With my project to install gen parts on a VS3235 movement currently stalled while I wait for a gen 3235 pallet fork, I opted to start my other gen parts project... installing a gen balance complete, balance bridge, and chronograph seconds wheel on my Noob 4130 Daytona. This will be my first time taking apart a chronograph movement. Wow... chrono movements are WAY more complicated than normal hour-minutes-seconds-date movements. But I do have a service manual for the 4130, so how hard could this be? (Famous last words).

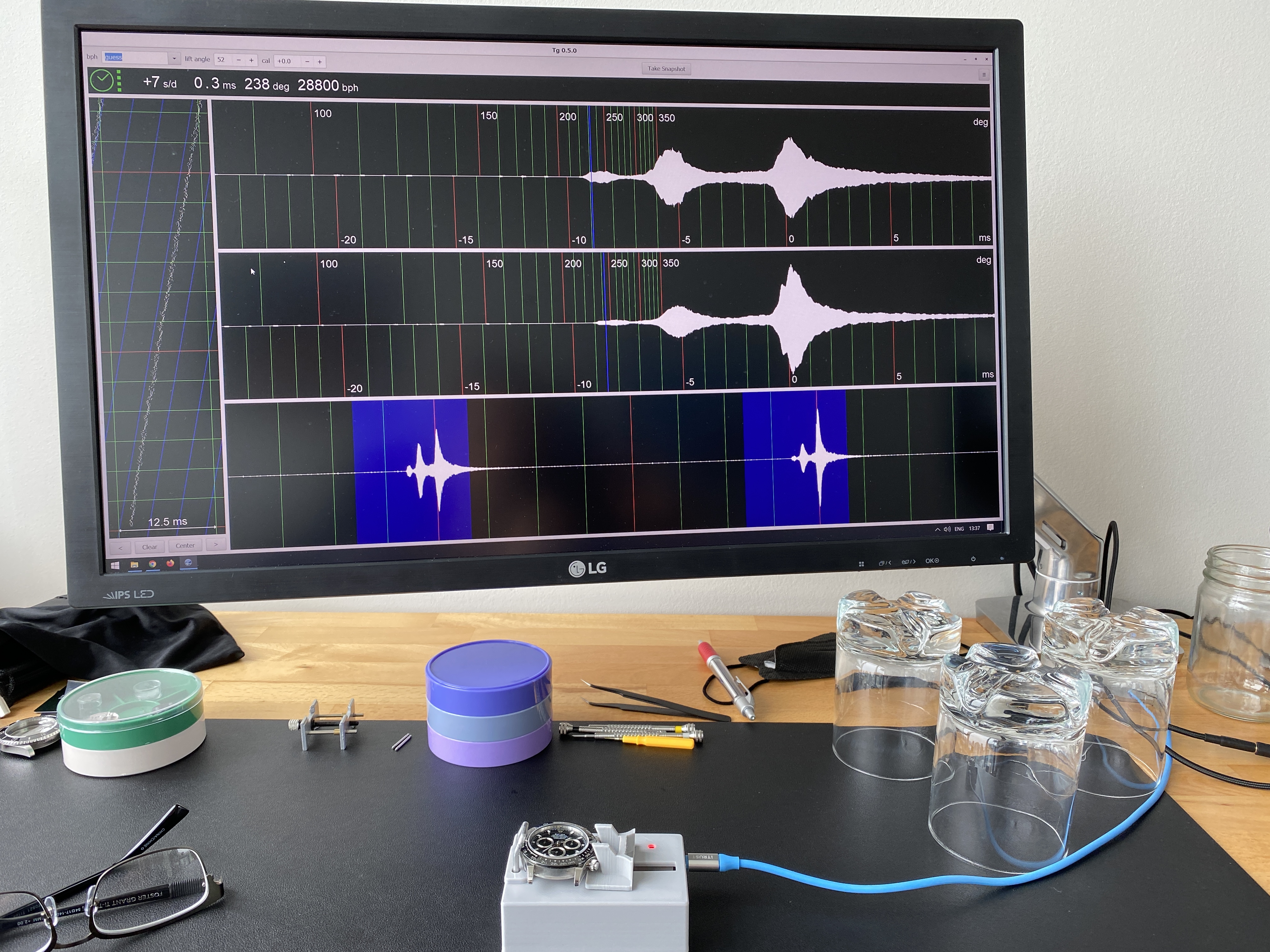

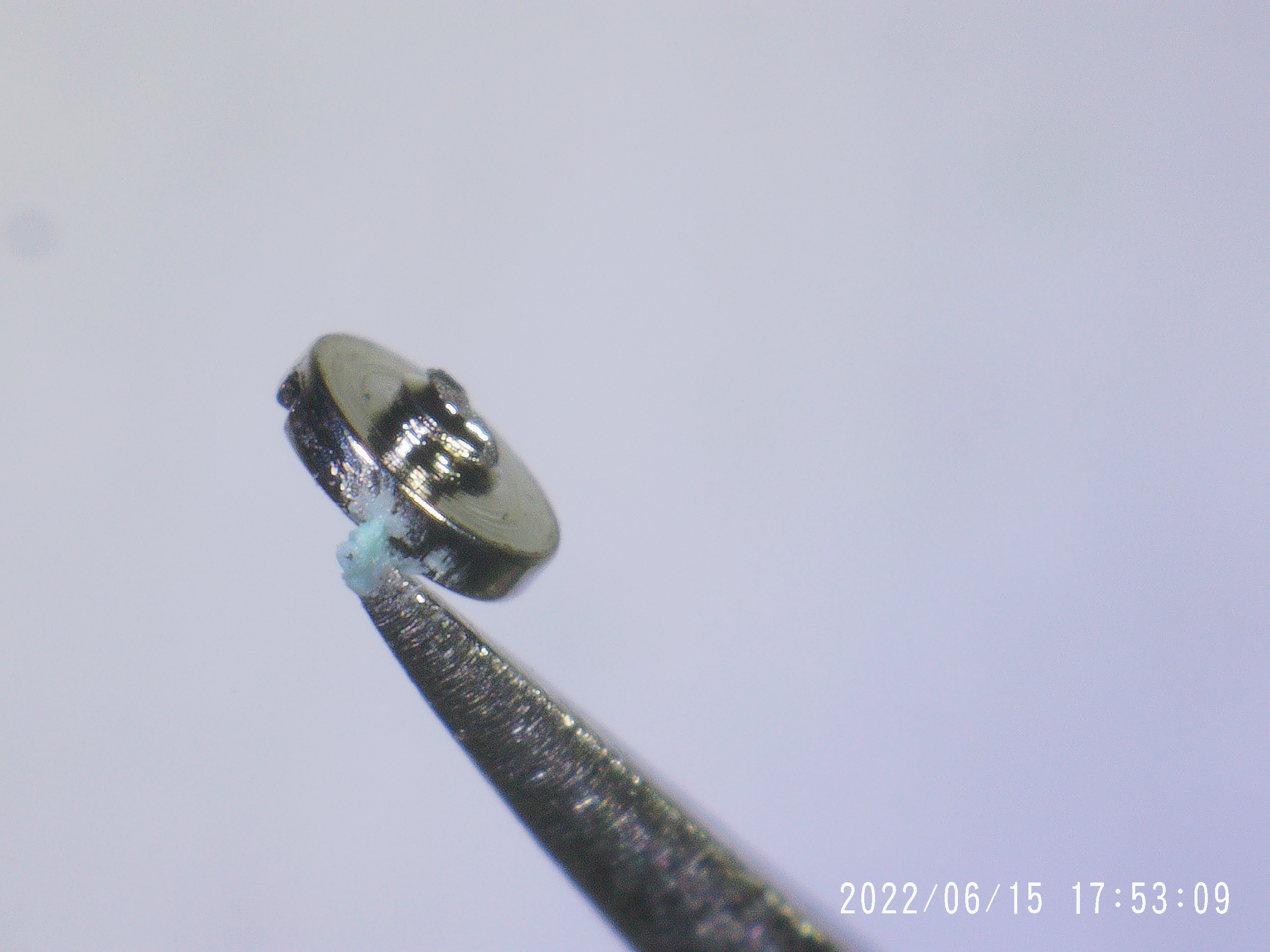

So let's start with the health of the movement before I started messing with it. This watch wasn't serviced after I bought it 9 months ago, and it's holding up pretty well:

A normal person would leave "good enough" alone... I'm not that kind of person.

Off we go... the process started out pretty well. No problems getting the case open, automatic module off, the movement out of the case, and the hands and dial removed. I've done those things a few times now, and they're starting to feel less scary; although I still go slowly and double / triple check things to make sure I'm not doing anything stupid (don't worry, stupid things happen on their own with me).

Unlike the VS3235 where the gen balance bridge fit nicely onto the VS mainplate, in this case, the gen balance bridge didn't fit well onto the noob 4130 mainplate, so I was going to have to use a broach to open up one of the screw holes.

I have an inexpensive set of six broaches (0.8mm to 2.3mm) that I bought from Perrin. I didn't have a good way of holding the gen balance bridge so I used a few layers of foam tape on a small movement holder to improvise a set of soft jaws and a vise. It worked pretty well.

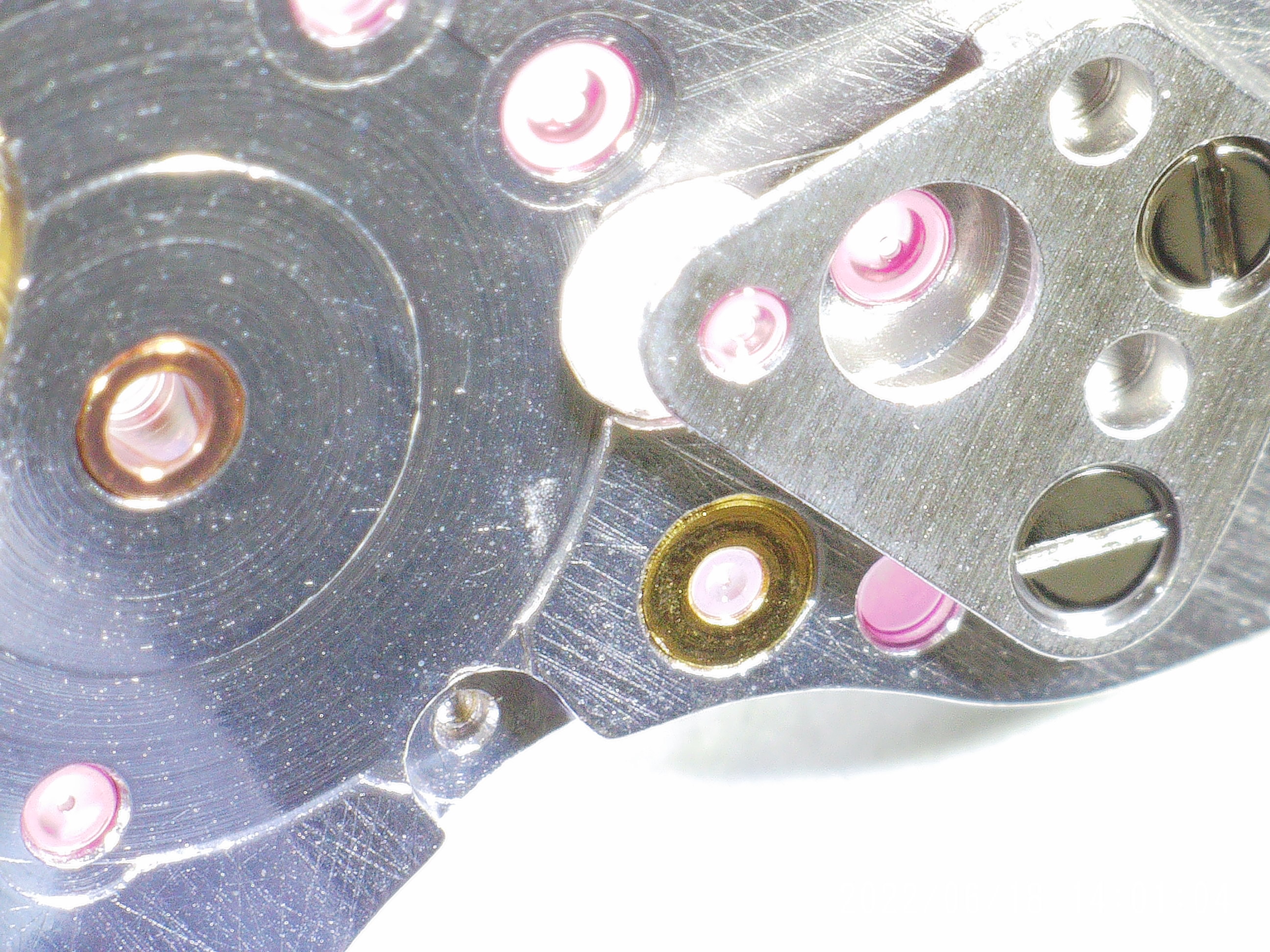

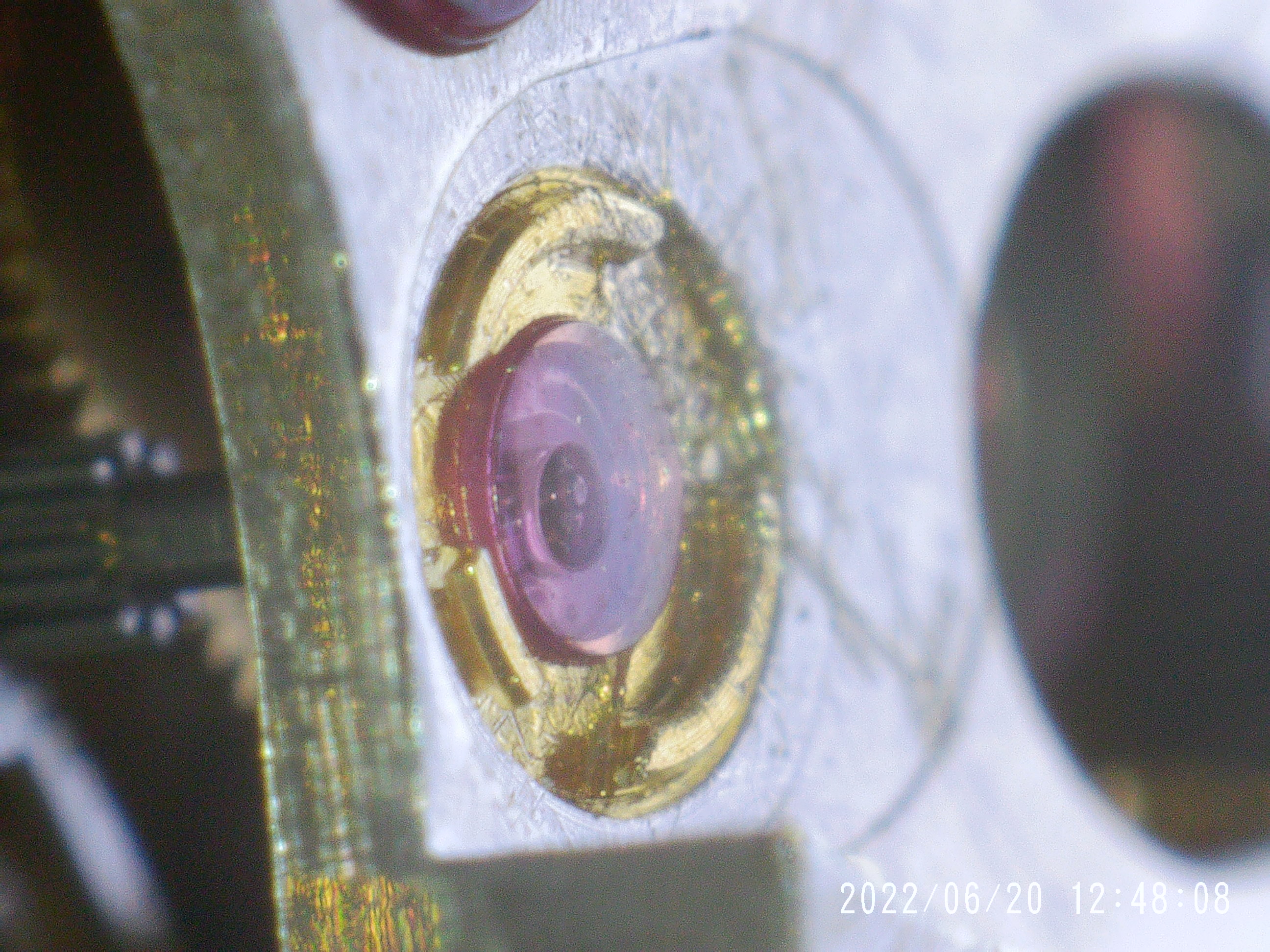

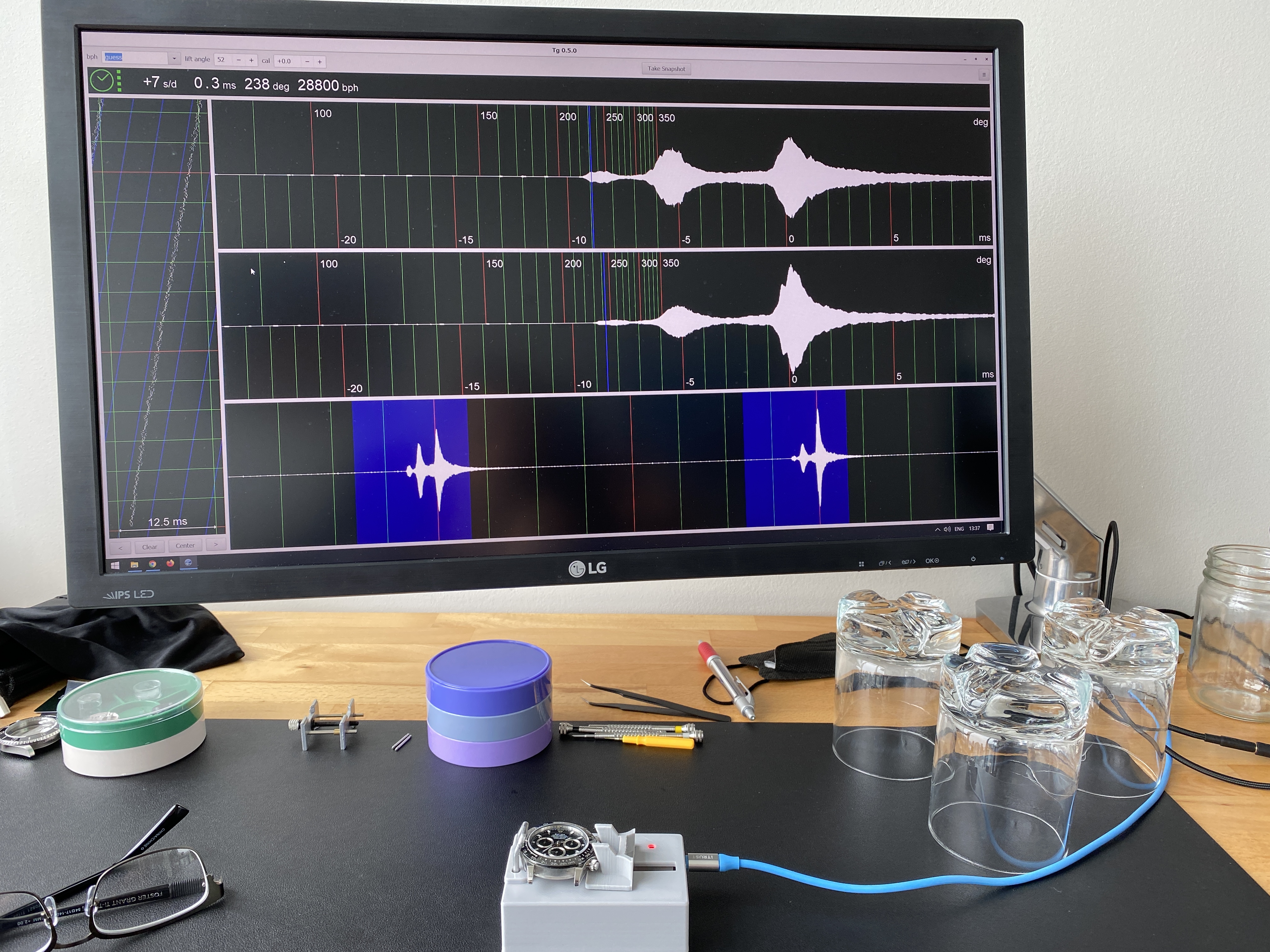

Here's a pic of the balance bridge hole that I boached... I cleaned up the metal shavings with one of those little between your teeth tooth brushes, so it ended up being pretty clean.

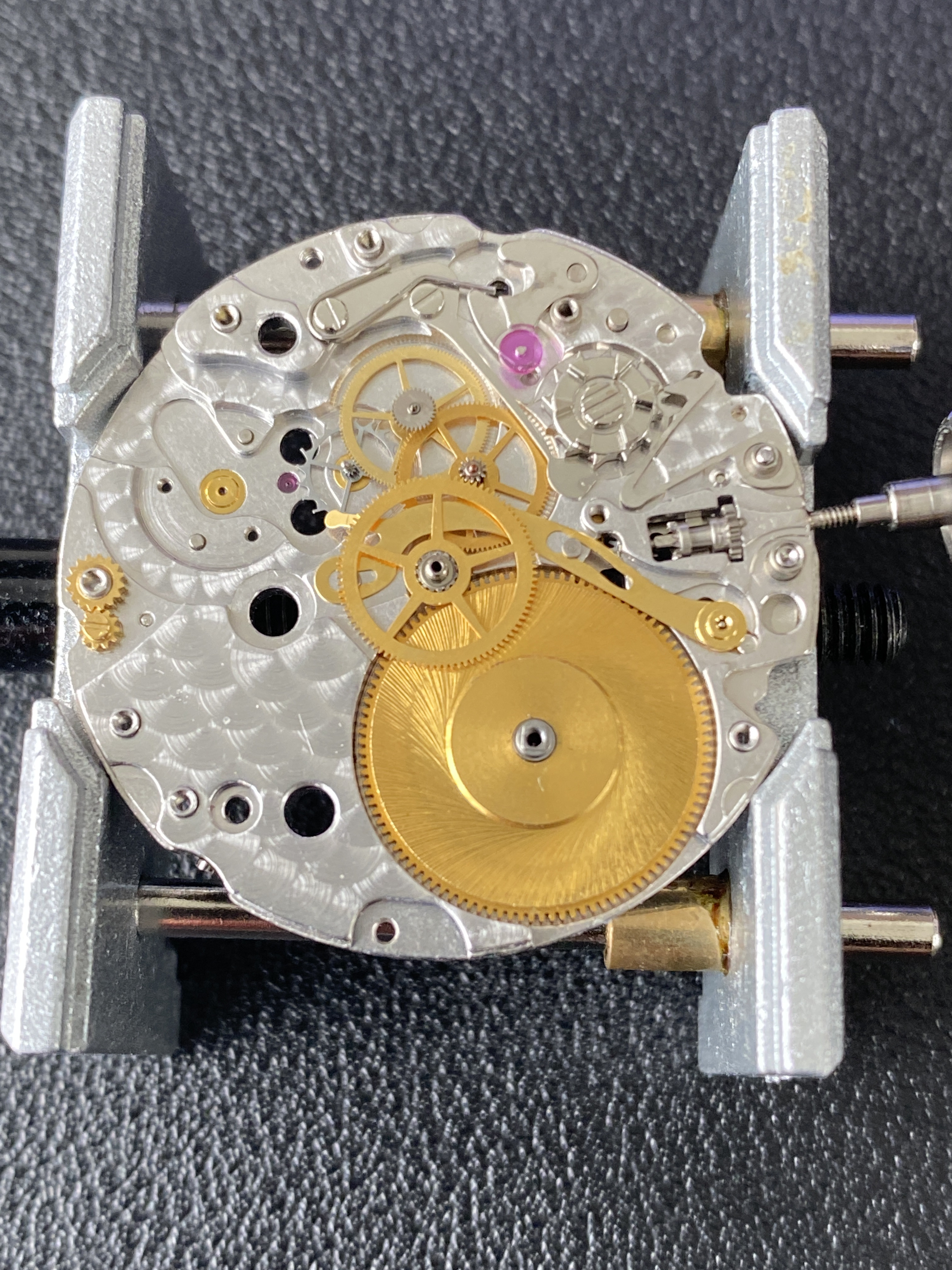

With the balance bridge broached, I was able to fit it nicely into place on the movement, and use the movement as a jig to connect the balance hairspring bridle to the balance bridge hairspring stud. Hat tip to Triplock for the suggestion to do it this way.

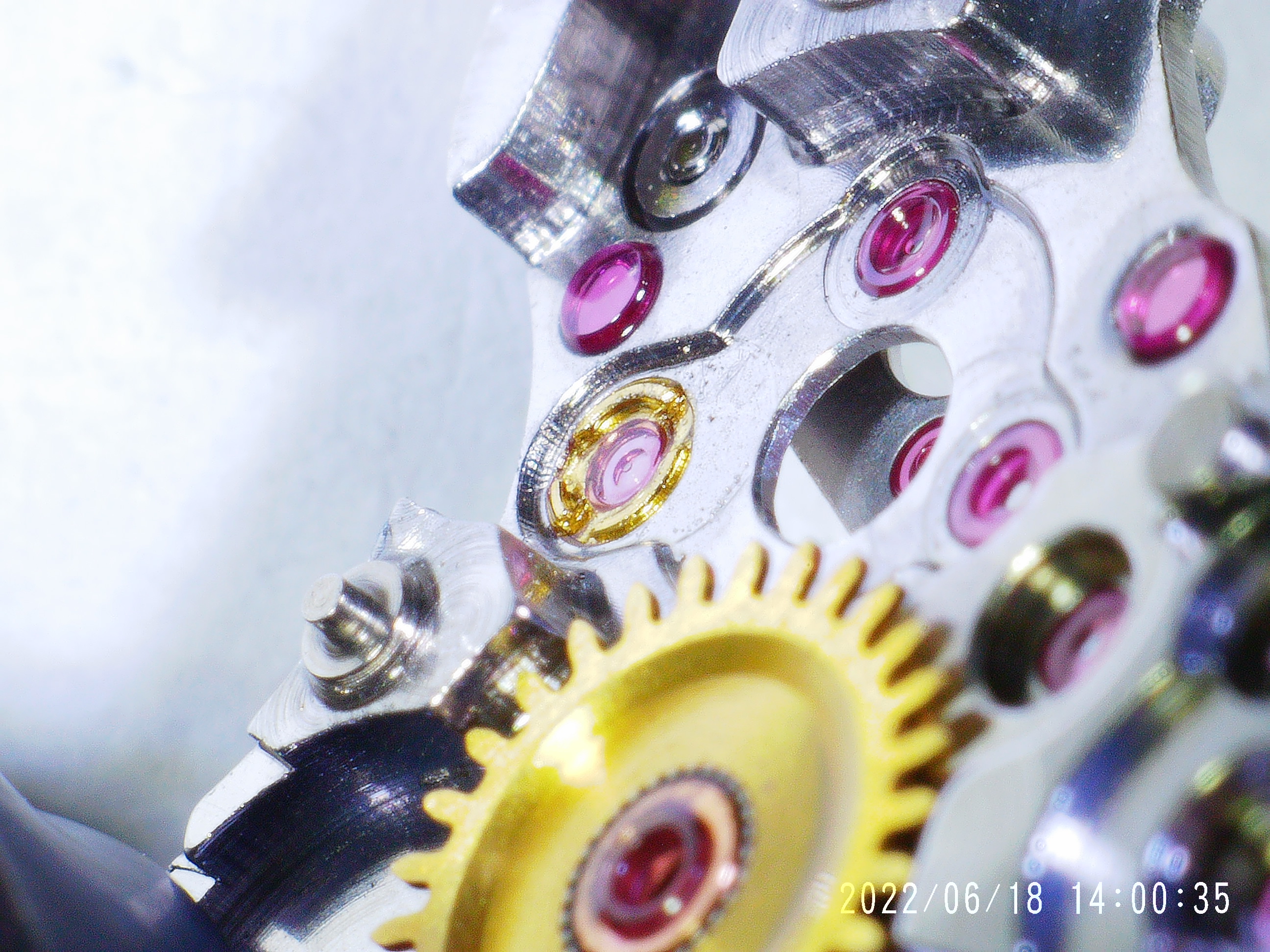

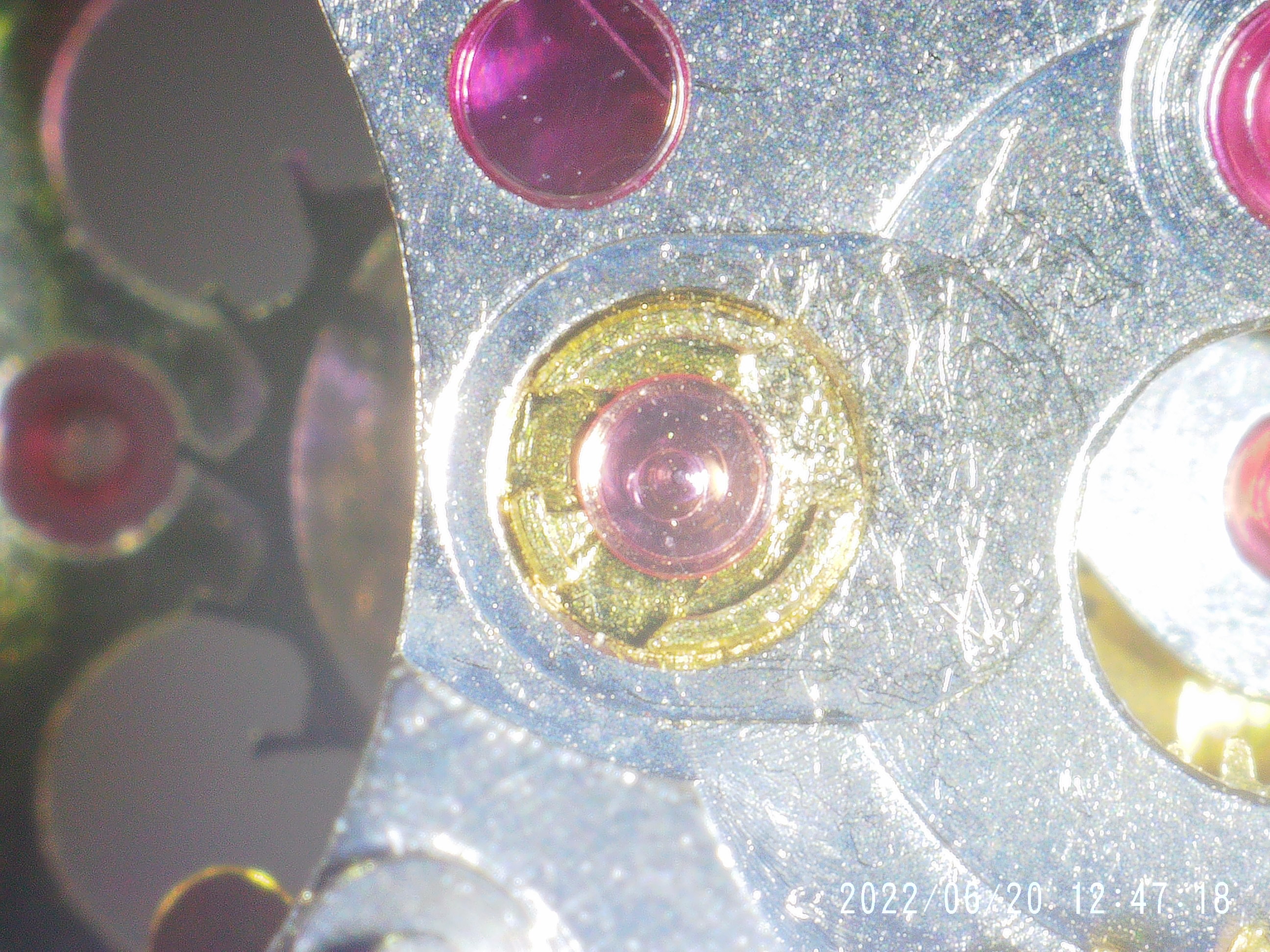

Next was swapping out the chronograph seconds wheel for the gen part. The gen part in a beautiful LIGA gear which is also a spring for gripping the teeth of the wheel driving it. These spring teeth basically eliminate backlash, meaning that the chronograph seconds hand should sweep more continuously than with the standard brass tooth gear which will cause the chronograph seconds hand to stutter from time to time.

The install was pretty simple, I simply needed to remove the chronograph bridge and pull out the noob part and drop in the gen. However, getting the chronograph bridge re-installed wasn't easy. There's a part called the "Jumper for counters" (part no. 4130-834) which sits under this bridge near the crown... this part is both incredibly delicate, and incredibly annoying to get aligned properly so that its pivot rests in the jewel in the chronograph bridge. This took me a couple of tries. But I eventually got it installed.

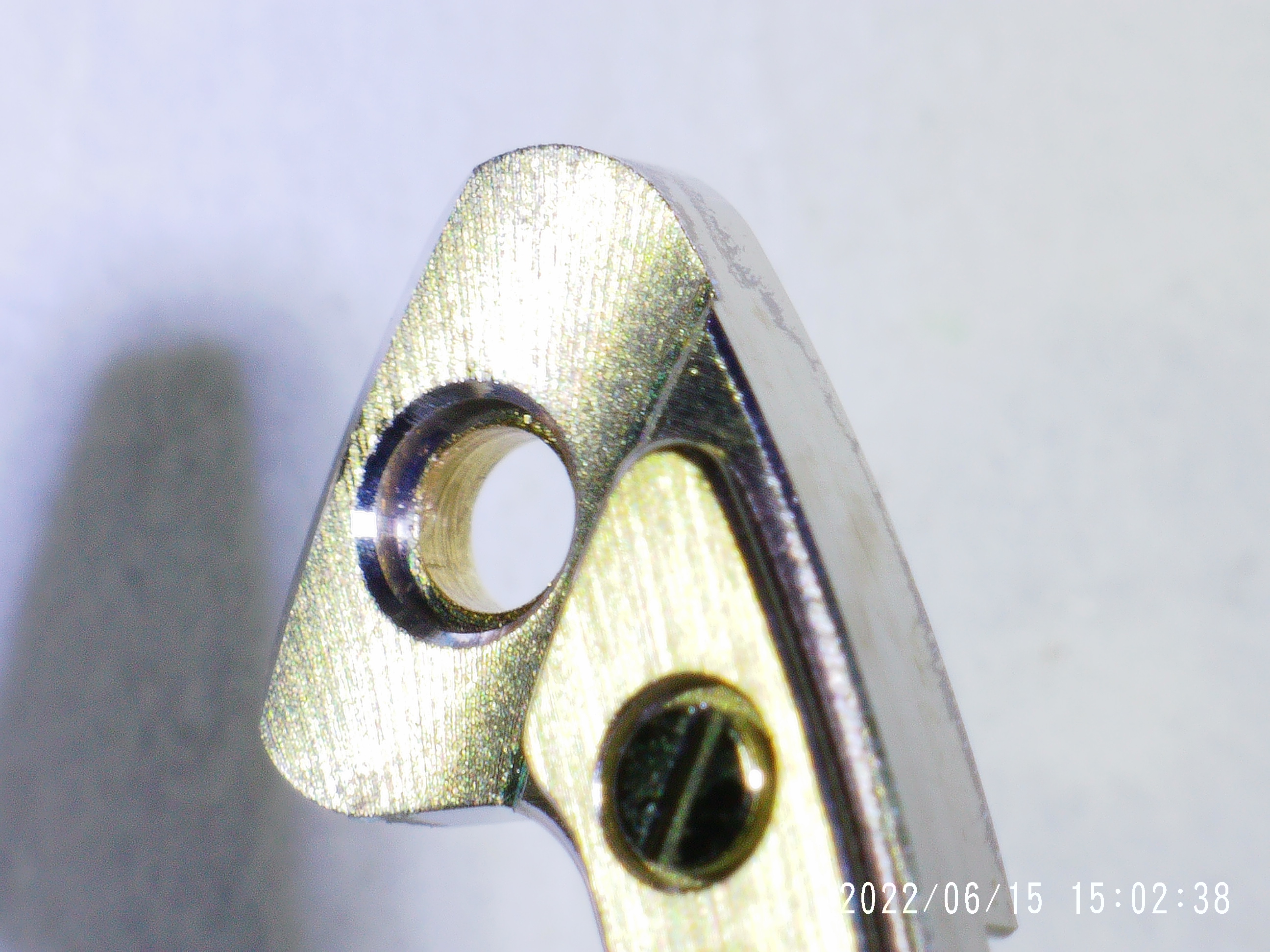

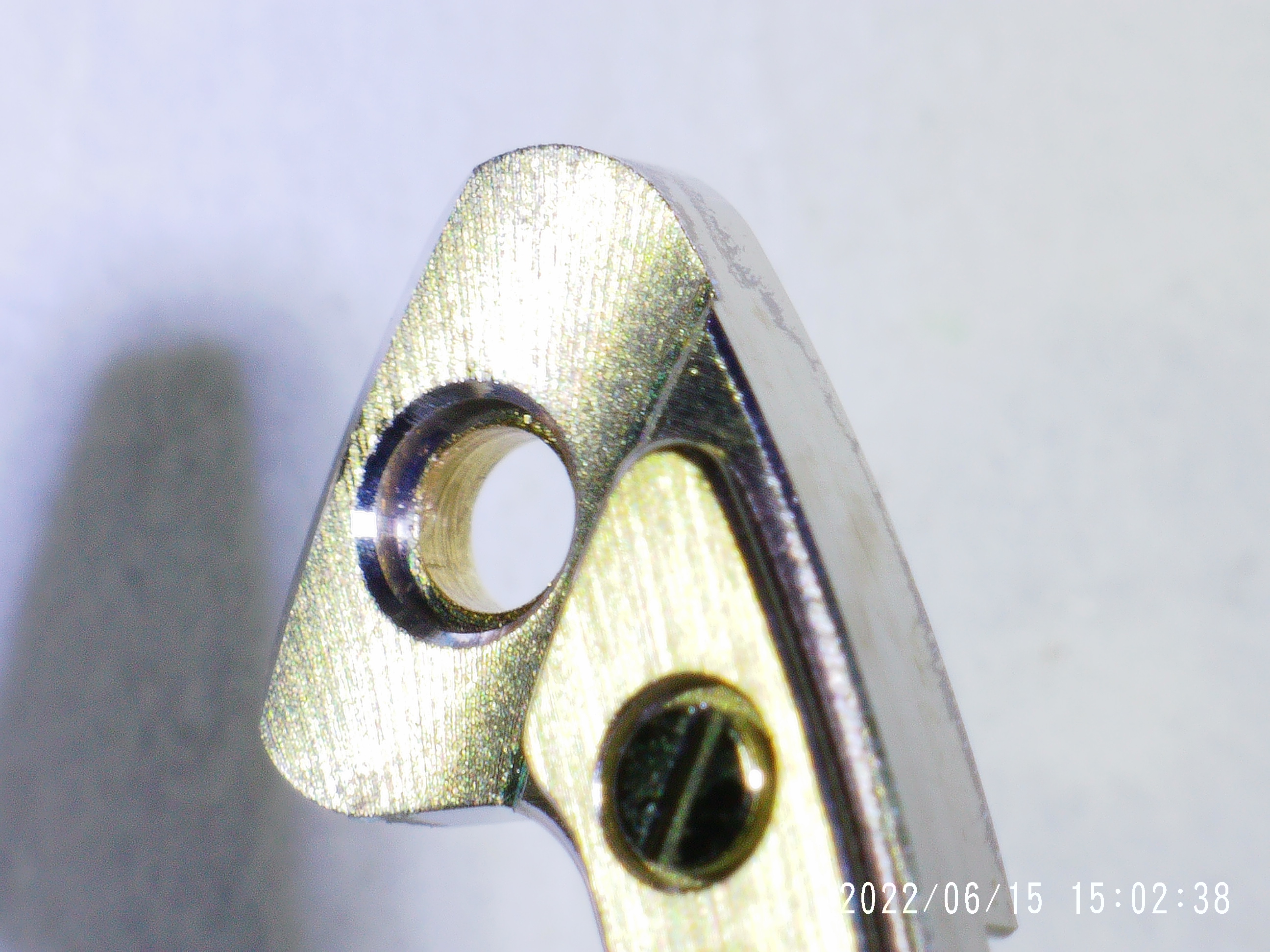

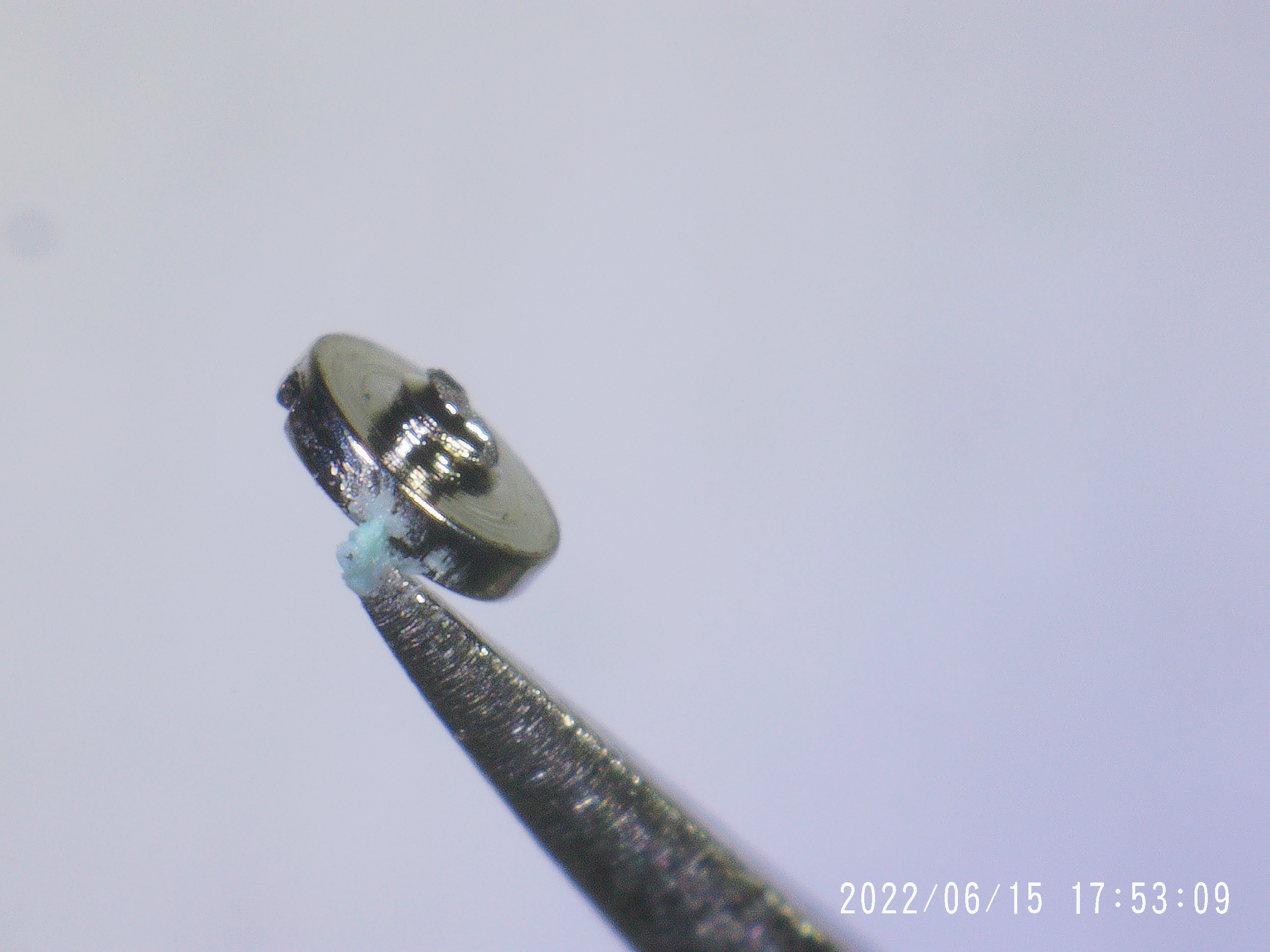

But just as I'd secured the chronograph bridge and was about to start the process of getting the dial and hands back on, I flipped the movement over, and something fell off it and hit the floor. I froze (remembering the hours I'd spent hunting screws when I first started tinkering with movements a few months ago. But this time, I was able to find the offending part reasonably easily... it was a screw. Or it was part of a screw. The screw holding down the Hammer Jumper (part no. 4130-883) had sheared off at the head.

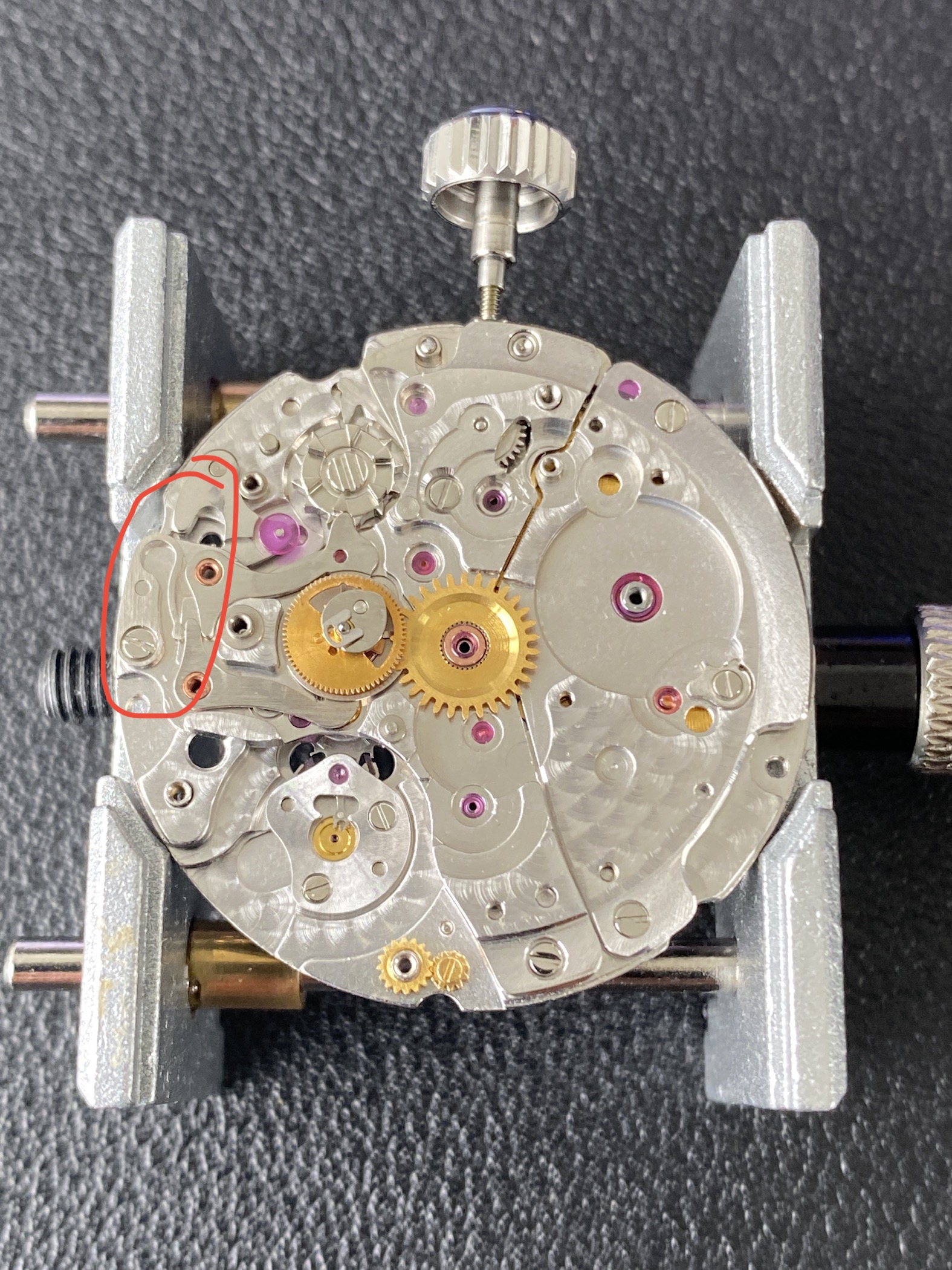

Here's a pic showing the movement with the missing screw head (look just above where the winding stem enters the movement).

This has me pretty worried. I'm sure I'll be able to find a replacement screw since I have a few spare rolex clone movements laying around... but I'm worried I won't be able to get the broken screw out. At least the screw didn't break flush to a plate or a bridge. If I take the movement apart, I'll be able to remove the Hammer Jumper and that will give me a few millimeters of threaded screw stem to work with. Regardless, this is turning into a project that's more involved that I'd hoped. I really didn't want to have to dis-assemble the entire 4130 chronograph works. But I have a feeling that I'm going to have to to replace this broken screw.

More learning ahead.

So let's start with the health of the movement before I started messing with it. This watch wasn't serviced after I bought it 9 months ago, and it's holding up pretty well:

A normal person would leave "good enough" alone... I'm not that kind of person.

Off we go... the process started out pretty well. No problems getting the case open, automatic module off, the movement out of the case, and the hands and dial removed. I've done those things a few times now, and they're starting to feel less scary; although I still go slowly and double / triple check things to make sure I'm not doing anything stupid (don't worry, stupid things happen on their own with me).

Unlike the VS3235 where the gen balance bridge fit nicely onto the VS mainplate, in this case, the gen balance bridge didn't fit well onto the noob 4130 mainplate, so I was going to have to use a broach to open up one of the screw holes.

I have an inexpensive set of six broaches (0.8mm to 2.3mm) that I bought from Perrin. I didn't have a good way of holding the gen balance bridge so I used a few layers of foam tape on a small movement holder to improvise a set of soft jaws and a vise. It worked pretty well.

Here's a pic of the balance bridge hole that I boached... I cleaned up the metal shavings with one of those little between your teeth tooth brushes, so it ended up being pretty clean.

With the balance bridge broached, I was able to fit it nicely into place on the movement, and use the movement as a jig to connect the balance hairspring bridle to the balance bridge hairspring stud. Hat tip to Triplock for the suggestion to do it this way.

Next was swapping out the chronograph seconds wheel for the gen part. The gen part in a beautiful LIGA gear which is also a spring for gripping the teeth of the wheel driving it. These spring teeth basically eliminate backlash, meaning that the chronograph seconds hand should sweep more continuously than with the standard brass tooth gear which will cause the chronograph seconds hand to stutter from time to time.

The install was pretty simple, I simply needed to remove the chronograph bridge and pull out the noob part and drop in the gen. However, getting the chronograph bridge re-installed wasn't easy. There's a part called the "Jumper for counters" (part no. 4130-834) which sits under this bridge near the crown... this part is both incredibly delicate, and incredibly annoying to get aligned properly so that its pivot rests in the jewel in the chronograph bridge. This took me a couple of tries. But I eventually got it installed.

But just as I'd secured the chronograph bridge and was about to start the process of getting the dial and hands back on, I flipped the movement over, and something fell off it and hit the floor. I froze (remembering the hours I'd spent hunting screws when I first started tinkering with movements a few months ago. But this time, I was able to find the offending part reasonably easily... it was a screw. Or it was part of a screw. The screw holding down the Hammer Jumper (part no. 4130-883) had sheared off at the head.

Here's a pic showing the movement with the missing screw head (look just above where the winding stem enters the movement).

This has me pretty worried. I'm sure I'll be able to find a replacement screw since I have a few spare rolex clone movements laying around... but I'm worried I won't be able to get the broken screw out. At least the screw didn't break flush to a plate or a bridge. If I take the movement apart, I'll be able to remove the Hammer Jumper and that will give me a few millimeters of threaded screw stem to work with. Regardless, this is turning into a project that's more involved that I'd hoped. I really didn't want to have to dis-assemble the entire 4130 chronograph works. But I have a feeling that I'm going to have to to replace this broken screw.

More learning ahead.