I will contact him tomorrow and inform you.This provider is german

Rebell | Custom-made tools - taps and dies

www.rebell-tools.de

-

Tired of adverts on RWI? - Subscribe by clicking HERE and PMing Trailboss for instructions and they will magically go away!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Correct tap for 7mm tube

- Thread starter Fraist

- Start date

Ok let me know how it goes

I contacted them today.

by phone they have told me app. 3-4 weeks delivery

price app.

1 piece 120 Euro

3 pieces 80 Euro

6 pieces 60 Euro

They are not able to measure the thread for me. They told me that they can cut M3x0.3 with normal tolerance.

Do you have a tube to measure and sent me the precise measurements?

As you all have found out, nearly every tap offered on the market for these tubes is indeed incorrect. People will say they work, but they don’t.

The tubes get way too tight after a few turns on the wrench.

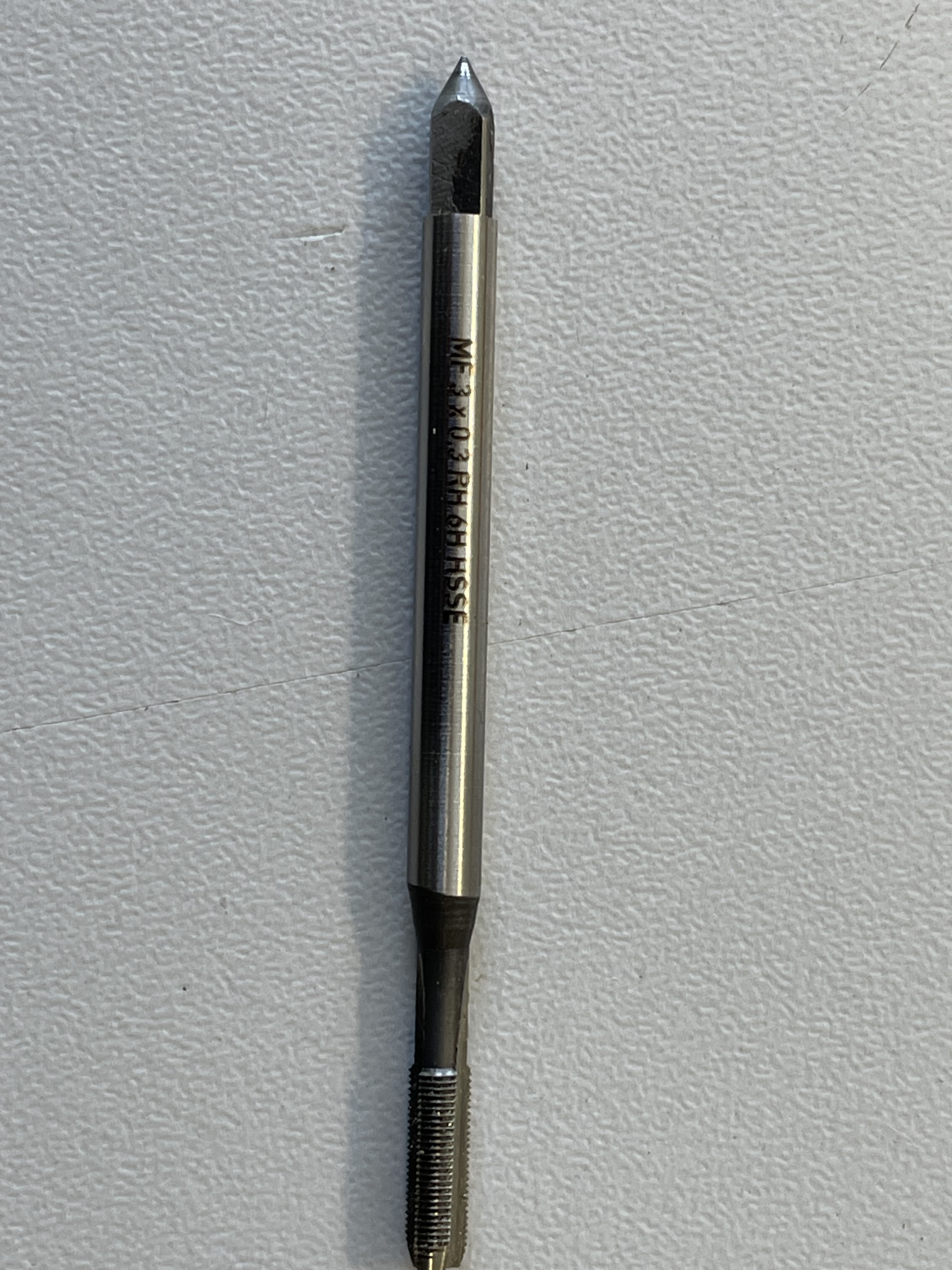

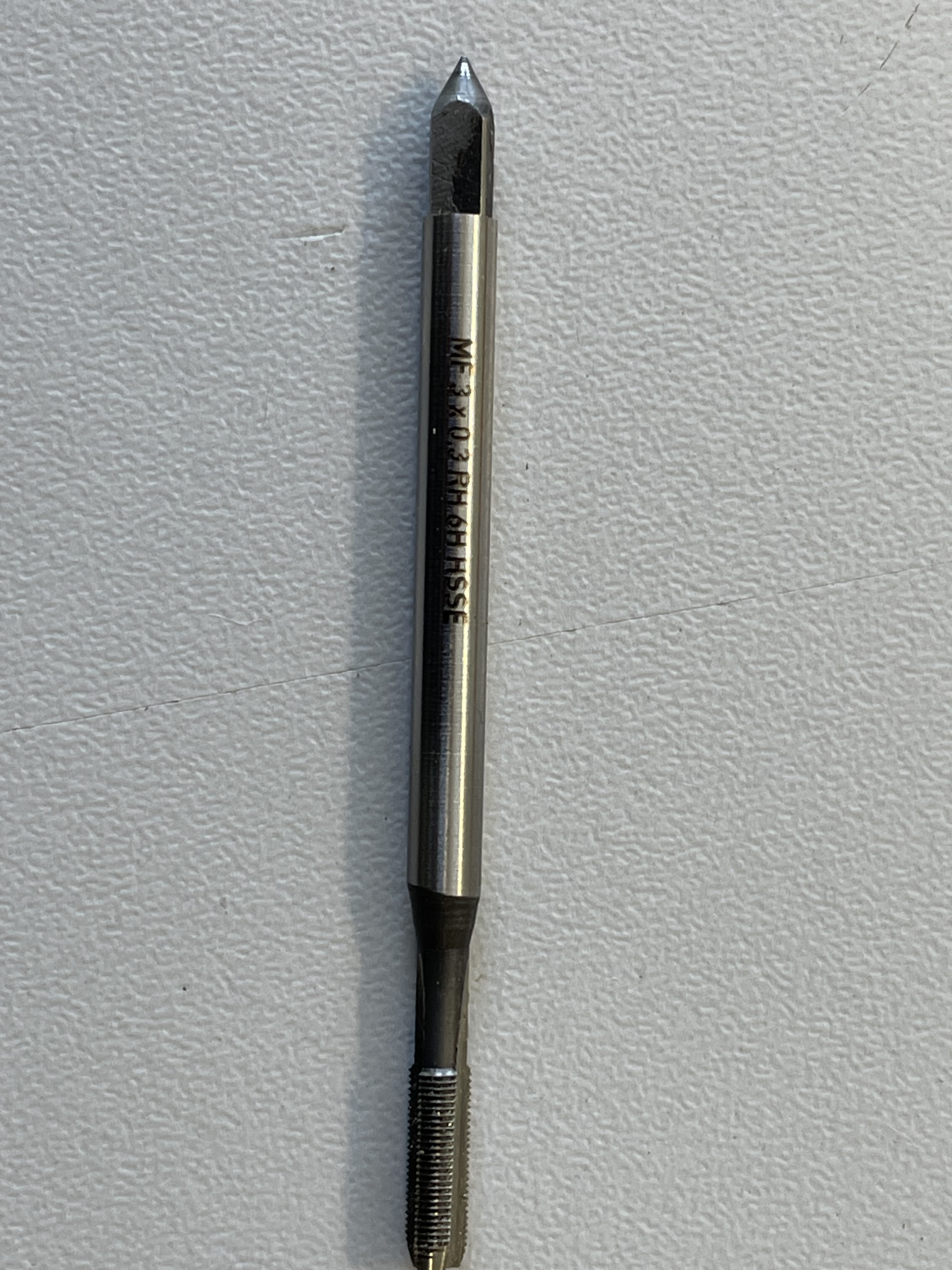

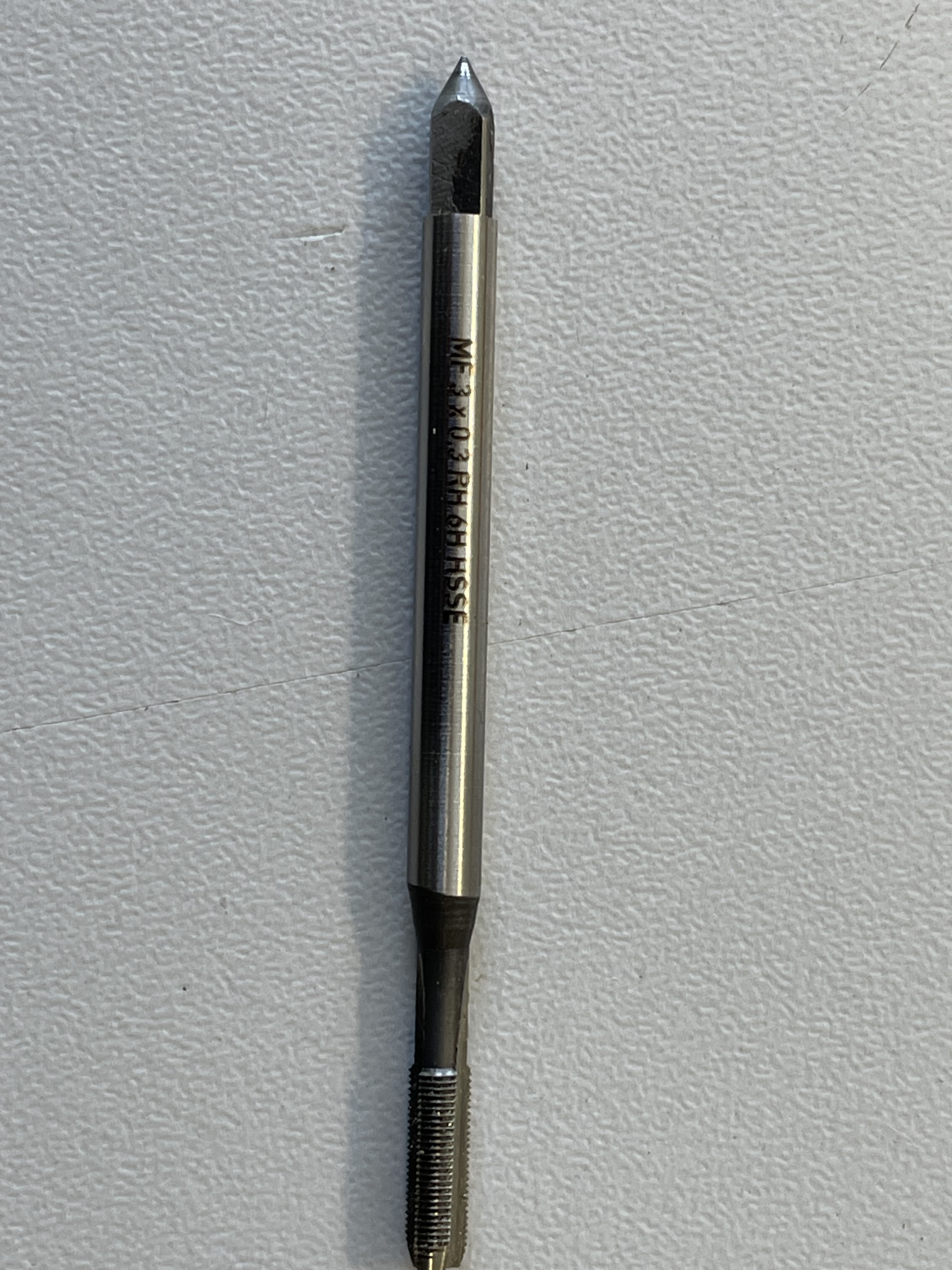

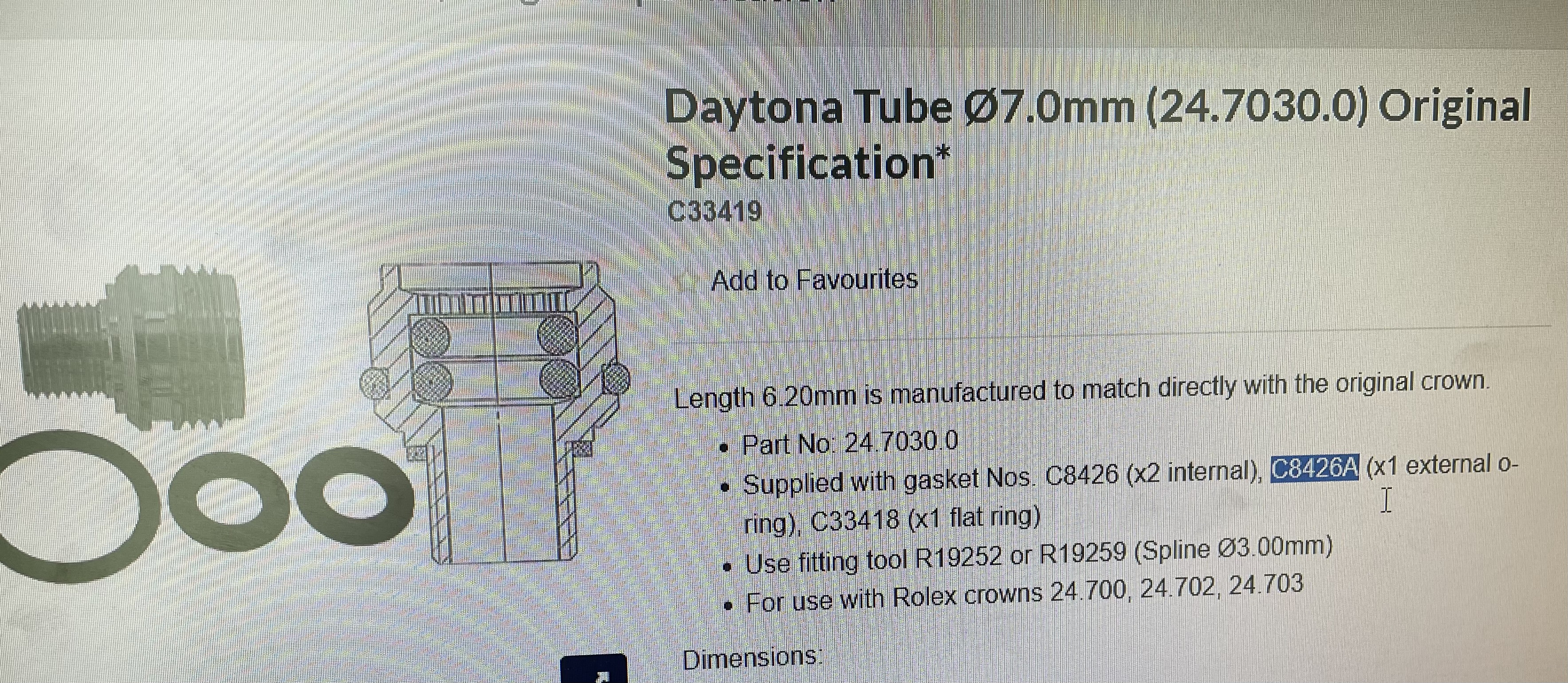

The correct tap size is : M3.05x.30-4H

Daytona pushers on the other had, do have options available on the market. That tap size is M2.5x.25, and can be found on CousinsUK.

I’ve had these made via the same USA manufacture as listed above and they turned out great.

Gen tubes thread in with no issues.

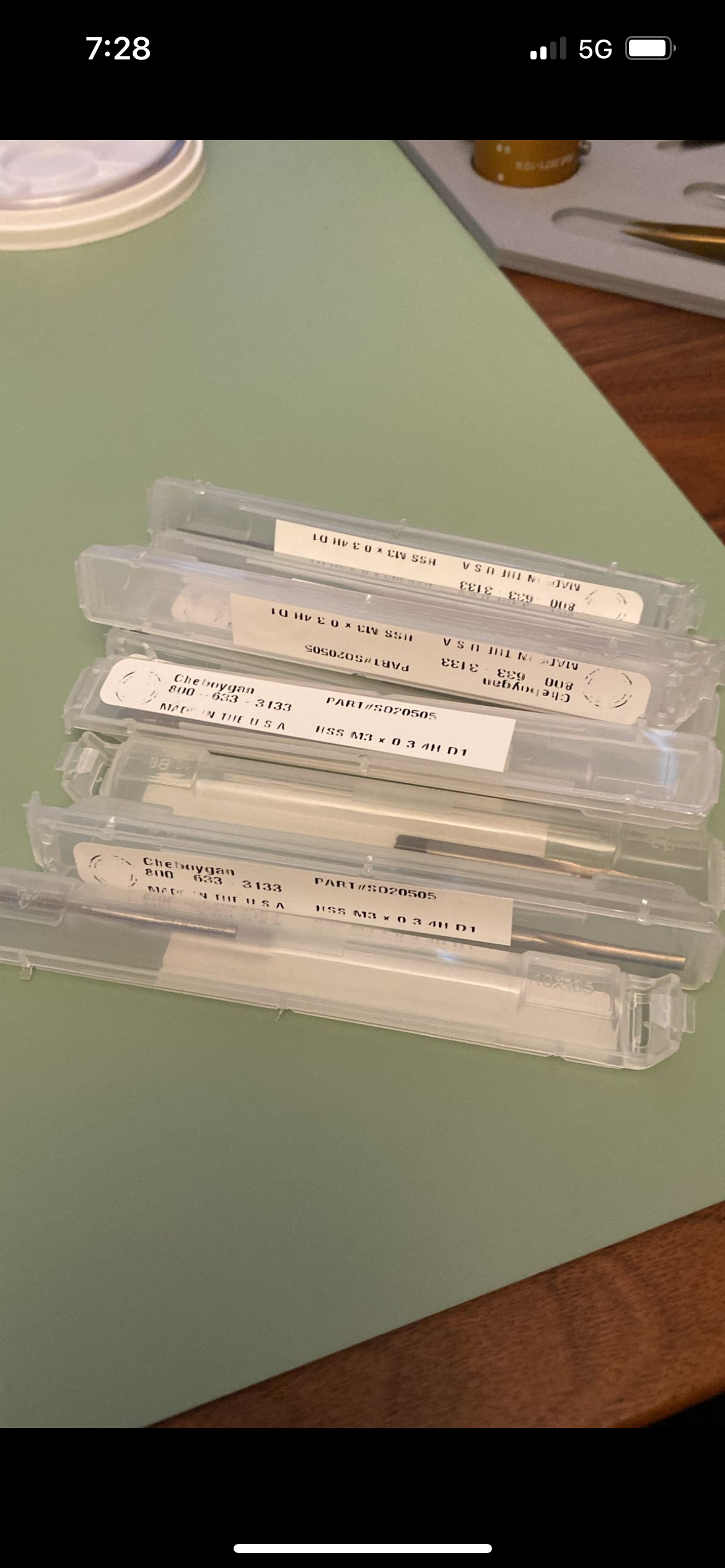

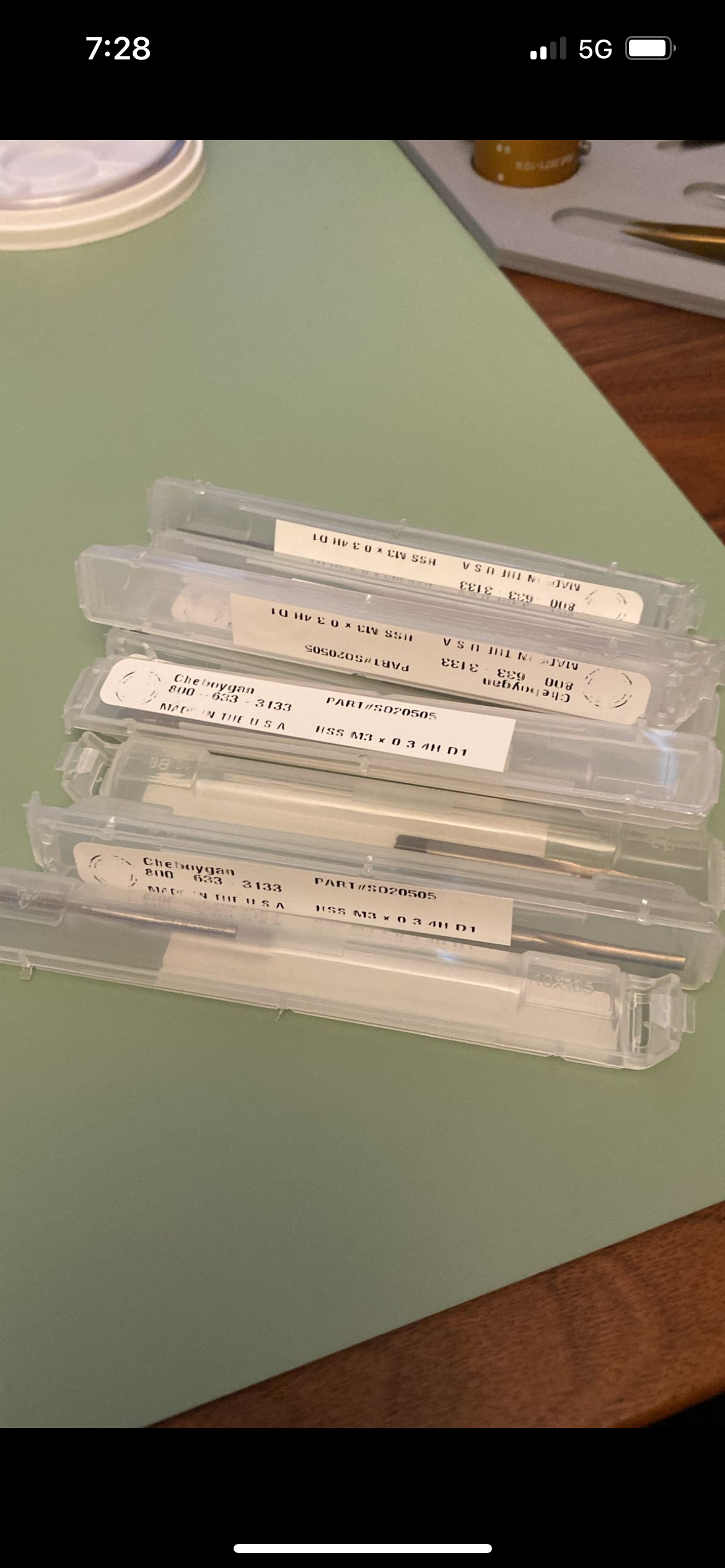

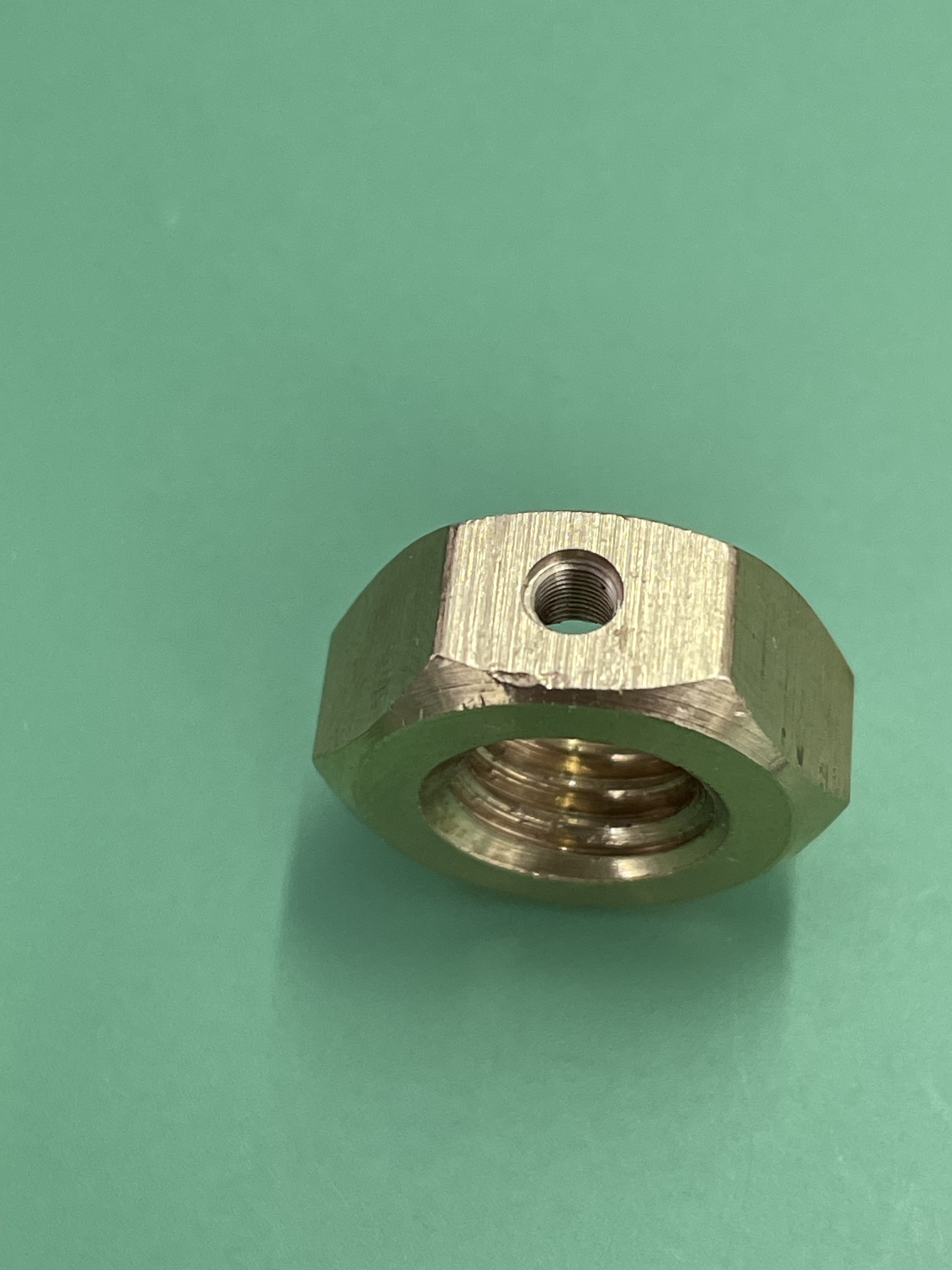

Couple pics

The tubes get way too tight after a few turns on the wrench.

The correct tap size is : M3.05x.30-4H

Daytona pushers on the other had, do have options available on the market. That tap size is M2.5x.25, and can be found on CousinsUK.

I’ve had these made via the same USA manufacture as listed above and they turned out great.

Gen tubes thread in with no issues.

Couple pics

Last edited:

update.

The supplier from Europe had already taps in stock from old order.

I purchase them and i will have them in sort time for test

The supplier from Europe had already taps in stock from old order.

I purchase them and i will have them in sort time for test

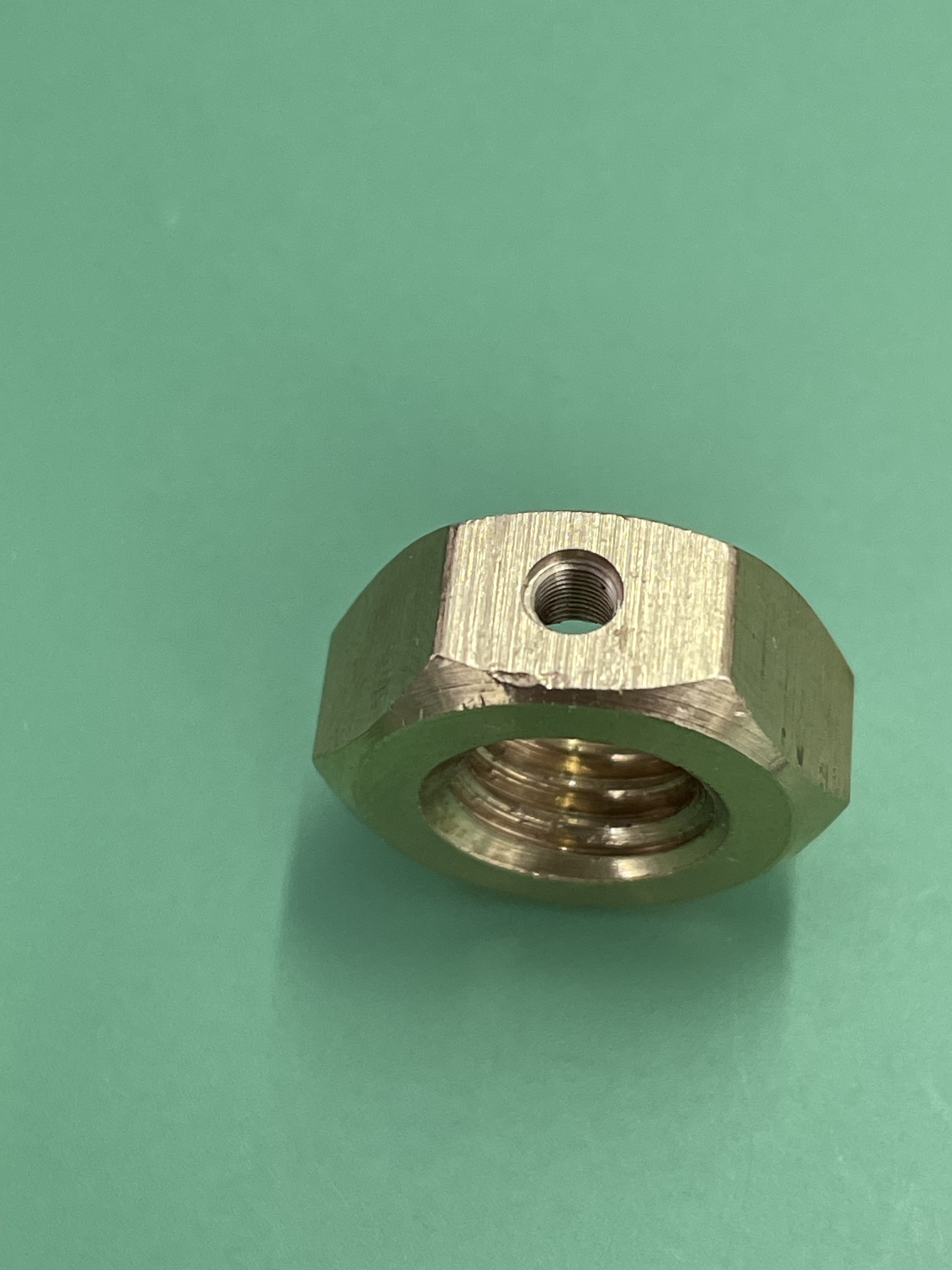

Today received the taps and test immediately in a bronze piece that have for testing.

success !!!

The tube goes in really smoothly and the fitment was excellent!

not too loose not too tight and without play during screwing.

Now I have to find what countersink or counterbore I need for the tube. Does anyone knows ???

success !!!

The tube goes in really smoothly and the fitment was excellent!

not too loose not too tight and without play during screwing.

Now I have to find what countersink or counterbore I need for the tube. Does anyone knows ???

Here is a thread about it check that out and see if it works for you.

forum.replica-watch.info

forum.replica-watch.info

Counterboring a Rolex case tube

Based on some research I’ve found on getting a gen 7030 case tube to fit properly in a rep case (GMF for my situation). It looks like tube hole has to be counterbored (as opposed to some generically suggesting countersunk). What I can’t seem to find is: 1) Proper counterboring bit to do...

I use a 4mm 120 degree chamfer bit. Or maybe it’s 90 degree…I’ll have to confirm.

This allows you to sit the tub a bit deeper so the crown doesn’t stick out.

I do warn people that do this, you could potentially impact water tightness.

This allows you to sit the tub a bit deeper so the crown doesn’t stick out.

I do warn people that do this, you could potentially impact water tightness.

Today received the taps and test immediately in a bronze piece that have for testing.

success !!!

The tube goes in really smoothly and the fitment was excellent!

not too loose not too tight and without play during screwing.

Now I have to find what countersink or counterbore I need for the tube. Does anyone knows ???

mrlemonjello

Known Member

- 22/4/20

- 111

- 26

- 28

I'm in for a tap if a 6+ Stateside order gets made. (First post in a while- I'm real, not hacked. Was spending way too much money on reps, but I'm bored and need projects again.)@Fraist, get in touch with those guys for the custom made taps and let us know how it goes

I think at least 6 taps to get good price so @Radiomir369 wants one, you as the first and me

We have already 3, I bet there will be more that 3 that wants that taps.

If you encounter any problem ordering cuz you are in Germany, let me know I can handle that

Just let me know.

Nice information. I am waiting for the confirmation to buy a chamfer bit.I use a 4mm 120 degree chamfer bit. Or maybe it’s 90 degree…I’ll have to confirm.

This allows you to sit the tub a bit deeper so the crown doesn’t stick out.

I do warn people that do this, you could potentially impact water tightness.

Regarding water tightness. I thought that it will be better with the chamfer, because inside there will pushed the o-ring and provide better sealing.

Nice information. I am waiting for the confirmation to buy a chamfer bit.

Regarding water tightness. I thought that it will be better with the chamfer, because inside there will pushed the o-ring and provide better sealing.

That is true, but the chamfer still will. Or match the profile of the Gen tube. So there is still a risk.

Be careful stainless steel is known for work hardening. You don’t wanna break that little tap in your case. Just saying

From my experiences, it isn’t a drastic difference and there isn’t a ton of resistance. And with the use of cutting fluid it’s all good!

I have experience in SS drilling / tapping but in much bigger threads M6 / M12Be careful stainless steel is known for work hardening. You don’t wanna break that little tap in your case. Just saying

for this tinny hole I will first make test in 316L SS to find the best conditions before tap the case.

- 9/11/23

- 1,148

- 1,174

- 113

Most of my thread cutting is done with a lathe and always use cutting fluid. Taps are unpredictable. I might get away without any problems for dozens of holes. Then from time to time I’ll come across a piece that breaks a tap and ruins something I’ve got a bunch of work in. Sometimes you can get your broken tap out without problems other times it’s a real pain. It’s just something you dive into and just do your best. Buy quality taps and use cutting fluid. It helps to have good equipment. Hand drill with a vise and t handle will work but a drill press with a vise would make life easier and minimize the risk of problems. You guys will be fine. Like I always say, when it’s all said and done they’ll be a whole lot more said than done.I have experience in SS drilling / tapping but in much bigger threads M6 / M12

for this tinny hole I will first make test in 316L SS to find the best conditions before tap the case.

I had a 3.3 counterbore laying around and i gave a test in brass. The result was very good.

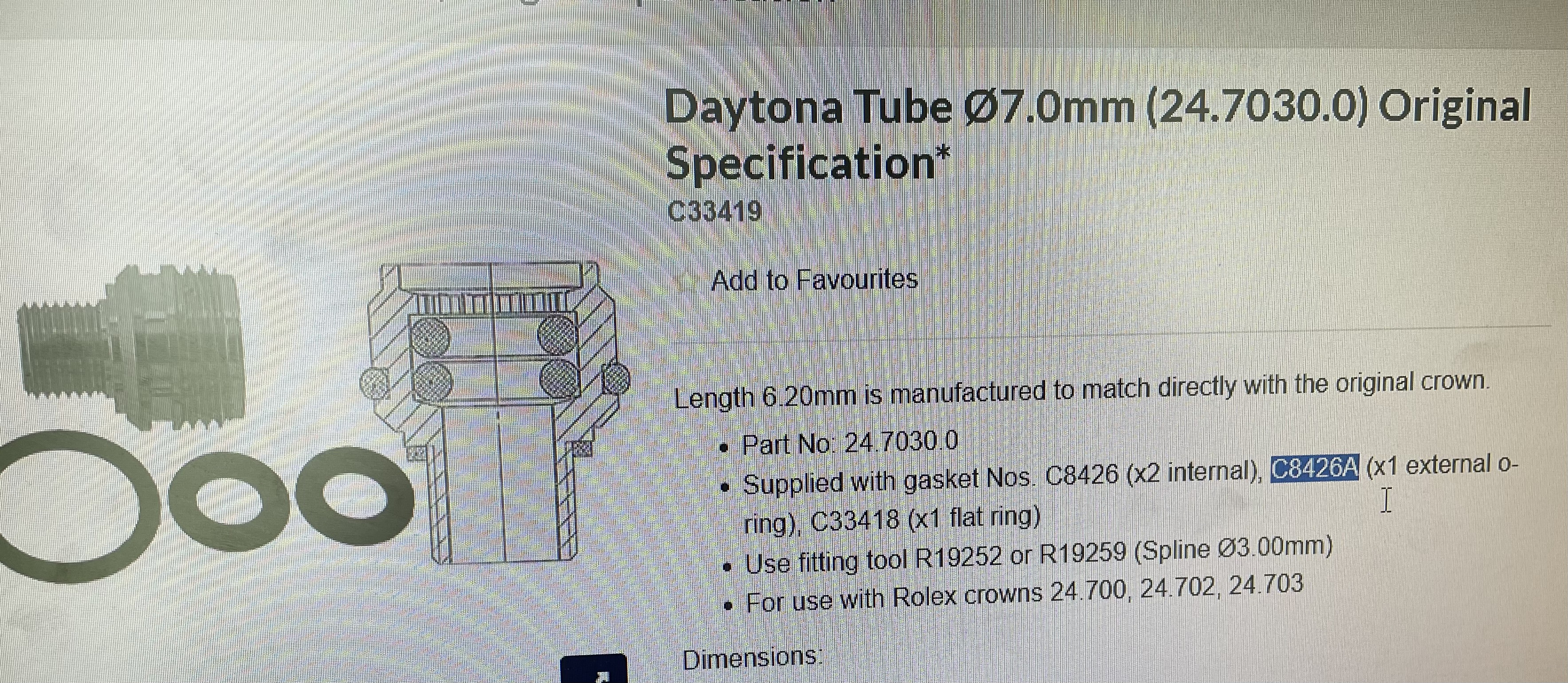

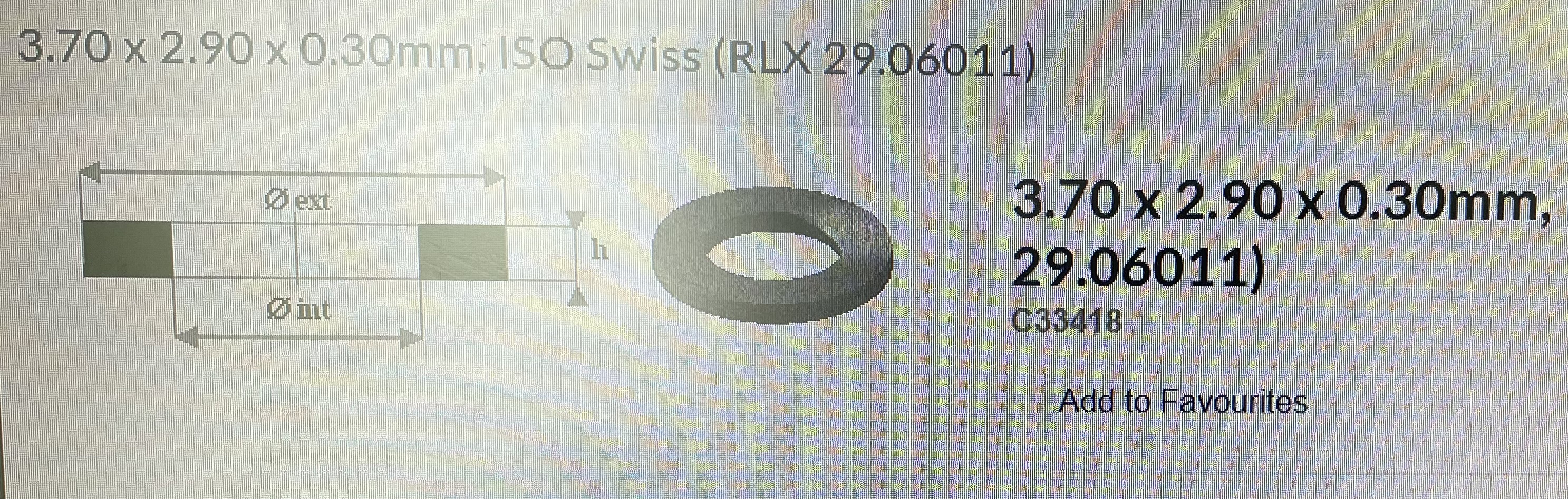

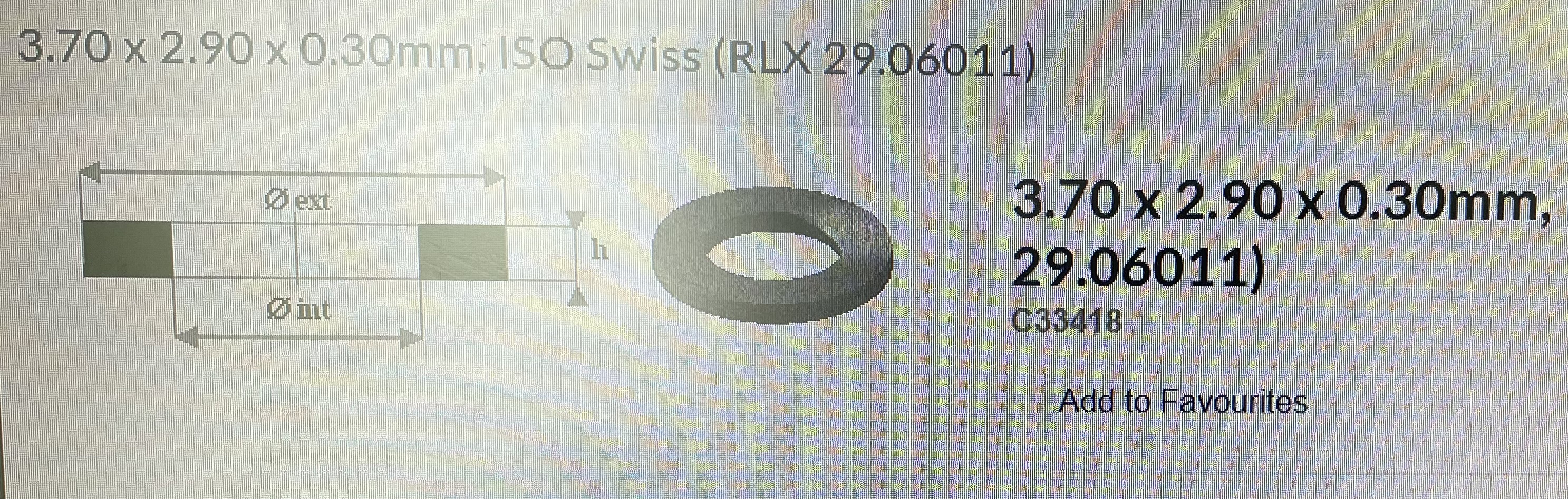

I have checked cousins and the gasket at the bottom has external diameter 3.7 mm so I believe 4 mm opening like @PsychoTee16 mentioned will be ok to pass threw the hole and the metal ring of the crown and stress the o-ring.

Other option is to go much tighter e.g 3.8 for better sealing .

.

Depth I believe 0.4 will be fine. 0.3 is the o-ring and i believe 0.1 more to enter a little the tube and stress the o-ring.

If someone have precise measurements from original case to share will be great !!!

I have checked cousins and the gasket at the bottom has external diameter 3.7 mm so I believe 4 mm opening like @PsychoTee16 mentioned will be ok to pass threw the hole and the metal ring of the crown and stress the o-ring.

Other option is to go much tighter e.g 3.8 for better sealing

Depth I believe 0.4 will be fine. 0.3 is the o-ring and i believe 0.1 more to enter a little the tube and stress the o-ring.

If someone have precise measurements from original case to share will be great !!!

Keep in mind you want to go deep enough to seat the tube deep enough.

If you don’t, the crown will stick out from the case and look off.

I don’t have a set depth, but rather I test the tube frequently until it’s at the depth that allows the crown to seat properly.

Here’s one I just did. 120 degree 4mm chamfer.

If you don’t, the crown will stick out from the case and look off.

I don’t have a set depth, but rather I test the tube frequently until it’s at the depth that allows the crown to seat properly.

Here’s one I just did. 120 degree 4mm chamfer.

Last edited: