This will be a detailed and ongoing read, continuously updated with new information. Please be prepared for a lengthy read.

I intend to maintain this post as a comprehensive resource by editing it with updates whenever there's news, ensuring that information remains organized rather than lost in the comments. After each edit, I'll leave a comment like "Updated OP - Crown Added" to alert those following along.

Please understand that my comments are not meant to be taken harshly. For instance, when I critique the 6610 Ruby dial, it's not a reflection on its quality—many beautiful builds have used it. However, I'm a perfectionist by nature, which can be both a blessing and a curse. I appreciate all builds equally; even full raffles builds can be stunning. Please don't take offense at my observations.

I've used spoilers to make this information more digestible and less overwhelming to read. Initially, I had planned to use toggles for each header, but it seems the forum doesn't support this feature.

First and foremost, I shall introduce myself - as I hadn't previously done so. I just joined RWI and appear to blend in, as if I had always been here - despite my joined date. I'm a young man from Europe, somewhere in my mid-20's. I take privacy and anonymity quite seriously, so I will remain vague in some areas.

Nonetheless, here we go. I have been into replica clothing for a long time, since 2015-16 before the Reddit board which I will not name grew ridiculously large, and only had around 20k members. Back in the day I had set up some connections in China and Korea, as I ran a middleman service for a short while, for high quality sneakers years ago. Because of this, I got some experience with finding things, people, parts... and talking to people in Chinese, despite the fact that I don't actually speak Chinese - this information is relevant for later.

I then found my way to DHGate shit-tier watches, and eventually made it to Reptime as I gathered some money - and splurged - on a VSF 126610LN. The watch showed some very weird behavior, losing minutes after running fine for a few months. This led me to send it over to Noolex (Gernot) FOUR times. First for a full service, pressure test and then each time because it kept losing time... He had a hard time finding what caused the issue, and often could not replicate it on the bench - eventually I read up on the Cannon Pinion tolerance issue VSF commonly has, and suggested tightening the Cannon Pinion. And so far, the watch doesn't lose time anymore.

I have never serviced or taken apart a watch myself, thus I feel like quite the imposter among you skilled people. Nonetheless, I do plan on getting into that part of the hobby sometime - when money and time allows it. I have exams coming up soon, so I will crawl back into the hole where I came from and be MIA for a while.

I like espresso, traditional wet shaving, oldtimers (not the American kind, sorry), cats, dogs, music, have ADHD, PTSD and according to the tests an above average IQ (which is a curse, not a blessing). I don't make a living anymore, as I went back to Uni.

Can I pull off wearing a 10-30k watch? Maybe, if you'd judge by the way I dress and the (oldtimer) car I drive. Does it make sense if you pull a full background check on me? No.

Do I care? Not much. I like watches, and have never been "called out". No one cares.

So, what led me into this rabbit hole is the 1016 model and tropical dials. I initially wanted a 1016 tropical dial. I thought about a way to turn Raffle's dials into a tropical kind of dial. I had someone else (Archaedin on Reddit) execute it, after I sent him 3 bottles of product to try and make me a dial. This was the result, a bit extreme, but nice.

Though not very realistic - and Archaedin was not able to relume the dial, nor modify case shape. So I sold the 1016 and dug deeper. This led me to RWI.

I contacted the Explorer aging god - @369mafia - through PM's and initially wanted him to make me a budget build. We discussed the potential project and had actually nearly agreed on something. However, the build would not be super accurate - though very nice - as that wasn't within my budget. My fear of customs interception from USA/CAD to Europe had eventually made me decide against a 600 euro gamble - and had me look elsewhere. (Sorry 369maffia).

As I dug deeper, did more research, and met more people here, on the forum and elsewhere (I had actually talked with manodeoro on Instagram before even knowing he was manodeoro, and before his disappearance (which I completely understand the reason for)). I found the Hodinkee website showcasing a beautifully aged 1957 6610 with big white lollipop. As soon as I saw it, I knew, that was it. I even spoke with Rolojack, who surprisingly replied to my messages - but unfortunately would never return to this hobby as his machinery is gone.

This led to the inspiration for my build.

As all of you know, there are quite some limitations when it comes to availability and accuracy of parts. As I read and dug deeper, the "top tier" dials are Vietnam, yet the Ruby 6610 dial is not gilt, and quite expensive. And it's not even all that accurate - it looks more like a service dial than an actual 6610 dial. Which made me have to walk different paths, more on that later in the "parts" category of this post.

Summed up there are three main sources of inspiration for this project:

1) Hodinkee website with stunning 6610 1957

2) Manodeoro's red depth 6610 build

3) Rolojack's 6610 build on RWG.

PART 2 - Because the forum is buggy...

Project Overview

I'm embarking on a watch-building project that involves sourcing components from various parts of the world. Some items are readily available, while others are more challenging to obtain. I'm leveraging the expertise of multiple RWI members, along with my global network of connections and friends, to bring this project to fruition. I extend my gratitude to all those who will assist in this endeavor. Thank you in advance for your support and assistance.

Dial

In my opinion, the dial is the most crucial component of this project. I refrained from purchasing any other parts until I was confident that the dial would work out. I spent countless hours researching dial production options, both on this forum and across the internet. Ruby's dials were too expensive and didn't meet my exacting standards. The impressive work by @manodeoro and other members inspired me, but with Mano currently unavailable, I had to explore other avenues, leading me to "reinvent the wheel," as someone mentioned in private messages.

I turned to Chinese secondhand markets, which are abundant with various items, although the watch hobby community is much smaller in China compared to Europe or the USA. I found a like-minded individual, who is now a friend, sharing the same passion. It was quite a challenge to connect with him since foreigners can't communicate with sellers on these platforms without a Chinese ID. After verifying my ID with Taobao and Alipay without success, I cleverly found his censored username, searched for it on WeChat, and fortunately, he used the same name there.

We engaged in extensive discussions, and he showcased some of his builds using Vietnam dials and other parts, as well as his self-made dials. This collaboration led us to work on creating a 6610 dial, a design we both admire.

Dial Design Process

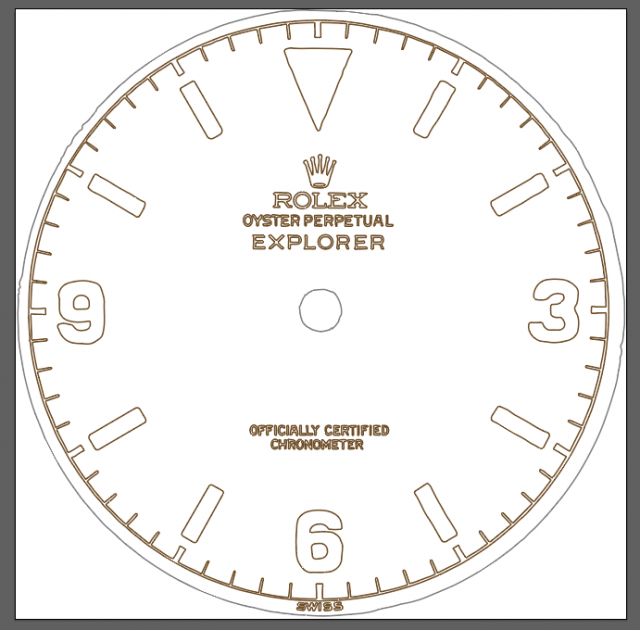

After numerous attempts to create a vector myself—which were satisfactory but not exceptional—I decided to hire a professional illustrator to assist with the design. Both of us aren't expert graphic illustrators. Moderators, am I allowed to share the illustrator's contact information here for others who might be interested?

Here’s the progress we made:

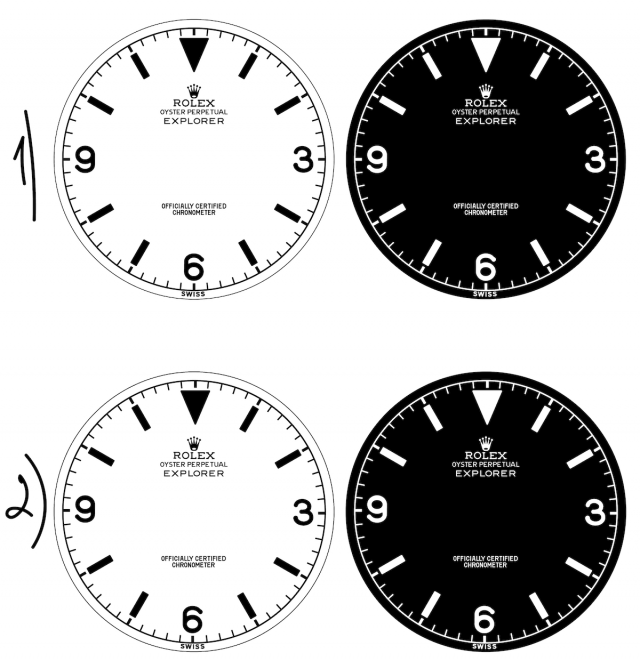

- My First Attempt:

- Second Adjustment After @369mafia's Feedback:

- First Version with the Professional Illustrator:

Although it looked good to the untrained eye, I had several remarks:

After extensive back-and-forth communication:

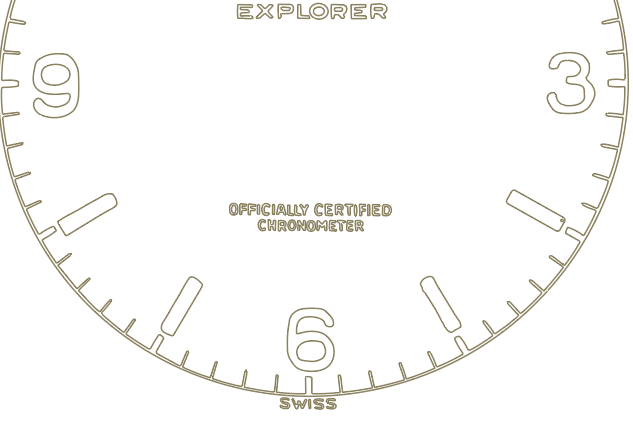

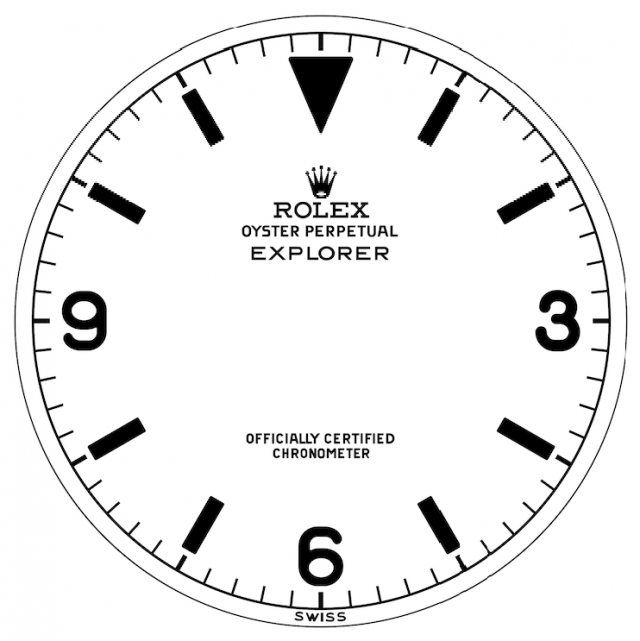

We made numerous adjustments and eventually reached this result:

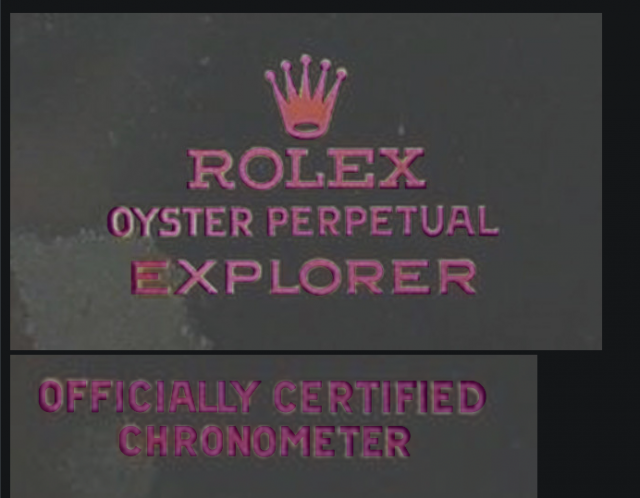

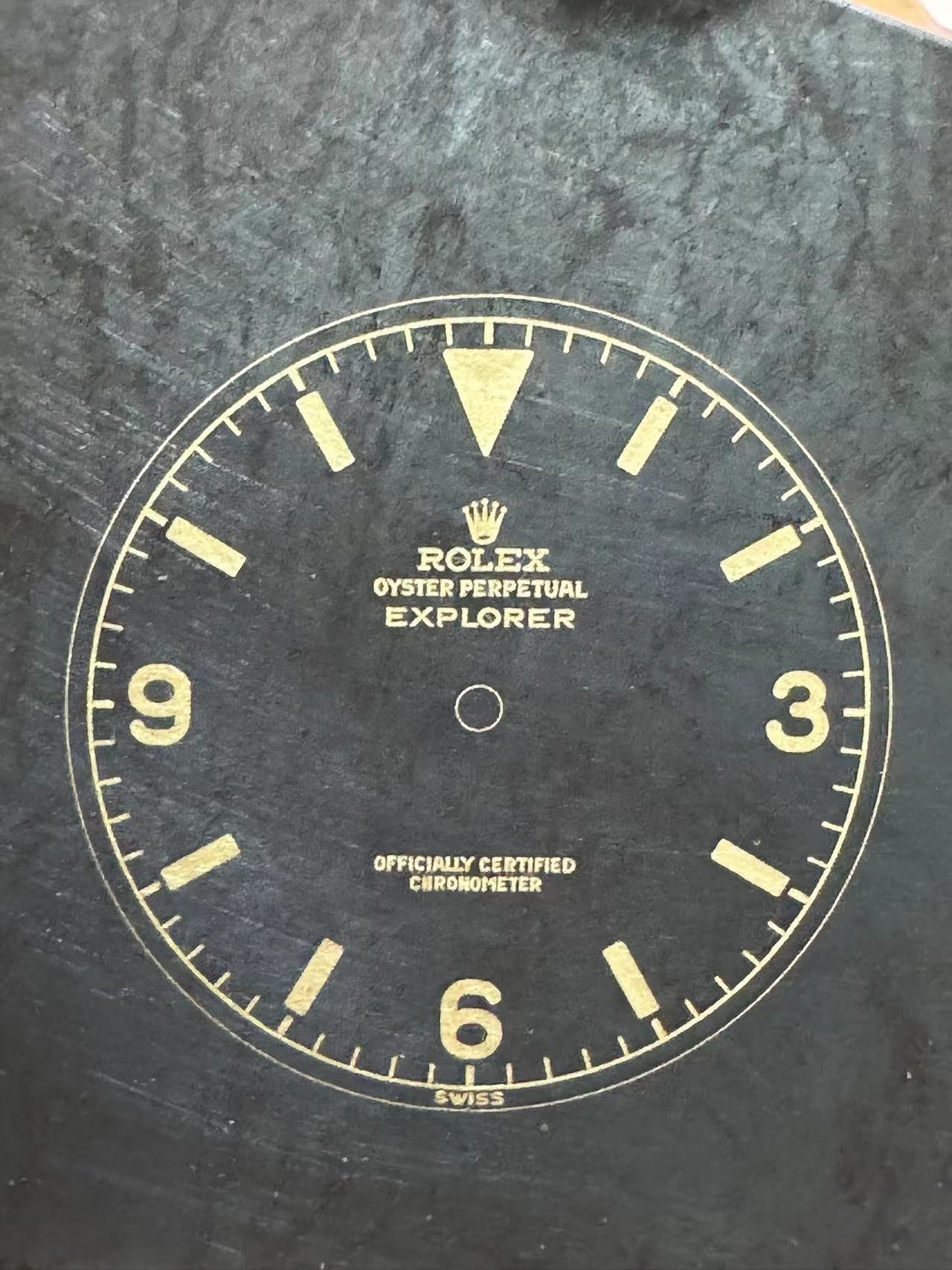

At first glance, it seemed perfect. To ensure accuracy, I overlaid the vector in purple transparency over an actual genuine NOS naked dial I found online:

However, I realized that the letters needed their characteristic "hooks":

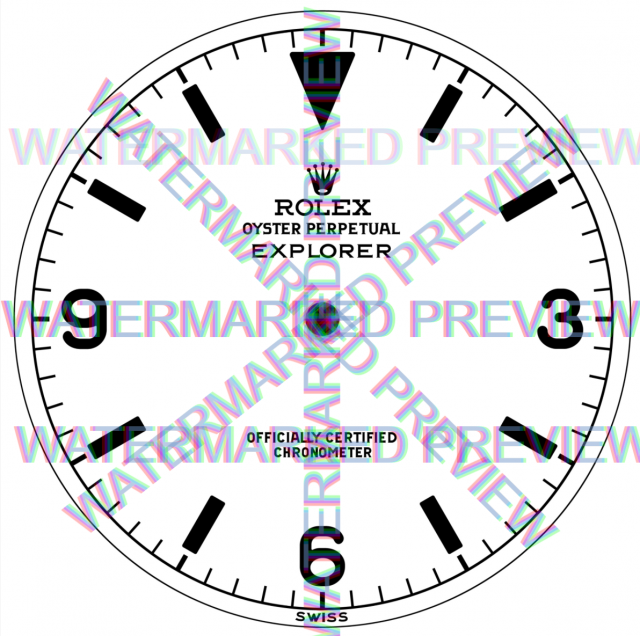

So, we made further adjustments. I essentially gave the illustrator, who initially knew nothing about watches, a crash course on Rolex 6610s—he's now quite knowledgeable! Here's the final result (watermarked to prevent unauthorized use):

- Initial Attempt Without the Vector for Engraving:

- With the Professional Vector:

We still need to refine the details and achieve sharper lines. Currently, we're experimenting with line thickness. Here's a closer look:

https://imgur.com/a/E1F2wAD

Note: The dial section will be updated in the future once it's finalized.

Crystal

Content to be added.

Case Sourced by @1016lover

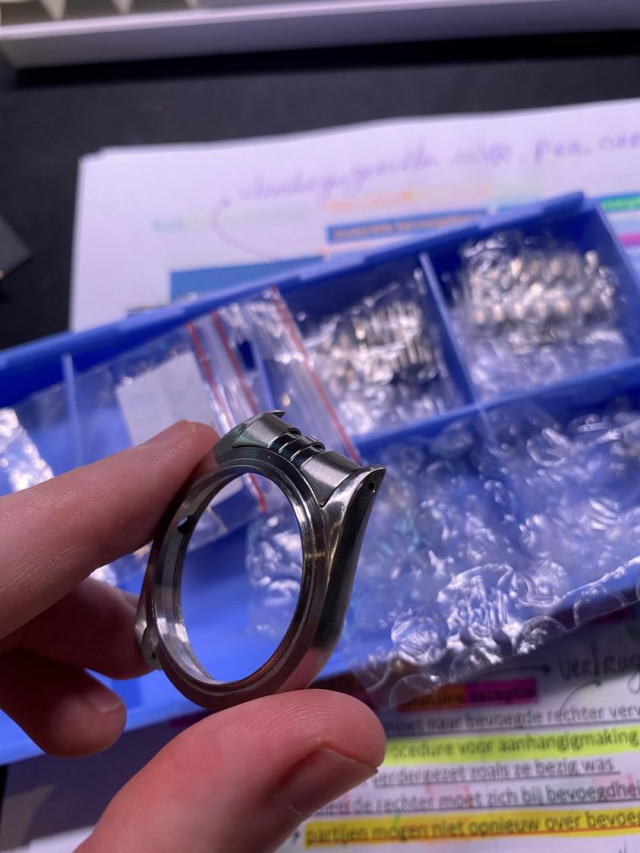

I'm facing some challenges with the case, which was sourced by @1016lover. The case features more aggressive lug curving, closely resembling the 6610 shape, at least in my opinion.

Comparison with Raffles Case

Here's a comparison between the larger hole case and the Raffles case:

Issue with Crown Tube Fitting

The primary issue with this case is that the Athaya Vintage crown tube doesn't fit properly—the hole is slightly too large. To address this, the hole needs to be filled, drilled, and tapped to the appropriate size. After discussing potential solutions with @1016lover and considering my metalworking and welding experience, we came up with three possible approaches:

1. Poly Metal Bonding to Fill the Hole

2. Welding with a Chalmo Torch Using a Copper/Aluminum and Flux Blended Rod

3. TIG Welding

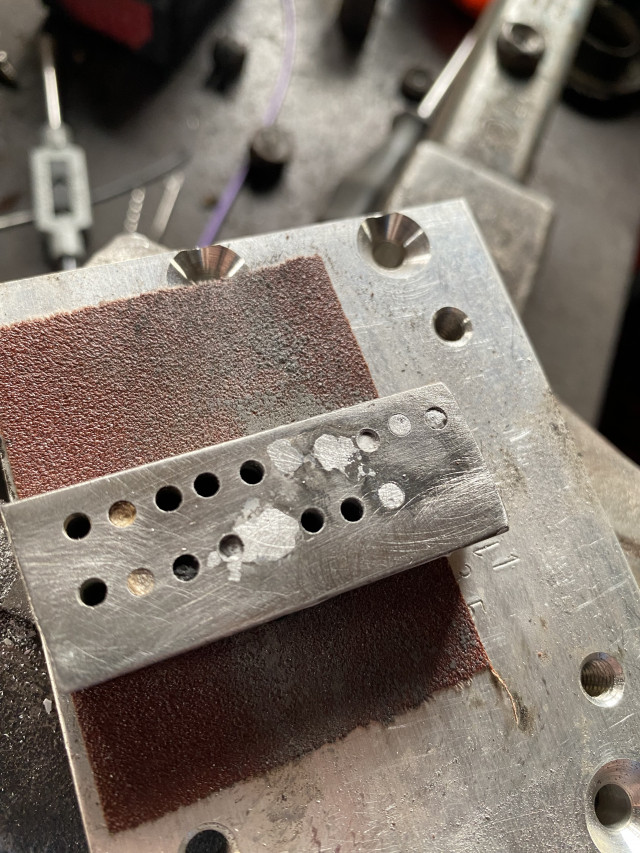

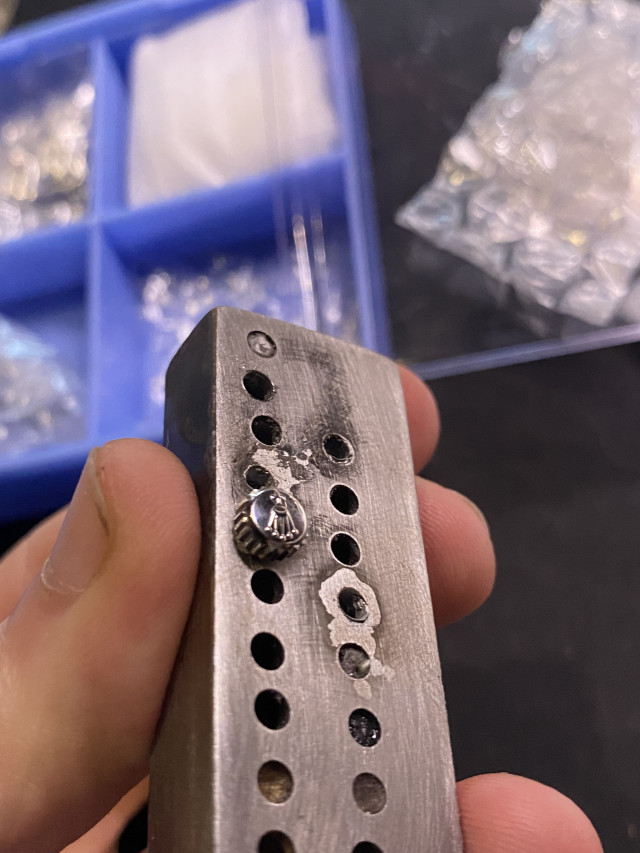

I was cautious about using torch and TIG welding due to the heat involved, so I conducted tests on a stainless steel dummy block.

1. Poly Metal Bonding

While this method worked, the thread strength wasn't optimal.

2. Chalmo Torch Welding

Using a copper/aluminum/flux blended rod:

The initial attempts were messy, but I eventually mastered the technique:

This method produced stronger threads but was challenging due to the heat. Precision is key to avoid damaging the case. I'm considering investing in a precision torch device for jewelry welding to improve this process.

@1016lover provided a test case for practicing the hole-filling technique. I also tested the 55 end links on this case, and they fit perfectly:

3. TIG Welding

I tested TIG welding on the dummy block with success. However, when applied to the stainless steel test case, I noticed the case material differed slightly from the block and didn't withstand the heat as well:

Alternative Solution

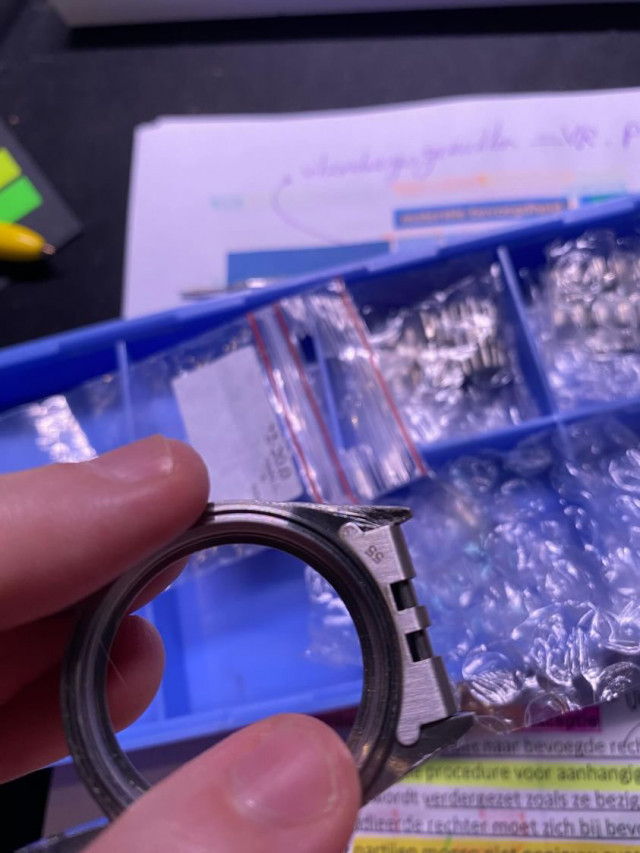

Due to the challenges, I explored alternative methods, such as using a crown tube with unique specifications (4.35 x 3.35 x 3.60 mm):

This approach allows @1016lover to tap a larger thread size in the case and fit the crown tube neatly, eliminating the need for welding or redrilling. The Athaya Vintage Brevet crown fits perfectly on the crown tube end, which is a significant advantage.

*Stock Athaya crown tube on the right.*

Bezel by @1016lover

Content to be added.

Caseback by @1016lover

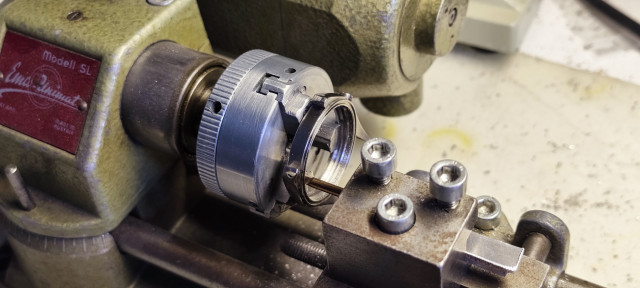

The case, bezel, and caseback have been completed and shipped off to @newest dude on the forum for pantograph engravings.

The case, made by @1016lover, originates from a NH Aliexpress case with more aggressive curvature than the Raffles case:

To accommodate ETA movements, a cut was made on the inside:

Click me for Part 3

(forum prohibits me from continuing as the post exceeds 60 images)

Last edited: