-

Tired of adverts on RWI? - Subscribe by clicking HERE and PMing Trailboss for instructions and they will magically go away!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

"The Official Big Crown Club" - post your pics!

- Thread starter GC

- Start date

My first rep build and decal dial

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

I’ve got a feeling like I’m going to ask a daft question and take some crap for it, anyway does anyone on here have either the technical drawings or a 3d model of the 6538 case? I have access to both CNC lathes and mills and I wouldn’t mind having a go at machining my own. And could anyone tell me if Ruby’s case is close? If I can’t get the drawings or model I could get one of Ruby’s and rip the dimensions of that.

deadpan

Active Member

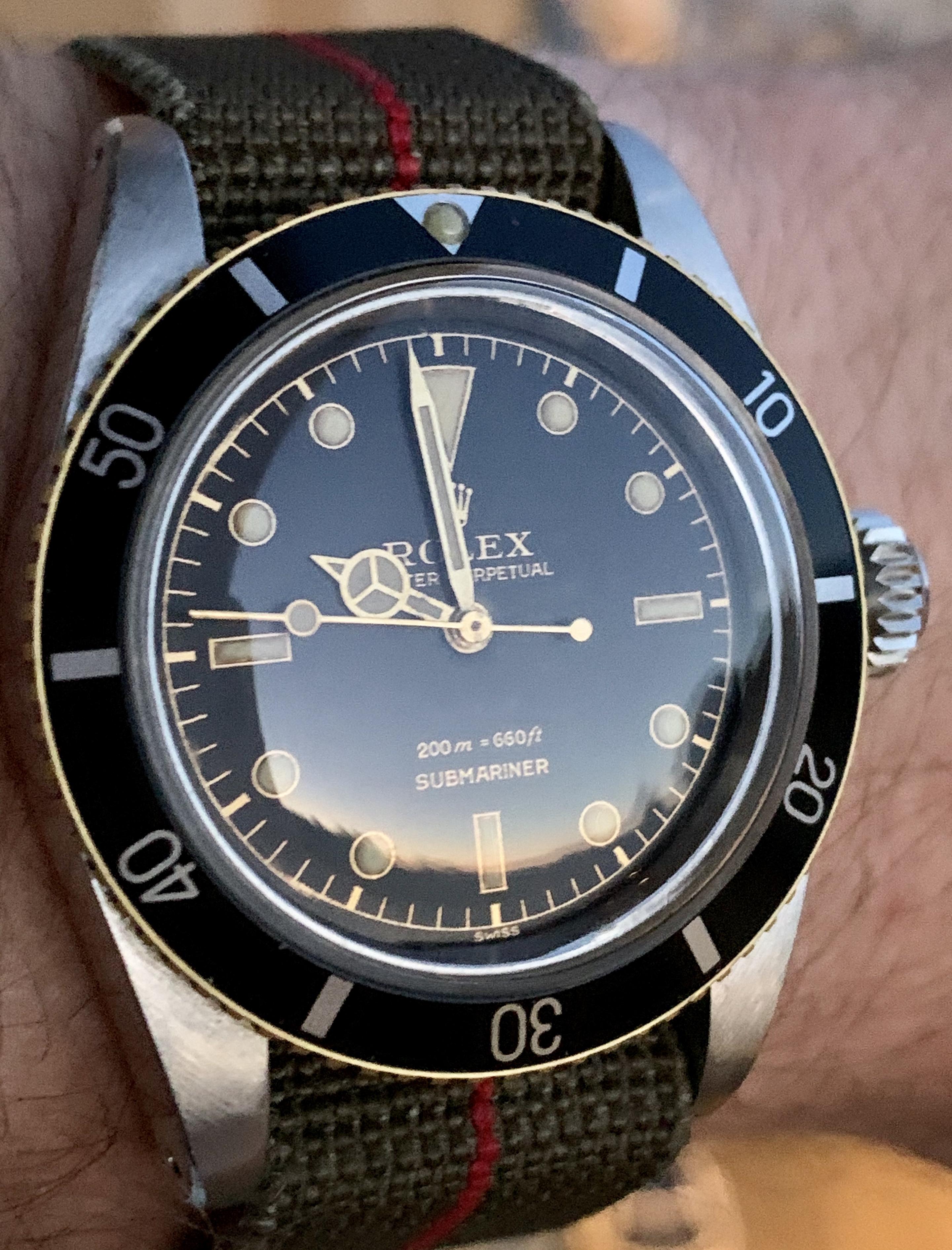

This watch has been (I’m sure many of you can empathise here) in a state of evolution for the last couple of years. Originally built by Dizzy , I bought it M2M on here when it looked like this;

So...I had a 6538 to learn with. The stem soon broke, so I set about looking at dials. An HR dial arrived along with a 2836 movement swap and a brass movement ring. The HR dial stayed in a while, and went from glossy (as HR supplies them) through to fully matte (with some various iterations along the way). I finally managed to ruin the HR dial by accidentally getting some acetone on it. But...I learned a lot of what works and what doesn’t, and when I run out of talent as well!

Over that period I’d been looking at a lot of reference material, and had settled on a few key ‘inspiration’ images for how I wanted the watch to look. This was my grail 6538...well used but a survivor.

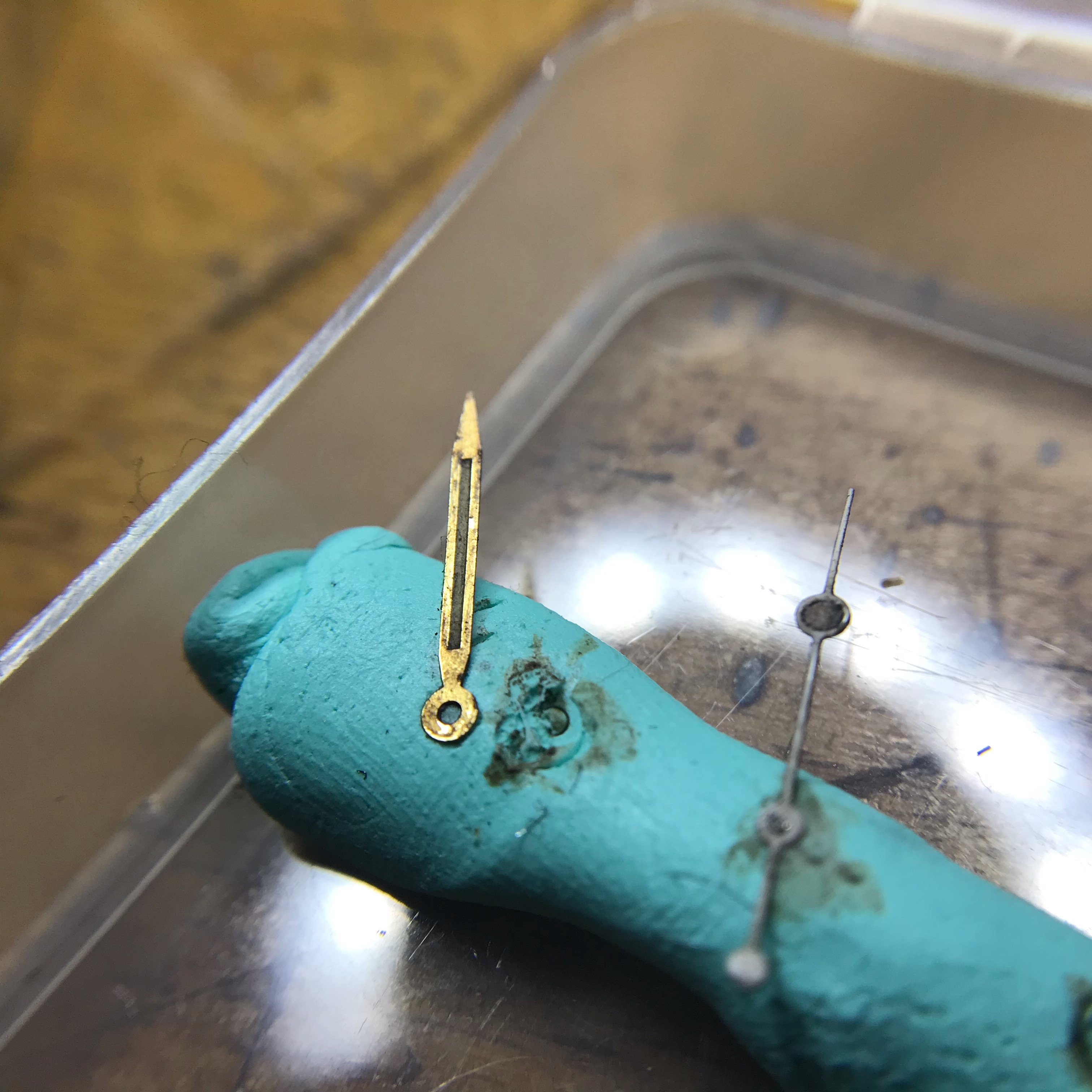

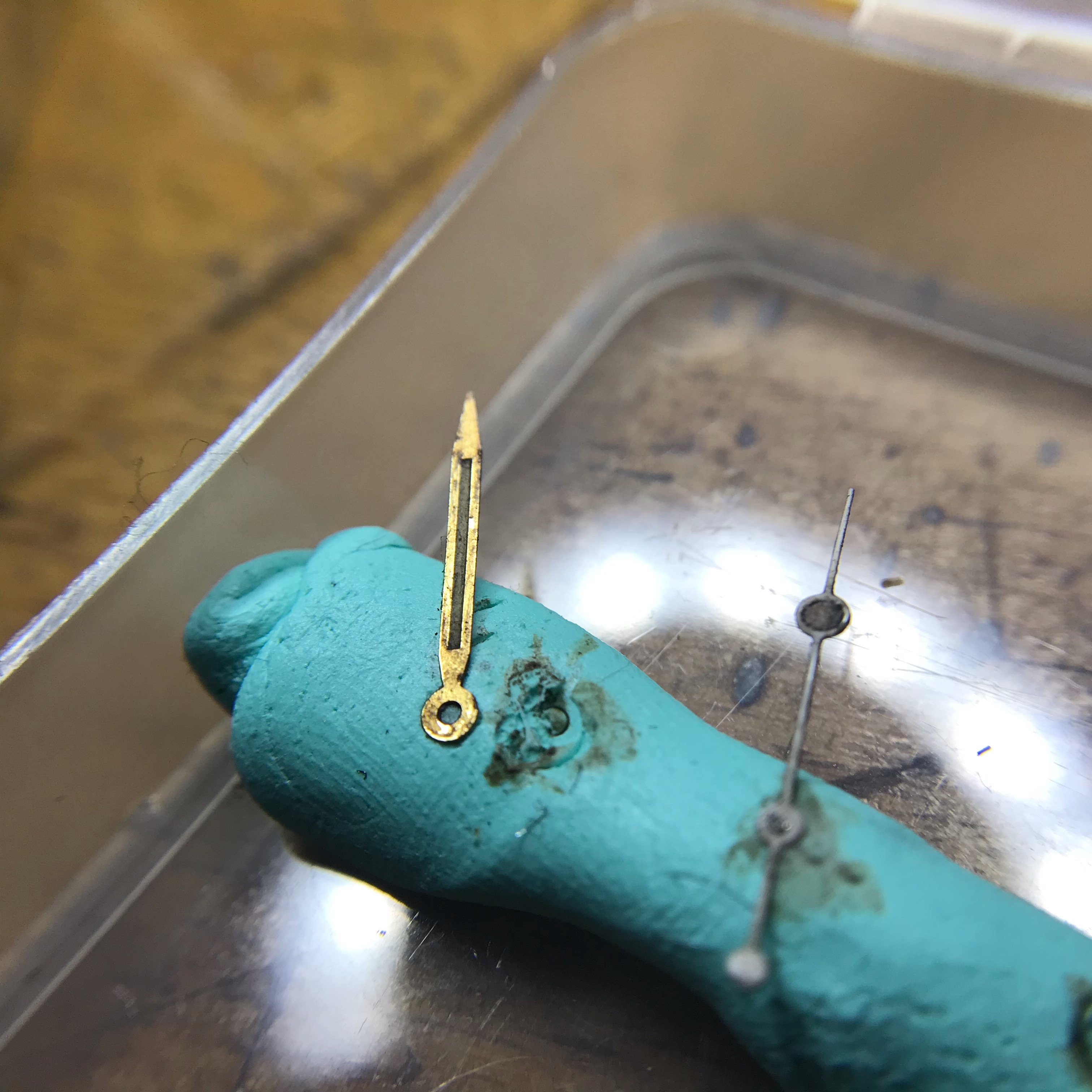

And these were my grail hands in terms of patina;

Dizzy had already aged the watch quite a bit long before I got it. The member I got it from had removed the brassing of the bezel, so along the way I re-plated the bezel in brass, and then aged it using sulphur etc.

About this time, I’d swapped out the insert. I ‘decided’ to ruin about 2 bezels in the process of finding a level of distressing/ ageing that reflected my grail 6538 above. I went through two sets of hands (lost an hour hand for about a month under my desk), and destroyed the original silix crown (over distressed).

After repeatedly coming back to the decal dial thread here;

https://forum.replica-watch.info/forum/vintage-watches/249254-decal-printed-dial

I managed to persuade Briteling to make me a decal dial. He was a massive help in all respects of the build from there on, and even donated a new Silix crown to replace the one I messed up! (thanks Briteling).

So now I had a gilt relief dial. I’d originally requested it glossy (so I could decide later if I wanted it matte). After taking a long look at it, I decided to give it a matte laquer coat. That worked well, and I’ve since given it a nice second coat with some matte/ coffee/ brush ‘stamping’ to give it a very organic/ random distressed texture, that is very hard to capture, but looks great IRL. I used a combination of sulphur, inks and matte lacquer on the hands until they matched the fantastic Lume job that Briteling did on the dial.

I’d had so many mishaps with mounting hands that I then sent it to ado213 for drilling of lugs and final assembly. I recut some chamfers by hand this morning, and am now really happy with how this has come out. I spent lots of money on parts that I’ve ruined along the way, but I’ve learnt loads from the process and this forum-mostly what I’m happy to attempt, and what I’d rather send to someone else to work on. It’s no high end VN build, but I’m happy with the result;

So...I had a 6538 to learn with. The stem soon broke, so I set about looking at dials. An HR dial arrived along with a 2836 movement swap and a brass movement ring. The HR dial stayed in a while, and went from glossy (as HR supplies them) through to fully matte (with some various iterations along the way). I finally managed to ruin the HR dial by accidentally getting some acetone on it. But...I learned a lot of what works and what doesn’t, and when I run out of talent as well!

Over that period I’d been looking at a lot of reference material, and had settled on a few key ‘inspiration’ images for how I wanted the watch to look. This was my grail 6538...well used but a survivor.

And these were my grail hands in terms of patina;

Dizzy had already aged the watch quite a bit long before I got it. The member I got it from had removed the brassing of the bezel, so along the way I re-plated the bezel in brass, and then aged it using sulphur etc.

About this time, I’d swapped out the insert. I ‘decided’ to ruin about 2 bezels in the process of finding a level of distressing/ ageing that reflected my grail 6538 above. I went through two sets of hands (lost an hour hand for about a month under my desk), and destroyed the original silix crown (over distressed).

After repeatedly coming back to the decal dial thread here;

https://forum.replica-watch.info/forum/vintage-watches/249254-decal-printed-dial

I managed to persuade Briteling to make me a decal dial. He was a massive help in all respects of the build from there on, and even donated a new Silix crown to replace the one I messed up! (thanks Briteling).

So now I had a gilt relief dial. I’d originally requested it glossy (so I could decide later if I wanted it matte). After taking a long look at it, I decided to give it a matte laquer coat. That worked well, and I’ve since given it a nice second coat with some matte/ coffee/ brush ‘stamping’ to give it a very organic/ random distressed texture, that is very hard to capture, but looks great IRL. I used a combination of sulphur, inks and matte lacquer on the hands until they matched the fantastic Lume job that Briteling did on the dial.

I’d had so many mishaps with mounting hands that I then sent it to ado213 for drilling of lugs and final assembly. I recut some chamfers by hand this morning, and am now really happy with how this has come out. I spent lots of money on parts that I’ve ruined along the way, but I’ve learnt loads from the process and this forum-mostly what I’m happy to attempt, and what I’d rather send to someone else to work on. It’s no high end VN build, but I’m happy with the result;

After all, I decided to keep my 6200 build and try to upgrade it little by little.

I’d like to swap the plexi to a flatter more true to the gen. Can you guys help me with what would be my options with the silix case I have?

Sent from my iPhone using Tapatalk

I’d like to swap the plexi to a flatter more true to the gen. Can you guys help me with what would be my options with the silix case I have?

Sent from my iPhone using Tapatalk

- 30/6/20

- 35

- 47

- 0

https://www.cousinsuk.com/product/glasses-acrylic-tropic-without-date-lensAfter all, I decided to keep my 6200 build and try to upgrade it little by little.

I’d like to swap the plexi to a flatter more true to the gen. Can you guys help me with what would be my options with the silix case I have?

Sent from my iPhone using Tapatalk

A t21 is a nice one to use in a silix case,

Sent from my LYA-L09 using Tapatalk

https://www.cousinsuk.com/product/glasses-acrylic-tropic-without-date-lens

A t21 is a nice one to use in a silix case,

Sent from my LYA-L09 using Tapatalk

Thank you ????????

Sent from my iPhone using Tapatalk

- 3/4/12

- 125

- 59

- 28

Hello,

I ordered and just received 2 pieces of 6538 Silix case and a full watch...

I'm very disappointed and afraid by the hole position on the lugs...too close to the edge. I'm not confident with the redrill and bevel process...

Did you already seen this issue?

Envoyé de mon Redmi Note 9S en utilisant Tapatalk

I ordered and just received 2 pieces of 6538 Silix case and a full watch...

I'm very disappointed and afraid by the hole position on the lugs...too close to the edge. I'm not confident with the redrill and bevel process...

Did you already seen this issue?

Envoyé de mon Redmi Note 9S en utilisant Tapatalk

You're only enlarging the holes by about 0.2mm (1.25mm)so you should be ok, you can always just enlarge just a little bit and use the slightly less fat 1.8mm bars and drill to 1.1mmHello,

I ordered and just received 2 pieces of 6538 Silix case and a full watch...

I'm very disappointed and afraid by the hole position on the lugs...too close to the edge. I'm not confident with the redrill and bevel process...

Did you already seen this issue?

Envoyé de mon Redmi Note 9S en utilisant Tapatalk

Sent from my LYA-L09 using Tapatalk

Another option is a clarks t 22 plexi, i think i have one or two of them in my parts box , it's bigger at 30.8mm so to fit it would need to be compressed with a spider clamp (crystal lift tool) once the clamp is released the crystal will be in very tight and there is no need for any glue, the sterncruz t21 fits quite snug but needs glueThank you ????????

Sent from my iPhone using Tapatalk

Sent from my LYA-L09 using Tapatalk

Another option is a clarks t 22 plexi, i think i have one or two of them in my parts box , it's bigger at 30.8mm so to fit it would need to be compressed with a spider clamp (crystal lift tool) once the clamp is released the crystal will be in very tight and there is no need for any glue, the sterncruz t21 fits quite snug but needs glue

Sent from my LYA-L09 using Tapatalk

Thanks! Let me check with Hungaryrolex if he has that tool needed to press the t22 plexi and I’m gonna get back to you.

Sent from my iPhone using Tapatalk

No problem,I'm sure he will have, its just one of theseThanks! Let me check with Hungaryrolex if he has that tool needed to press the t22 plexi and I’m gonna get back to you.

Sent from my iPhone using Tapatalk

Sent from my LYA-L09 using Tapatalk

deadpan

Active Member

No problem,I'm sure he will have, its just one of these

Sent from my LYA-L09 using Tapatalk

I always assumed those were for removal, rather than install. I assume I was incorrect and they do both?

They can be used for both, it evenly compresses the crystal so when you release the pressure its in super tight,I always assumed those were for removal, rather than install. I assume I was incorrect and they do both?

Sent from my LYA-L09 using Tapatalk