How much you wanna bet @Karbon74 joins us?Great to see another pantograph on the forum!!

We're gonna need a pantograph thread, lol.

How much you wanna bet @Karbon74 joins us?Great to see another pantograph on the forum!!

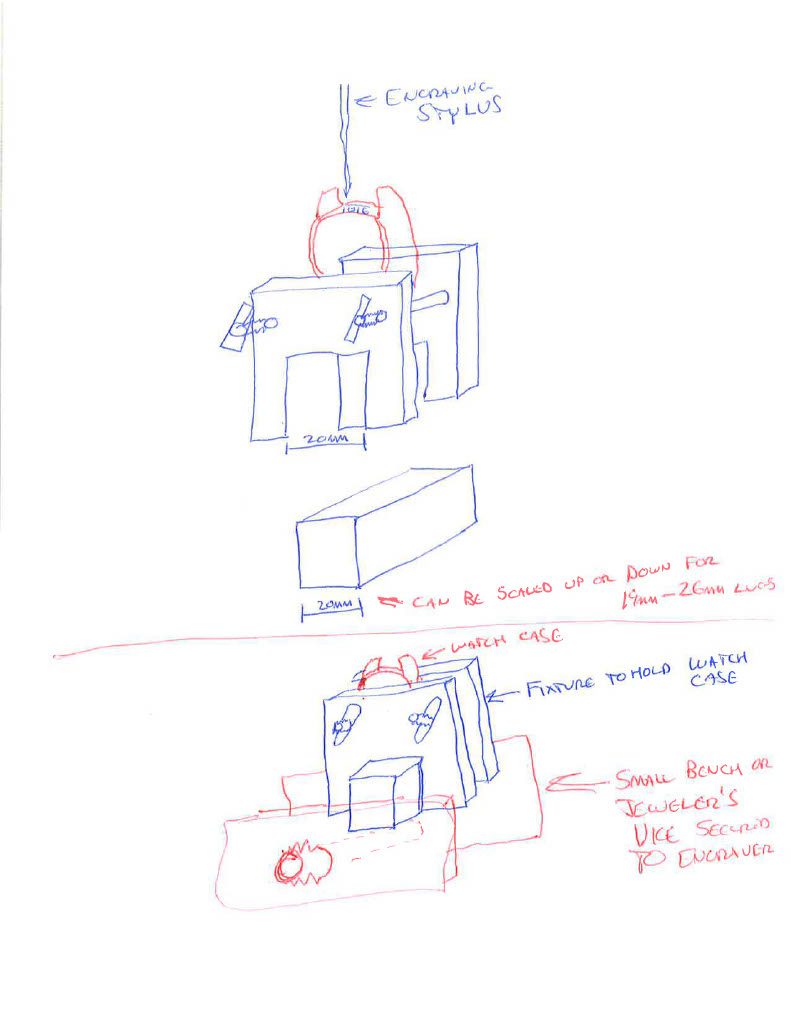

It should, it's what Rolex (allegedly) used. You'd need to make some kind of fixture to hold the case steady and aligned, but I'm thinking a small vice, like for a drill press, would work as a basis, and a 3D printer (and a few hours of head scratching) would fill in the rest.would that fit into a 1016 for engraving?

There is one somewhere but it has gone a bit quiet and the salt water etching thread has taken over

I would love to. But I live in a flat (albeit quite roomy >170m2) and I am already pushing it with my existing watchmaking gear. The wife is not happy

Fast forward 10 years, and we’re all going to be a little cult, living together in an abandoned monestary, with a full machine shop.I would love to. But I live in a flat (albeit quite roomy >170m2) and I am already pushing it with my existing watchmaking gear. The wife is not happy

Once the kids are in Uni, we plan to move to a house. Then I will splurge. I already am thinking about a CNC machine and a lathe.maybe even a forge and a mecanical hammer machine.

- bivintage caseVietnam dial + Vietnam case?

Raffles hands?

Interesting combination of hands!- bivintage case

- vietnam dial

- 116610 seconds hand

- rafflestime minute hand

- aliexpress hour hand

^^this is the spec list i got

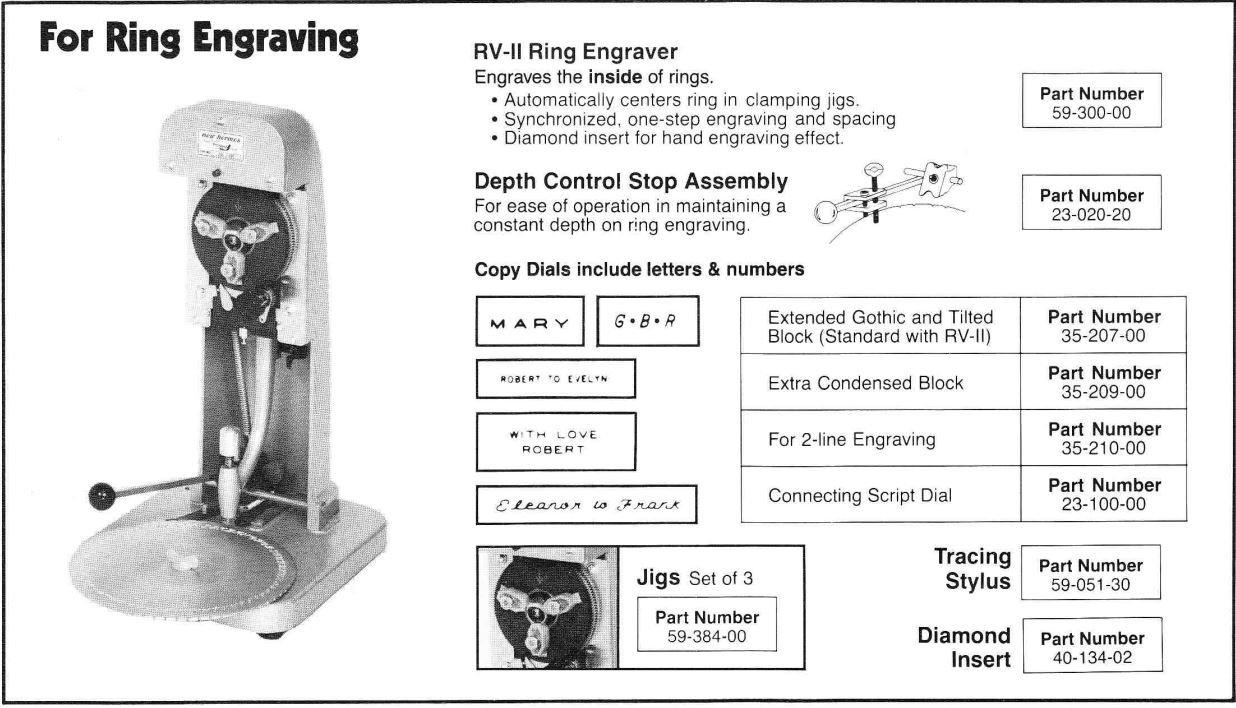

Very exciting indeed. A lovely piece of equipment to have on the bench.This is a New Hermes drag engraver. Supposedly, these are the same machines that Rolex used in the factory. The machine was $200. I'm told people are finding them for about $150, but I didn't want to wait so I got the first one I found that looked to be complete and in good condition. It actually arrived much better than the photos in the listing. I found them on Facebook Marketplace, Craigslist, and Ebay. Ebay was the most expensive option, but had more to choose from, and this time of year, I just didn't have the time available to make 4 hour round trips to buy locally. Shipping was kinda outrageous, lol.

The "fonts" were about $100 each. I wound up buying two different ones, because I still can't decide if the Rolex Factory used "Regular Block" or "Condensed Block." To my eye, it looks more like "Regular," but I haven't tried doing a curved case yet, which I assume will change the width of the letters as you approach the edges, since you're engraving on a slight angle. There's also "Helvicta" and "Futura," which have more accurate looking numbers than the "Block" sets. That said, I'm stuck with what comes up for sale, so I'll keep an eye out, but very happy with what I have.

Once I figure out some kind of jig to hold the cases, I should be able to do case engravings in just a few minutes...literally, the time it takes to arrange the letters and trace them. It's pretty easy to use, once you figure it out.

I'm actually thinking this would work for the lug engravings on a 5517. Maybe the caseback engravings, but that would require a template. I think I could make one with saltwater etching, but now I'm opening yet another huge can of worms, lol.

I am guessing that the engraving stylus is mounted on a sort of spring loaded mecanism that adjusts mechanically to the curveVery exciting indeed. A lovely piece of equipment to have on the bench.

Are you going to make some sort of sliding, rotating stand so the watch can be turned in it as you engrave to allow for the curviture between lugs?

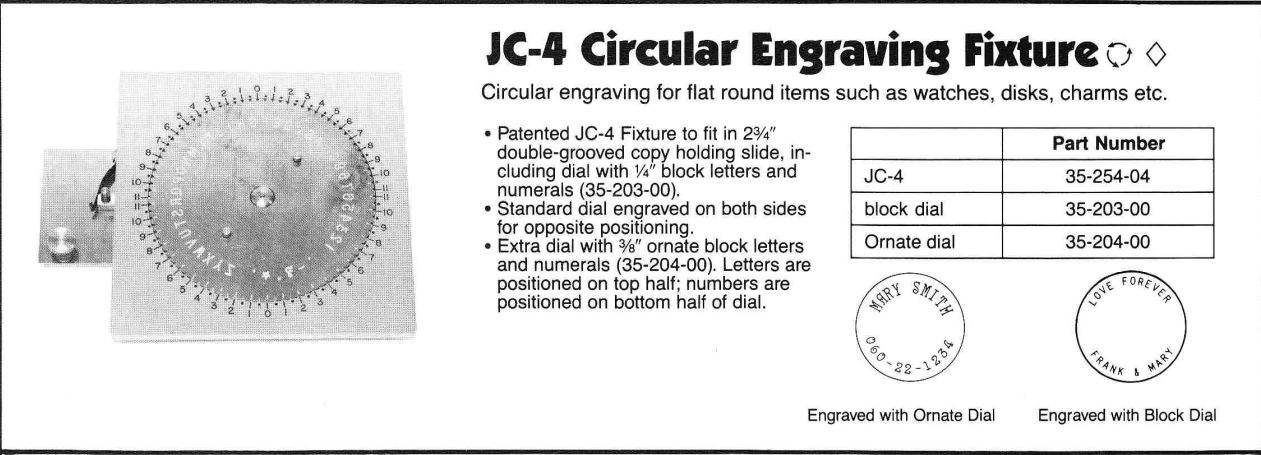

I might have to, eventually, if it doesn't look right, but that's a wildly complicated thing that I'd like to avoid. Technically, it would need to be something like a small vice or clamp, that rotates along a central axis, with a type of clockwork, that would rotate the piece one space for every letter, which is probably beyond my technical abilities. New Hermes did have something similar already produced (and there are Chinese knockoffs, ironically, but the font looks wrong...more script than block lettering)...there's a machine for engraving rings that rotates the piece for every character, but I don't know if it could be adapted to a watch case...it's designed to write on the INSIDE of the ring, rather than the OUTSIDE of a watch case.Very exciting indeed. A lovely piece of equipment to have on the bench.

Are you going to make some sort of sliding, rotating stand so the watch can be turned in it as you engrave to allow for the curviture between lugs?

Yes, it's basically a parallelogram. One side traces the numbers/letters, and the other side engraves.I am guessing that the engraving stylus is mounted on a sort of spring loaded mecanism that adjusts mechanically to the curve

Believe me, the first few practice runs went about like that. I was using an old Altoids tin (I couldn't find anything to practice on) and damn near scribed through it.@dpd3672 " and I was barely pressing down...about as much pressure as I'd use to hold a sandwich, lol."

Interesting comparison. I am going to start using this as a unit of measure. lol

"The equivalent pressure to hold a sandwich. "

If your sandwich looks like this....dial it back a bit bud.