This is an Excerpt by clockmakers.com.au, just thought it will be interesting for all of us!

Restoring or refinishing a stainless steel watch case is not as difficult as may be thought. Unfortunately most watchmakers are either not interested in doing it properly or were never taught how to do it. Those few who have mastered the skill of hand-polishing would rather die then to revel their secret of the trade! The trick in obtaining mirror-like finish is simple : a) to use correct polishing medium and b) to master polishing skills by following the correct procedure.

This tutorial is aimed not only at watchmakers, but also at watch dealers and collectors wanting to familiarize themselves with the process of hand-polishing. The procedure shown below was passed to me by my father (an to him by his brother Mihajlo Hacko, Master Watchmaker since 1948. who still does his own watch repairs!)

Guinea pig: 15 years old Explorer II Ref 16570, long overdue for decent case re-polishing.

I prefer to do all case polishing by hand.

Step 1:

To get rid of scratches start with coarse sand paper, grade 220

Keep it parallel and keep polishing until you remove ALL scratches, no matter how deep. This step is very important

All scratches are gone, but the surface is very coarse and dull. That's OK. The most important thing here is to remove ALL scratches and to have the grain lines parallel with the case.

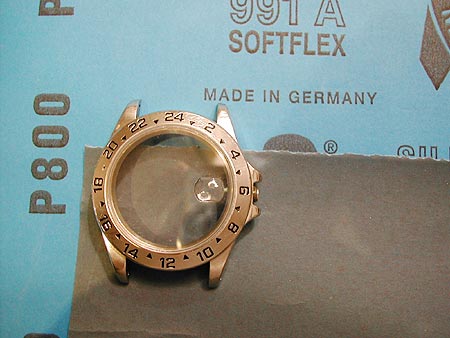

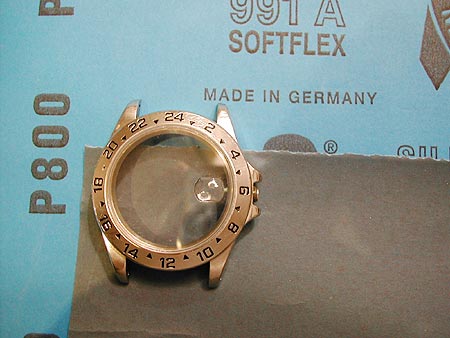

Step 2: Switch to dry paper grade 800. I use German made, but most sand papers of similar quality will do the trick. You can buy this grade at any automotive shop supplier.

Don't rush - take your time (at least 5 minutes per side). The surface is still dull but we are heading in the right direction.(note how more light is now reflected form steel surface)

Same surface, magnified. Keep it parallel

If I can do it, you can do it too

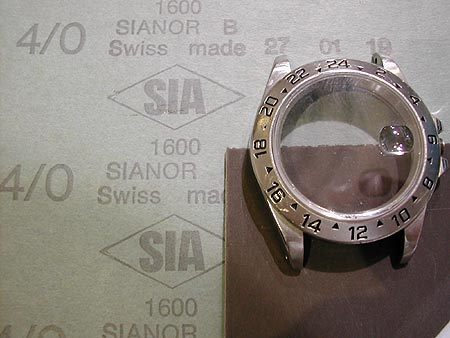

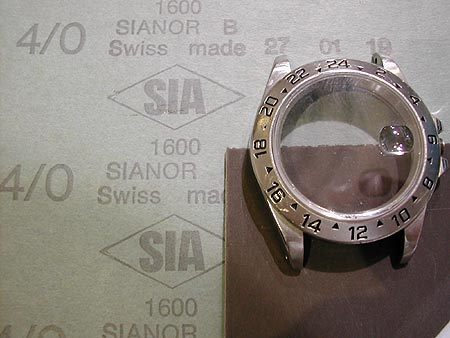

Step 3: very much the same, now with finer grade dry paper - here I use Swiss made 1600 powder coated jewellers paper available form jewellers suppliers. This is jewellers stuff so they prefer to call is 4/0

Take your time, don't rush - 5 min. per side

The steel surface now reflects even more light and looks fairly smooth.

Step 4: More of the same. Medium: 3M Film sheet polishing (plastic)grade 60 microns and 10 microns (2-3 minutes each).Available from jewellery suppliers only. On touch 3M film eels like ordinarily plastic sheet, definitely not your ordinarily sand paper

If there are still any visible imperfection go back to Step 3

magnified

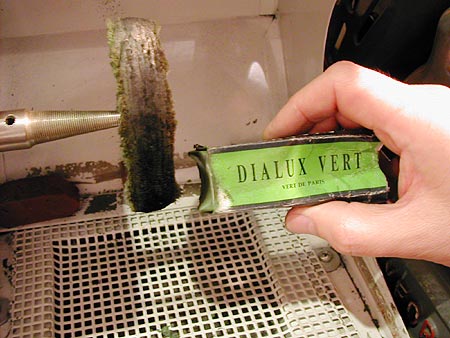

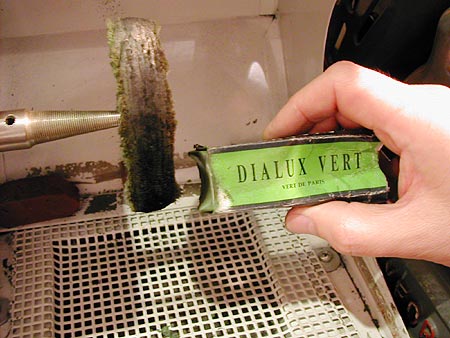

Step 5: polishing on buffing wheel

There are too many different polishing cotton wheels available;go for medium soft cotton disk, 10cm diameter. Apply some chromium oxide rouge (known as Green Steel Rouge)

Keep polishing. Be careful not to over-buff edges!

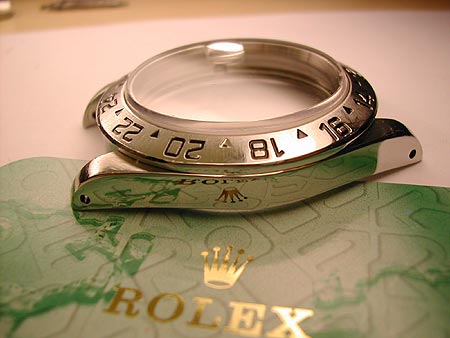

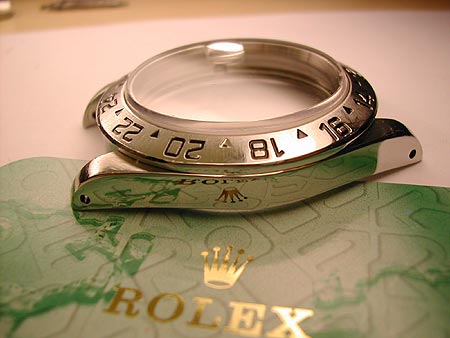

Once you achieve mirror-like finish, clean in ultrasonic.

piece of cake!

one more shot

Cheers !

Restoring or refinishing a stainless steel watch case is not as difficult as may be thought. Unfortunately most watchmakers are either not interested in doing it properly or were never taught how to do it. Those few who have mastered the skill of hand-polishing would rather die then to revel their secret of the trade! The trick in obtaining mirror-like finish is simple : a) to use correct polishing medium and b) to master polishing skills by following the correct procedure.

This tutorial is aimed not only at watchmakers, but also at watch dealers and collectors wanting to familiarize themselves with the process of hand-polishing. The procedure shown below was passed to me by my father (an to him by his brother Mihajlo Hacko, Master Watchmaker since 1948. who still does his own watch repairs!)

Guinea pig: 15 years old Explorer II Ref 16570, long overdue for decent case re-polishing.

I prefer to do all case polishing by hand.

Step 1:

To get rid of scratches start with coarse sand paper, grade 220

Keep it parallel and keep polishing until you remove ALL scratches, no matter how deep. This step is very important

All scratches are gone, but the surface is very coarse and dull. That's OK. The most important thing here is to remove ALL scratches and to have the grain lines parallel with the case.

Step 2: Switch to dry paper grade 800. I use German made, but most sand papers of similar quality will do the trick. You can buy this grade at any automotive shop supplier.

Don't rush - take your time (at least 5 minutes per side). The surface is still dull but we are heading in the right direction.(note how more light is now reflected form steel surface)

Same surface, magnified. Keep it parallel

If I can do it, you can do it too

Step 3: very much the same, now with finer grade dry paper - here I use Swiss made 1600 powder coated jewellers paper available form jewellers suppliers. This is jewellers stuff so they prefer to call is 4/0

Take your time, don't rush - 5 min. per side

The steel surface now reflects even more light and looks fairly smooth.

Step 4: More of the same. Medium: 3M Film sheet polishing (plastic)grade 60 microns and 10 microns (2-3 minutes each).Available from jewellery suppliers only. On touch 3M film eels like ordinarily plastic sheet, definitely not your ordinarily sand paper

If there are still any visible imperfection go back to Step 3

magnified

Step 5: polishing on buffing wheel

There are too many different polishing cotton wheels available;go for medium soft cotton disk, 10cm diameter. Apply some chromium oxide rouge (known as Green Steel Rouge)

Keep polishing. Be careful not to over-buff edges!

Once you achieve mirror-like finish, clean in ultrasonic.

piece of cake!

one more shot

Cheers !