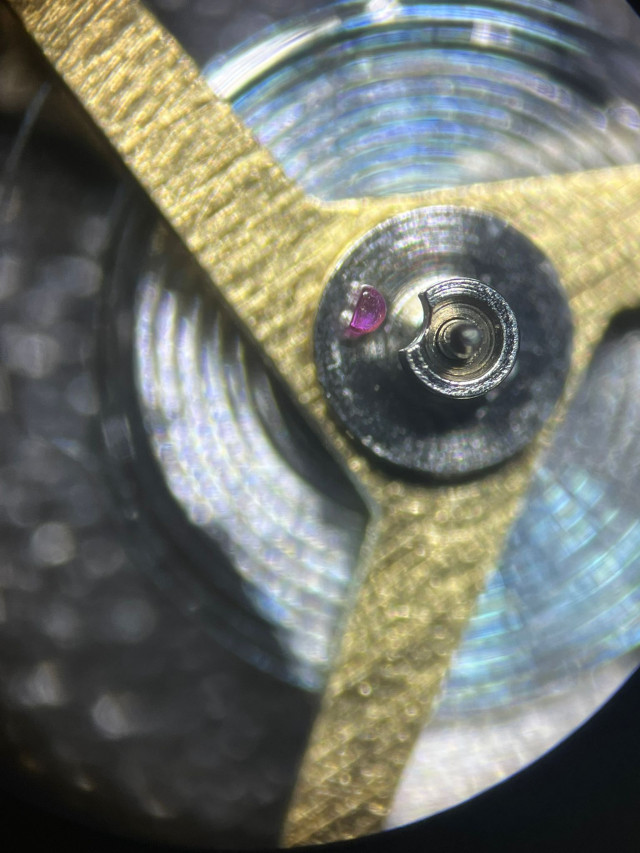

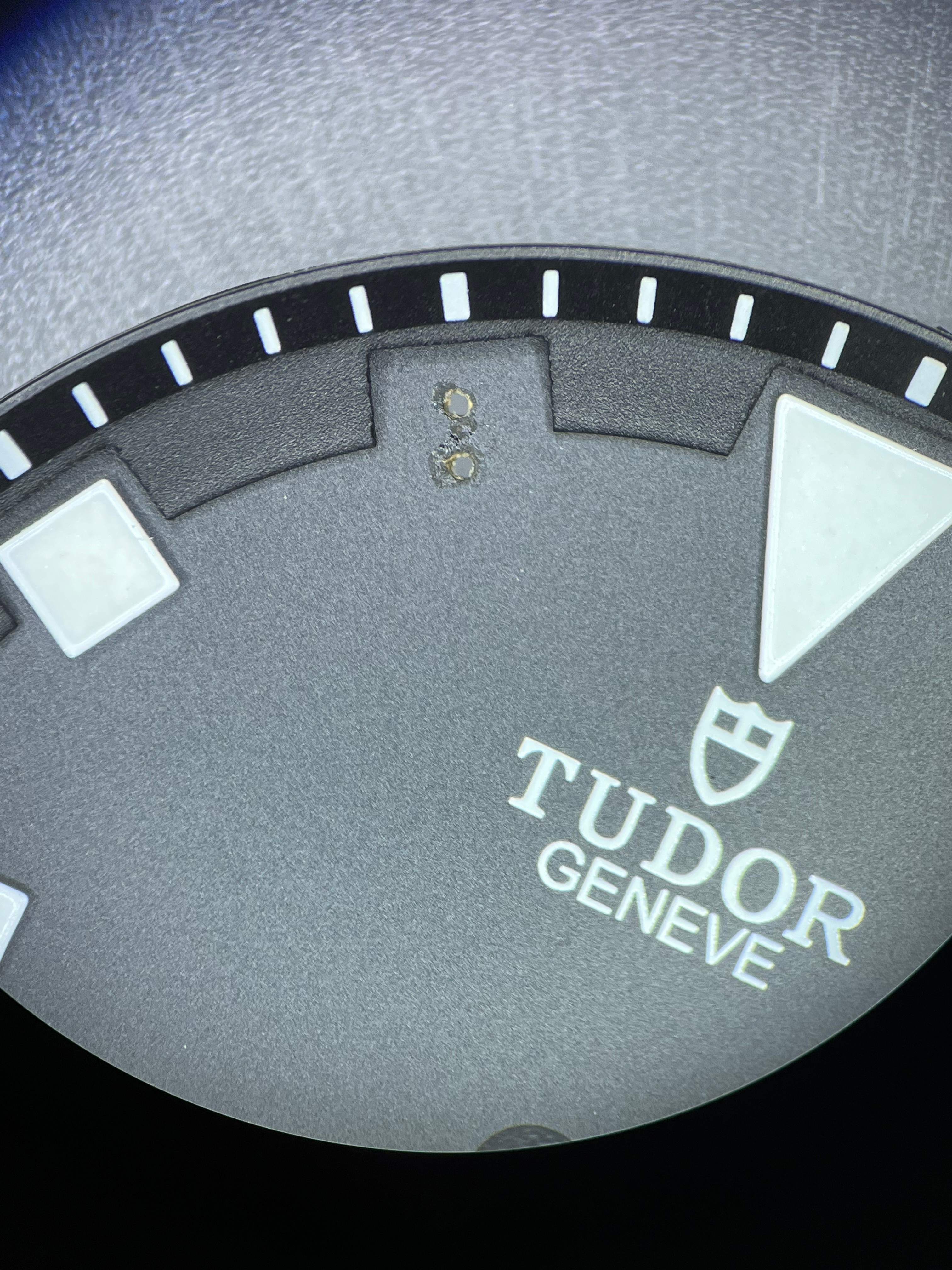

The Explore's Stone.

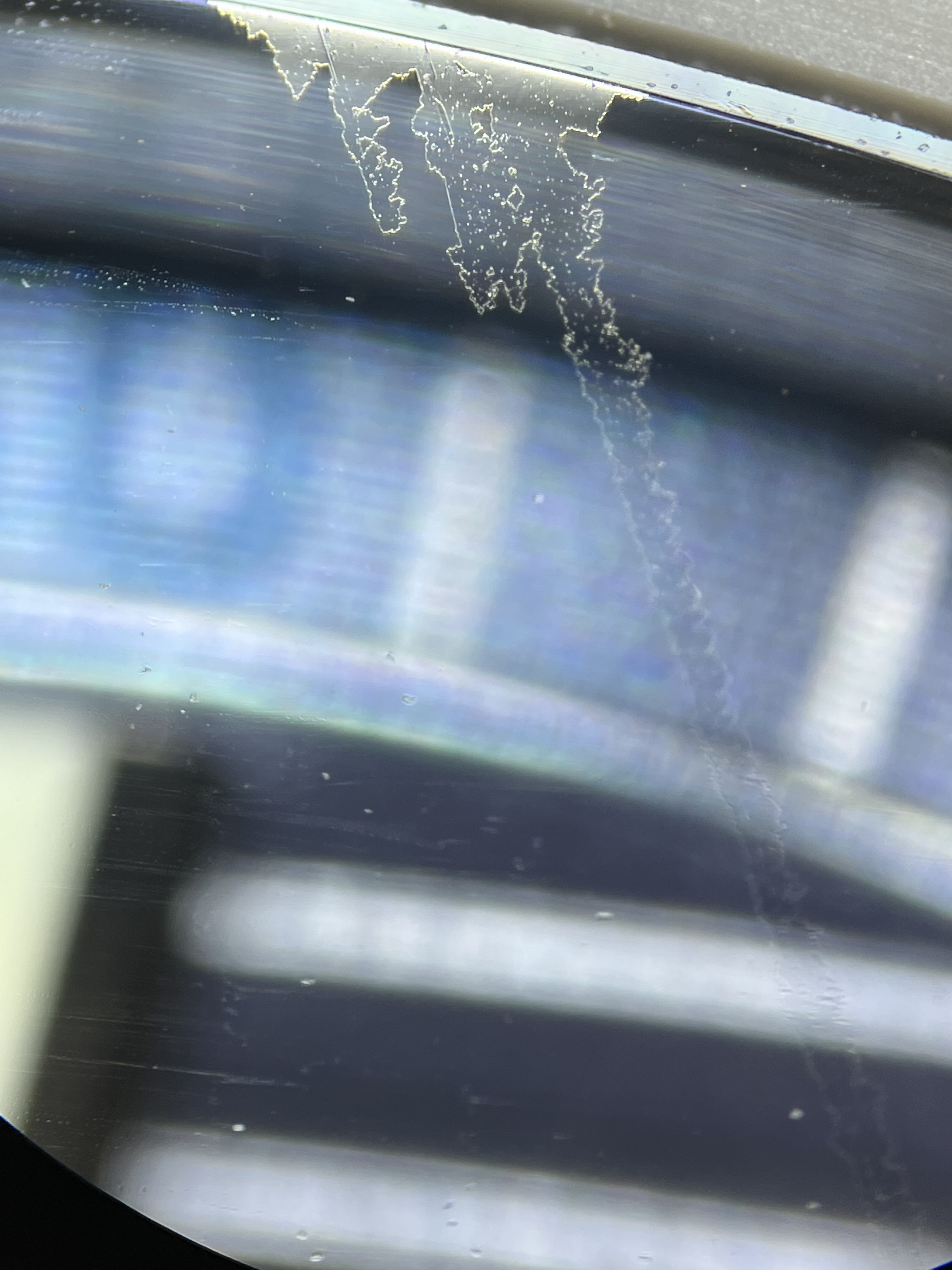

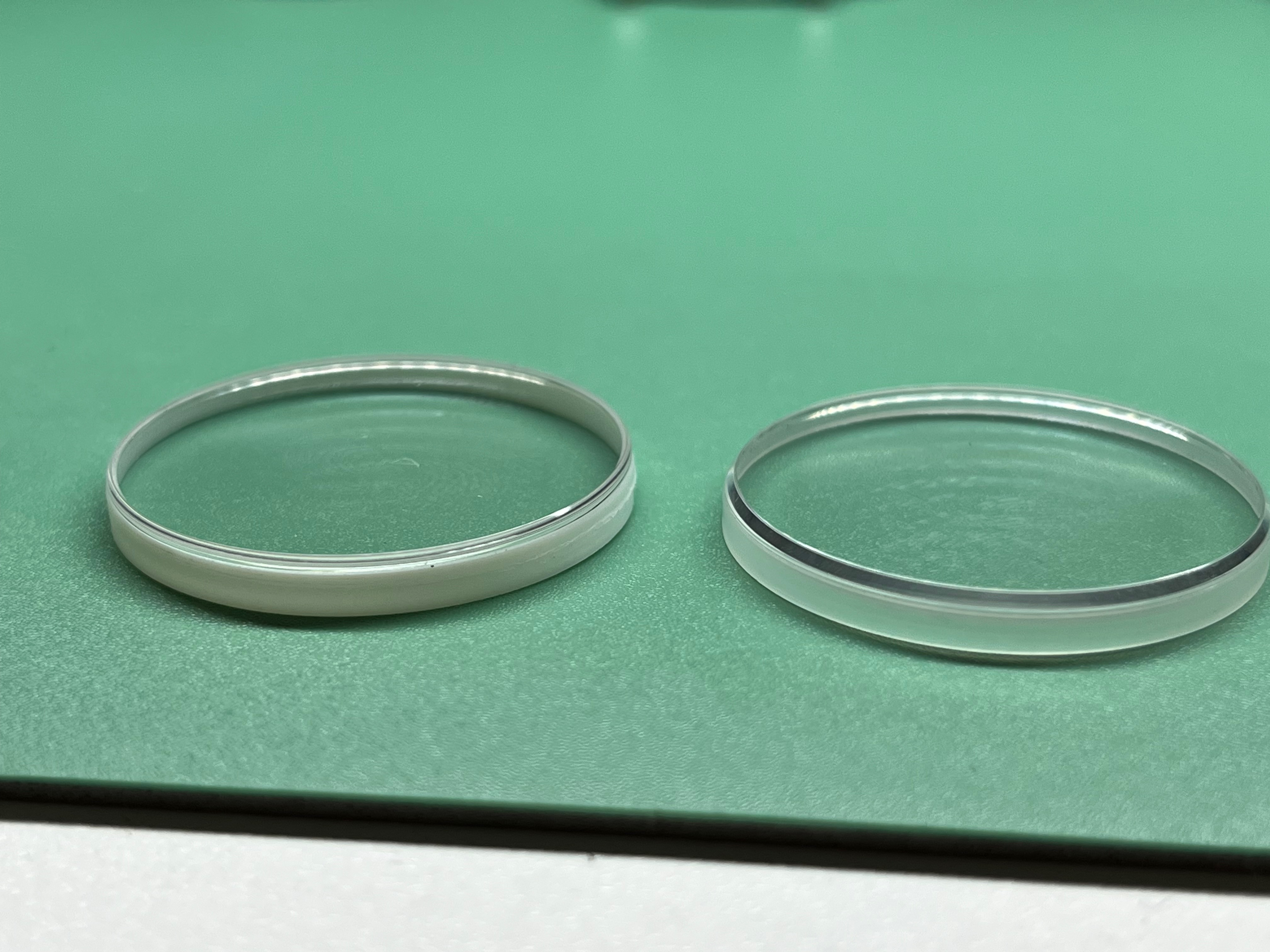

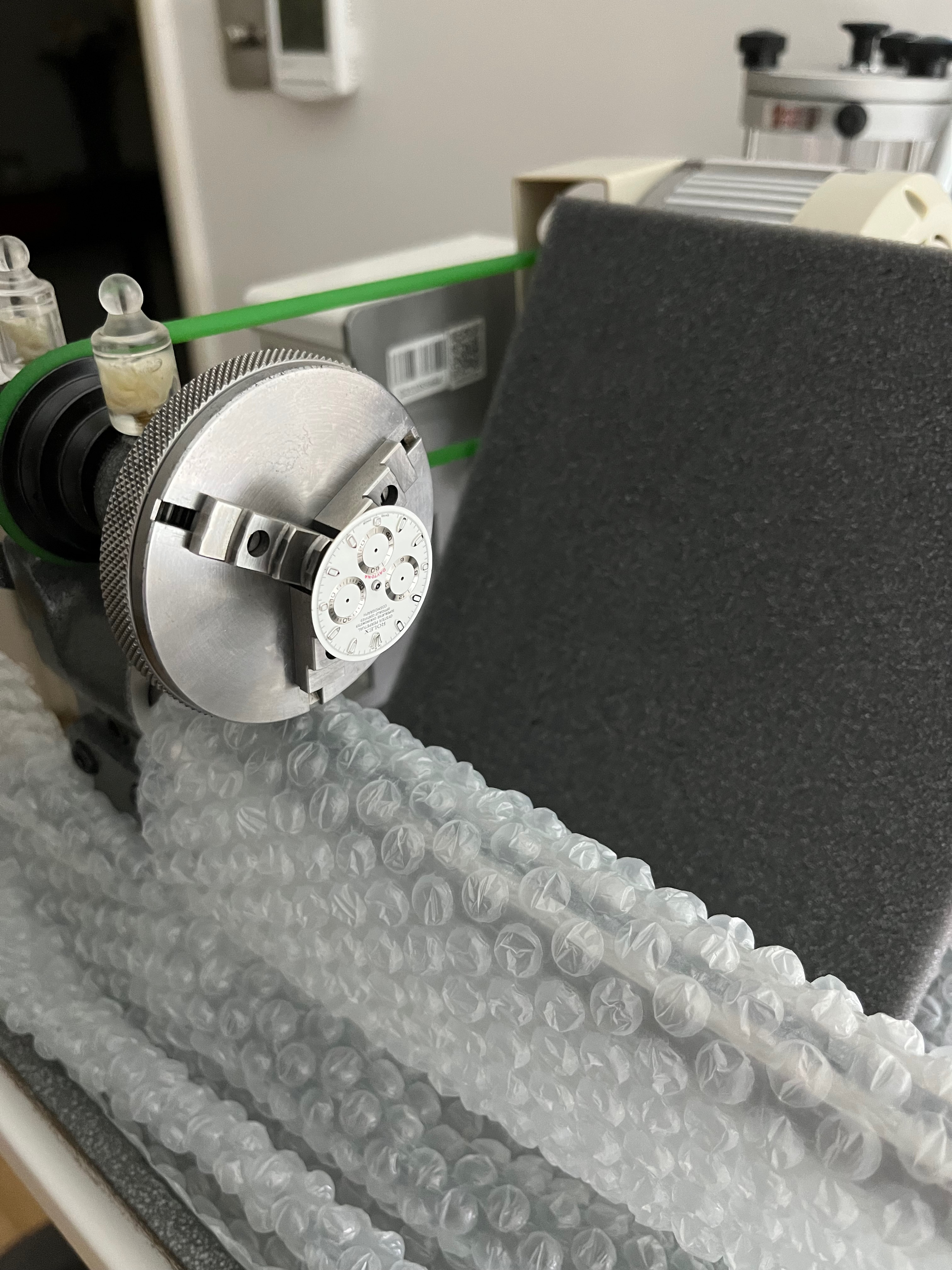

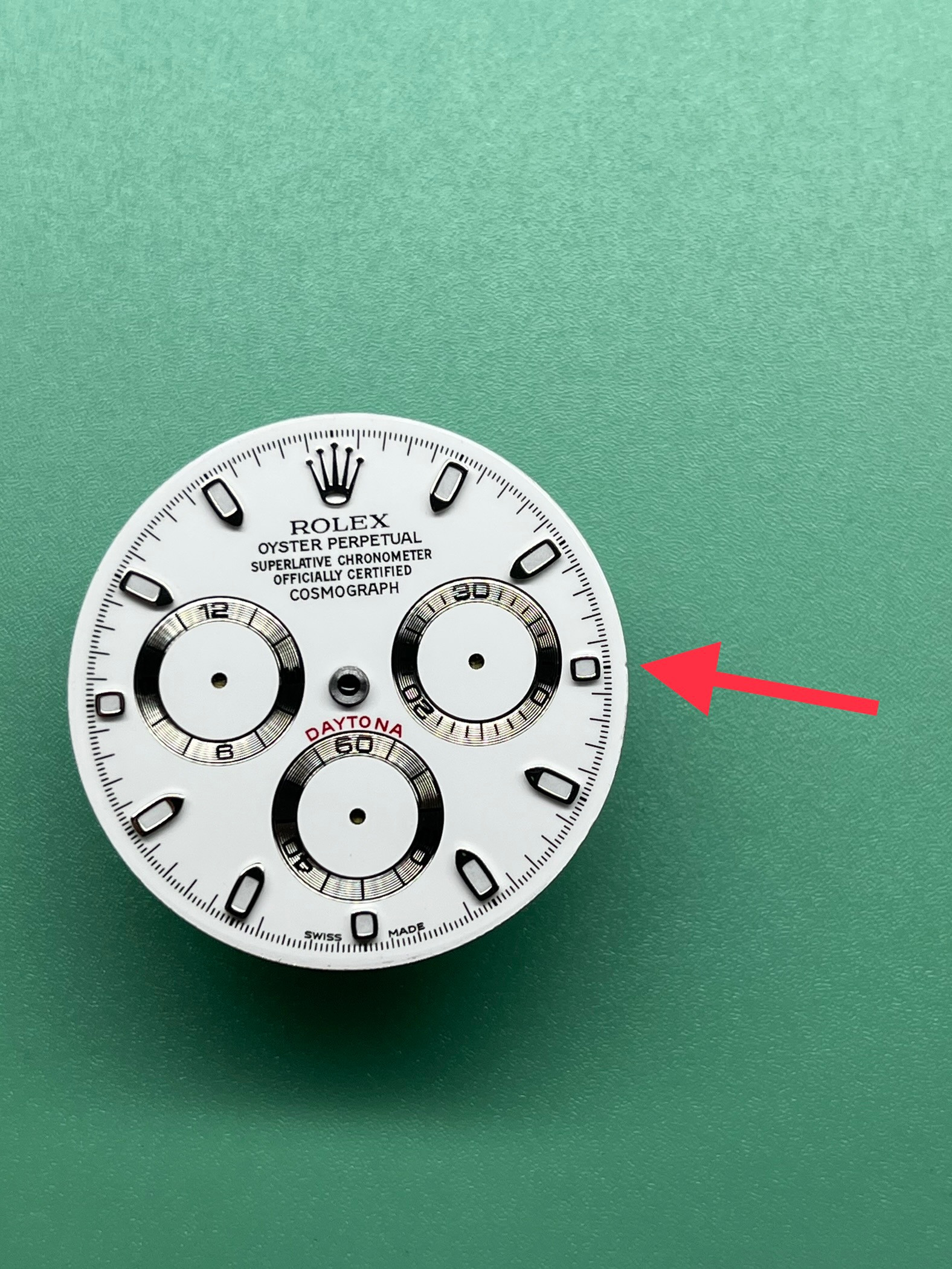

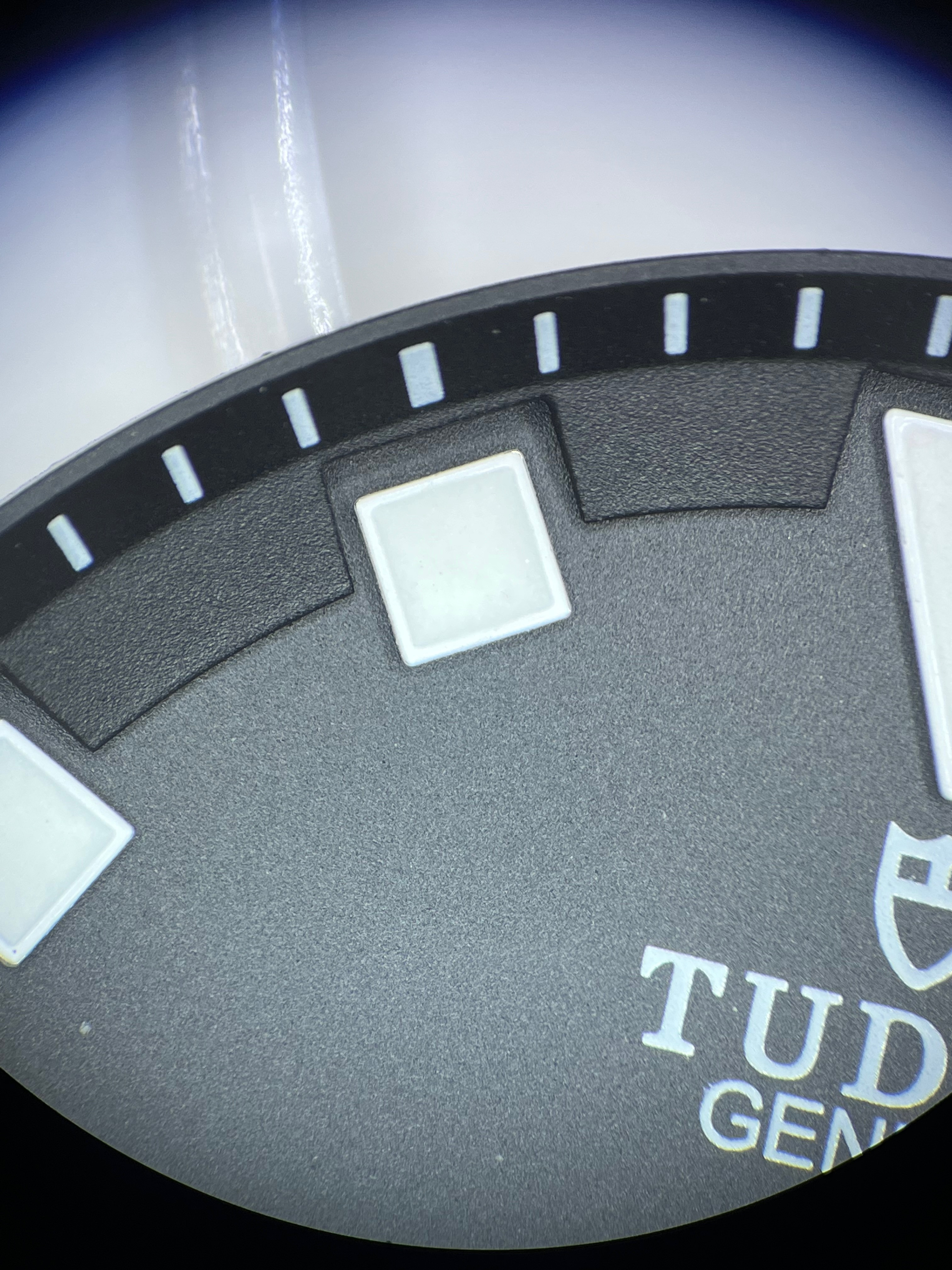

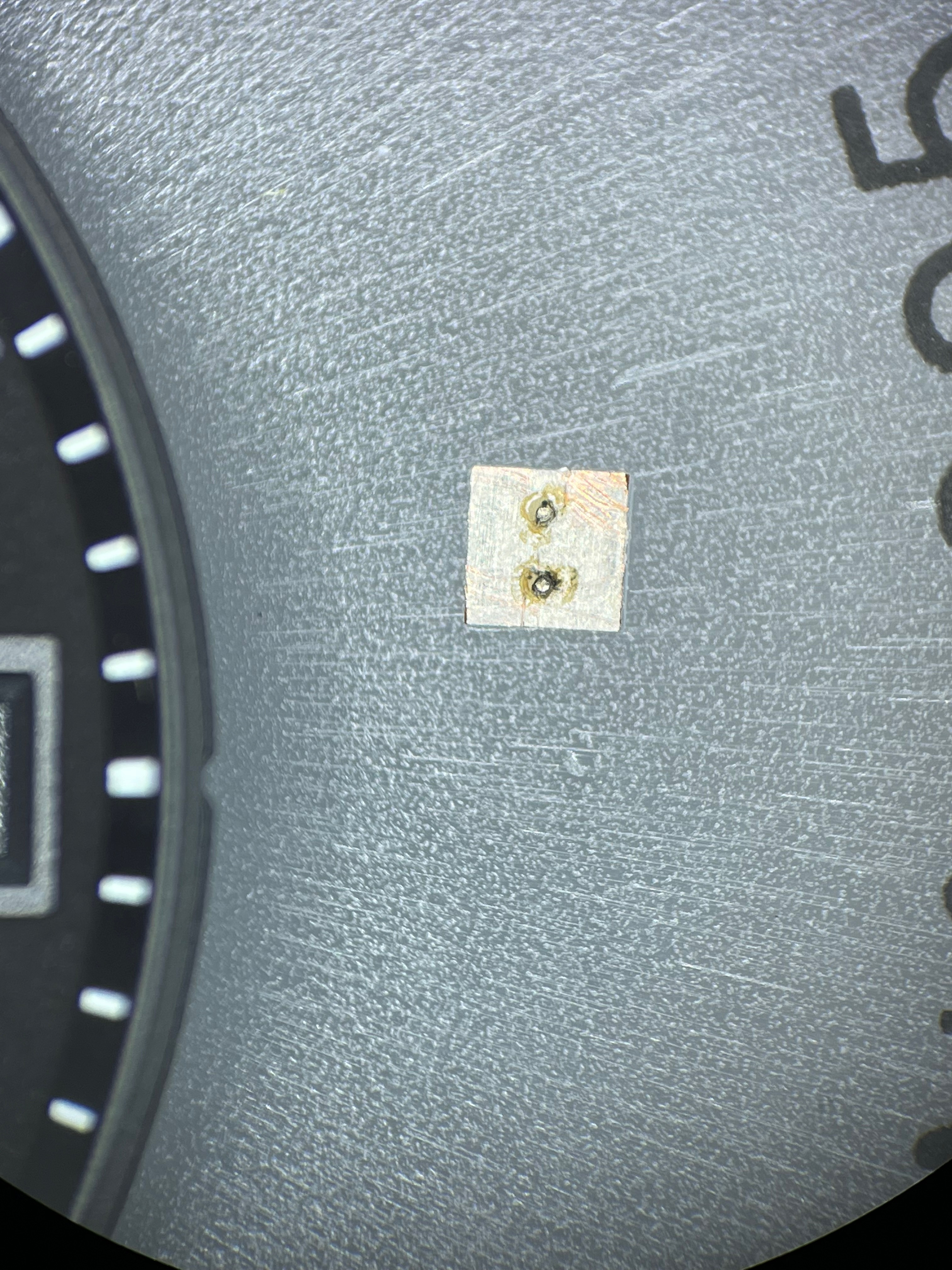

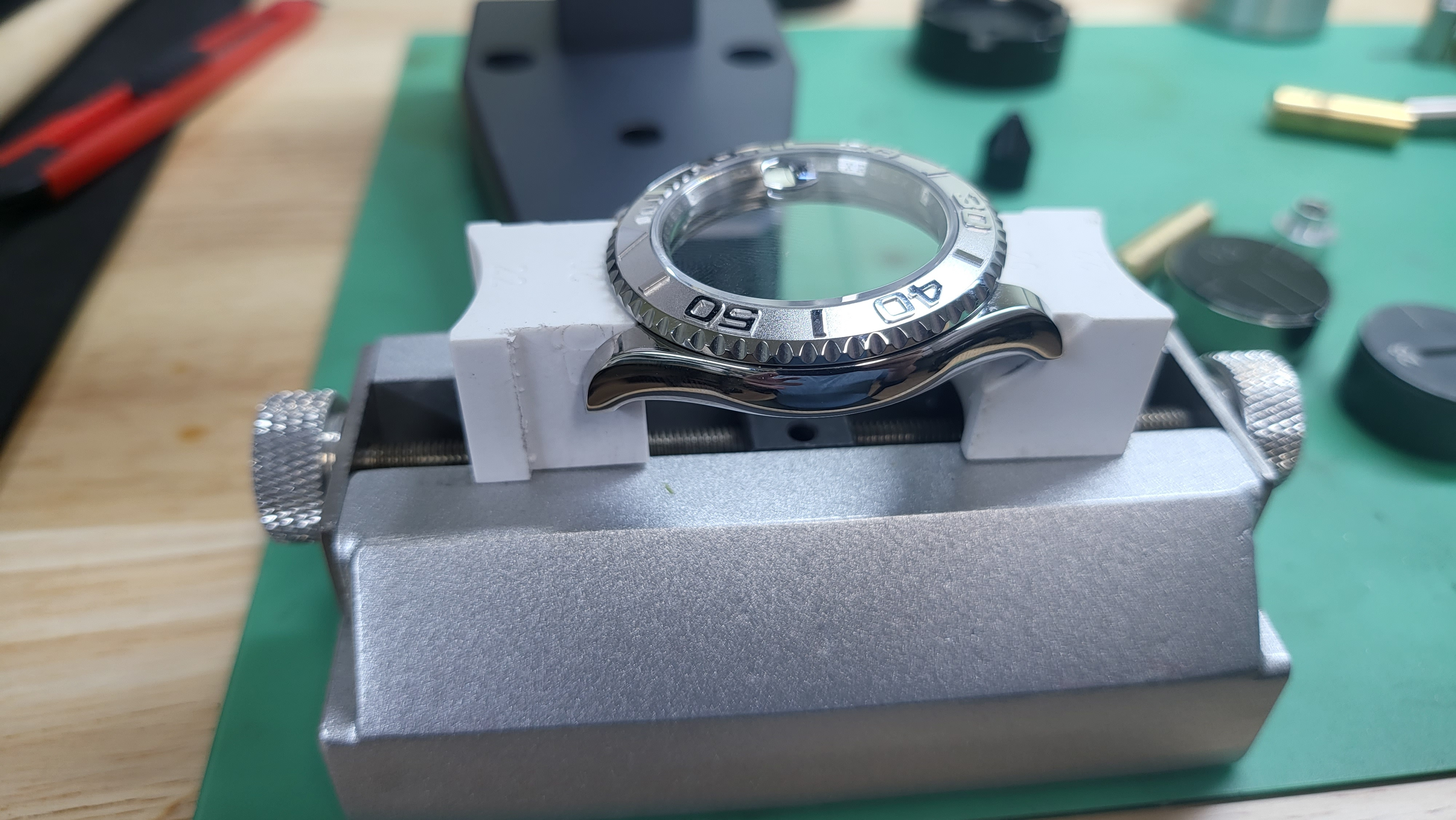

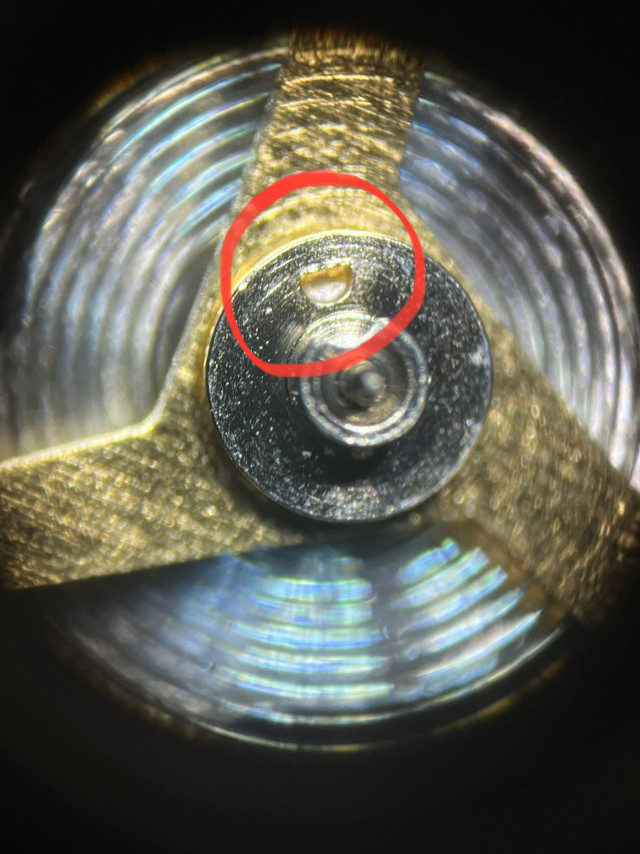

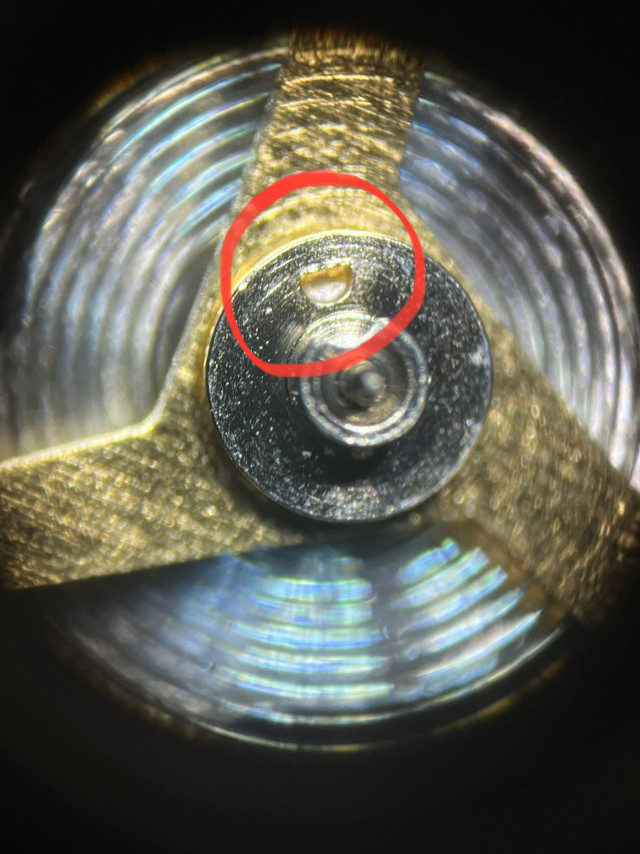

Another Indiana Jones adventure? Almost, a trusty and well loved 3 year old Explorer which seized up and lost its impulse stone (roller impulse pin jewel).

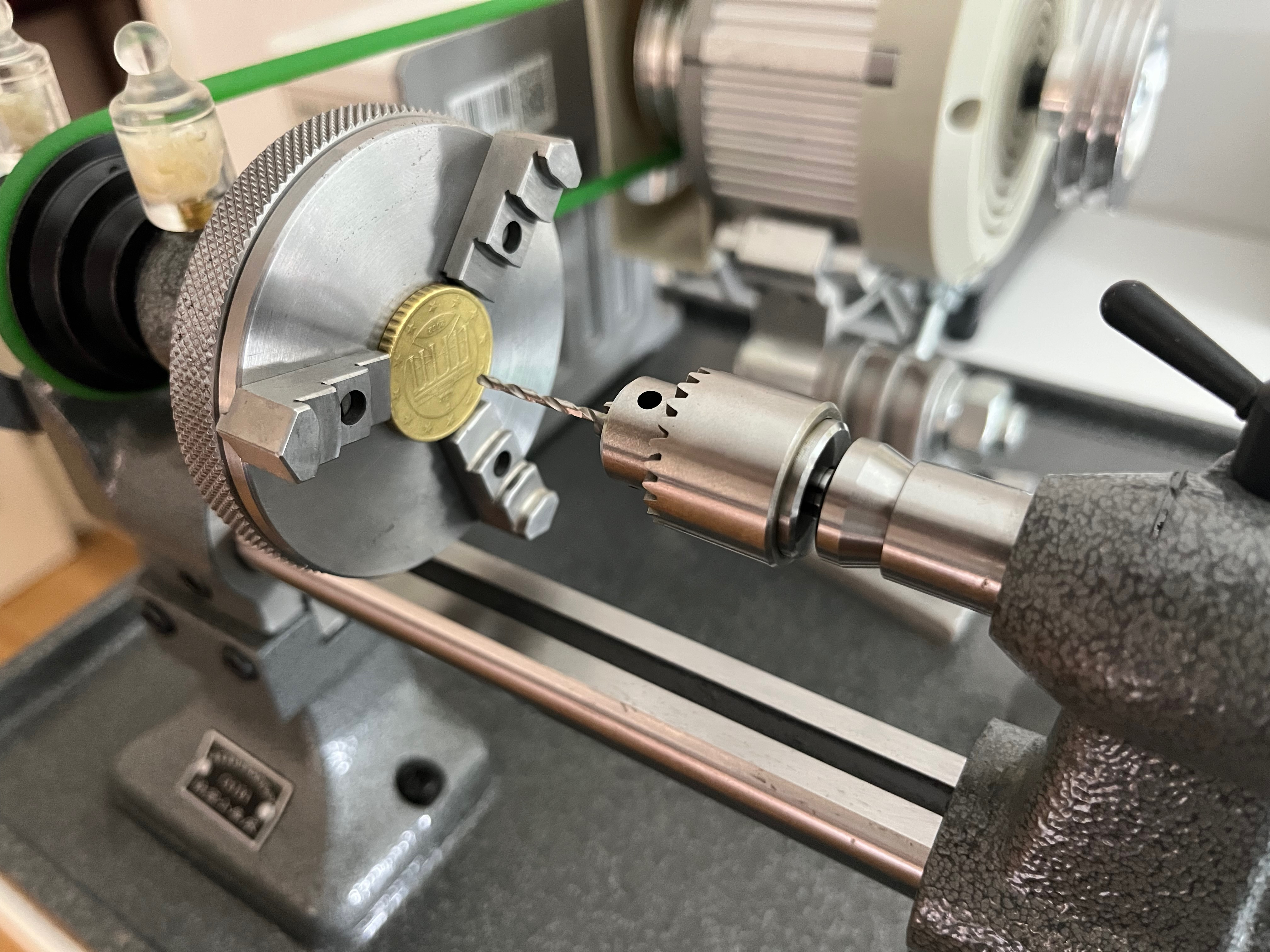

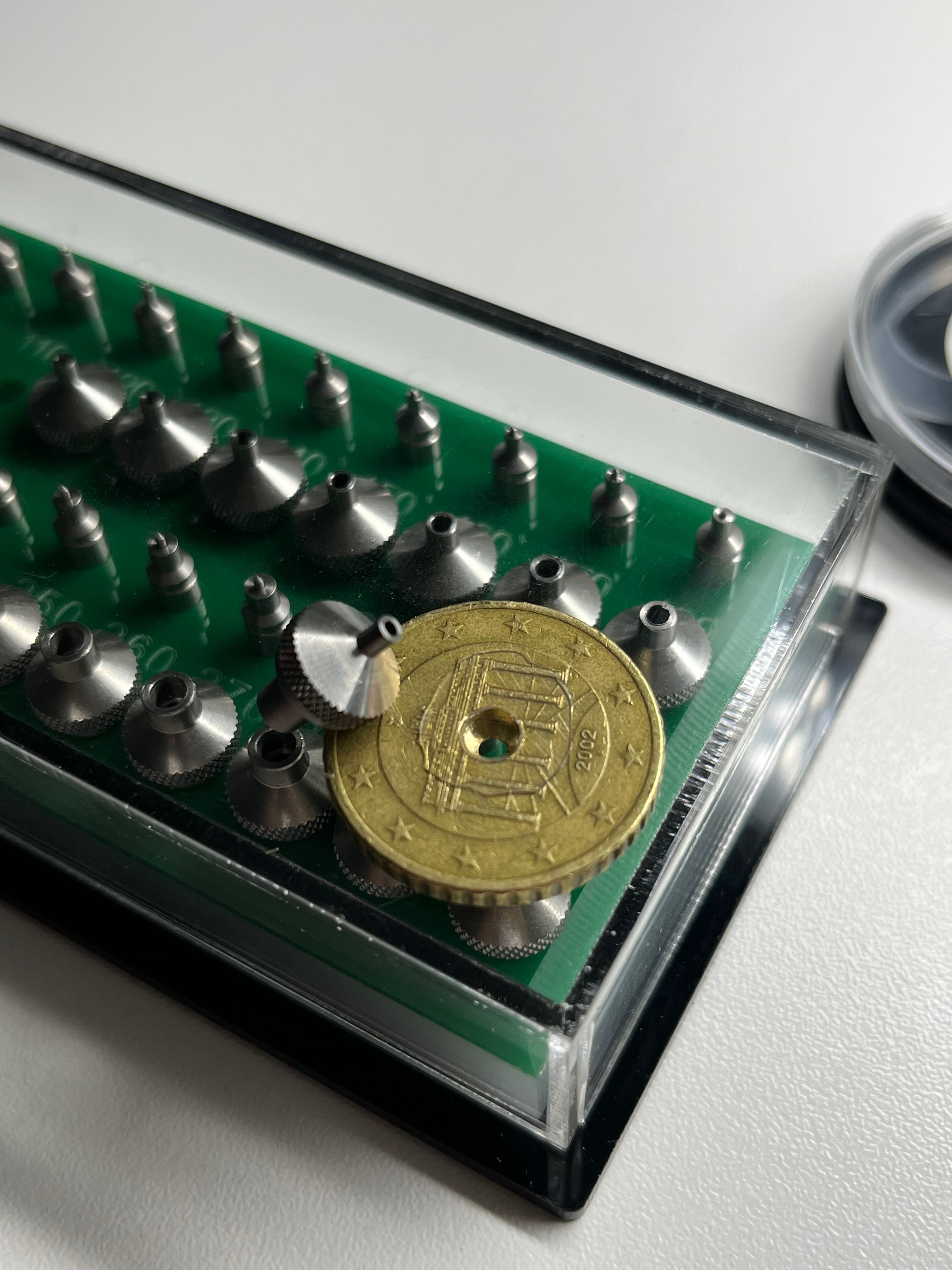

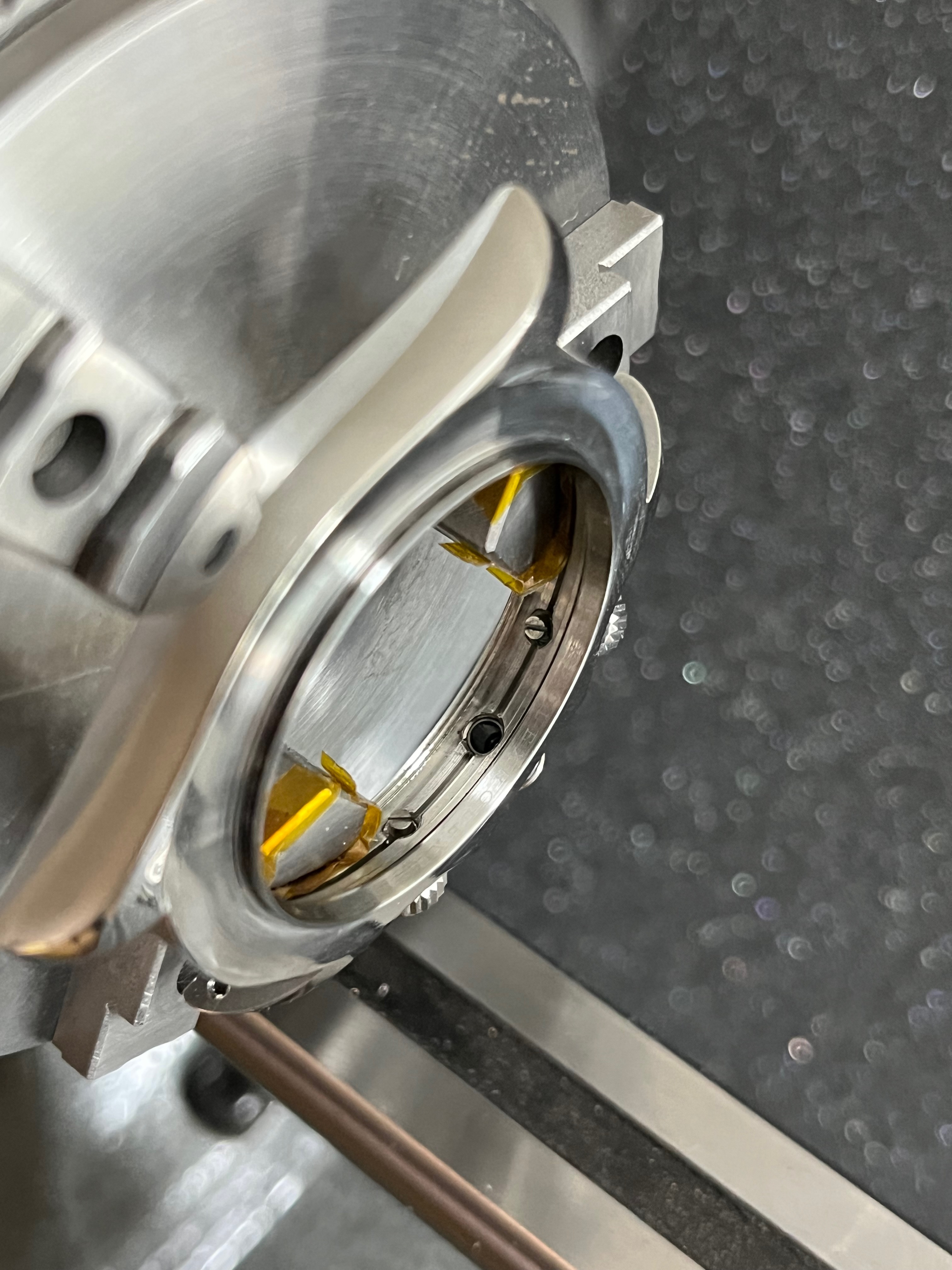

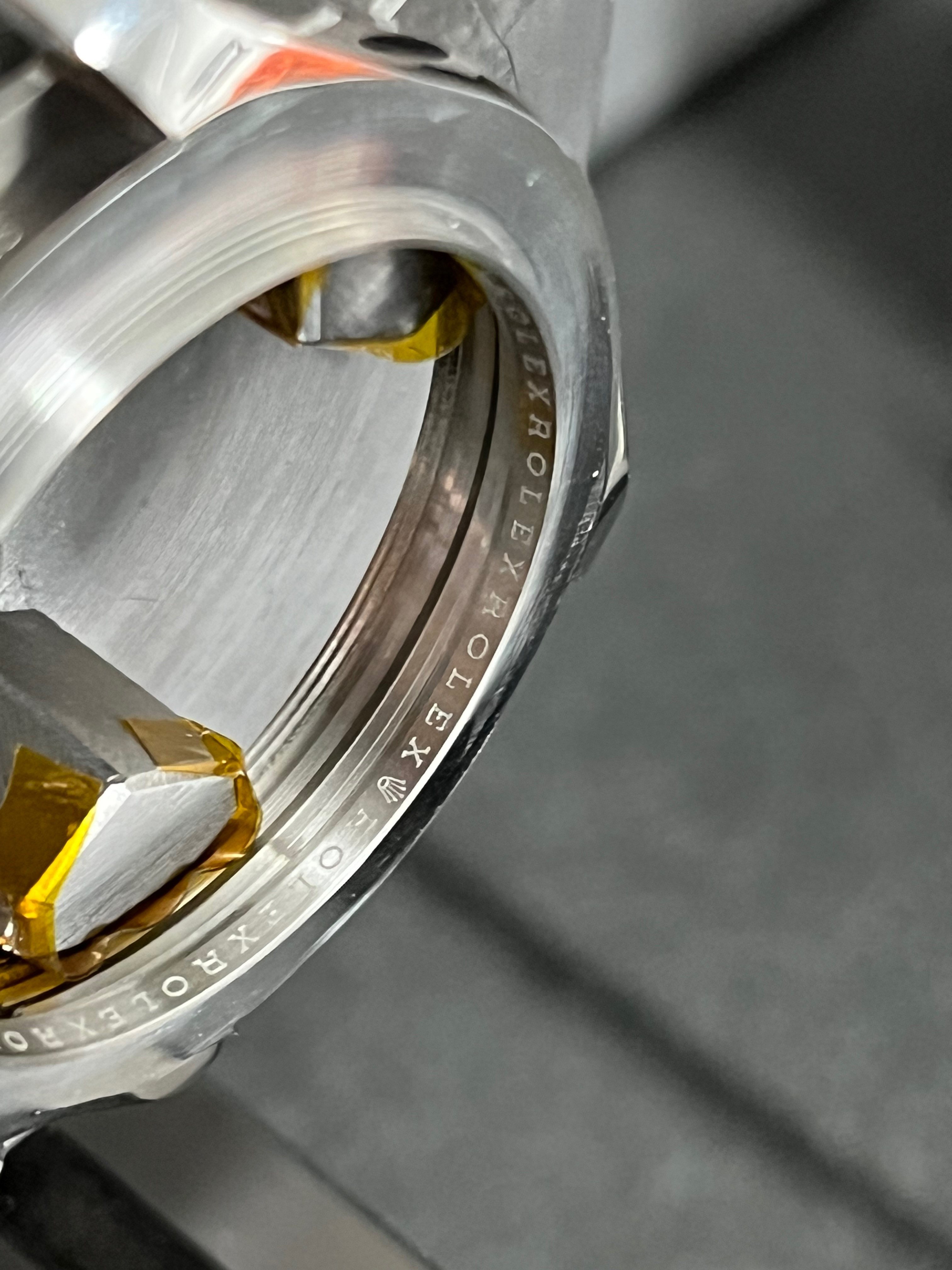

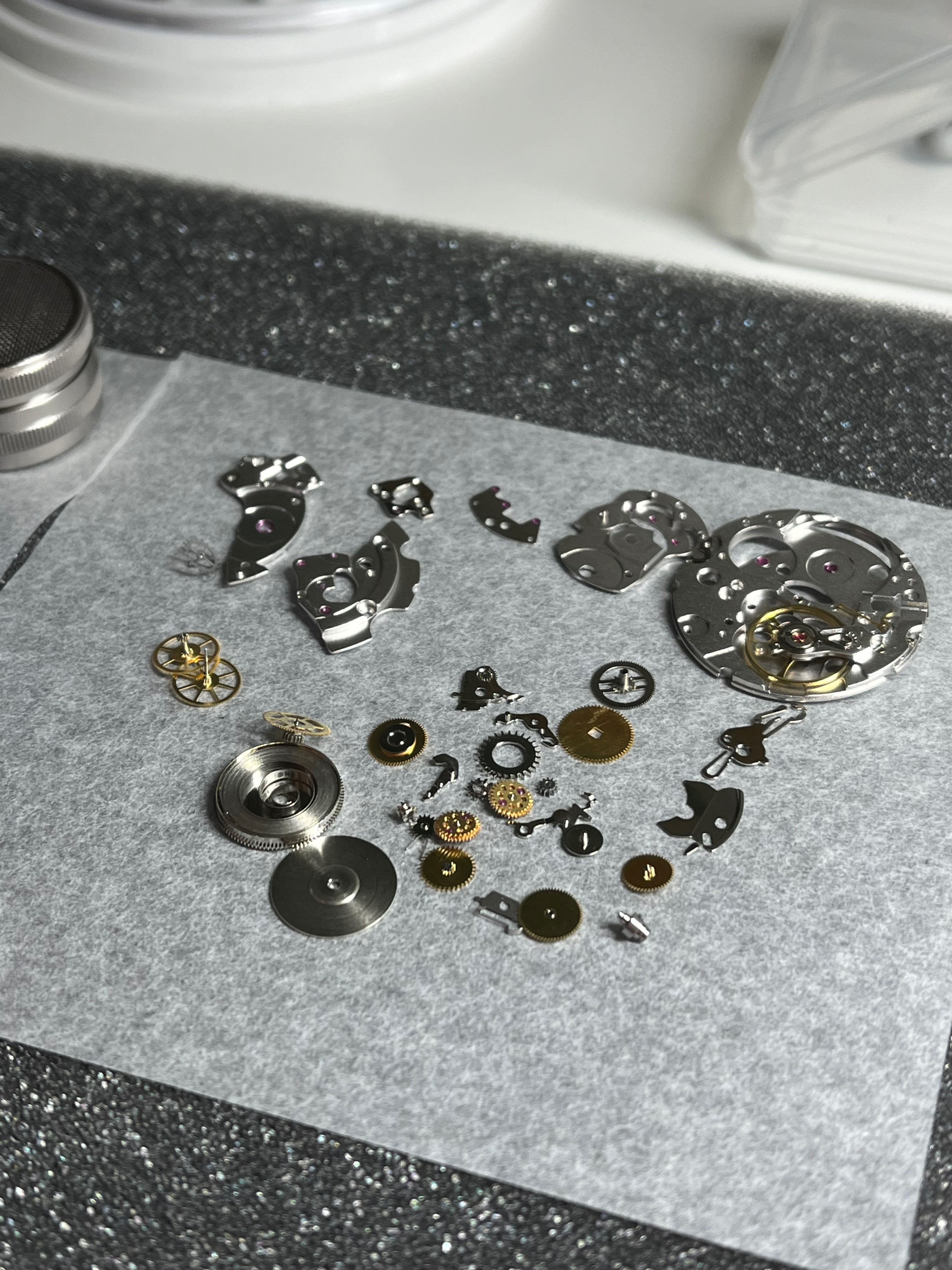

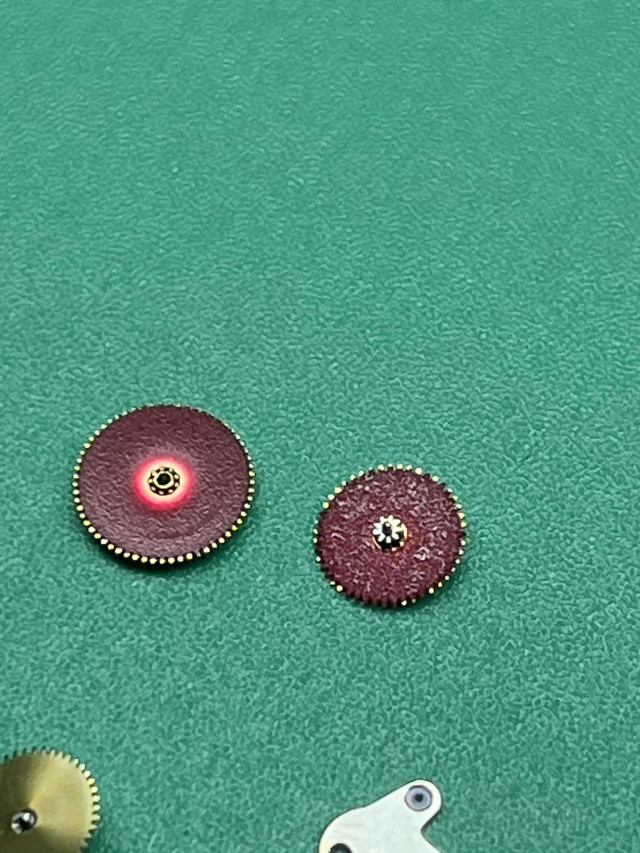

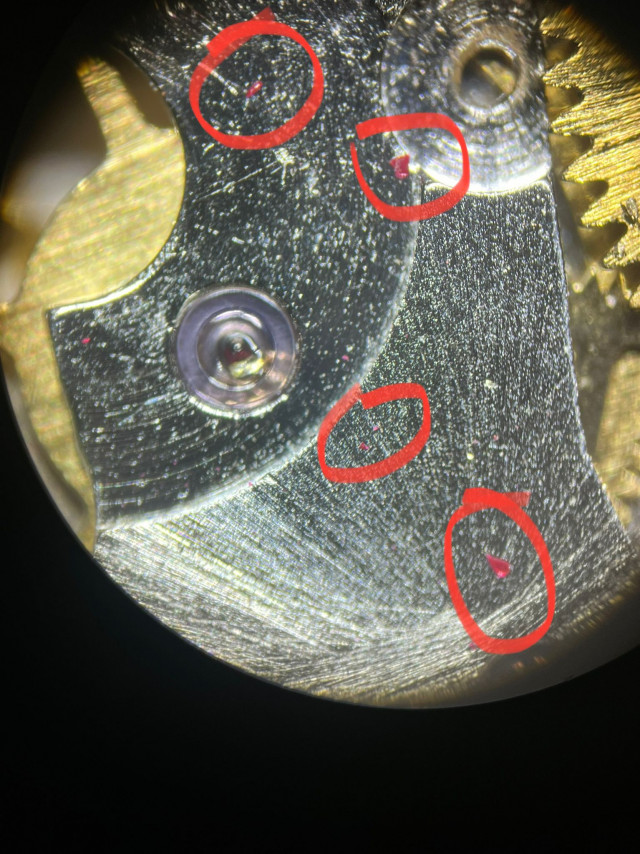

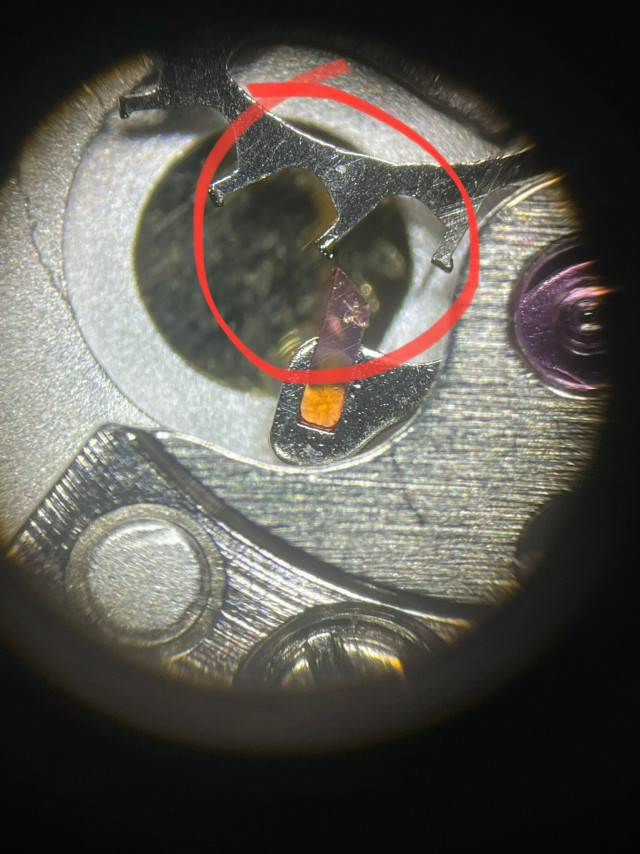

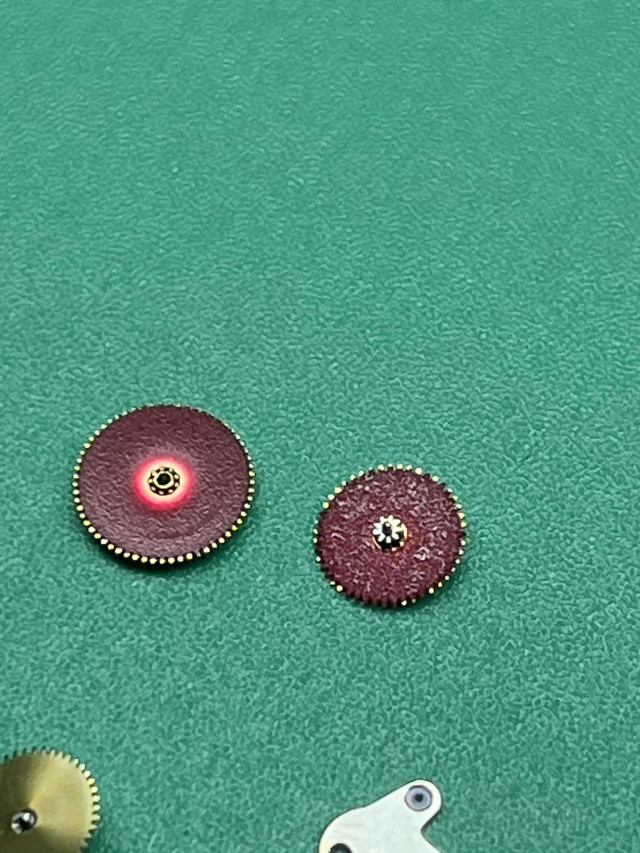

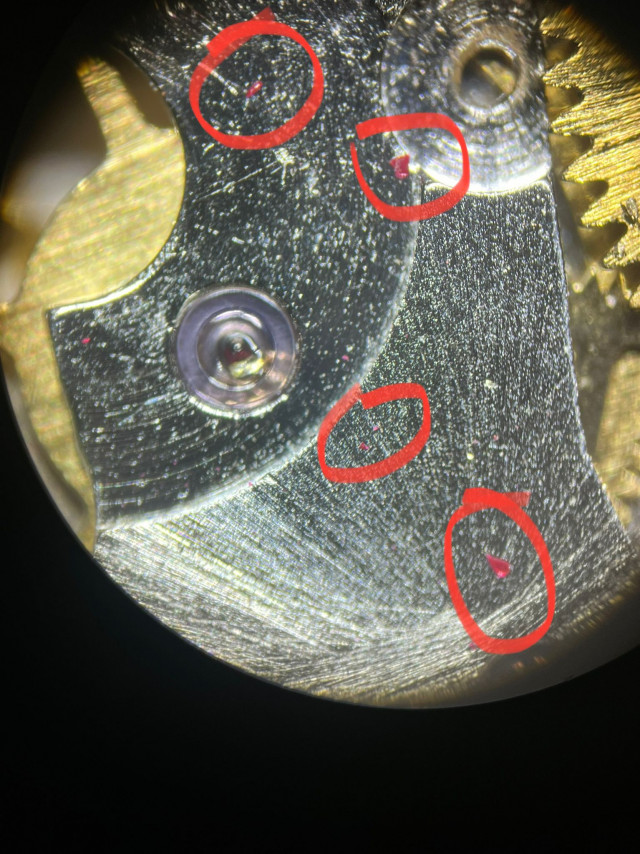

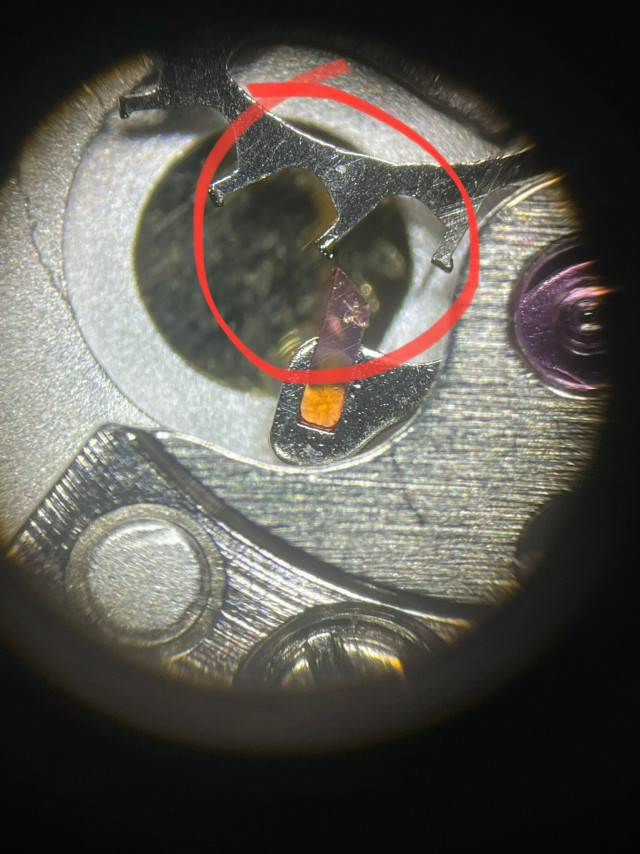

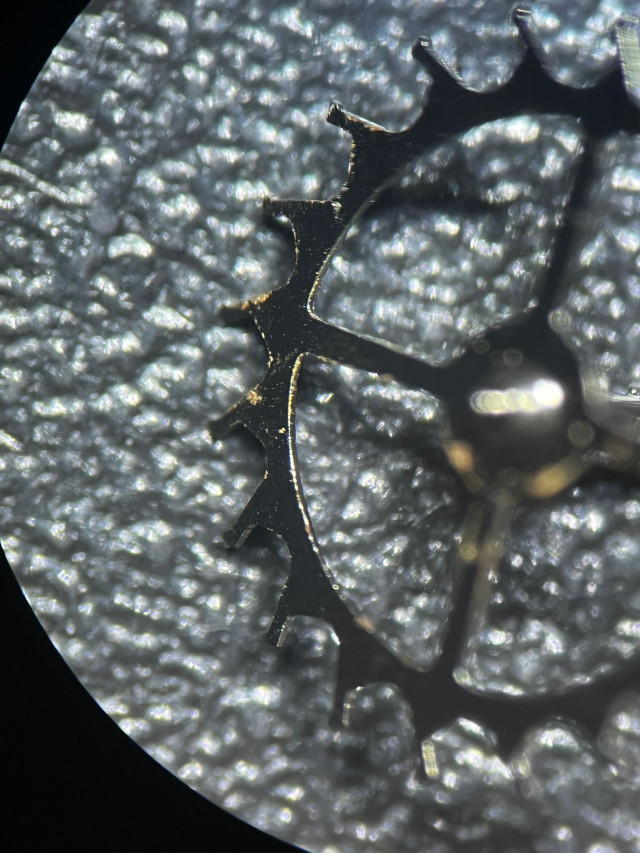

A decorated Asian 2836 with red painted auto wheels. Over time the paint flaked and spread around the movement. That mixed with poor quality oils from the factory, turned into the perfect formula for disintegrating parts. The pressure resulted into the balance impulse jewel to make a run for it.

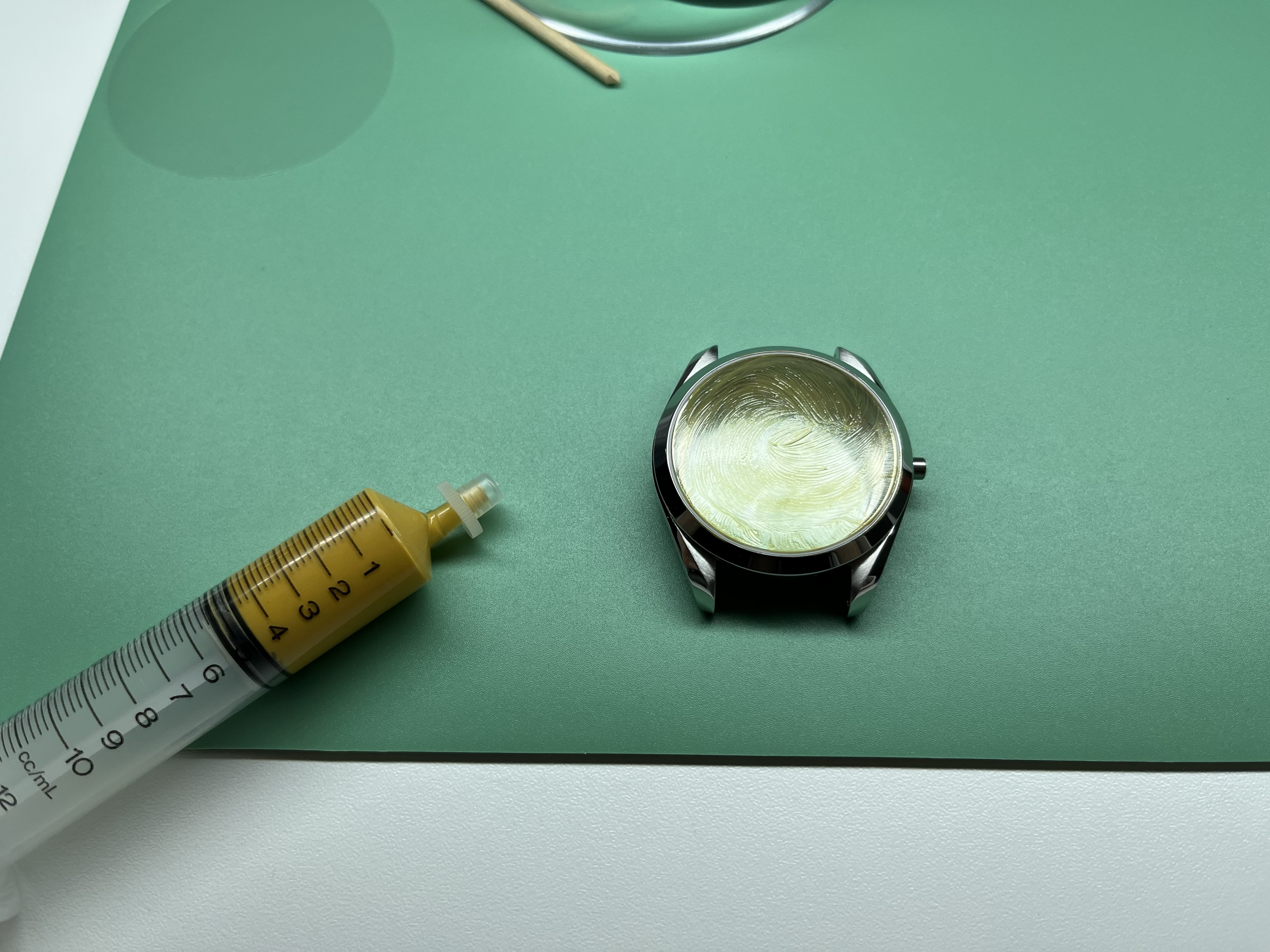

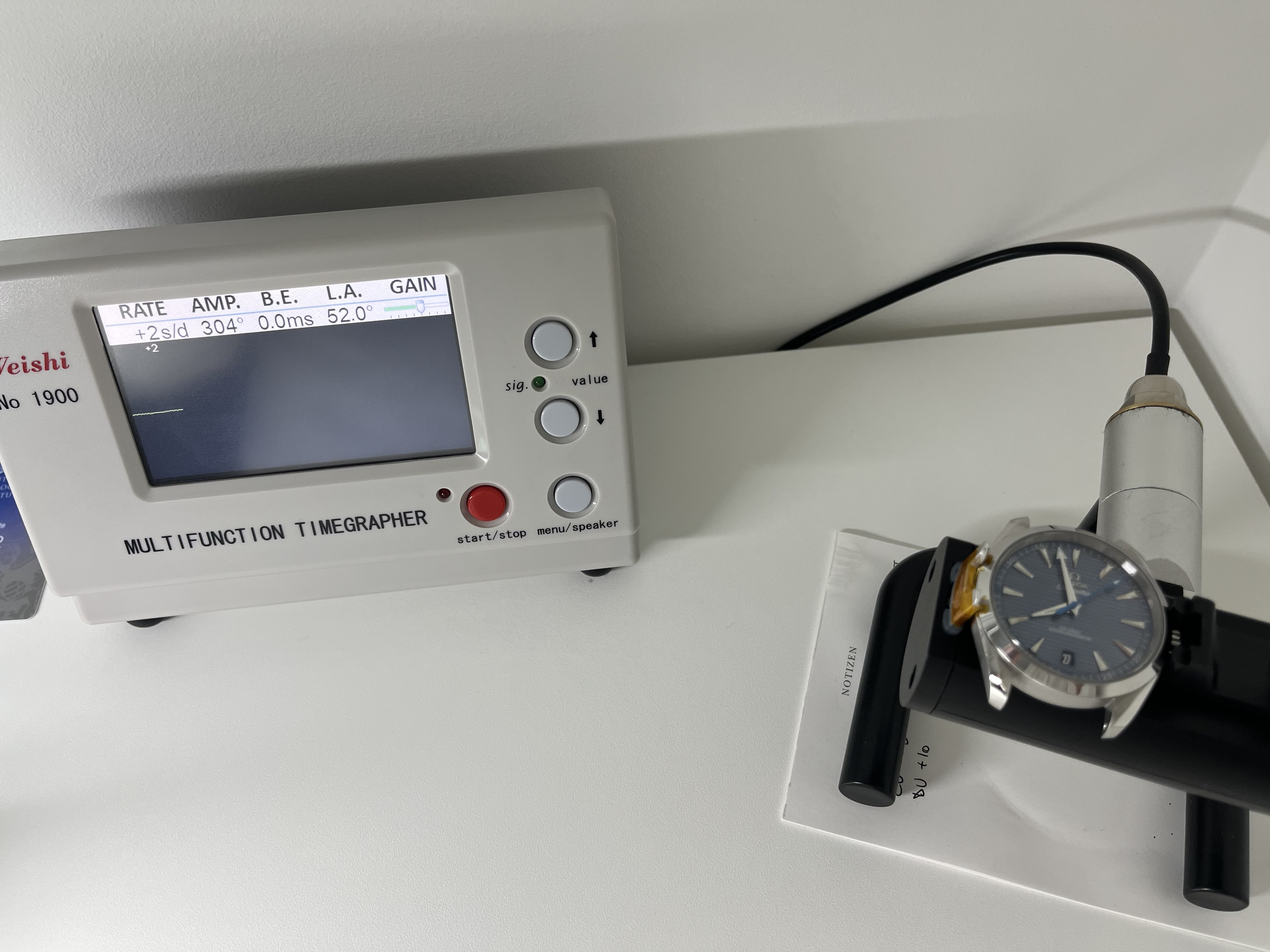

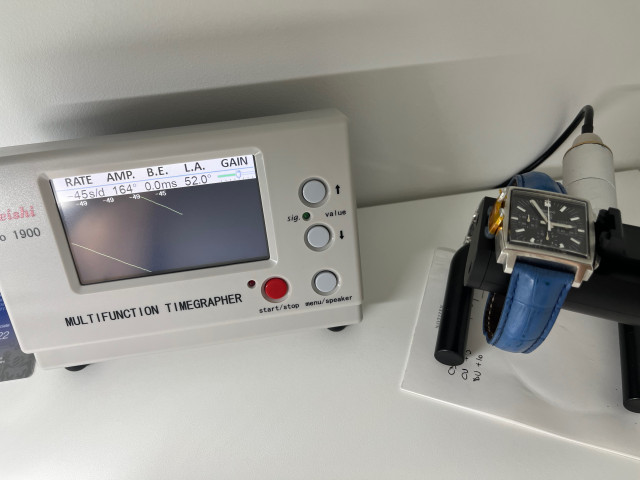

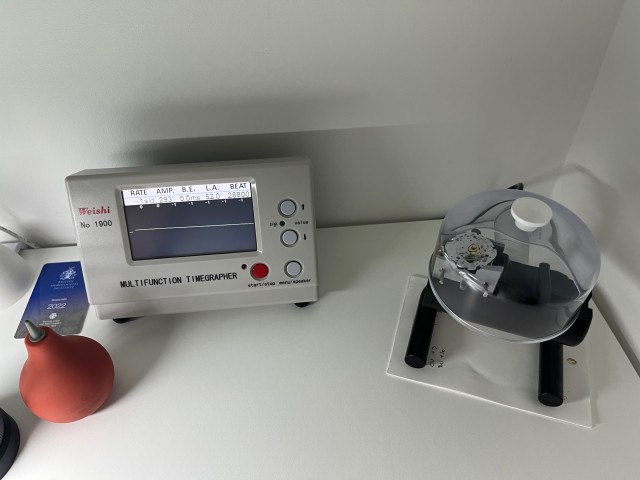

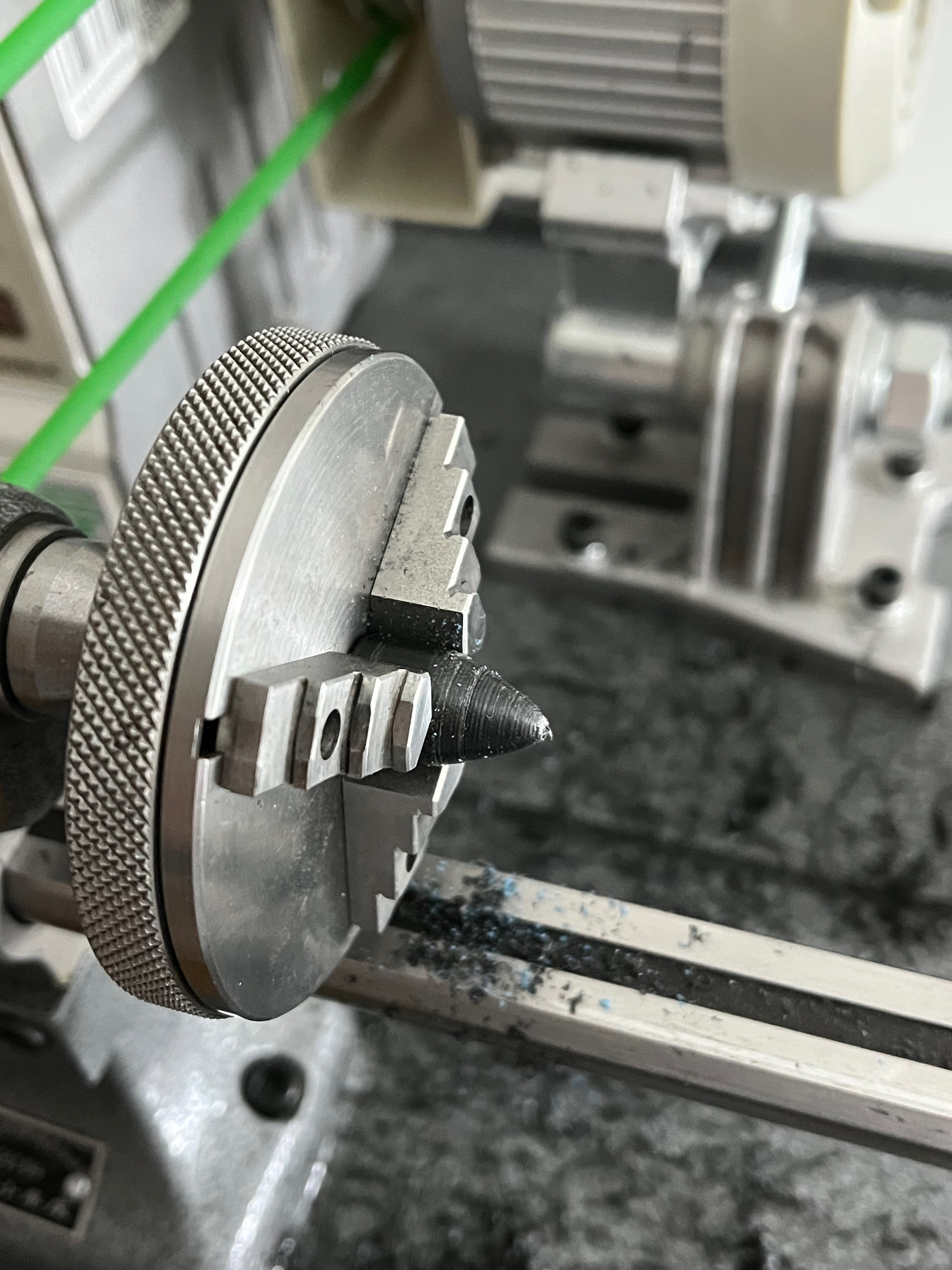

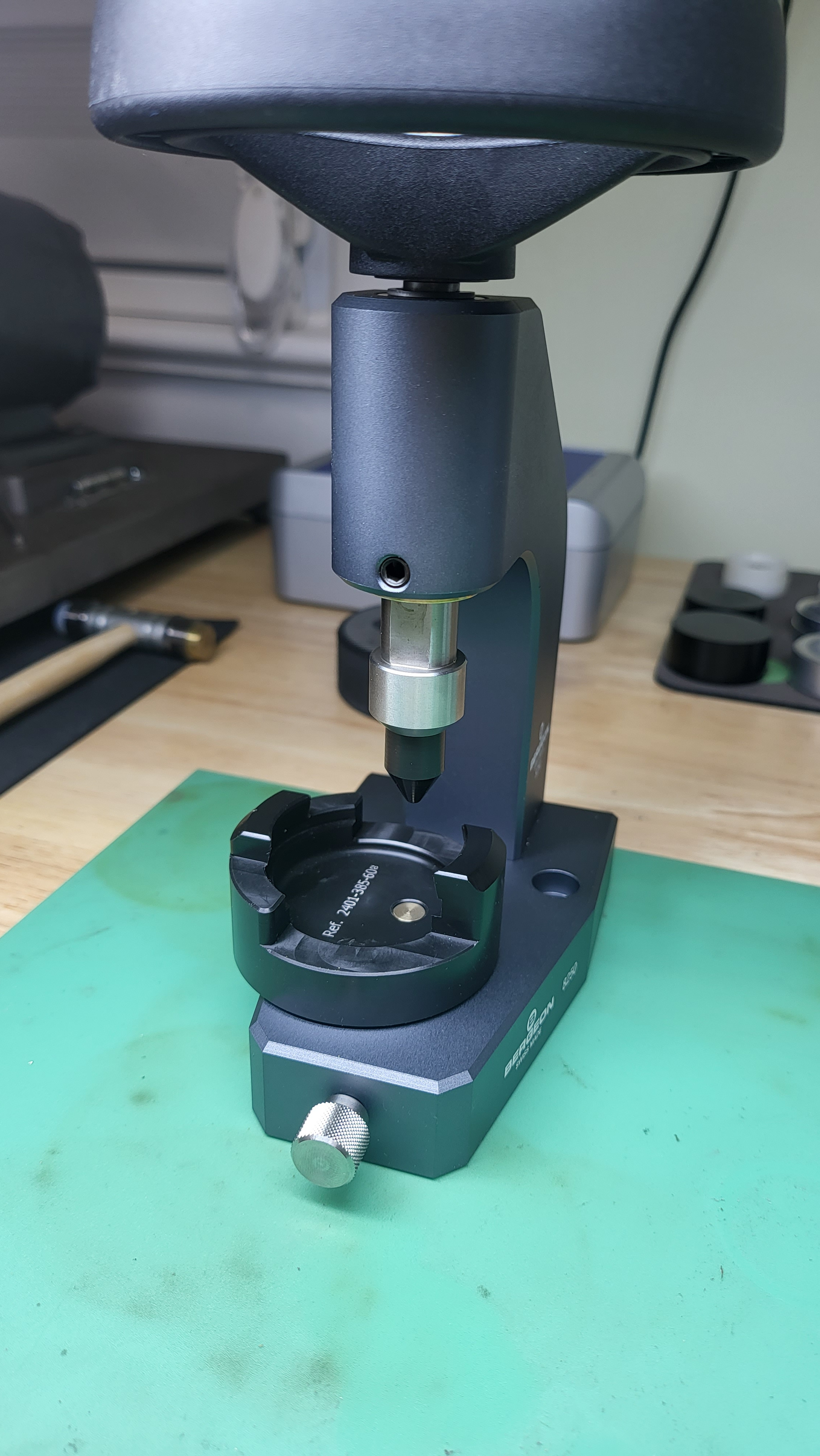

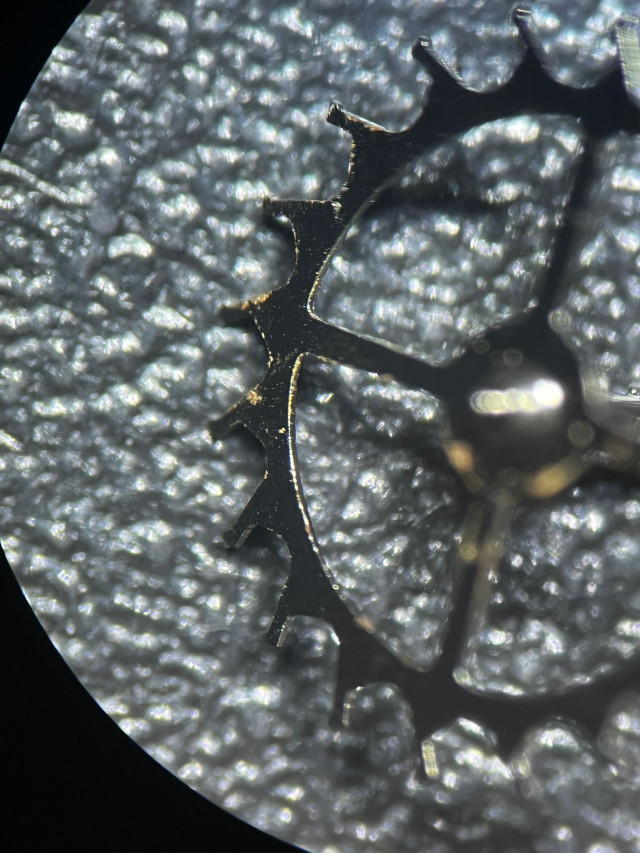

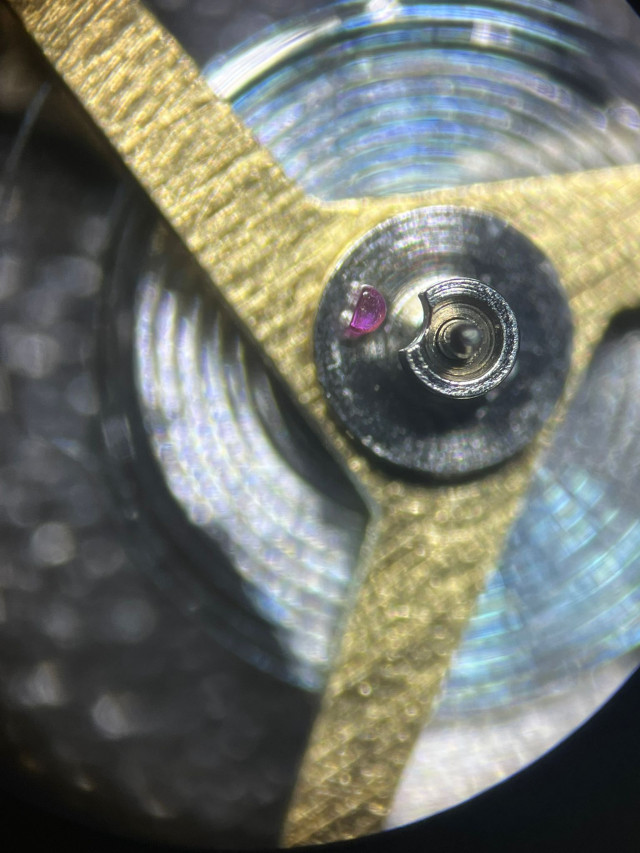

As this is a solid movement with plenty of replacement parts available, the impulse jewel, ETA genuine auto wheels and escape wheel all replaced, plus a full service, had it ready for its next adventures

Another Indiana Jones adventure? Almost, a trusty and well loved 3 year old Explorer which seized up and lost its impulse stone (roller impulse pin jewel).

A decorated Asian 2836 with red painted auto wheels. Over time the paint flaked and spread around the movement. That mixed with poor quality oils from the factory, turned into the perfect formula for disintegrating parts. The pressure resulted into the balance impulse jewel to make a run for it.

As this is a solid movement with plenty of replacement parts available, the impulse jewel, ETA genuine auto wheels and escape wheel all replaced, plus a full service, had it ready for its next adventures