Please elaborate

As far as I know some old PAMs had welded lugs, but I think that modern PAM 372 is made in one piece case

Already discussed in Reep Geek

ALE

...and here comes surprise!

I just got from my business trip hence so short reply yesterday…. I was not active on the forum for a week or so since I was leading a group of professionals for training in an abrasive manufacturer’s training facility in Switzerland, skipping the names. Day after day we had opportunity to see cutting edge industrial abrasive technology and to get some experience in using it. The abrasive manufacturer is delivering its tools and technology to IWC (which they can officially admit to and use as reference) and to other watch manufacturers they cannot confirm directly. On Friday we had a course of drum sanding tools with another technician with …a gen 372 in his wrist. I was cursing at myself for not taking my H-factory 372 to compare (but I will do that next time, in January 2014). Anyway, during the coffee break I jumped on the topic of how good is to be well paid technician in Switzerland pointing at his nice watch. “I got huuuuge discount from our customer

†- he replied smiling.

Then I asked him how is Panerai able to achieve so perfect shape of a case with so nice lugs flat surfaces and so on.

“They shape and polish case and lugs separately and then they insert lugs, mill and polish the back side in assembled state.†- he explained.

“Ah… so they weld the lugs in?â€

“Not necessarily. If you do it right all you have to do is to freeze lugs in liquid nitrogen, insert them with some force and wait.â€.

“WOW!†I said, “… but can’t we achieve the same with just milling and sanding?â€.

“No, since the weak point will be sanding with belt sanders which will always lead to not flat, wavy surfaces, especially close to the case, where you need special care not to ruin the shape of main case. Of course, you can try to use drum sander after the belt sander to reverse unwanted shape change but it would be even more difficult to avoid damage to the main case. The welding / inserting is the cheapest way provided you can do lugs and mill square holes with high accuracy.â€

“OK, but the lugs dissection is of rectangular shape, not square one... Milling the square hole - I know how, but rectangular with high accuracy? Not easy…â€

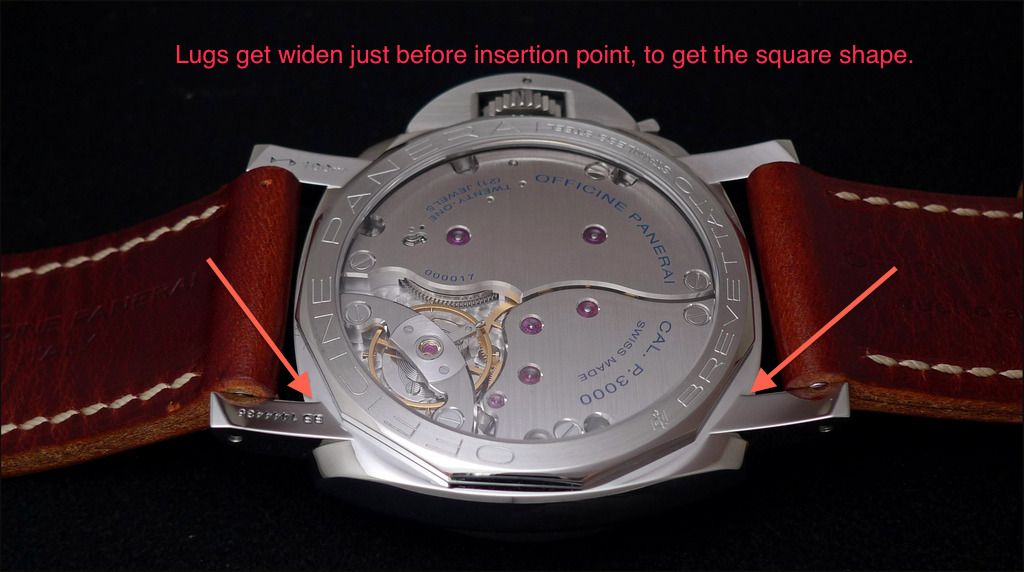

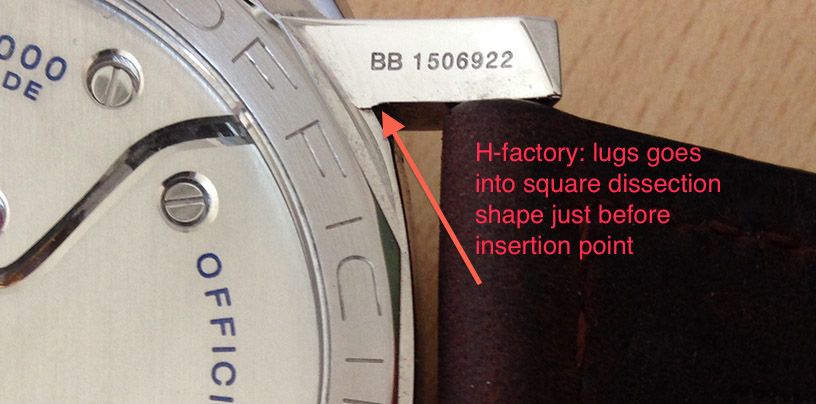

“Look, lugs are rectangular in shape JUST before the insertion point.â€. And they were. I got home and gave a look at H rep, and lugs were widening themselves just before they enter the case…

So now I know, from probably almost the original source, that the lugs are inserts. Which is logical from production point of view. Panerai experimented with this technology in 1940's and 1950's. Hence it is reference to this historical fact in modern pam 1940 case-based watches.

Noob just got it wrong due to lack of technology/tools or just to trump “we have it done different wayâ€. On the other side, H-factory seemed to take right approach but failed on high accuracy and sometimes you can see hairline gaps between lugs and the rest of case…

Now to photos:

Interesting fact, there is similar photo on Puretime website, showing the quality of Noob's engravings but avoiding to show the quality of areas around lugs…?