A solution I have used for the too thick gen crystal gaskets is to thin the outer perimeter of the gasket. Just put the gasket on a junk crystal, hold it on edge and swipe/roll it in measured even strokes across a flat piece of 400 grit sandpaper on a bench. This is the same technique I use for shaving aluminum inserts when they are too big in diameter. There is plenty of material on the gen gasket to be able to remove 0.1mm or so (0.05mm all around) and not impact WR. Similarly, any gasket height can be achieved by shaving the bottom edge while gently pressing the crystal and gasket flat onto the sandpaper. 400 grit can leave a gasket surface slightly rough, but this is an unseen cosmetic issue. The seal that matters is the inner gasket perimeter against the outside of the rehaut. Finer grade paper can be used for a smoother finish if desired - 600 or 800. Black sandpaper should not be used as it can stain a gasket.

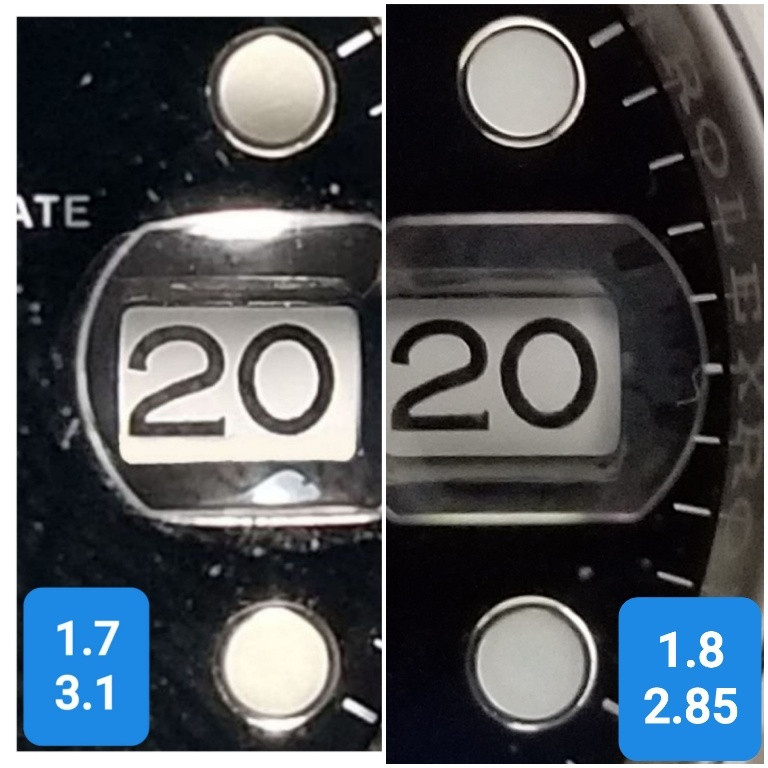

I've done this multiple times successfully without compromising WP. I prioritize correct date mag, then try to get as close to proper sitting height as possible. Often you can get very close to achieving both goals.

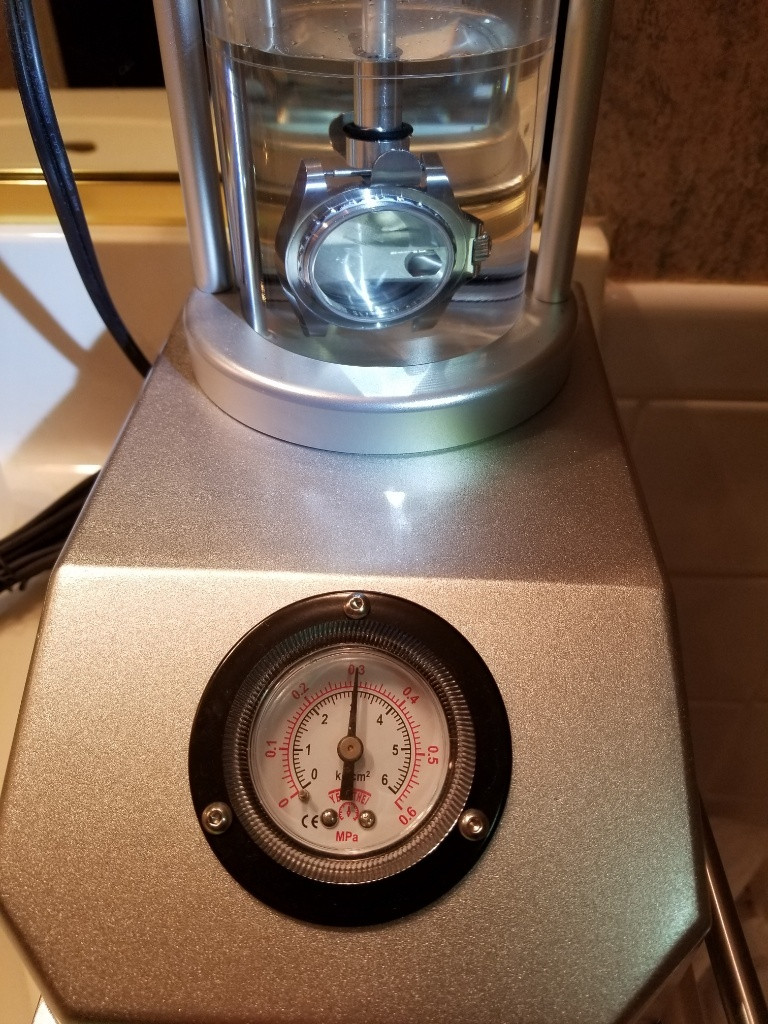

I can’t tell enough how I appreciate your extreme knowledge of the rep world, but sadly this is not a viable solution for us (us intended as our lab) because it’s extremely time consuming

Same reason why we stopped doing case reworking, thinning and stuff like that. Takes too much time away from actual services and we currently can’t afford that..