (drilling would require a measurement of the exact distance to the center for the dial foot hole, but I don't have a gen dial handy).There's also a couple generic 2824 movement holders, because I don't know what size is needed for a 15xx case.

www.tinkercad.com

www.tinkercad.com

How to modify ETA movement to take Rolex dials - without cutting the dial feets

Like most of you know, Rolex vintage dials for 15xx movements have feet positioned at 30/57min. which doesn’t fit to any ETA. So how to can these been fitted together without cutting the Rolex dial feet (which make them worth less)? Let‘s see… Putting dial & movement side by side shows that...

Gen Rolex case with ETA movement

Hello, Does anyone can tell me if the ETA movement 2836-2 may fit in the gen rolex 1675 case? I'm not worry about the diameter as I can put the adaptor. But the thickness might be the one of major problem. Thanks Jay

rwg.cc

Essentially, since gen Rolex dials have feet at 30 and 57 minutes, one has to either drill or notch the main plate at 57 minutes and 30 minutes and the gen dial will work. There is almost no margin for error, however.

That said, I always liked a challenge, so playing around with CAD software, I came up with this. It's a jig designed to hold a 2824 main plate snugly (as in, you might need to sand a little bit of the inside diameter so it will fit), and notches that are 1mm wide at exactly 30 minutes and 57 minutes.

You would then either drill or file/cut within the notch (drilling would require a measurement of the exact distance to the center for the dial foot hole, but I don't have a gen dial handy).There's also a couple generic 2824 movement holders, because I don't know what size is needed for a 15xx case.

3D design Adapter for ETA 2824 to RLX 15XX - Tinkercad

3D design Adapter for ETA 2824 to RLX 15XX created by David Patterson with Tinkercad

I am glad to see that people had made progress on this , I remember people talking about it a few years ago . The jig you made should do the trick nicely. I suggest you add a pin to the jig like Hoots did to lock in the main plate at the keyless so that it can not move while drilling.Not sure if this will work or not, but did a little research on using gen dials with ETA movements WITHOUT cutting the dial feet. It's possible, it just takes a very precise modification of the 28XX main plate. Here are a couple threads discussing the process:

How to modify ETA movement to take Rolex dials - without cutting the dial feets

Like most of you know, Rolex vintage dials for 15xx movements have feet positioned at 30/57min. which doesn’t fit to any ETA. So how to can these been fitted together without cutting the Rolex dial feet (which make them worth less)? Let‘s see… Putting dial & movement side by side shows that...forum.replica-watch.info

Gen Rolex case with ETA movement

Hello, Does anyone can tell me if the ETA movement 2836-2 may fit in the gen rolex 1675 case? I'm not worry about the diameter as I can put the adaptor. But the thickness might be the one of major problem. Thanks Jayrwg.cc

Essentially, since gen Rolex dials have feet at 30 and 57 minutes, one has to either drill or notch the main plate at 57 minutes and 30 minutes and the gen dial will work. There is almost no margin for error, however.

That said, I always liked a challenge, so playing around with CAD software, I came up with this. It's a jig designed to hold a 2824 main plate snugly (as in, you might need to sand a little bit of the inside diameter so it will fit), and notches that are 1mm wide at exactly 30 minutes and 57 minutes.

You would then either drill or file/cut within the notch (drilling would require a measurement of the exact distance to the center for the dial foot hole, but I don't have a gen dial handy).There's also a couple generic 2824 movement holders, because I don't know what size is needed for a 15xx case.

3D design Adapter for ETA 2824 to RLX 15XX - Tinkercad

3D design Adapter for ETA 2824 to RLX 15XX created by David Patterson with Tinkercadwww.tinkercad.com

I have seen some people notch the late as well which is a nice feature of your jig as you can do either .

Yes, had to find the measurements, but added a little thing for the date window so it shouldn't rotate within the jig. 2mm high, 2.7mm wide, and 8.85mm from the center to the left edge of the date window. I made it a tiny bit smaller to account for tolerances, but it should be solid enough.I am glad to see that people had made progress on this , I remember people talking about it a few years ago . The jig you made should do the trick nicely. I suggest you add a pin to the jig like Hoots did to lock in the main plate at the keyless so that it can not move while drilling.

I have seen some people notch the late as well which is a nice feature of your jig as you can do either .

The notch is 1mm wide, which is the size of a dial foot pin, and roughly the size of a hacksaw blade (some are slightly wider, some are slightly narrower...you're looking for one with a 1mm kerf (or very slightly larger) and a very fine cut (more teeth > less). The movement plate is not high tensile steel, so it should cut fast and easily. If it goes well, you should be able to hold the jig and carefully run it up and down the saw blade until the notch is deep enough to accept the Rolex dial. As long as you go slowly, test fit repeatedly, and don't rush it, you shouldn't be able to remove enough material to interfere with the moving parts of the ETA movement.

Then it's just a matter of thoroughly cleaning the base plate of any metal shavings, and reassembling everything (basically, a full service). I think it would still be a good idea to use dial dots to stick the dial to the movement/ring, but on paper, at least, you should be able to use gen dials in gen cases with ETA movements, WITHOUT butchering what might one day be a very valuable dial.

When I get home, I think I will take a micrometer to a gen dial, and make an insert to squeeze the movement inside the jig, with a hole to drill, so that's a more accurate option.

Last edited: