-

Tired of adverts on RWI? - Subscribe by clicking HERE and PMing Trailboss for instructions and they will magically go away!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

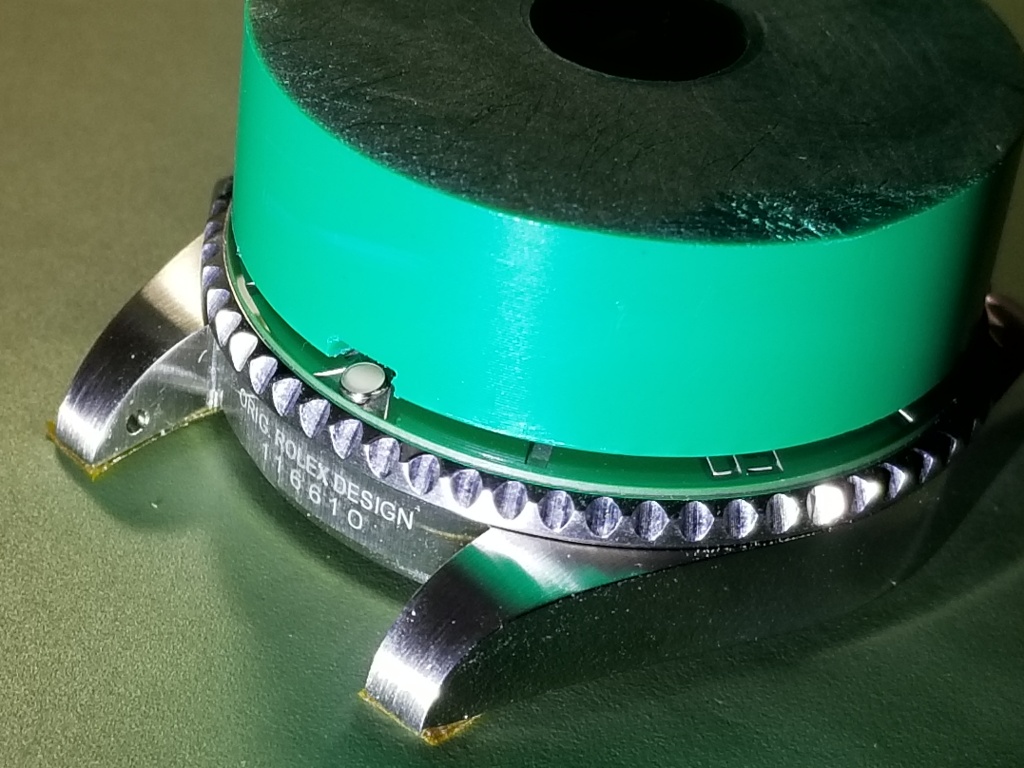

CERAMIC INSERT REMOVAL GUIDE.

- Thread starter Oascom

- Start date

- 9/9/19

- 2,608

- 1,787

- 113

- 12/3/18

- 36,887

- 76,810

- 113

Hi friend.

anything i can do about my zzf v3 insert popping out on one side. I press it down and it pops on the other side

thanks in advance

I had one like this. You can remove the insert, then remove the insert support ring that allows it to be pressure fitted. You can try shaving (sanding) some thickness off the insert support ring and see if that fixes the issue. Or, just keep the insert support ring out and use tape/glue to seat the insert like most reps use anyway.

Last edited:

- 9/9/19

- 2,608

- 1,787

- 113

I had one like this. You can remove the insert, then remove the insert support ring that allows it to be pressure fitted. You can try shaving (sanding) some thickness off the insert support ring and see if that fixes the issue. Or, just keep the insert support ring out and use tape/glue to seat the insert like most reps use anyway.

Thanks m8. Will try the first one.

beyondx4

Getting To Know The Place

Dear watchmakers,

I have a gen GMT master 116710LM that I would like to install a complete aftermarket Batman bezel assembly onto; However, I don't have any experience with the ceramic bezels of the new generation Rolex. Unlike the 16710, I believe the 116710 bezel is friction fitted with a bezel ring/gasket. If you have any experience on dealing with Rolex GMT ceramic bezels and inserts, can you share your knowledge? I have basic watchmaking skills like overhauling ETA 2824, but nothing advanced. I'm planning to buy a set of the Omega style bezel removing pliers with the nylon dies from Aliexpress, but I'm not sure if this tool would would work on Rolex bezels. Thanks so much.

I have a gen GMT master 116710LM that I would like to install a complete aftermarket Batman bezel assembly onto; However, I don't have any experience with the ceramic bezels of the new generation Rolex. Unlike the 16710, I believe the 116710 bezel is friction fitted with a bezel ring/gasket. If you have any experience on dealing with Rolex GMT ceramic bezels and inserts, can you share your knowledge? I have basic watchmaking skills like overhauling ETA 2824, but nothing advanced. I'm planning to buy a set of the Omega style bezel removing pliers with the nylon dies from Aliexpress, but I'm not sure if this tool would would work on Rolex bezels. Thanks so much.

- 19/1/16

- 4,412

- 5,079

- 113

Dear watchmakers,

I have a gen GMT master 116710LM that I would like to install a complete aftermarket Batman bezel assembly onto; However, I don't have any experience with the ceramic bezels of the new generation Rolex. Unlike the 16710, I believe the 116710 bezel is friction fitted with a bezel ring/gasket. If you have any experience on dealing with Rolex GMT ceramic bezels and inserts, can you share your knowledge? I have basic watchmaking skills like overhauling ETA 2824, but nothing advanced. I'm planning to buy a set of the Omega style bezel removing pliers with the nylon dies from Aliexpress, but I'm not sure if this tool would would work on Rolex bezels. Thanks so much.

Yes it's friction fitted. 4 jaw tool will work ok to remove the bezel if you are careful.

Then you need crystal press to fit it back on the watch.

beyondx4

Getting To Know The Place

The tool below is what I'm planning to buy to remove the bezel on my 116710LM. It is also useful for me because I have an Omega SMP 2531.80 that needs an adjustment on the bezel insert. Do you think it's a less risky tool for use on the Rolex ceramics? Thanks.

- 19/1/16

- 4,412

- 5,079

- 113

The tool below is what I'm planning to buy to remove the bezel on my 116710LM. It is also useful for me because I have an Omega SMP 2531.80 that needs an adjustment on the bezel insert. Do you think it's a less risky tool for use on the Rolex ceramics? Thanks.

I have this if you want i can sell it to you. (It's a garbage

beyondx4

Getting To Know The Place

Oh it's really bad? I just can't justify paying $800 for the real Omega set. Is there a good alternative that is reasonable in quality for beginning watchmakers?

- 19/1/16

- 4,412

- 5,079

- 113

Oh it's really bad? I just can't justify paying $800 for the real Omega set. Is there a good alternative that is reasonable in quality for beginning watchmakers?

Try four jaw tool they are cheap and should work but be extremely careful as they can scratch case/bezel

I have this if you want i can sell it to you. (It's a garbage)

This is a Chinese product trying to mimic the Bergeon 2290 but its bezel removal mechanism is totally different.

https://www.youtube.com/watch?v=i1Ejt4blhYs&t=1s

- 19/1/16

- 4,412

- 5,079

- 113

This is a Chinese product trying to mimic the Bergeon 2290 but its bezel removal mechanism is totally different.

https://www.youtube.com/watch?v=i1Ejt4blhYs&t=1s

Yup i know. And Chinese version is garbage

- 13/3/16

- 1,307

- 2,058

- 113

oascom I have read this excellent thread and would like to thank you for your efforts.

I have a question. When pressing in an insert using a modified die like yours, with the inside carved to sloping shape of the insert, the insert never wants to sit flat in the bezel opening. It's slippery and always one side drops in and the other side is high like my drawing. Do you find it acceptable to press in the insert when it's angled like this? Am I overlooking a simple solution? Any comments will be greatly appreciated!

Last edited:

- 12/3/18

- 36,887

- 76,810

- 113

oascom I have read this excellent thread and would like to thank you for your efforts.

I have a question. When pressing in an insert using a modified die like yours, with the inside carved to sloping shape of the insert, the insert never wants to sit flat in the bezel opening. It's slippery and always one side drops in and the other side is high like my drawing. Do you find it acceptable to press in the insert when it's angled like this? Am I overlooking a simple solution? Any comments will be greatly appreciated!

That's exactly how all mine go in bro. As much as you try to keep things even all the way around, it never works out that way. It's probably better because you don't have two sides trying to overcome a bezel rim simultaneously. At the stage I am at in the second pic, I use a lever type crystal press and exert just the tiniest bit of force necessary to pop it home. As soon as you are sure it's going, ease off the pressure completely. It usually doesn't take much to seat the insert.

- 19/1/16

- 4,412

- 5,079

- 113

oascom I have read this excellent thread and would like to thank you for your efforts.

I have a question. When pressing in an insert using a modified die like yours, with the inside carved to sloping shape of the insert, the insert never wants to sit flat in the bezel opening. It's slippery and always one side drops in and the other side is high like my drawing. Do you find it acceptable to press in the insert when it's angled like this? Am I overlooking a simple solution? Any comments will be greatly appreciated!

It might angle a little but it's should be fine as long as as the bottom of the insert edge don't catch the metal on the top of the bezel if you know what I mean... Then you will break it.

I personally never broke any insert when pressing them.

- 13/3/16

- 1,307

- 2,058

- 113

KJ2020 oascom Thank you guys very much. It gave me the confidence to proceed and it went well. I'm now sporting a gen bezel and gen insert on my 126610. Worth it? Not really as there's very little difference between the VSF bezel and the gen, but it gives me that warm fuzzy feeling to have it

It's tighter than the rep bezel so I might have to adjust, but I never turn it anyway. I used a WSO replacement hytrel ring that might not be exactly gen spec.

It's tighter than the rep bezel so I might have to adjust, but I never turn it anyway. I used a WSO replacement hytrel ring that might not be exactly gen spec.