Keep in mind you want to go deep enough to seat the tube deep enough.

If you don’t, the crown will stick out from the case and look off.

I don’t have a set depth, but rather I test the tube frequently until it’s at the depth that allows the crown to seat properly.

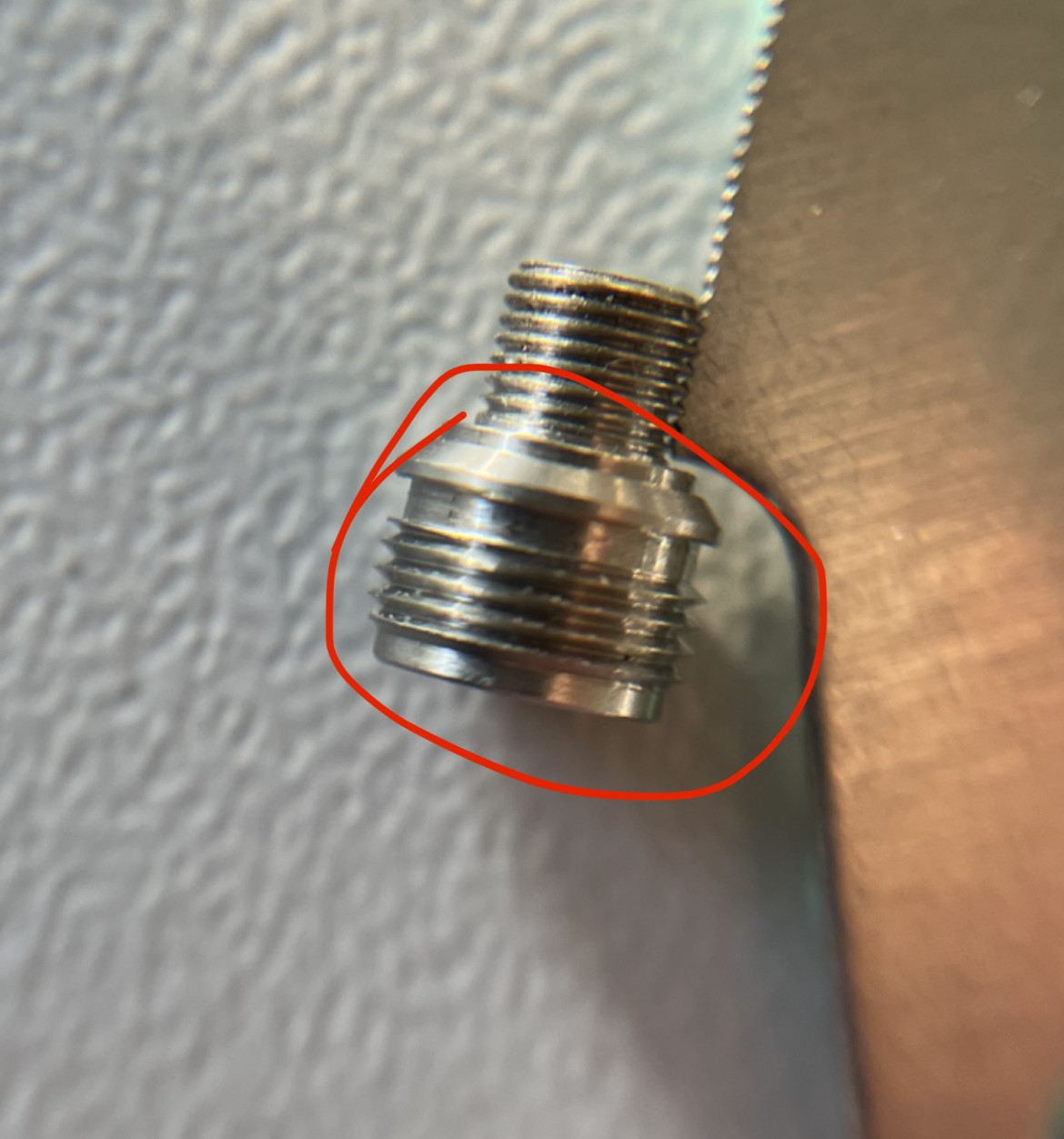

Here’s one I just did. 120 degree 4mm chamfer.

Thank you for the picture. The sealing needs a lot of pressure to be watertight?

Can you also share a picture without the tube to see the opening ?