Another option is to use a 2.65mm drill bit and attach it to something that allows you to turn in slowly by hand and to apply some force. Like a tap wrench for example. Then it may be possible to turn the tube clockwise so that it gets pushed into the watch case.

The above method should work on the following assumptions:

1. The tube snapped clean and is not a wider diameter at the part that broke off

2. The 2.65mm drill is sharp and new so it can bite into the end of the (softer) tube

3. There is no loctite holding the tube in place but to be sure, you could try an old drill bit that fiis inside the tube and blast the sticking out end of it with heat from a torch or soldering iron but it will have to be a powerful one 80-100w.

4. You have removed the movement from the case (I’m sure you have)

Hope that helps and maybe worth a try

Yeah, I've got about 3 steps I'm going to try now. Need to wait for the extractor set to arrive and see if that works after a little WD40 bath.

The snap is pretty clean. It's completely even around the round part that's visible in the threads. The tube seems to be even diameter from the broken part, measured.

I am worried that there is loctite holding in place, because I took the precautions to heat it up, chemically loosen, and used an appropriate tool, but it still broke off. I even took a soldering iron to it for a good bit of time before I tried, and it still snapped.

Everything has been removed from the case. It's just the bare case.

I'll give it a go if nothing else works, before dropping it off at a watchmaker.

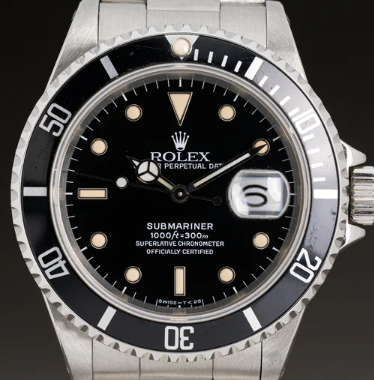

I really appreciate you guys helping me out here. This watch has been nothing but headache after headache, despite good QC. I just want to wear a 5 digit, dammit!