-

Tired of adverts on RWI? - Subscribe by clicking HERE and PMing Trailboss for instructions and they will magically go away!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Decal printed dial

- Thread starter Bart Cordell

- Start date

Problem is that you can't print white on decal.

The only way is to put a black printed decal on a white sprayed dial plate nut the writings won't have no 3D effect.

Everything will be "flat" ... like that 6429 dial

I think that dial looks great!

The only thing I would change is the coronet. It looks a bit too high up there.

Sent from my iPhone using Tapatalk

Thanks Briteling, I know your technique is closer to a correct gilt print but I’m still going to persevere with the water slide technique, at least a little longer. But I appreciate the offer of help.I can help you through the process or help you get something printed, just PM me an we can talk things through. If I get some spare time I can see about making a write up about the process step by step. But that is just my process, there are more than one way to get results.

I’m determined to get this technique to work - as it’s already well-proven time and again in this thread.

chrome72 - you just reminded me of something, and I’ve had a “D’oh!” moment... before I went away on holiday, I noticed one edge of my decal wasn’t quite attached to the dial. So, I dampened it down. That’ll be why it’s gone wrinkly this time. I’d just forgotten about doing it! My memory is so lousy... thanks for prompting it!

Sent from my iPad using Tapatalk

nobby, fair enough, you can yield great results with film decals. At first I used this method and it looked really good with an enamel clear coat on top, then sanded and polished. What happened a few times though, was that the edges of the dial would flake off, on one even further than just the edge. That bummed me out so much, after nailing a perfect lume job, and having had a great build... I have even found a way to provide for silver depth.

itgoes211

Active Member

- 10/4/19

- 373

- 188

- 43

I wonder if Bart Cordell or Briteling could advise... Every dial decal I've applied to my dial blank so far has wrinkled up - some of them days after being applied. My last attempt had been in place for about 4-5 days and looked okay, so I thought "hooray!" But then I went on holiday for a fortnight and when I got back the decal had winkled again and the brass had tarnished underneath.

Would it be possible for one of you gurus to set out the basic procedure of the water slide process clearly in a single post? I'll happily go back and read all 59 pages again, because I really want to get this to work! But a summary of each step would be really appreciated. And also advice on what brand of decals you're using.

I’ve solved the wrinkling problem with my slide decals. I’m happy to chat if you want to pm me. Here are the basics though:

1) After printing it, let the printout dry for a day if possible. Really, it made a difference for me. It also keeps the ink from running.

2) After printout is completely dry, spray a thin layer of waterproof krylon.

3) When that is dry, spray another thicker layer of waterproof Krylon. Let that dry as well - even if it’s the quick dry type. (waiting is the hardest part).

4) Then again more layers of Kylon - spray and walk away - let it dry.

**** Ive tried different types in different multiple and alternating layers. I’ve had most success against wrinkling by using a layer or two of the Krylon triple-thick version in between layers of the waterproof Krylon. ****

5) Repeat - spray and walk away.

Note: The keys appear to be 1) waterproof spray first AND last (for waterproofing of course), 2) the triple-thick spray which provides some rigidity to the decal I guess, and 3) ensuring complete dryness of layers before adding the next one. The whole thing is a total time-suck, and waiting for the drying is super hard. But that’s what I found out so far.

Hope this helps.

itgoes211

Active Member

- 10/4/19

- 373

- 188

- 43

Briteling The next experiment for me is to try Briteling’s film free method to try for some 3D relief with some film free paper that arrived. I don’t have a laser printer, so I’m thinking of trying it with my regular printer first - I’m mentally prepare for failure already. If it doesn’t work, I might have to go to Kinkos or a copy store, but finding that time in the day is tough. Thanks to everyone for all their input into this thread !!!

You can't use that paper with ink, the glue will dissolve the ink 100%. Also beware of the fact Sunnyscopa has two types of glue. W2 for porous surfaces, which needs no heat to dry, this is useless for dial printing. Then there is W1, which is as thin as water and has the most peculiar smell. This is barely a glue, but it does help to make the decal adhere to the surface.

I use a heat gun/blower for everything. I blow hot air from about 1 foot away to dry the glue for about two minutes. The let it cool down and peel away the film. Then it is just toner on metal basically, still very vulnerable and unsmooth. Then I apply a lot of heat with the heat gun really close by. I use the second highest setting as the air speed is then low, you don't want the dial to lift off. I use a small slab of steel to install the dial on, got a few little holes drilled in it to let the dial feet rest in. The slab sits on four "feet" so I can place it on amy surface without burning it.

At one point the toner will become fluid and the surface will turn kinda glossy, that's when you stop. If I want flat black, I gently push down a slab of a silicone baking mat on top while still hot and remove that when everything is cooled down...

I use a heat gun/blower for everything. I blow hot air from about 1 foot away to dry the glue for about two minutes. The let it cool down and peel away the film. Then it is just toner on metal basically, still very vulnerable and unsmooth. Then I apply a lot of heat with the heat gun really close by. I use the second highest setting as the air speed is then low, you don't want the dial to lift off. I use a small slab of steel to install the dial on, got a few little holes drilled in it to let the dial feet rest in. The slab sits on four "feet" so I can place it on amy surface without burning it.

At one point the toner will become fluid and the surface will turn kinda glossy, that's when you stop. If I want flat black, I gently push down a slab of a silicone baking mat on top while still hot and remove that when everything is cooled down...

Problem is that you can't print white on decal.

The only way is to put a black printed decal on a white sprayed dial plate nut the writings won't have no 3D effect.

Everything will be "flat" ... like that 6429 dial

I want that dial!!

Thanks itgoes211I’ve solved the wrinkling problem with my slide decals. I’m happy to chat if you want to pm me. Here are the basics though:

1) After printing it, let the printout dry for a day if possible. Really, it made a difference for me. It also keeps the ink from running.

2) After printout is completely dry, spray a thin layer of waterproof krylon.

3) When that is dry, spray another thicker layer of waterproof Krylon. Let that dry as well - even if it’s the quick dry type. (waiting is the hardest part).

4) Then again more layers of Kylon - spray and walk away - let it dry.

Something you don't mention in your checklist is at what point you actually apply the decal to the dial. Is it at the end of this entire process, or at the beginning, or at some point during all those clear coat layer applications?

itgoes211

Active Member

- 10/4/19

- 373

- 188

- 43

n0bby : good point, sorry. I apply decal to the dial after the waterproof & triple thick multi-layer spray “sandwich” is completely dry. (Painful to wait). But it really gives the decal some rigidity when applying wet.

Off-point side note: Depending on what I’m making or the effect going for, I will sometimes apply other sprays or paint or matte after the decal is dry on the dial. I’ve even tried a special mixture of thick coffee, a vinegar-based concoction, bleach-mixes, paints, and more - almost anything I can find just to see what happens and learn.

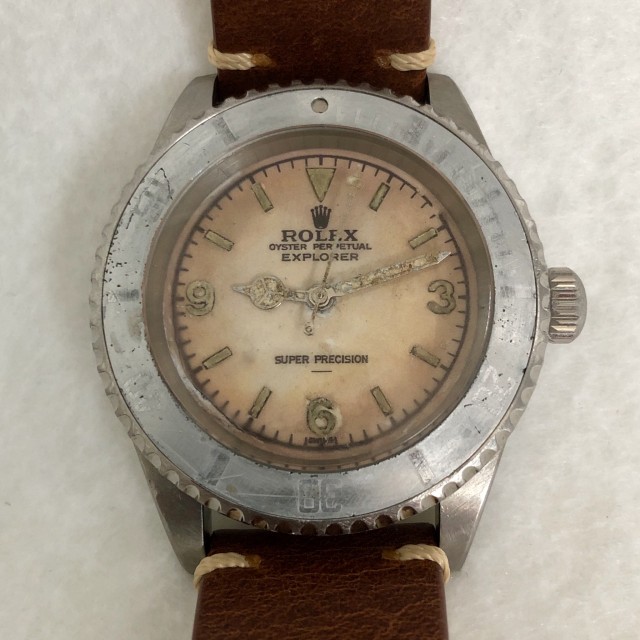

Heres a sample of some hard-core ageing I tried. I was going for a “found on the reef after 20 years under water - and it still works” look. I think it was some combo of dehydrated coffee and soy sauce, bleach, salt, and maybe hydrogen peroxide. Let’s see if I can get the pic to load...

Off-point side note: Depending on what I’m making or the effect going for, I will sometimes apply other sprays or paint or matte after the decal is dry on the dial. I’ve even tried a special mixture of thick coffee, a vinegar-based concoction, bleach-mixes, paints, and more - almost anything I can find just to see what happens and learn.

Heres a sample of some hard-core ageing I tried. I was going for a “found on the reef after 20 years under water - and it still works” look. I think it was some combo of dehydrated coffee and soy sauce, bleach, salt, and maybe hydrogen peroxide. Let’s see if I can get the pic to load...

itgoes211

Active Member

- 10/4/19

- 373

- 188

- 43

See if this works now via Tapatalk.

Sent from my iPad using Tapatalk

And yes it’s the wrong case, hands, bezel, etc.

Sent from my iPad using Tapatalk

See if this works now via Tapatalk.

Sent from my iPad using Tapatalk

did you make that dial? Albino 6610

itgoes211

Active Member

- 10/4/19

- 373

- 188

- 43

itgoes211

Active Member

- 10/4/19

- 373

- 188

- 43

You can't use that paper with ink, the glue will dissolve the ink 100%. Also beware of the fact Sunnyscopa has two types of glue. W2 for porous surfaces, which needs no heat to dry, this is useless for dial printing. Then there is W1, which is as thin as water and has the most peculiar smell. This is barely a glue, but it does help to make the decal adhere to the surface.

I use a heat gun/blower for everything. I blow hot air from about 1 foot away to dry the glue for about two minutes. The let it cool down and peel away the film. Then it is just toner on metal basically, still very vulnerable and unsmooth. Then I apply a lot of heat with the heat gun really close by. I use the second highest setting as the air speed is then low, you don't want the dial to lift off. I use a small slab of steel to install the dial on, got a few little holes drilled in it to let the dial feet rest in. The slab sits on four "feet" so I can place it on amy surface without burning it.

At one point the toner will become fluid and the surface will turn kinda glossy, that's when you stop. If I want flat black, I gently push down a slab of a silicone baking mat on top while still hot and remove that when everything is cooled down...

Britelingn0bby : What laser printer(s) do you recommend?

After tons of research, I bought a Xerox Workstation (LED/Laser) and a Xerox Phaser (Laser) - specifically because they have 2400dpi resolution and are supposed to be great for high-res printing. ... But of course, the first test prints are worse than my old Canon inkjet. After fiddling with every setting I could find, and then 3 hours on the phone with Xerox L2 Tech Support, it turns out that the Xerox software/drivers don’t allow the level of customization to get better prints than my inkjet! It’s hard to believe that high end 2400dpi Xerox printers don’t offer detailed adjustments more than “Standard”, “Photo”, “Presentation” options. Even the Xerox tech support was surprised. So, I’m going to try again more this week to find settings and get better prints. I might returns these and buy a Canon laser printer even if the max dpi is 1200dpi or even 900dpi. I’m dying to try the film free decal method!

But if you have suggestions on a laser printer, I’d love to know them.

Thanks and cheers!

itgoes211 Unfortunately I made the same choice as you and went for the Xerox because of the low price and stated high resolution... But hit a wall thanks to their lousy software, same as you. So my wife now uses that printer as a simple workhorse and I've gone back to using the inkjet....it turns out that the Xerox software/drivers don’t allow the level of customization to get better prints than my inkjet! It’s hard to believe that high end 2400dpi Xerox printers don’t offer detailed adjustments more than “Standard”, “Photo”, “Presentation” options.