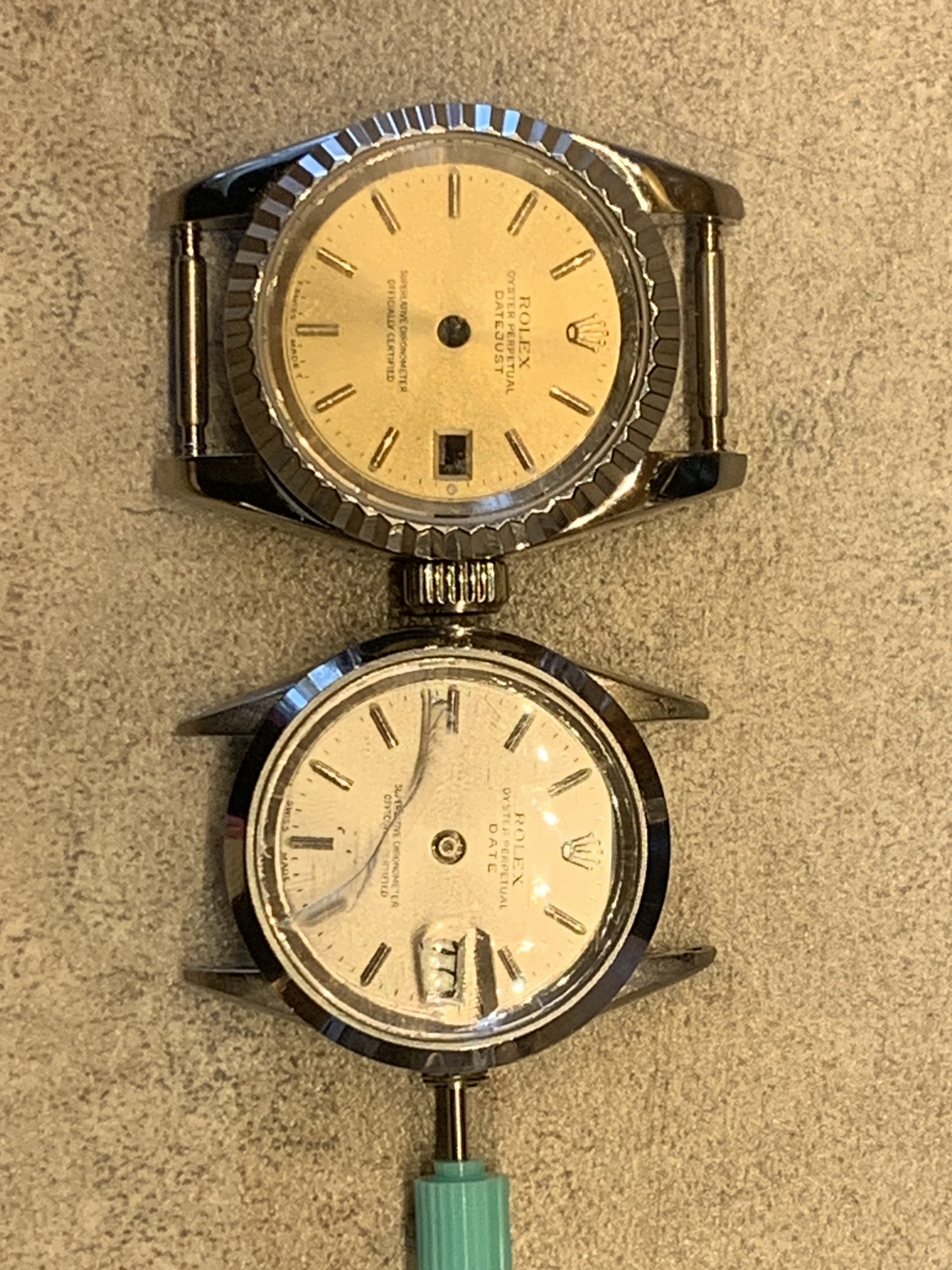

Oh I see now. So my spacer was to clear the lip of the movement so the DWO would not rub against the movement. Your problem is that there is TOO MUCH SPACE between the DW and Dial. My problem was that there was NOT ENOUGH space between the datewheel and dial as the DW rubbed with too much friction against the dial.Yes.

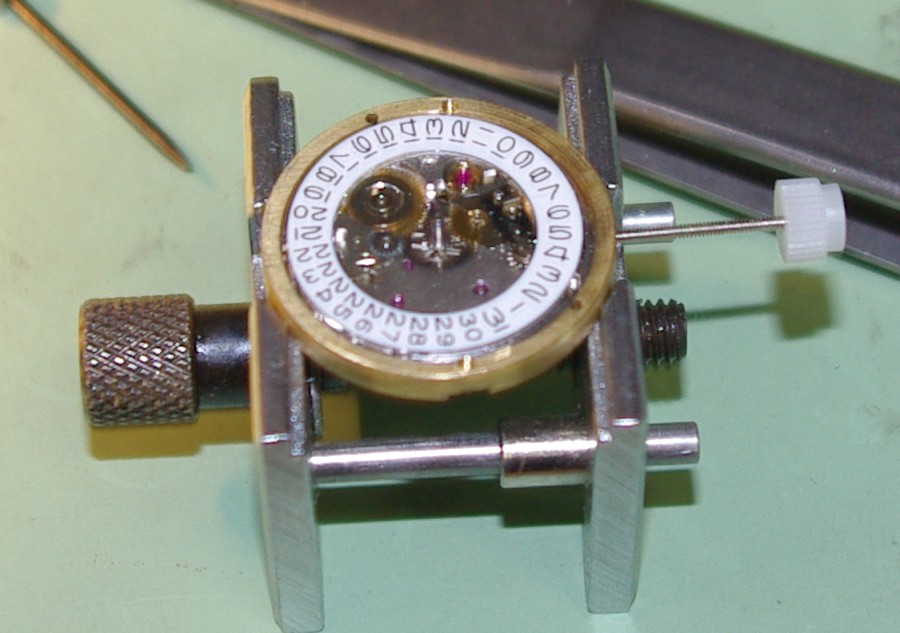

In order to set the movement in the case so that the stem lines up with the hole, you need to recess the movement a little bit. That causes the movement to be spaced a bit from the dial, so the date appears sunken. The solution I'm hoping works is to mount a spacer disk, maybe 1mm in height (maybe more, maybe less, it's too small to measure with the tools I have, so I'll just use different thicknesses until it works) on the date wheel, then the DWO on the spacer.

It sounds like what you did with the ETA date wheel you ground the teeth off of, I'm just hoping to use a 3D printed spacer, or something I cut from thin metal stock. I've got some sheets of .4mm brass that I used to cut dial blanks, one or two thicknesses of that should get me in the ballpark.

The stock plastic movement ring on the NH05 is fairly thick, the 3D printed one is much thinner, but still leaves too much of a gap.

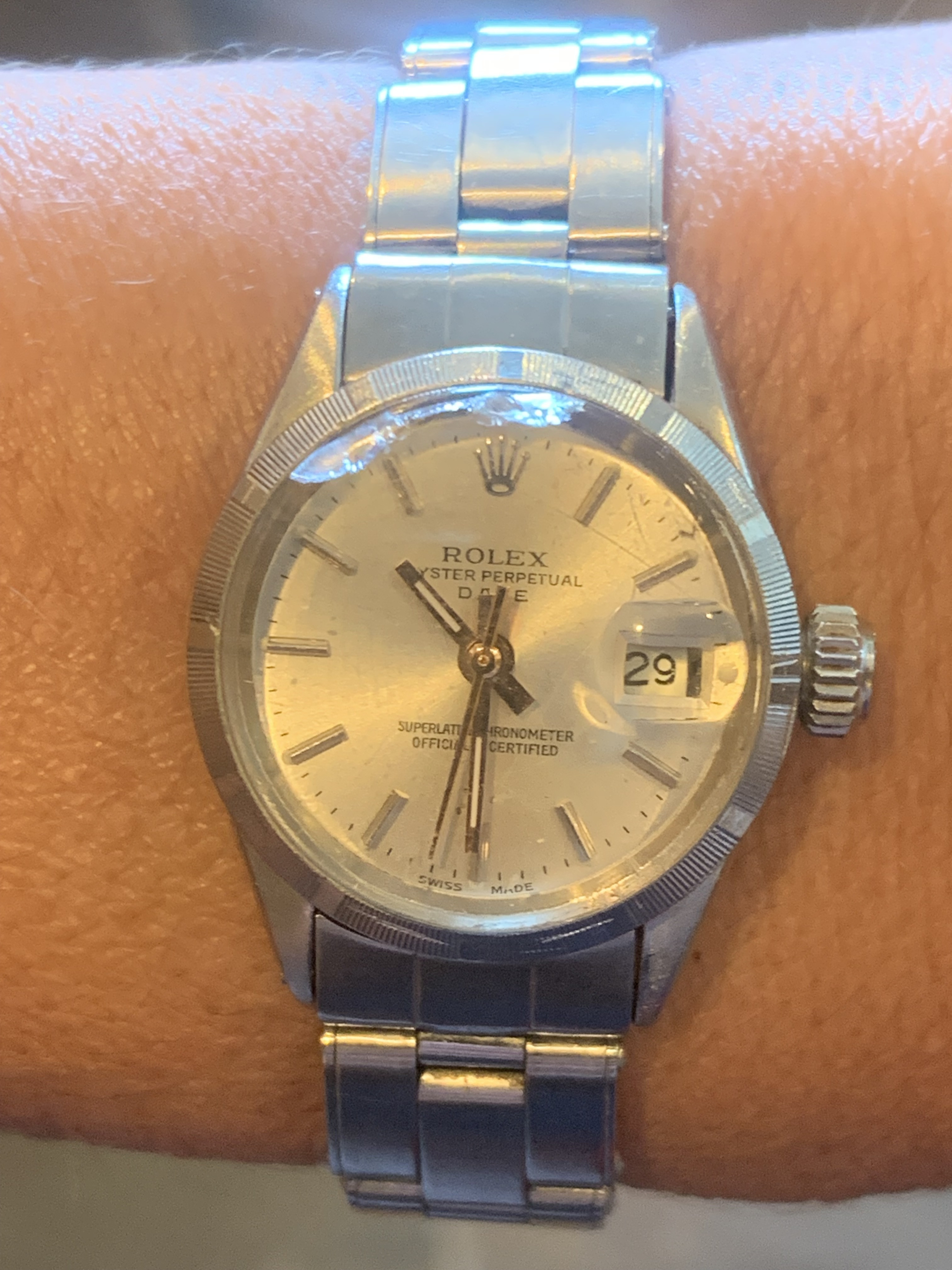

The 2671 was actually in a decent position with the stem in. Maybe if I had that actual brass ring, it would have given me enough clearance for the datewheel not to rub as badly against the dial.