Serial number starting with m would indicate this would be a 2007 or 2008 ,meaning there should be a engraveing on the Rehaut , trying to figure that out if I am correct or wrong ?

-

Tired of adverts on RWI? - Subscribe by clicking HERE and PMing Trailboss for instructions and they will magically go away!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

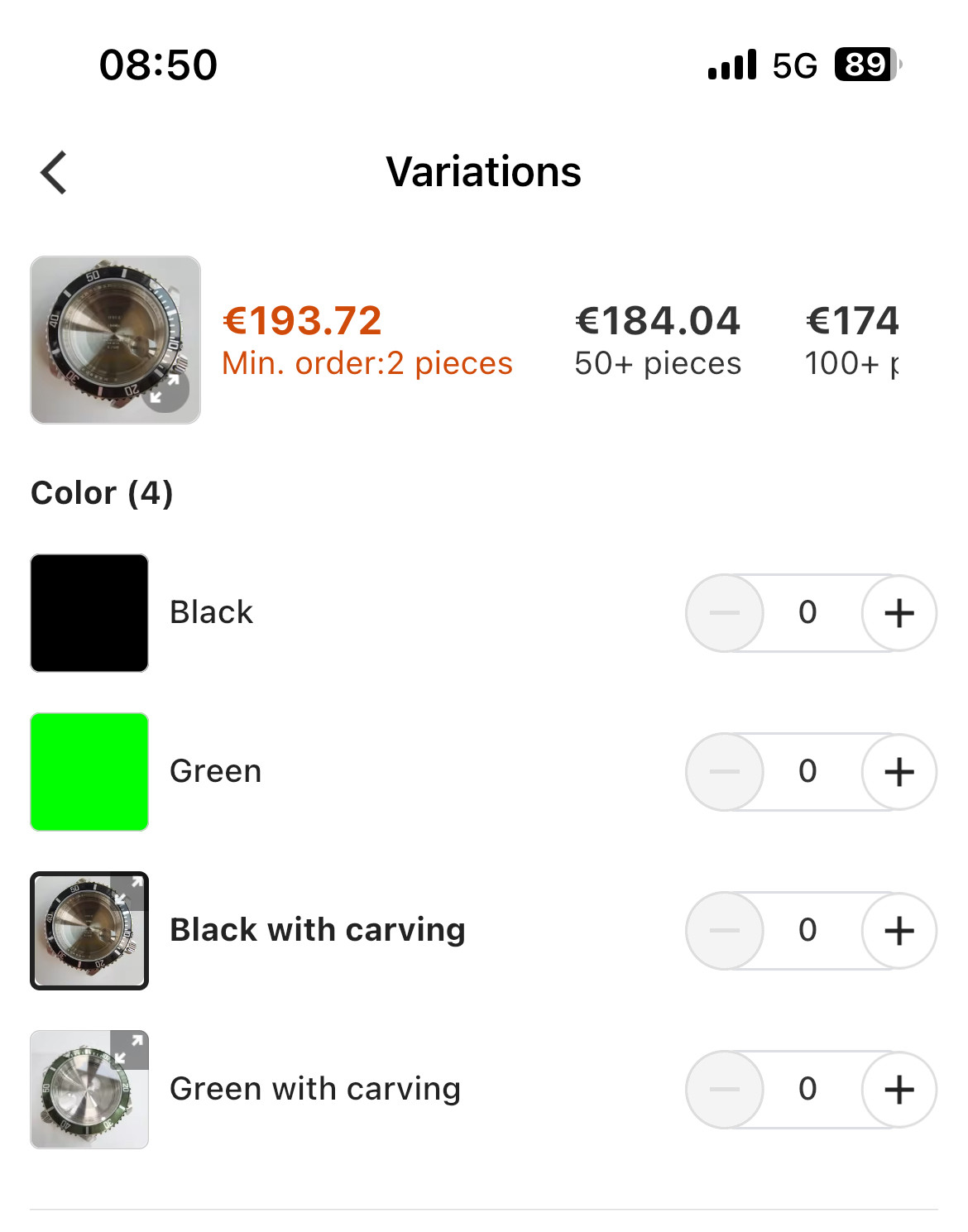

I purchased a Sillan 16610 case from Alibaba.

- Thread starter trash3939

- Start date

- 2/11/12

- 1,126

- 1,078

- 113

Serial number starting with m would indicate this would be a 2007 or 2008 ,meaning there should be a engraveing on the Rehaut , trying to figure that out if I am correct or wrong ?

There is an engraved option if that’s what you want.

Engraved on lugs but not the rehaut?There is an engraved option if that’s what you want.

- 14/10/19

- 2,633

- 11,732

- 113

Originally, M number 16610 is stamped on the rehaut.Serial number starting with m would indicate this would be a 2007 or 2008 ,meaning there should be a engraveing on the Rehaut , trying to figure that out if I am correct or wrong ?

In this case, it is a replica.

ARF had some with and without engraving on the rehout.

It is not accurate.

JKF, for example, has a 5513 case with 1680 engraved on it.

If only we could get a drilled lug option...

Thanks sir appreciate it . Trying to figure the best case for 16610 build after my 5513 on the way from jkf.Originally, M number 16610 is stamped on the rehaut.

In this case, it is a replica.

ARF had some with and without engraving on the rehout.

It is not accurate.

JKF, for example, has a 5513 case with 1680 engraved on it.

Nice job

Would love to know your techniques and what tools you use for this!

- 2/11/12

- 1,126

- 1,078

- 113

Would love to know your techniques and what tools you use for this!

Dremel with 0.8mm bit from the inside of the lugs to get the pilot hole. Then 1.25mm from the exterior with a small drill press with high speed.

For the initial Dremel bit, how are you getting the bit to come out straight and not at an angle? Tight fit between the lugs!Dremel with 0.8mm bit from the inside of the lugs to get the pilot hole. Then 1.25mm from the exterior with a small drill press with high speed.

- 2/11/12

- 1,126

- 1,078

- 113

For the initial Dremel bit, how are you getting the bit to come out straight and not at an angle? Tight fit between the lugs!

Tape the back of the case, make sure the chuck doesn’t hit the lug. It will be a slight angle. That’s why I use a 0.8mm bit, it reduces the angle. Then you widen the hole with the 1.25mm from the exterior.

That makes sense, thank you! I'll have to practice on some AliX cases to get this down.Tape the back of the case, make sure the chuck doesn’t hit the lug. It will be a slight angle. That’s why I use a 0.8mm bit, it reduces the angle. Then you widen the hole with the 1.25mm from the exterior.

- 2/11/12

- 1,126

- 1,078

- 113

- 14/10/19

- 2,633

- 11,732

- 113

I use the same thing.

Drilling through holes in a rug this way is not difficult once you get used to it.

That little press has enough power to do the job? Good to know!

- 2/11/12

- 1,126

- 1,078

- 113

That little press has enough power to do the job? Good to know!

It doesn’t have to do with “power”. It goes up to 9000 rpms which is really what helps.

That and cutting oil and fresh bits.

When you come down into the pilot hole, do you start with the bit in contact? Or clear and down?

- 2/11/12

- 1,126

- 1,078

- 113

When you come down into the pilot hole, do you start with the bit in contact? Or clear and down?

Clear and down. Don’t start in the hole.