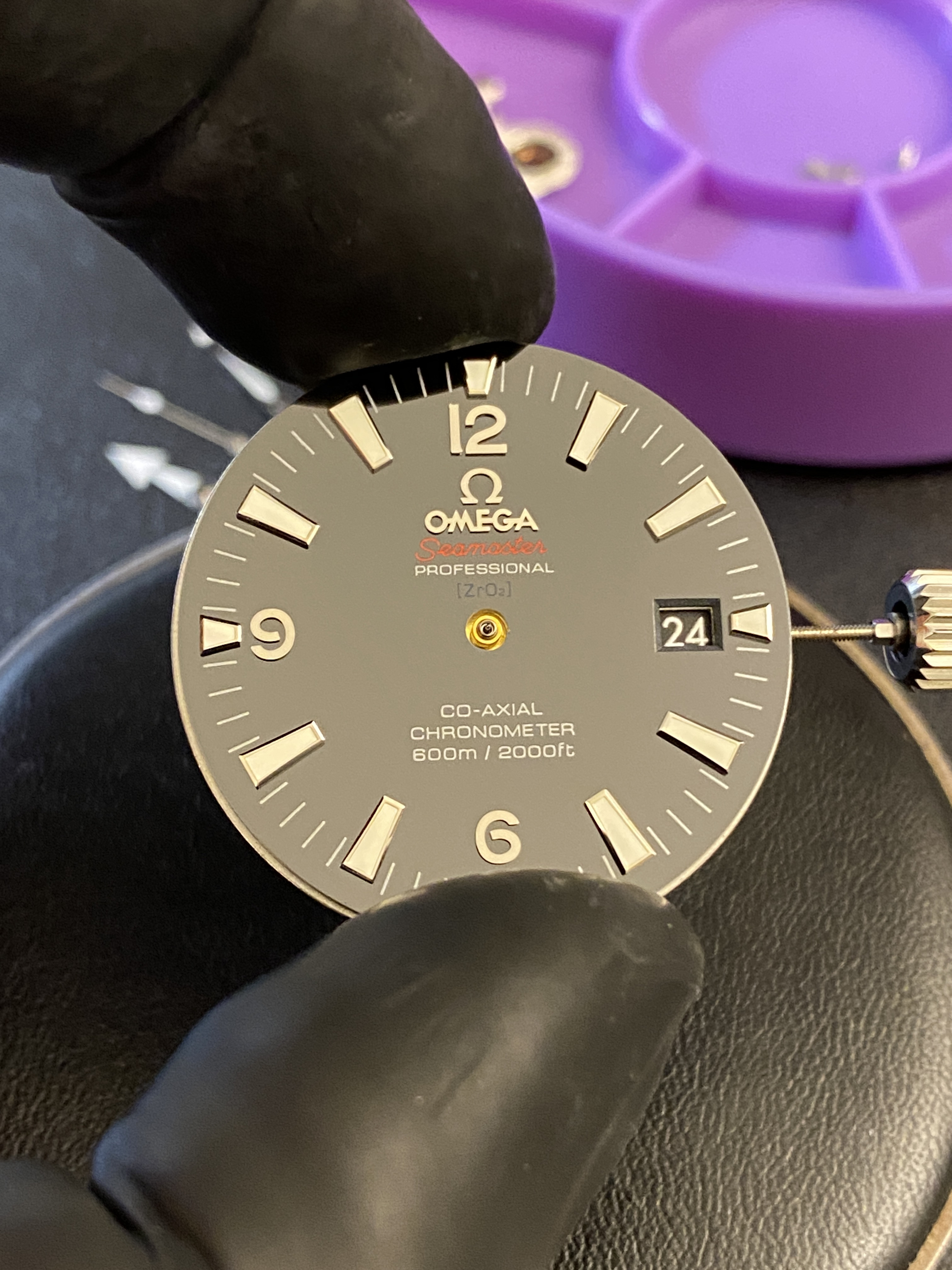

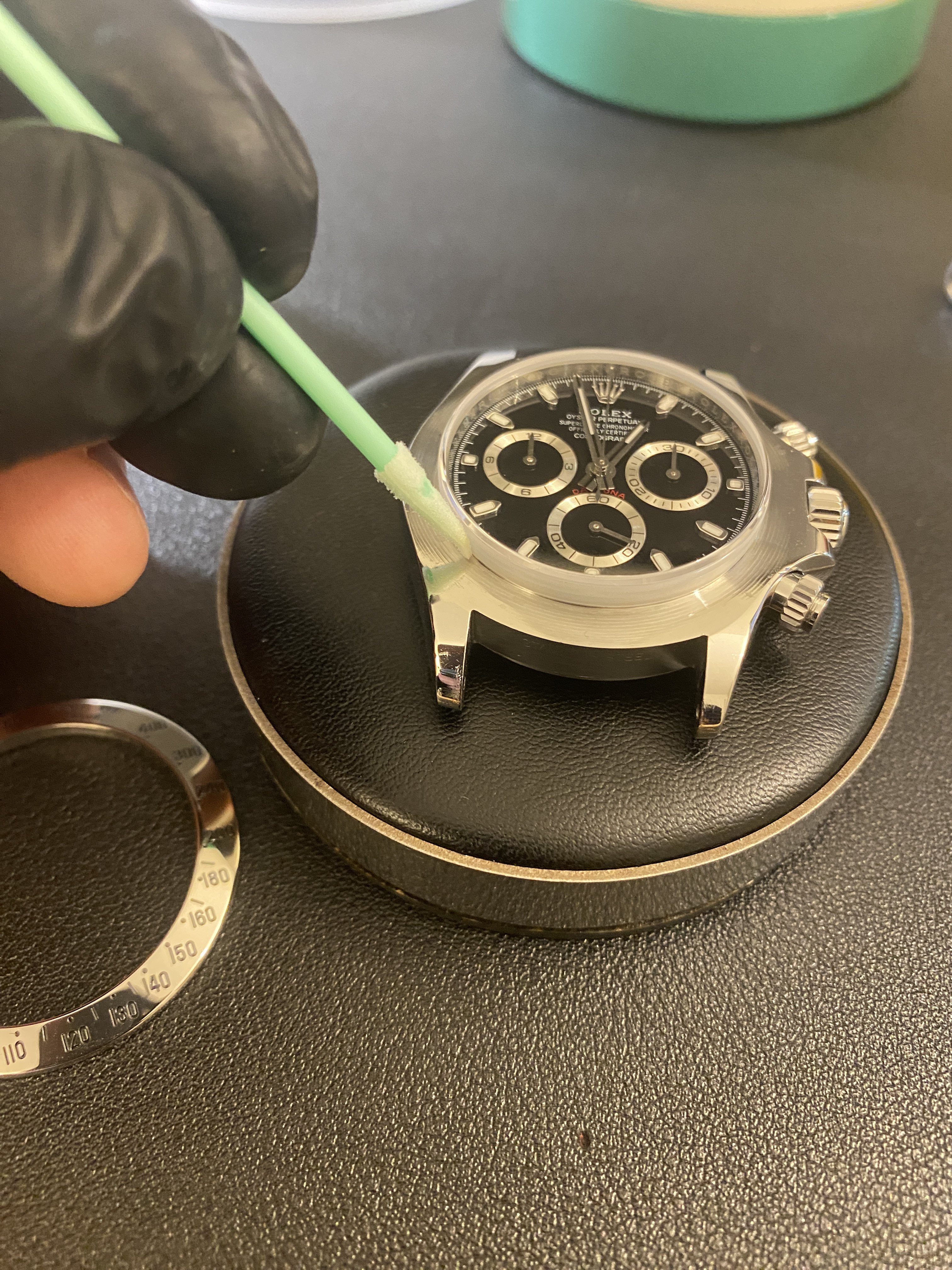

A few days ago I received a beautifully modded 3KF Nautilus with buff dial, hands, and datewheel. This was my first 5711 and I have to say, this watch is not over hyped. It is a stunning design.

However, less than a week later it suddenly stopped working. I know clone movements can be unreliable and expensive to fix since getting spare parts is nearly impossible. But without any options, I decided to open the watch up and take a look at what might be wrong. I decided to keep the movement in the case since I was hoping the problem would be obvious and superficial... and I didn't want to risk marring up the buff dial and hands.

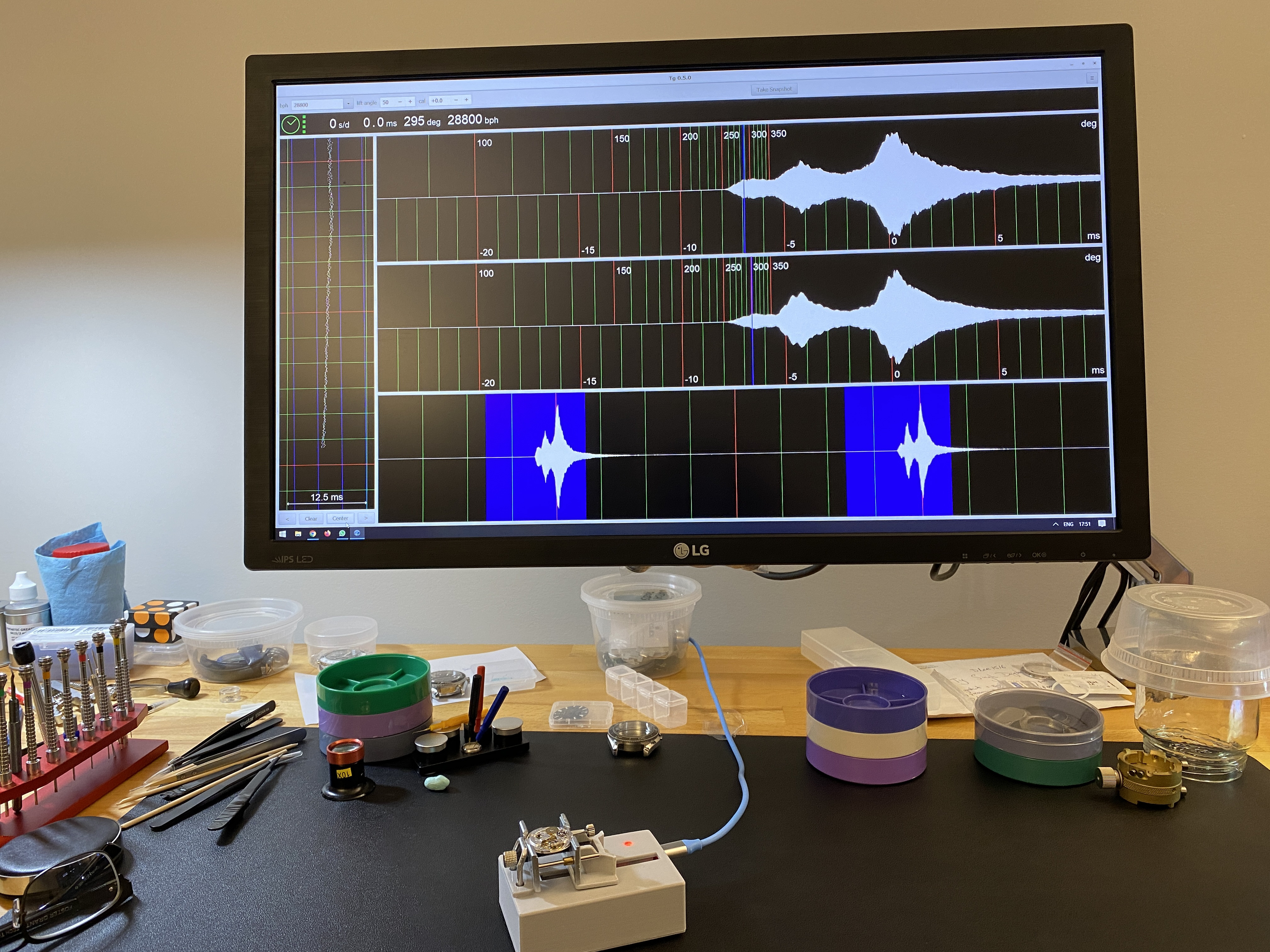

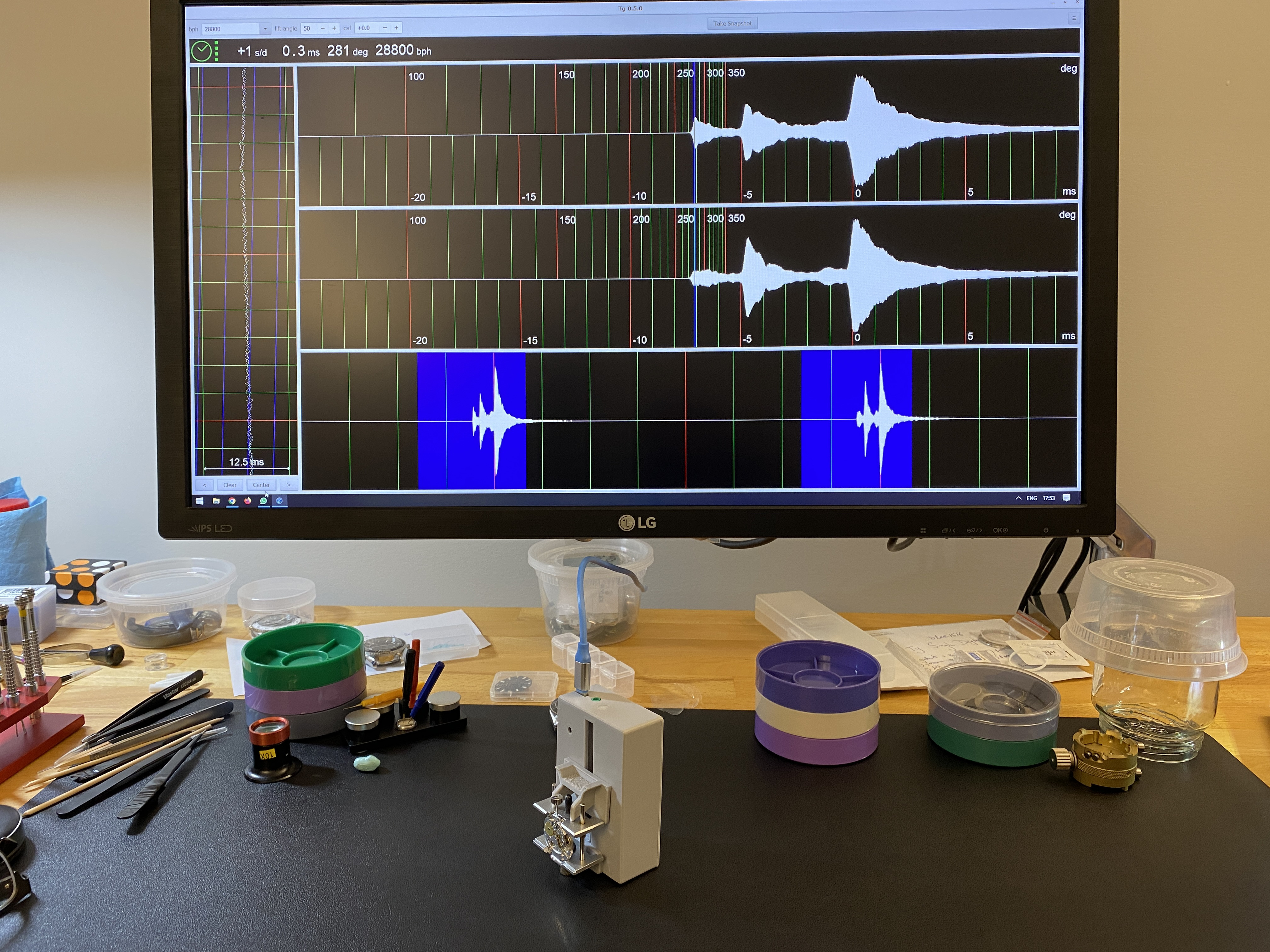

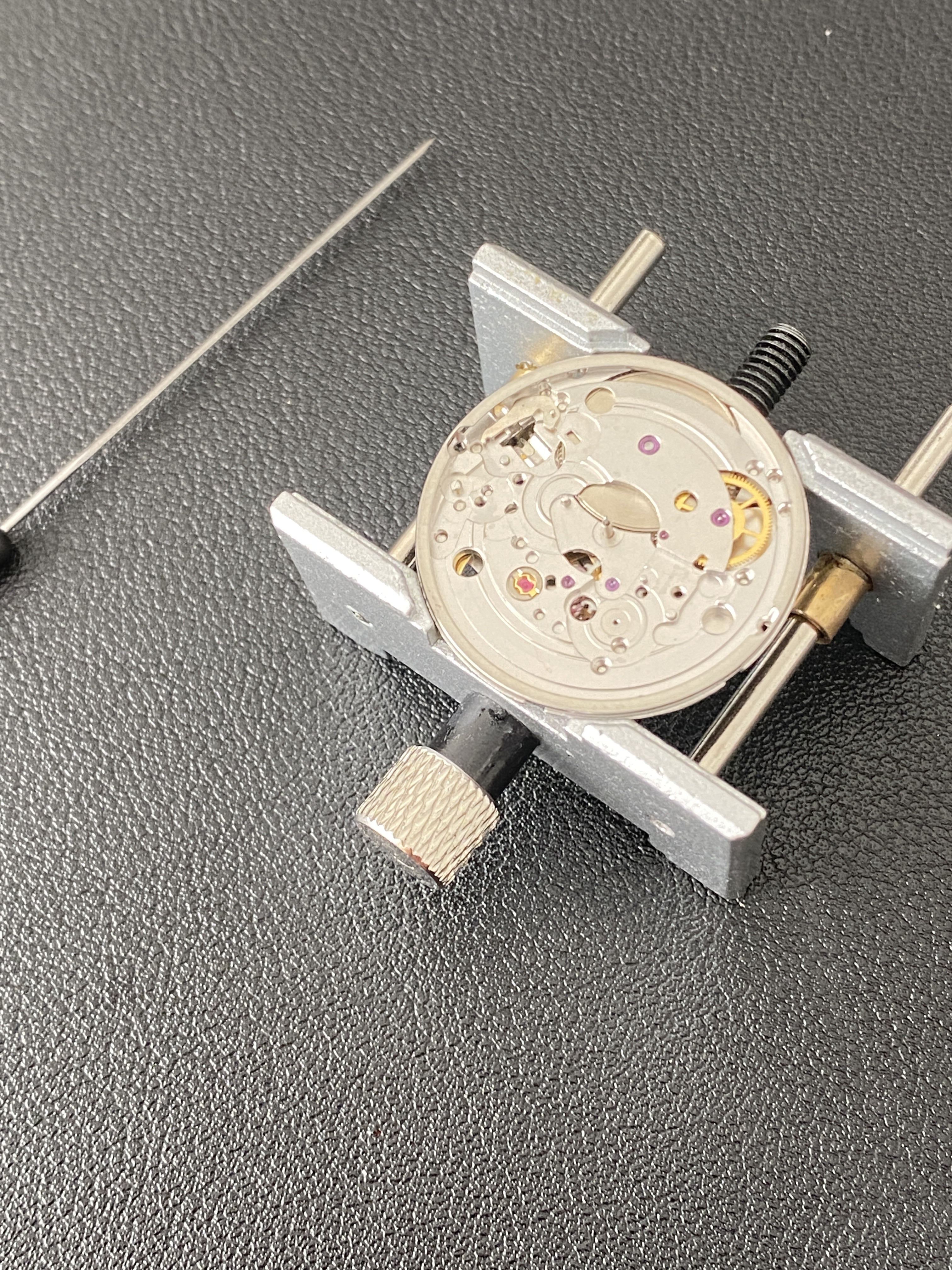

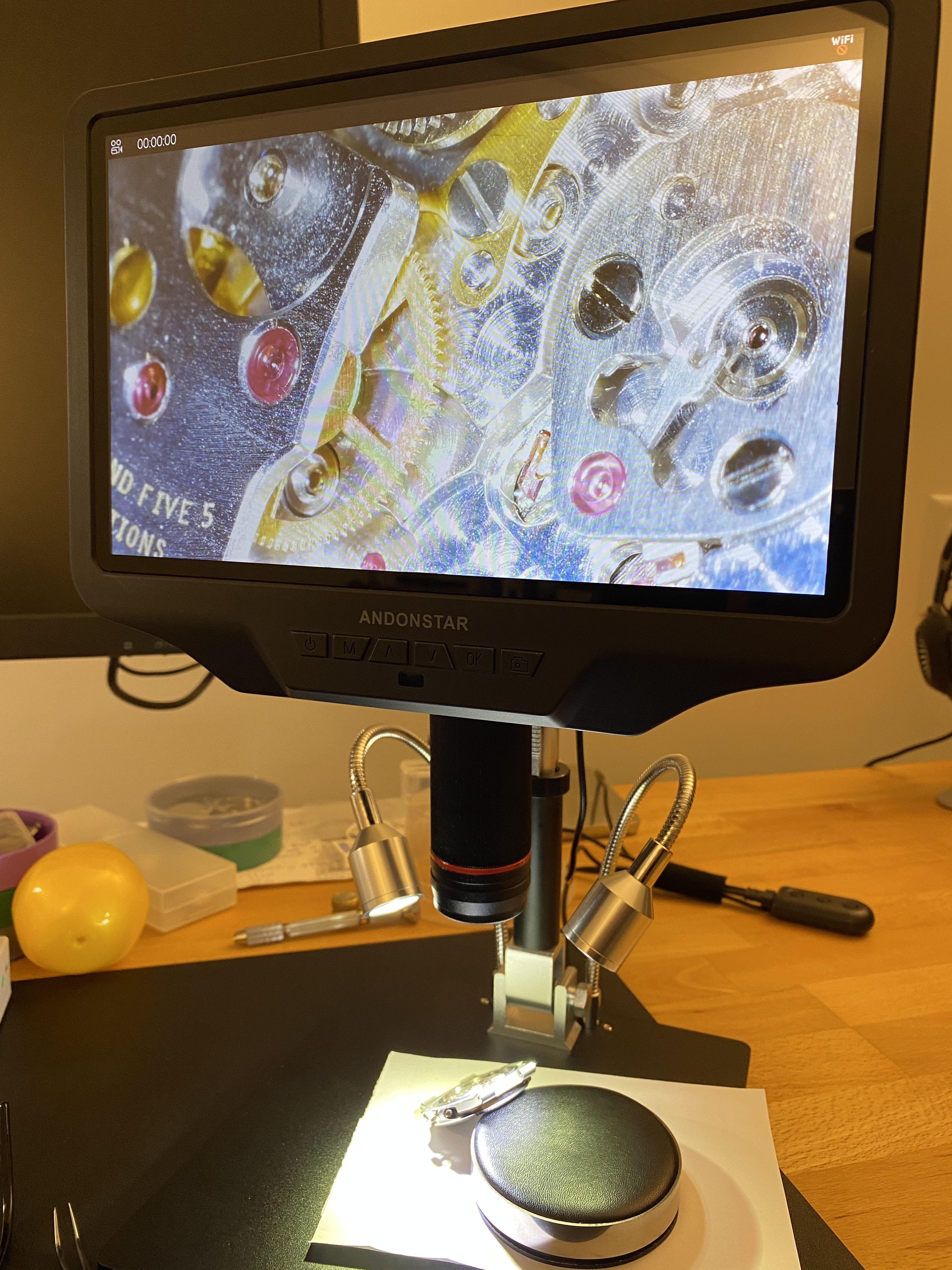

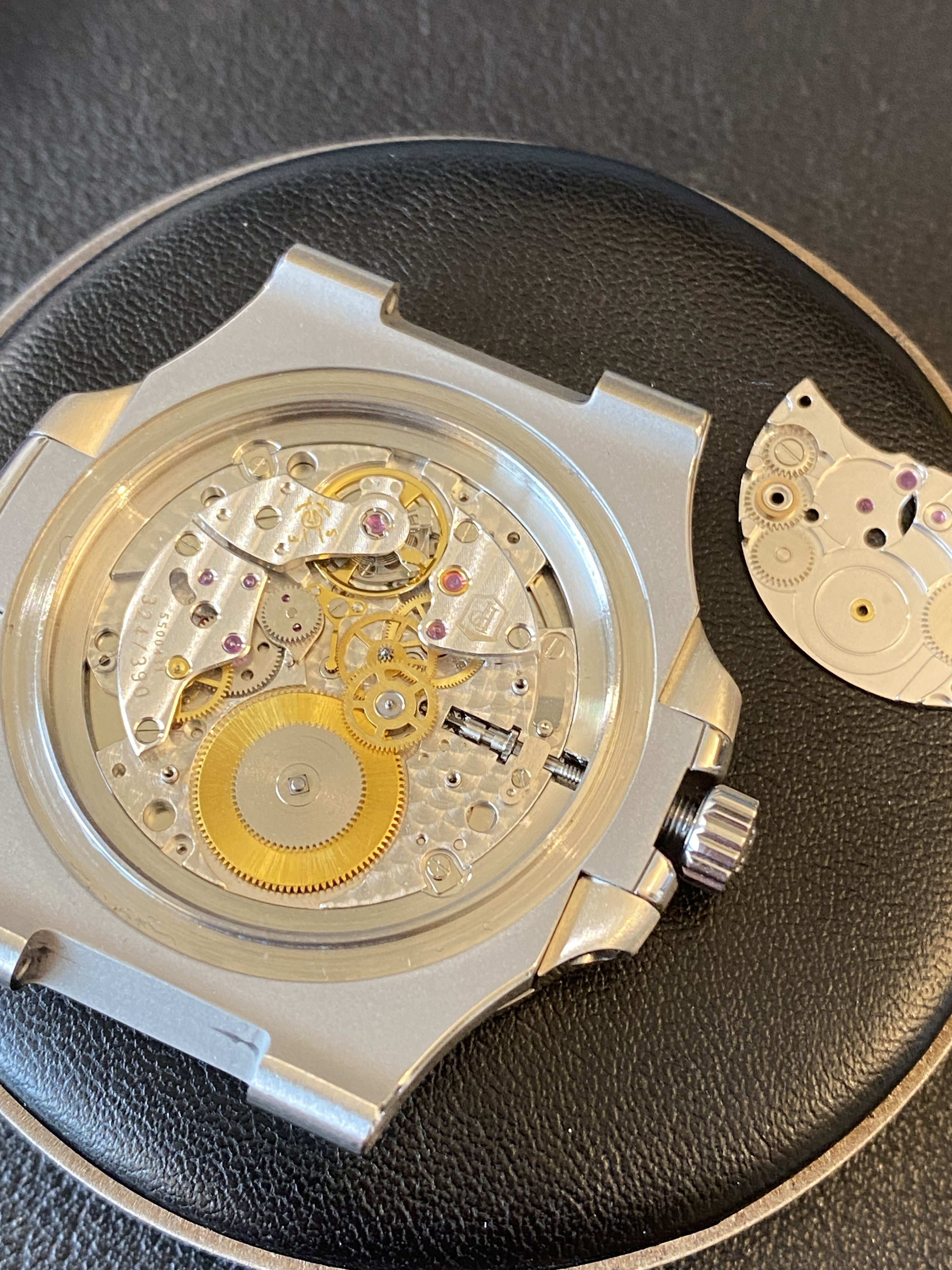

Digging into the movement is pretty straight forward and most of the movement is accessible from the back.

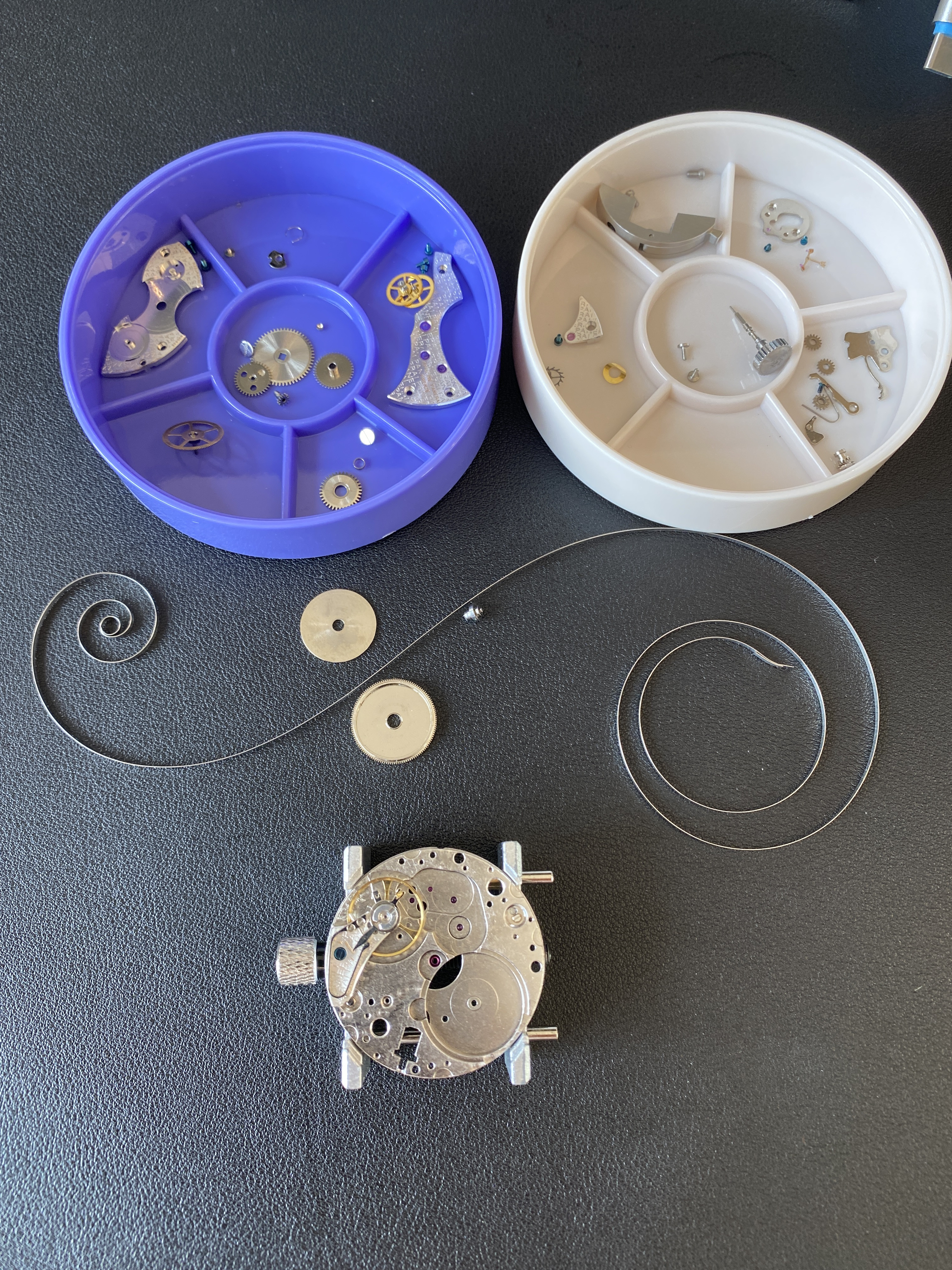

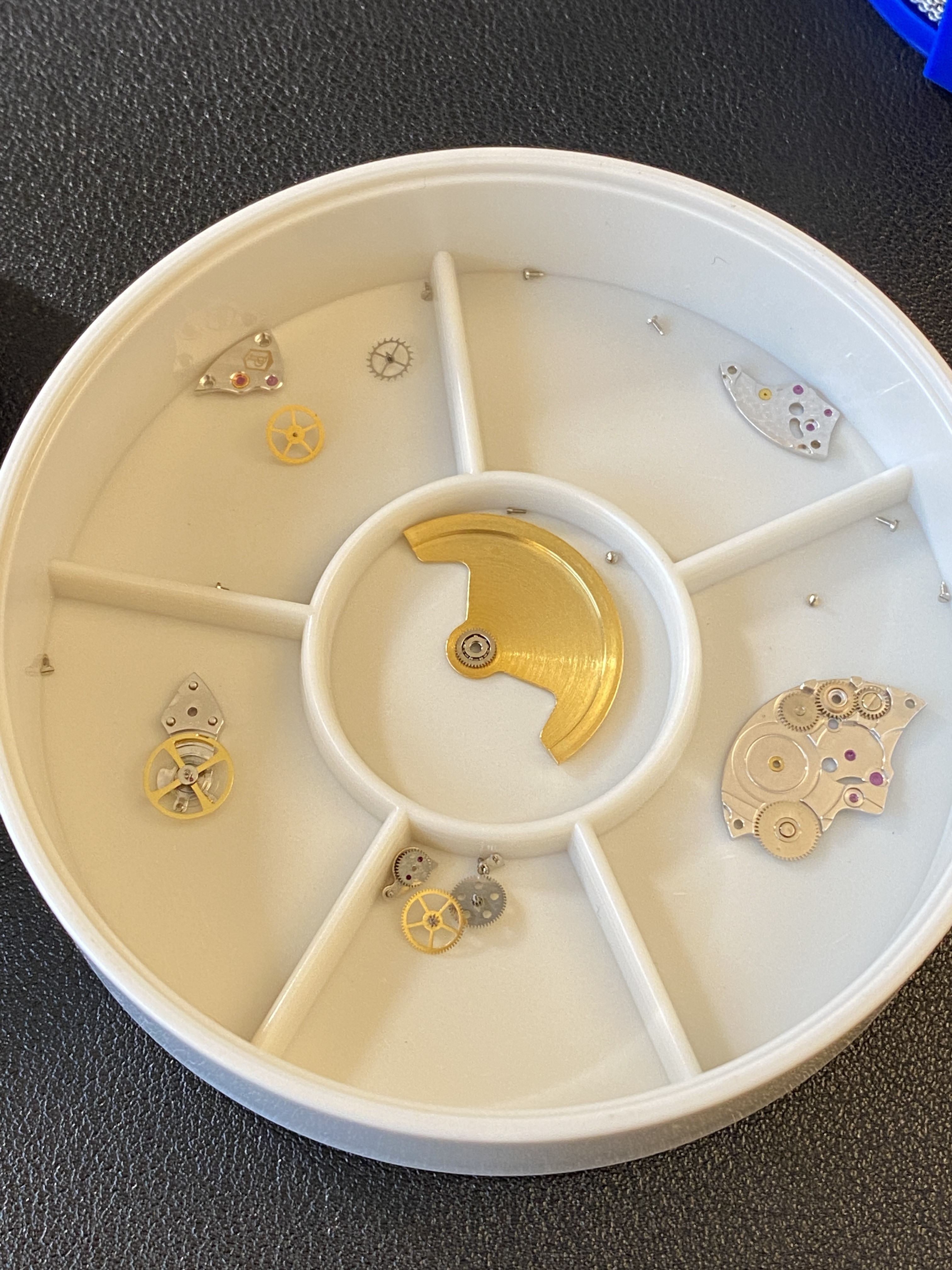

The balance cock and automatic bridge came away easily. At this point I couldn't see anything obviously wrong, and I should have fully removed the movement from the watch to continue disassembly since the click isn't accessible from the bottom of the movement so there was no way to remove power from the main spring. But I forged ahead since I was on a roll, and it turns out, there was no power in the mainspring for reasons that will become obvious in a moment.

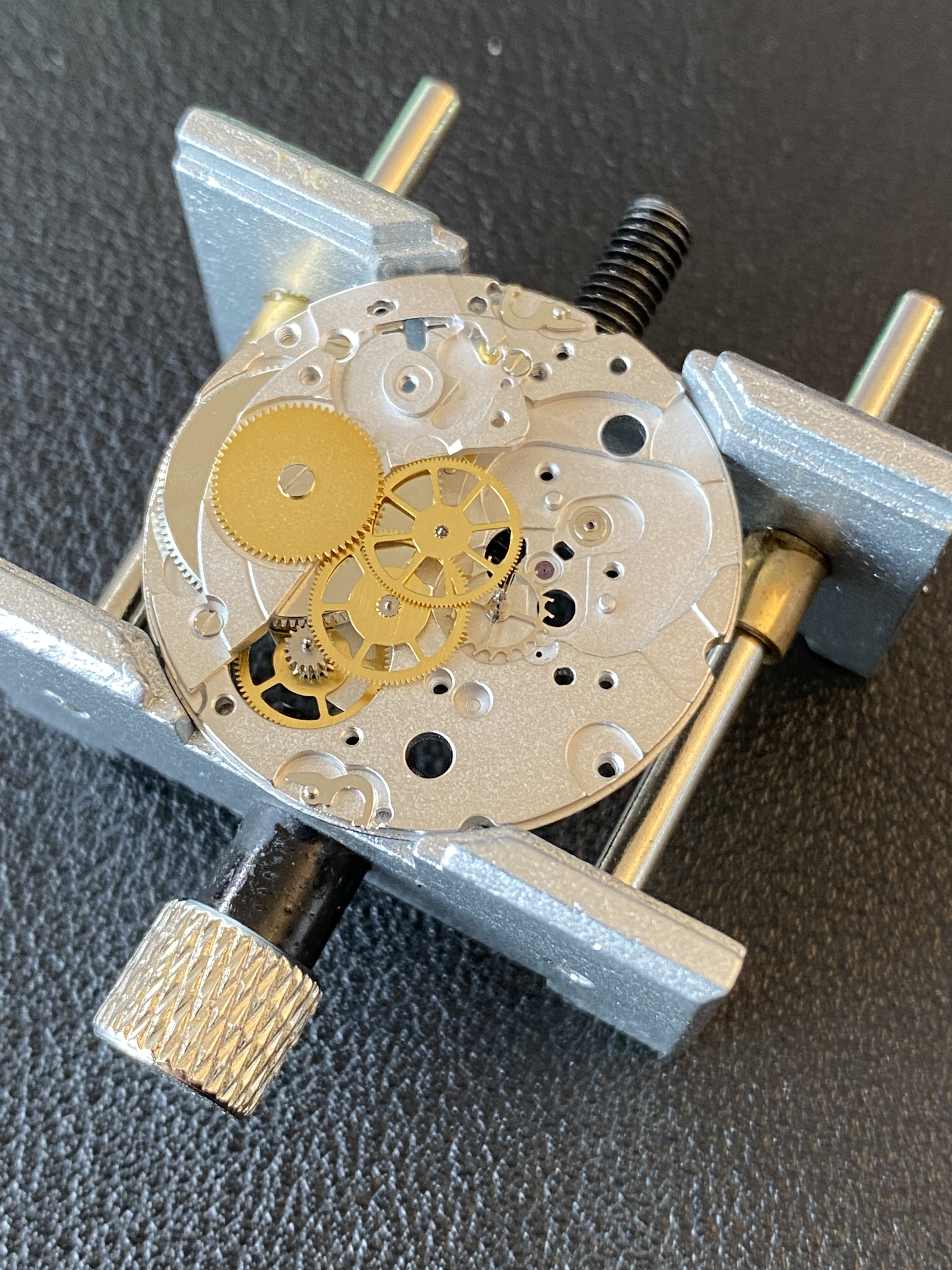

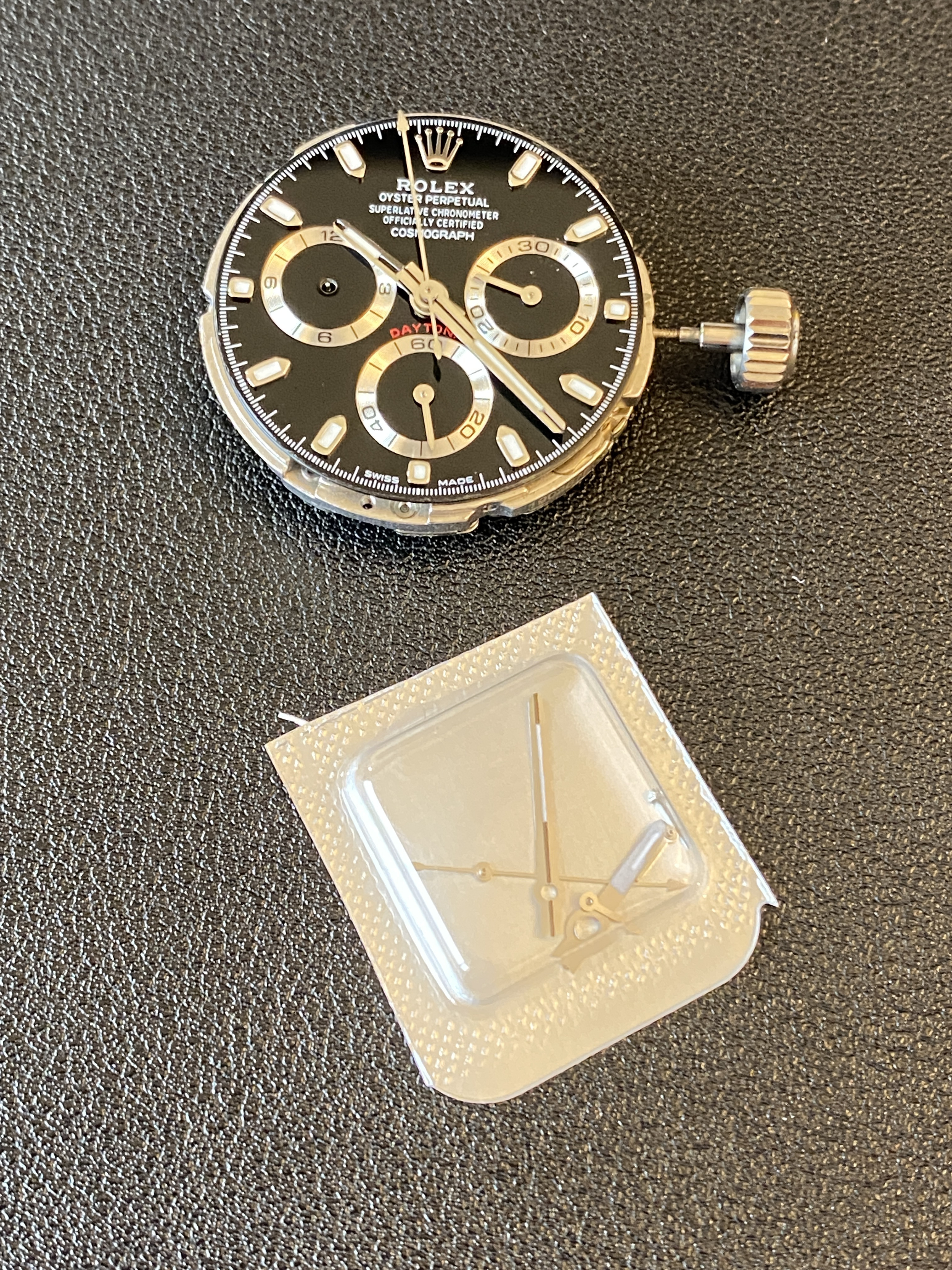

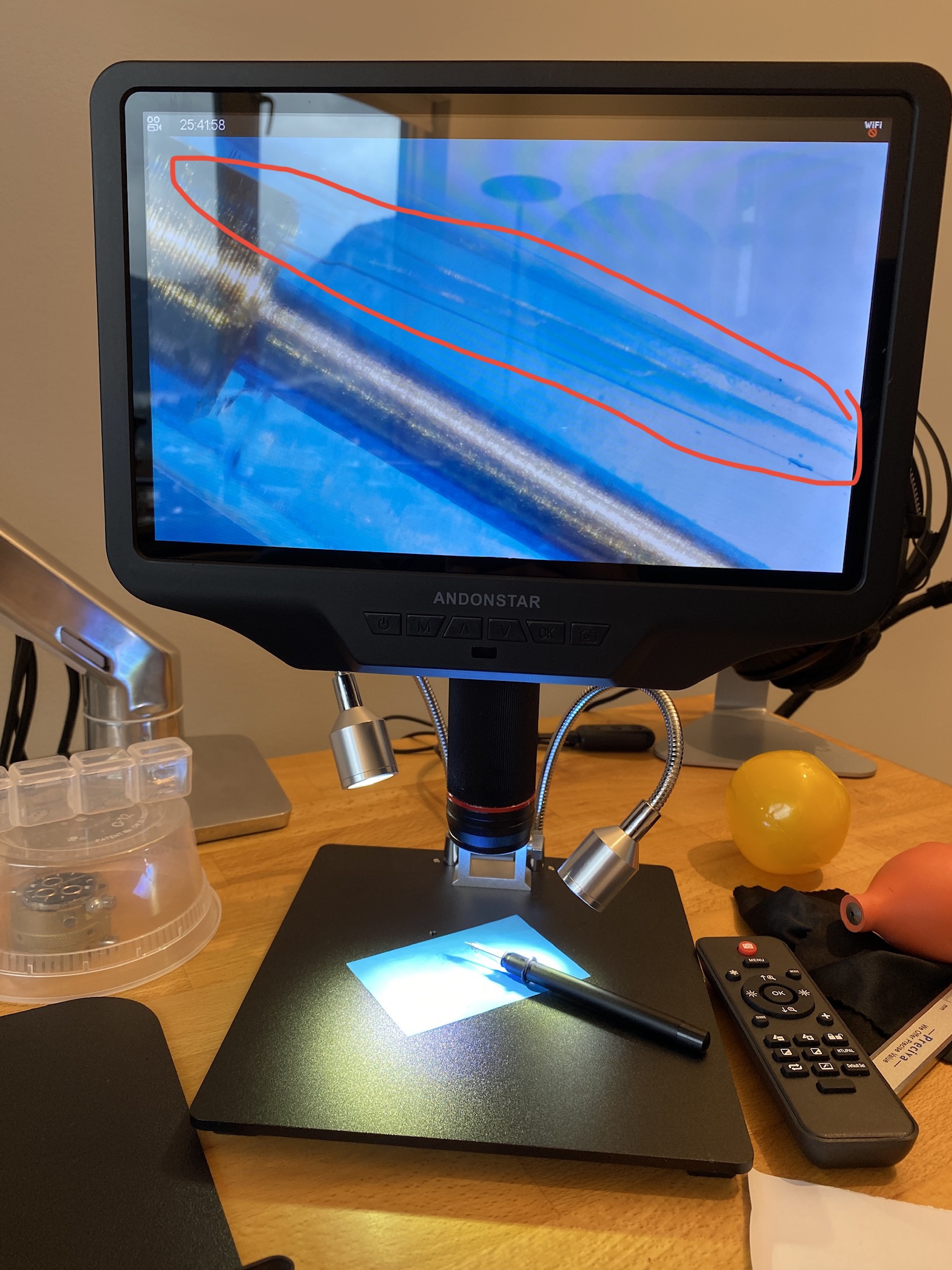

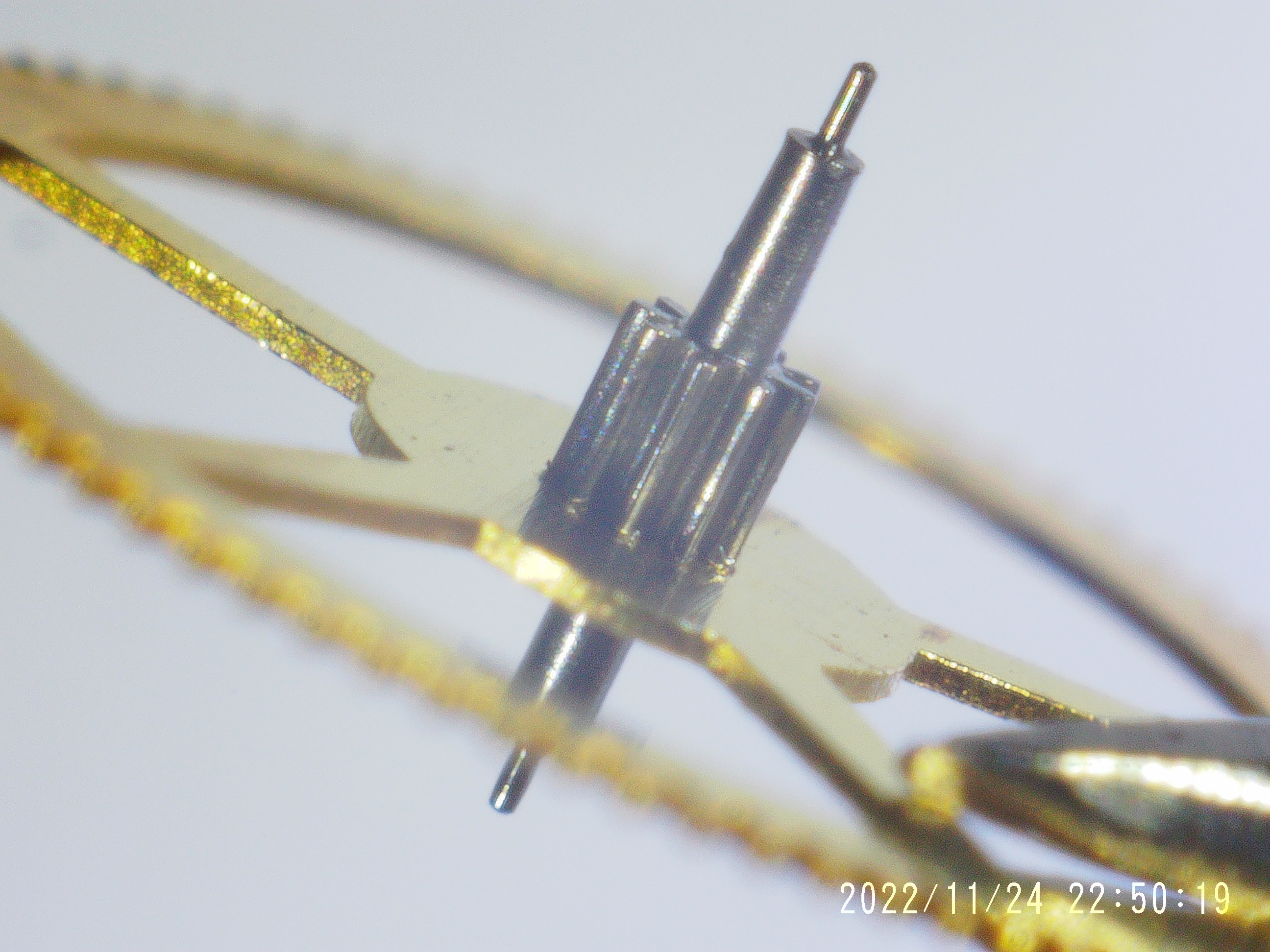

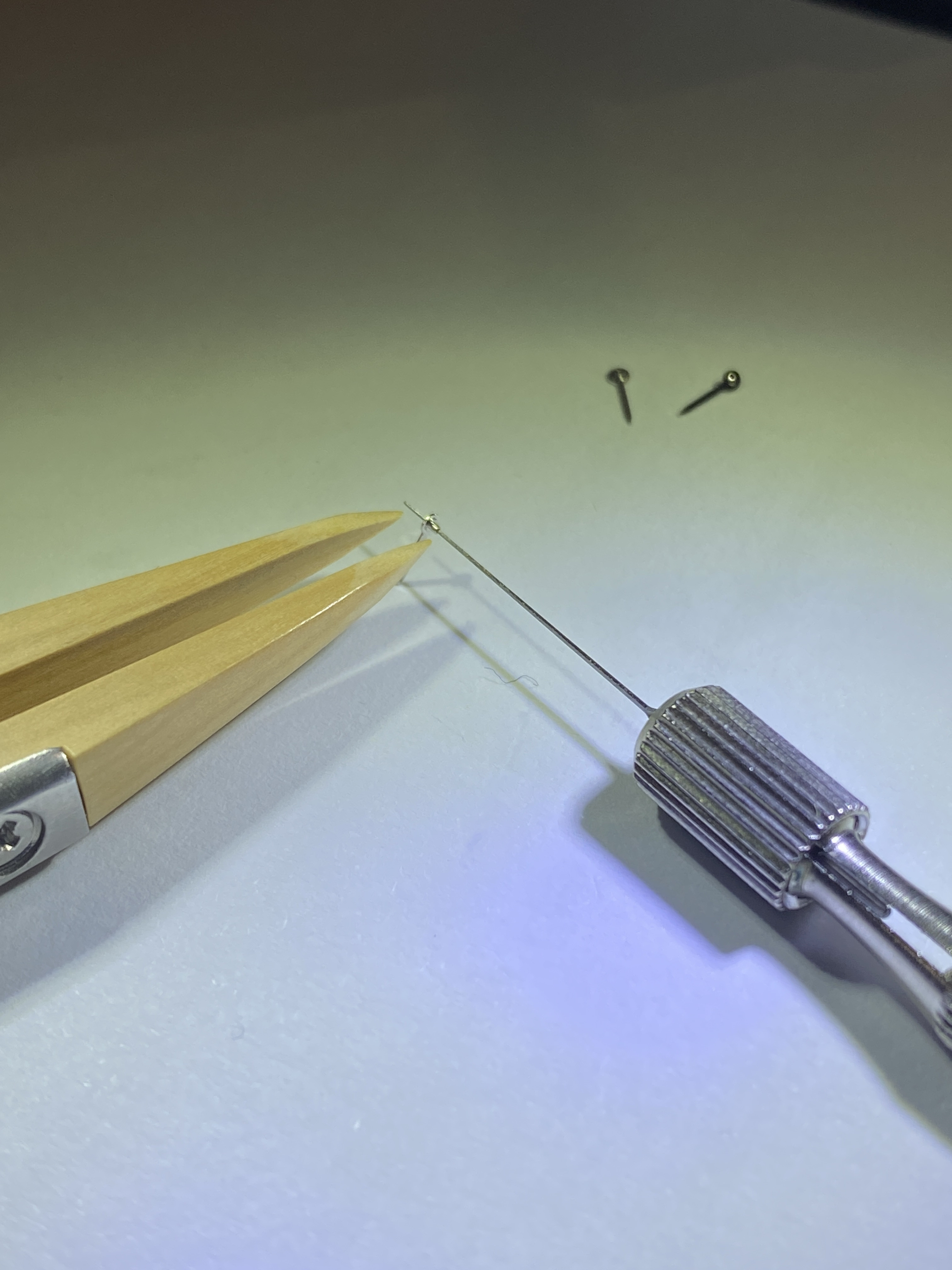

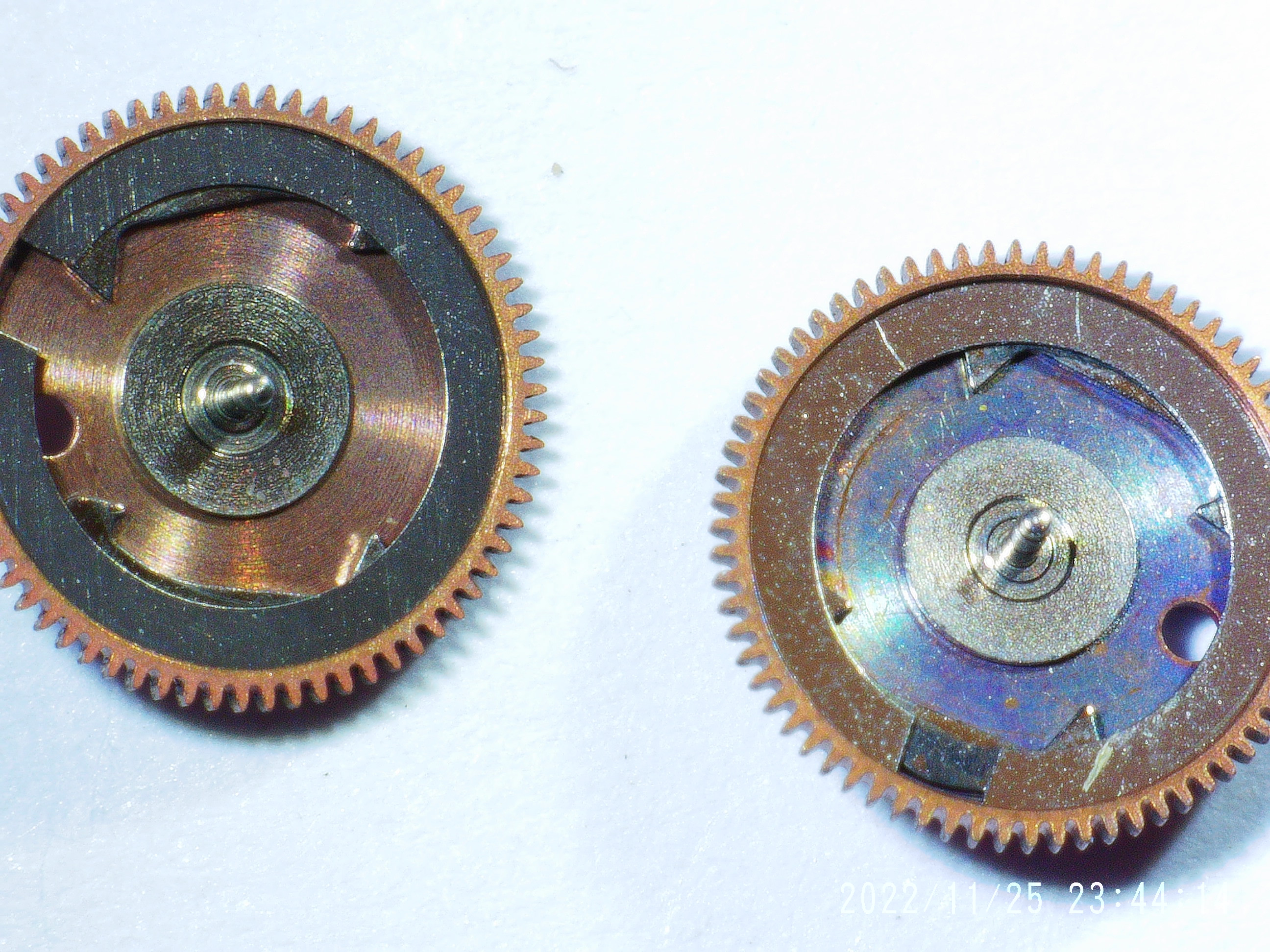

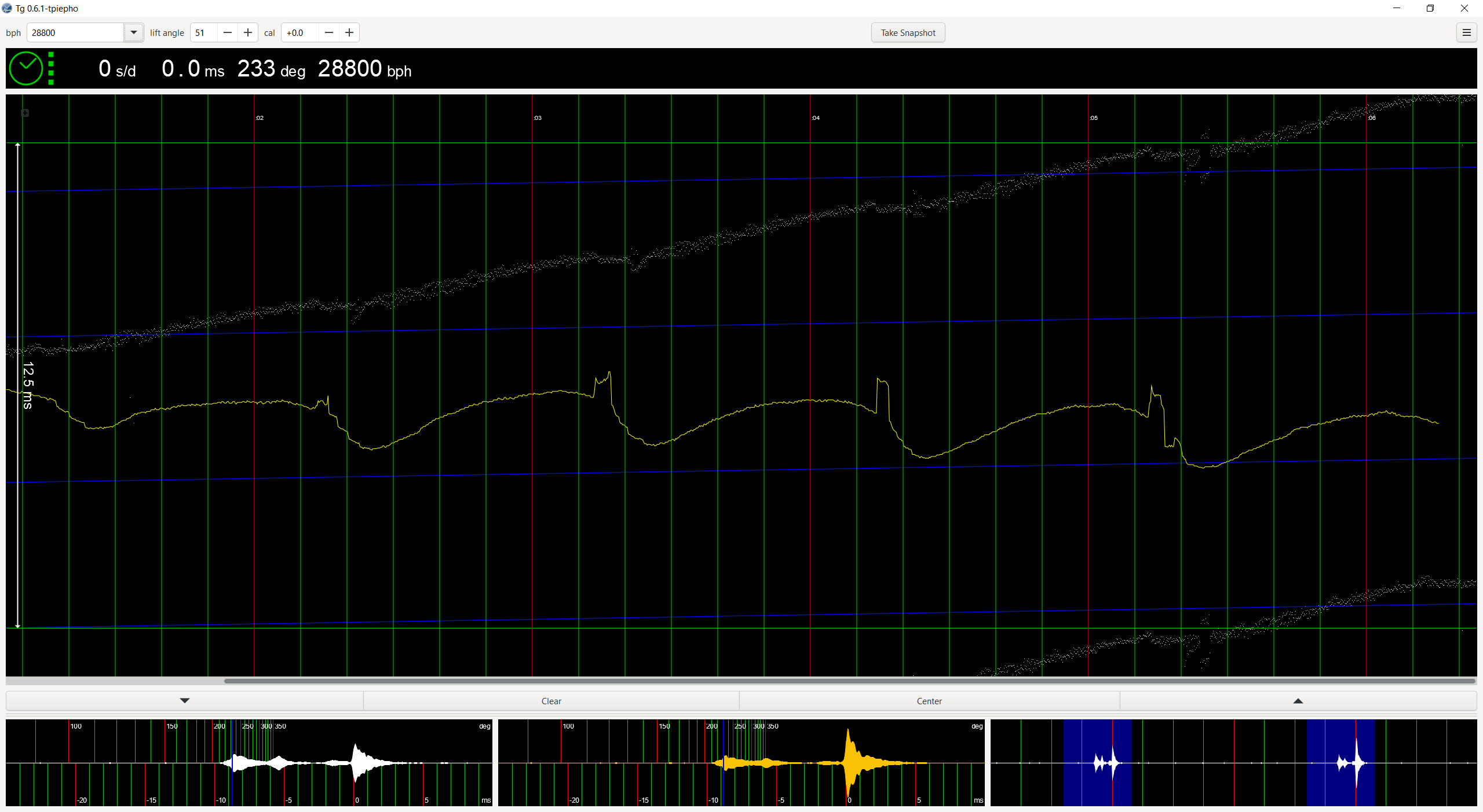

When I removed the barrel / train bridge, there was no power in the mainspring. But I did find a random 0.4mm screw jammed under the bridge. This screw isn't from the movement, so I assume it got in there either during assembly, or during the modding process in China. But as bad as an unsecured screw floating around the movement was, the reason the movement stopped was because the 3rd wheel's arbor had broken in half.

In the pic above, you can see the third wheel and the pinion still in its jewel pivot hole and the grey of the metal failure on both sides.

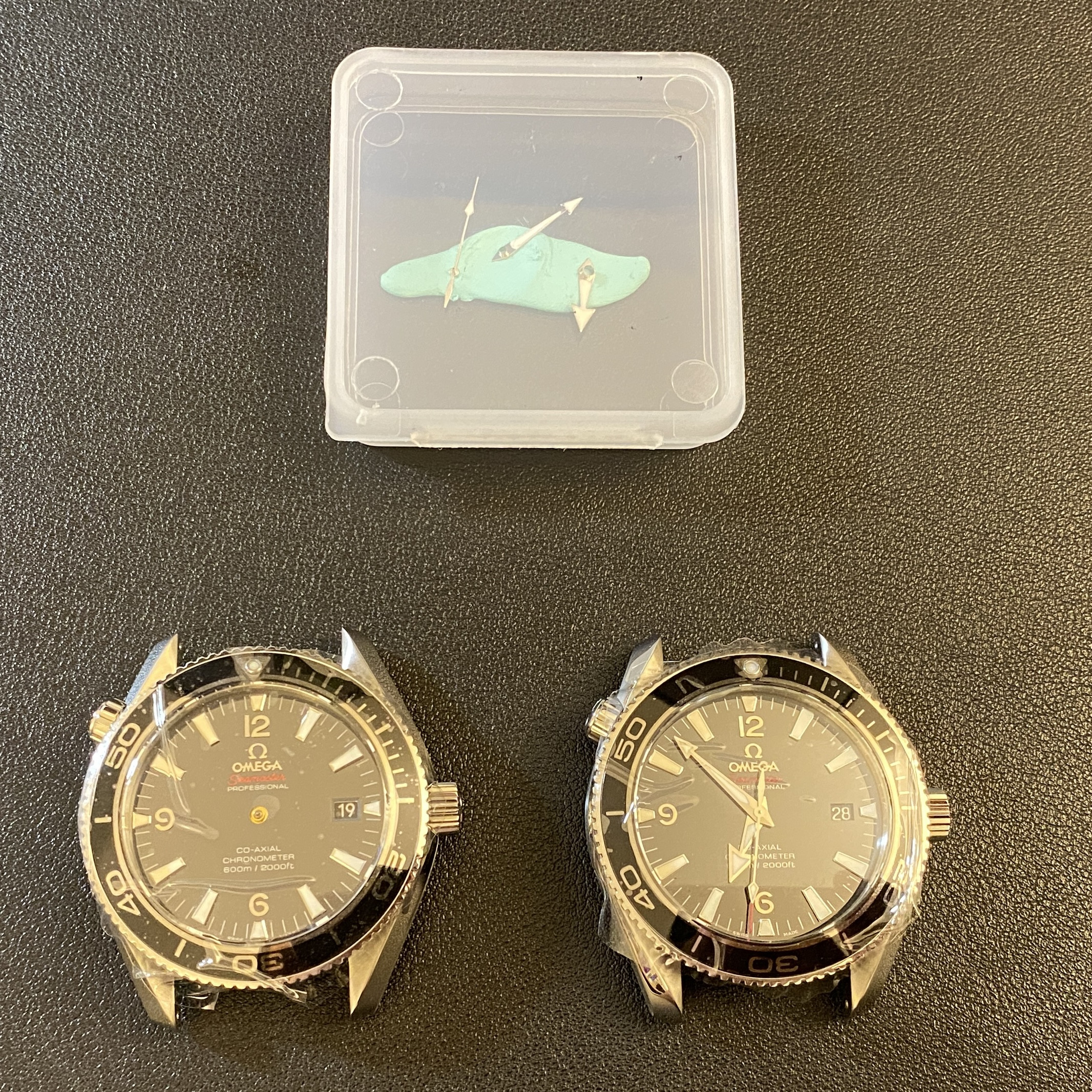

Needless to say I'm a little sad since according to my WeChat dealer, 3KF doesn't sell these movements on their own. So that means I'll have to buy a whole new 3KF watch just to get a spare 3rd wheel for the 324 SC movement. But, before I pull the trigger on that... if anybody out there has a broken 3KF 324 SC movement with an intact 3rd wheel, I would love to buy it form you