I tried fixing the keyless works - went through the tutorial step by step and it seemed to we working well. Then went to take the stem out and rebuild the watch, tried to put the stem back in after recasing - no dice.

I’ll try again tomorrow.

Plus found that I’d fucked the new minute hand - it won’t go on the pinion. I must have pushed it too hard on the cocktail stick when I was luming it up.

All in all a great days work.

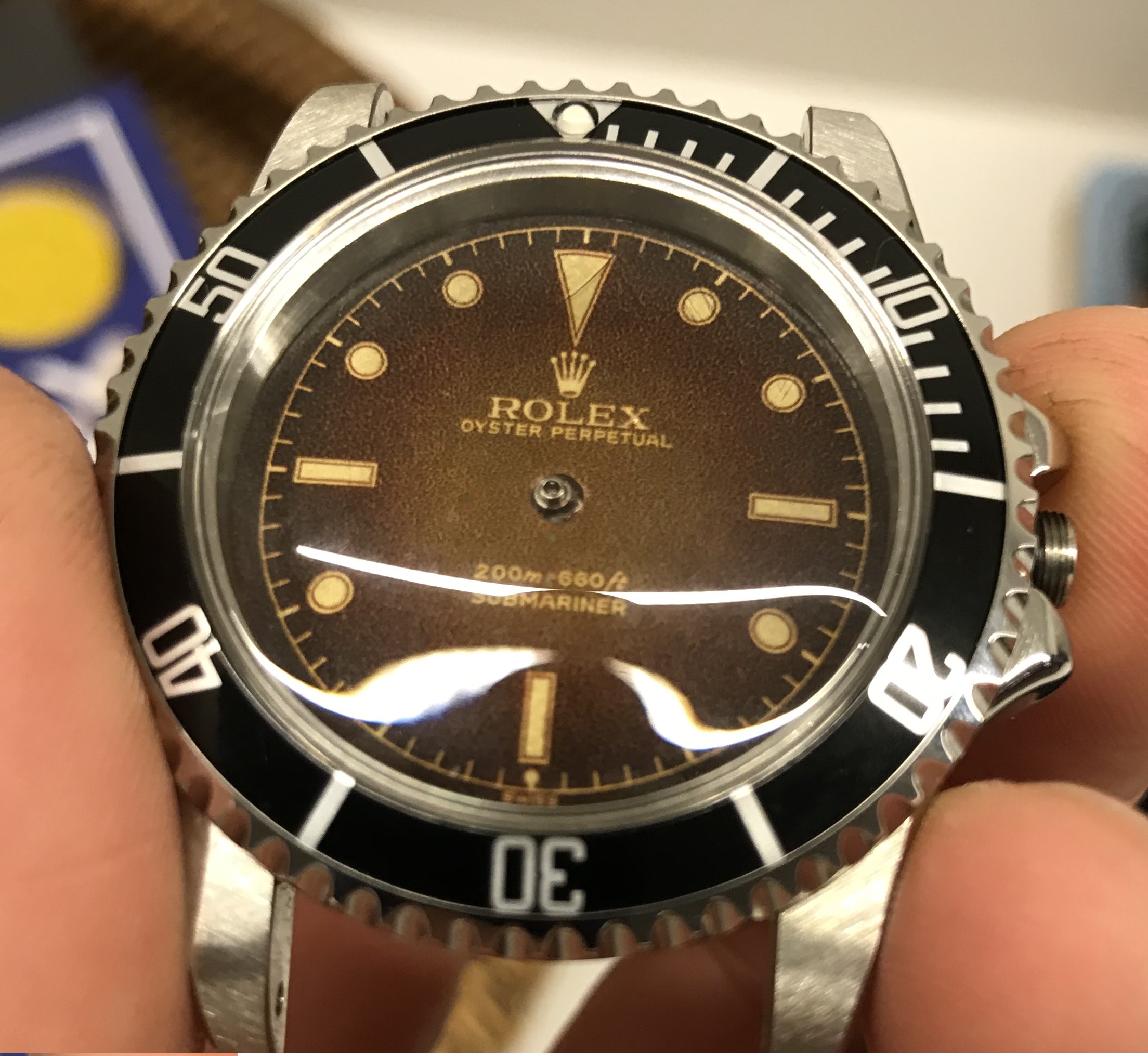

At least I managed to put the new dial on.

[mention]Alhig72 [/mention] - thanks for the advice. So far I’ve only been experimenting with Lume and binder. I’ll see how it goes with some acrylics.

I‘ve nicked some hypodermic needles and syringes from work, they seem to work quite well - I might try filing the needle points down a bit as they were a bit scratchy.

I’ll try again tomorrow.

Plus found that I’d fucked the new minute hand - it won’t go on the pinion. I must have pushed it too hard on the cocktail stick when I was luming it up.

All in all a great days work.

At least I managed to put the new dial on.

[mention]Alhig72 [/mention] - thanks for the advice. So far I’ve only been experimenting with Lume and binder. I’ll see how it goes with some acrylics.

I‘ve nicked some hypodermic needles and syringes from work, they seem to work quite well - I might try filing the needle points down a bit as they were a bit scratchy.

Last edited: