Well that’s why we are discussing a full tungsten set hereSadly I do not know if I could go for one of these Tungsten builds, only due to the clasp not being the same weight like gen. It would not be of tungsten, and therefore a weak spot imho.

-

Tired of adverts on RWI? - Subscribe by clicking HERE and PMing Trailboss for instructions and they will magically go away!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Daytona full tungsten case

- Thread starter 2841

- Start date

The scammy reddit seller i follow says they are)

- 31/8/22

- 748

- 624

- 93

Well that’s why we are discussing a full tungsten set hereWhere case, bracelet and clasp is tungsted, giving it a 220 g weight.

Which factory has tungsten clasp?

@iliketosmile has a full tungsten Daytona for sale, perhaps he can offer some insight here on his build for others to follow?

It didnt claim to be full tungsten - it was full tungsten. Given the molar masses of Tungsten and Gold, there is no way to achieve gen gold weight on a specific part without being near 100 percent tungsten (unless of course you add extra links - GMF QF THB ARF are all known to do this). Tungsten molar mass is 183.84 u and our 24k gold is 196.96657 u. Molar mass is the measurement of mass/volumeThis one claimed to be full tungeston....

Perhaps the member who bought it can offer more insight on it as I was not clear on the origins from the original seller[SOLD] - Solid Tungsten YG Daytona 211g - Reserved Sale for @kentfung1210

Reserved sale for my good friend @kentfung1210 over in HK Specs/Cost attached $2890 + shipping bomb proof to HKforum.replica-watch.info

Let me share a bit of background in light of my experience.@iliketosmile has a full tungsten Daytona for sale, perhaps he can offer some insight here on his build for others to follow?

Most precious metal watches in this hobby are steel-plated. Steel is an excellent material—it is easy to cast, machine, and finish (brushing, polishing, anglage, perlage, etc.), and it exhibits strong molecular adhesion for electroplating. However, its primary drawback is weight, which is significantly lower than gold.

Tungsten is an ideal substitute because it closely matches the density of 18k gold (~15.6 g/cm³ vs. 15.8 g/cm³). However, its physical properties make traditional watch manufacturing methods ineffective:

- Tungsten carbide cannot be CNC-machined or cast like steel. Instead, it must be sintered—where powdered tungsten is subjected to high heat and isostatic pressure to form a solid.

- Finishing limitations. Due to its extreme hardness (~9 on the Mohs scale), tungsten carbide is difficult to brush and polish using conventional methods. Diamond polishing compounds and high-RPM lapping processes are required.

- Structural weaknesses. Variations in sintering lead to porosity and grain boundary defects, making the material brittle and prone to chipping.

- Electroplating challenges. Tungsten has poor cathodic activity, leading to weak adhesion of plated layers, which can flake or darken over time.

1. Tungsten "Stuffed" (GMF/QF Day Dates, QF Daytona, THB/ARF Day Date Bracelet)

The most rudimentary and cost-effective approach. Tungsten blocks are inserted into steel cores and welded shut.

- GMF/QF Day Dates use tungsten weights in bracelet center links and a tungsten ring inside the movement (hence why they cannot fit 3255 clones).

- This approach is imprecise—weight distribution is inconsistent, and the tungsten components are not machined to high tolerances.

- Misalignment of the center links due to poor press-fit tolerances results in crooked bracelets, a common flaw in GMF/QF Day Dates.

This method involves wrapping solid tungsten in a thin leaf (~0.1mm) of steel.

- Achieves near-gen weight but introduces structural weaknesses.

- The outer steel layer is prone to de-lamination and intergranular corrosion, particularly in high-stress areas like the lug horns.

- Over time, microscopic cracks develop at the foil interface due to galvanic corrosion between the tungsten core and the steel shell.

This approach encapsulates tungsten within a precision-milled 316L steel shell (~1mm thick).

- Theoretically ideal but execution has been poor due to cost constraints and difficulty maintaining <10µm machining tolerances.

- Edge bonding failures occur due to differences in thermal expansion coefficients between tungsten carbide and 316L steel (~4.3 µm/m·K vs. ~16 µm/m·K), leading to eventual delamination under temperature fluctuations.

This is, in my opinion, the only correct and long-term viable method. Instead of relying on structural encasement, tungsten cases and links are fully sintered, finished, and directly electroplated.

Electroplating tungsten is significantly more complex than plating steel or brass due to its low cathodic efficiency and high surface energy. Traditional electroplating techniques fail due to poor adhesion and rapid oxidation. However, speaking from personal experiences, advances in electrochemical deposition have made significant improvements:

1. Surface Preparation & Pretreatment:

- Tungsten is first subjected to a plasma etching process or electropolishing in a phosphoric acid bath to remove surface oxides.

- An activation layer (typically a nickel-cobalt diffusion barrier) is applied via a strike bath to enhance adhesion.

- The plating bath typically consists of a cyanide-free gold or rhodium solution with an added complexing agent such as EDTA or citrate to enhance deposition uniformity.

- Pulse electrodeposition is used to improve layer integrity, alternating between high and low current densities to mitigate porosity.

- To prevent intermetallic diffusion (which leads to darkening or peeling over time), manufacturers have started incorporating intermediate layers such as palladium-nickel or platinum-group metal alloys.

- This prevents the formation of tungsten oxides that degrade adhesion over time.

Previous Problems (First-Gen Tungsten Electroplating - JBL Daytonas, etc.):

- Rough finishing, as tungsten carbide required diamond-based lapping compounds to achieve a mirror polish.

- Plating adhesion failures due to incorrect electrolyte pH balance and lack of a proper diffusion barrier.

- Galvanic wear in high-friction areas (bracelets, lugs), where the plating would thin out, exposing the darker tungsten beneath.

Adoption of nano-particle-assisted electroplating to improve uniformity and reduce surface defects.

- Use of double-layer electroplating with a sacrificial nickel-palladium sub-layer to improve long-term adhesion.

- Better control of pulse current plating parameters to create a denser, more wear-resistant plated layer.

The new CBD Daytonas look promising in photos, and I have some on order with friends. However, long-term durability remains unknown. Without confirmation of their production method, it’s hard to determine if they are employing direct tungsten electroplating or using an inferior alternative.

In my experience, the only truly lasting and viable approach is direct electroplated tungsten with multi-layer adhesion barriers. If the CBD Daytonas have implemented the latest advancements, they may represent the best tungsten-based alternatives to gold watches to date.

CBD is likely using a steel rehaut attached to a tungsten mid case (THB and ARF do the same). Although, I have seen rehauts coming off and separating completely in some cases. Visually this is great. Hoping the rest of it checks out with longevity and finishing.

It didnt claim to be full tungsten - it was full tungsten.

I was not trying to accuse you of anything. Since you haven't disclosed the source of the case and bracelet, I cannot say anything definitively beyond the weight is closer to genuine then anything else I've seen which is why I worded it that way, no offense meant. I'm sure there at least a few guys in this thread that would be interested in obtaining the tungsten case set and or tungsten bracelet . Any light you can shine on the source would be appreciated.

- 31/8/22

- 748

- 624

- 93

The early tungsten jbl watches weighed as much as gen but this one was taken by customs. It has the usual bad rehaut and didn’t have the rg model protruding end links.I was not trying to accuse you of anything. Since you haven't disclosed the source of the case and bracelet, I cannot say anything definitively beyond the weight is closer to genuine then anything else I've seen which is why I worded it that way, no offense meant. I'm sure there at least a few guys in this thread that would be interested in obtaining the tungsten case set and or tungsten bracelet . Any light you can shine on the source would be appreciated.

- 25/3/21

- 920

- 726

- 93

Will these be in a 116XXX shape case?Apparently the 2.0 has a tungsten clasp which should be finished sometime after cny

Thanks bud, this is extremely helpful. Not much useful information floating around atm.It didnt claim to be full tungsten - it was full tungsten. Given the molar masses of Tungsten and Gold, there is no way to achieve gen gold weight on a specific part without being near 100 percent tungsten (unless of course you add extra links - GMF QF THB ARF are all known to do this). Tungsten molar mass is 183.84 u and our 24k gold is 196.96657 u. Molar mass is the measurement of mass/volume

Let me share a bit of background in light of my experience.

Most precious metal watches in this hobby are steel-plated. Steel is an excellent material—it is easy to cast, machine, and finish (brushing, polishing, anglage, perlage, etc.), and it exhibits strong molecular adhesion for electroplating. However, its primary drawback is weight, which is significantly lower than gold.

Tungsten is an ideal substitute because it closely matches the density of 18k gold (~15.6 g/cm³ vs. 15.8 g/cm³). However, its physical properties make traditional watch manufacturing methods ineffective:

To address these challenges, manufacturers have experimented with different methods:

- Tungsten carbide cannot be CNC-machined or cast like steel. Instead, it must be sintered—where powdered tungsten is subjected to high heat and isostatic pressure to form a solid.

- Finishing limitations. Due to its extreme hardness (~9 on the Mohs scale), tungsten carbide is difficult to brush and polish using conventional methods. Diamond polishing compounds and high-RPM lapping processes are required.

- Structural weaknesses. Variations in sintering lead to porosity and grain boundary defects, making the material brittle and prone to chipping.

- Electroplating challenges. Tungsten has poor cathodic activity, leading to weak adhesion of plated layers, which can flake or darken over time.

1. Tungsten "Stuffed" (GMF/QF Day Dates, QF Daytona, THB/ARF Day Date Bracelet)

The most rudimentary and cost-effective approach. Tungsten blocks are inserted into steel cores and welded shut.

2. Solid Tungsten Wrapped in Thin Steel Foil (THB/ARF Day Date Head, APSF Daytona Head)

- GMF/QF Day Dates use tungsten weights in bracelet center links and a tungsten ring inside the movement (hence why they cannot fit 3255 clones).

- This approach is imprecise—weight distribution is inconsistent, and the tungsten components are not machined to high tolerances.

- Misalignment of the center links due to poor press-fit tolerances results in crooked bracelets, a common flaw in GMF/QF Day Dates.

This method involves wrapping solid tungsten in a thin leaf (~0.1mm) of steel.

3. Solid Tungsten with Steel Capping (David Chen & Xing Iterations)

- Achieves near-gen weight but introduces structural weaknesses.

- The outer steel layer is prone to de-lamination and intergranular corrosion, particularly in high-stress areas like the lug horns.

- Over time, microscopic cracks develop at the foil interface due to galvanic corrosion between the tungsten core and the steel shell.

This approach encapsulates tungsten within a precision-milled 316L steel shell (~1mm thick).

4. Direct Tungsten Electroplating (The Most Viable but Technically Challenging Approach)

- Theoretically ideal but execution has been poor due to cost constraints and difficulty maintaining <10µm machining tolerances.

- Edge bonding failures occur due to differences in thermal expansion coefficients between tungsten carbide and 316L steel (~4.3 µm/m·K vs. ~16 µm/m·K), leading to eventual delamination under temperature fluctuations.

This is, in my opinion, the only correct and long-term viable method. Instead of relying on structural encasement, tungsten cases and links are fully sintered, finished, and directly electroplated.

Electroplating tungsten is significantly more complex than plating steel or brass due to its low cathodic efficiency and high surface energy. Traditional electroplating techniques fail due to poor adhesion and rapid oxidation. However, speaking from personal experiences, advances in electrochemical deposition have made significant improvements:

1. Surface Preparation & Pretreatment:

2. Electroplating Bath Composition:

- Tungsten is first subjected to a plasma etching process or electropolishing in a phosphoric acid bath to remove surface oxides.

- An activation layer (typically a nickel-cobalt diffusion barrier) is applied via a strike bath to enhance adhesion.

3. Layer Bonding & Diffusion Barriers:

- The plating bath typically consists of a cyanide-free gold or rhodium solution with an added complexing agent such as EDTA or citrate to enhance deposition uniformity.

- Pulse electrodeposition is used to improve layer integrity, alternating between high and low current densities to mitigate porosity.

Early Issues & Recent Improvements

- To prevent intermetallic diffusion (which leads to darkening or peeling over time), manufacturers have started incorporating intermediate layers such as palladium-nickel or platinum-group metal alloys.

- This prevents the formation of tungsten oxides that degrade adhesion over time.

Previous Problems (First-Gen Tungsten Electroplating - JBL Daytonas, etc.):

Recent Solutions (Latest Gen Tungsten Daytonas):

- Rough finishing, as tungsten carbide required diamond-based lapping compounds to achieve a mirror polish.

- Plating adhesion failures due to incorrect electrolyte pH balance and lack of a proper diffusion barrier.

- Galvanic wear in high-friction areas (bracelets, lugs), where the plating would thin out, exposing the darker tungsten beneath.

Adoption of nano-particle-assisted electroplating to improve uniformity and reduce surface defects.

The New CBD Daytonas:

- Use of double-layer electroplating with a sacrificial nickel-palladium sub-layer to improve long-term adhesion.

- Better control of pulse current plating parameters to create a denser, more wear-resistant plated layer.

The new CBD Daytonas look promising in photos, and I have some on order with friends. However, long-term durability remains unknown. Without confirmation of their production method, it’s hard to determine if they are employing direct tungsten electroplating or using an inferior alternative.

In my experience, the only truly lasting and viable approach is direct electroplated tungsten with multi-layer adhesion barriers. If the CBD Daytonas have implemented the latest advancements, they may represent the best tungsten-based alternatives to gold watches to date.

Im very much looking forward to your take on the CBD once you have it it hand. Looks like the best solution atm

Stuvetjee

For all your RM Watch/Straps & 18K Jewelry needs!

Vendor (Strap Maker)

Moderator Sales

Section Moderator

Certified

can you please make a seperate thread for this? its such good info that need to be stickied!! we can follow your CBD journey in there aswell!It didnt claim to be full tungsten - it was full tungsten. Given the molar masses of Tungsten and Gold, there is no way to achieve gen gold weight on a specific part without being near 100 percent tungsten (unless of course you add extra links - GMF QF THB ARF are all known to do this). Tungsten molar mass is 183.84 u and our 24k gold is 196.96657 u. Molar mass is the measurement of mass/volume

Let me share a bit of background in light of my experience.

Most precious metal watches in this hobby are steel-plated. Steel is an excellent material—it is easy to cast, machine, and finish (brushing, polishing, anglage, perlage, etc.), and it exhibits strong molecular adhesion for electroplating. However, its primary drawback is weight, which is significantly lower than gold.

Tungsten is an ideal substitute because it closely matches the density of 18k gold (~15.6 g/cm³ vs. 15.8 g/cm³). However, its physical properties make traditional watch manufacturing methods ineffective:

To address these challenges, manufacturers have experimented with different methods:

- Tungsten carbide cannot be CNC-machined or cast like steel. Instead, it must be sintered—where powdered tungsten is subjected to high heat and isostatic pressure to form a solid.

- Finishing limitations. Due to its extreme hardness (~9 on the Mohs scale), tungsten carbide is difficult to brush and polish using conventional methods. Diamond polishing compounds and high-RPM lapping processes are required.

- Structural weaknesses. Variations in sintering lead to porosity and grain boundary defects, making the material brittle and prone to chipping.

- Electroplating challenges. Tungsten has poor cathodic activity, leading to weak adhesion of plated layers, which can flake or darken over time.

1. Tungsten "Stuffed" (GMF/QF Day Dates, QF Daytona, THB/ARF Day Date Bracelet)

The most rudimentary and cost-effective approach. Tungsten blocks are inserted into steel cores and welded shut.

2. Solid Tungsten Wrapped in Thin Steel Foil (THB/ARF Day Date Head, APSF Daytona Head)

- GMF/QF Day Dates use tungsten weights in bracelet center links and a tungsten ring inside the movement (hence why they cannot fit 3255 clones).

- This approach is imprecise—weight distribution is inconsistent, and the tungsten components are not machined to high tolerances.

- Misalignment of the center links due to poor press-fit tolerances results in crooked bracelets, a common flaw in GMF/QF Day Dates.

This method involves wrapping solid tungsten in a thin leaf (~0.1mm) of steel.

3. Solid Tungsten with Steel Capping (David Chen & Xing Iterations)

- Achieves near-gen weight but introduces structural weaknesses.

- The outer steel layer is prone to de-lamination and intergranular corrosion, particularly in high-stress areas like the lug horns.

- Over time, microscopic cracks develop at the foil interface due to galvanic corrosion between the tungsten core and the steel shell.

This approach encapsulates tungsten within a precision-milled 316L steel shell (~1mm thick).

4. Direct Tungsten Electroplating (The Most Viable but Technically Challenging Approach)

- Theoretically ideal but execution has been poor due to cost constraints and difficulty maintaining <10µm machining tolerances.

- Edge bonding failures occur due to differences in thermal expansion coefficients between tungsten carbide and 316L steel (~4.3 µm/m·K vs. ~16 µm/m·K), leading to eventual delamination under temperature fluctuations.

This is, in my opinion, the only correct and long-term viable method. Instead of relying on structural encasement, tungsten cases and links are fully sintered, finished, and directly electroplated.

Electroplating tungsten is significantly more complex than plating steel or brass due to its low cathodic efficiency and high surface energy. Traditional electroplating techniques fail due to poor adhesion and rapid oxidation. However, speaking from personal experiences, advances in electrochemical deposition have made significant improvements:

1. Surface Preparation & Pretreatment:

2. Electroplating Bath Composition:

- Tungsten is first subjected to a plasma etching process or electropolishing in a phosphoric acid bath to remove surface oxides.

- An activation layer (typically a nickel-cobalt diffusion barrier) is applied via a strike bath to enhance adhesion.

3. Layer Bonding & Diffusion Barriers:

- The plating bath typically consists of a cyanide-free gold or rhodium solution with an added complexing agent such as EDTA or citrate to enhance deposition uniformity.

- Pulse electrodeposition is used to improve layer integrity, alternating between high and low current densities to mitigate porosity.

Early Issues & Recent Improvements

- To prevent intermetallic diffusion (which leads to darkening or peeling over time), manufacturers have started incorporating intermediate layers such as palladium-nickel or platinum-group metal alloys.

- This prevents the formation of tungsten oxides that degrade adhesion over time.

Previous Problems (First-Gen Tungsten Electroplating - JBL Daytonas, etc.):

Recent Solutions (Latest Gen Tungsten Daytonas):

- Rough finishing, as tungsten carbide required diamond-based lapping compounds to achieve a mirror polish.

- Plating adhesion failures due to incorrect electrolyte pH balance and lack of a proper diffusion barrier.

- Galvanic wear in high-friction areas (bracelets, lugs), where the plating would thin out, exposing the darker tungsten beneath.

Adoption of nano-particle-assisted electroplating to improve uniformity and reduce surface defects.

The New CBD Daytonas:

- Use of double-layer electroplating with a sacrificial nickel-palladium sub-layer to improve long-term adhesion.

- Better control of pulse current plating parameters to create a denser, more wear-resistant plated layer.

The new CBD Daytonas look promising in photos, and I have some on order with friends. However, long-term durability remains unknown. Without confirmation of their production method, it’s hard to determine if they are employing direct tungsten electroplating or using an inferior alternative.

In my experience, the only truly lasting and viable approach is direct electroplated tungsten with multi-layer adhesion barriers. If the CBD Daytonas have implemented the latest advancements, they may represent the best tungsten-based alternatives to gold watches to date.

Exactly true. I’ve still got one of these. It’s held up well. The longevity issues were hit and miss. Like a lot of the early tungsten sets, you were at the mercy of the luck of the draw. Seems like if you got a good one, you were okay.

All that aside - each variant was wrong in some way. Mismatched end links and mis matched case shapes. I don’t think they nailed a single bracelet Daytona variant.

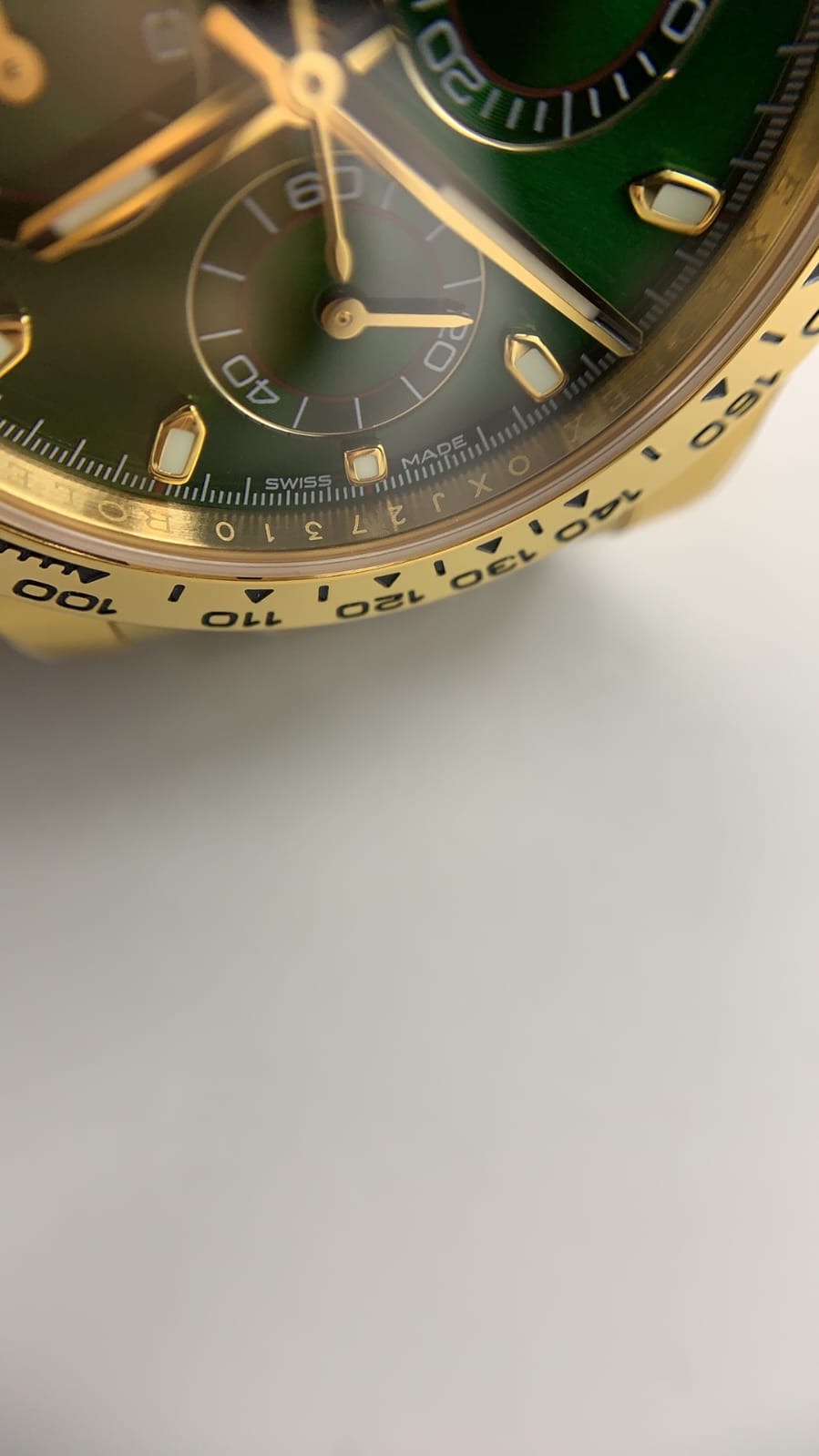

Pictured: my JBL rose -

Thank you for the high praise! I’ve got a plethora of pictures and process related tidbits. I should really sit down and make a dedicated post.can you please make a seperate thread for this? its such good info that need to be stickied!! we can follow your CBD journey in there aswell!

- 31/8/22

- 748

- 624

- 93