Very informative post. I found you guys posts when doing research on comparison between 316L and 904L.

Allow me add some comments.

In watch industry here in HK/China. The most widely use is 316L. 316F is only for making small components such as tube, crown because of its' good machining property. "F" means free cutting, not sure it is correct or not. If making small parts by 316L, lots of burrs found after cutting.

I can say no one use SS440, it is too hard and practically not as good as 316L in corrosion resistant.

We usually use 304 and 316L in producing case and bracelet. 304 is mostly for low end products and cap bracelets. The majority is 316L case and bracelet.

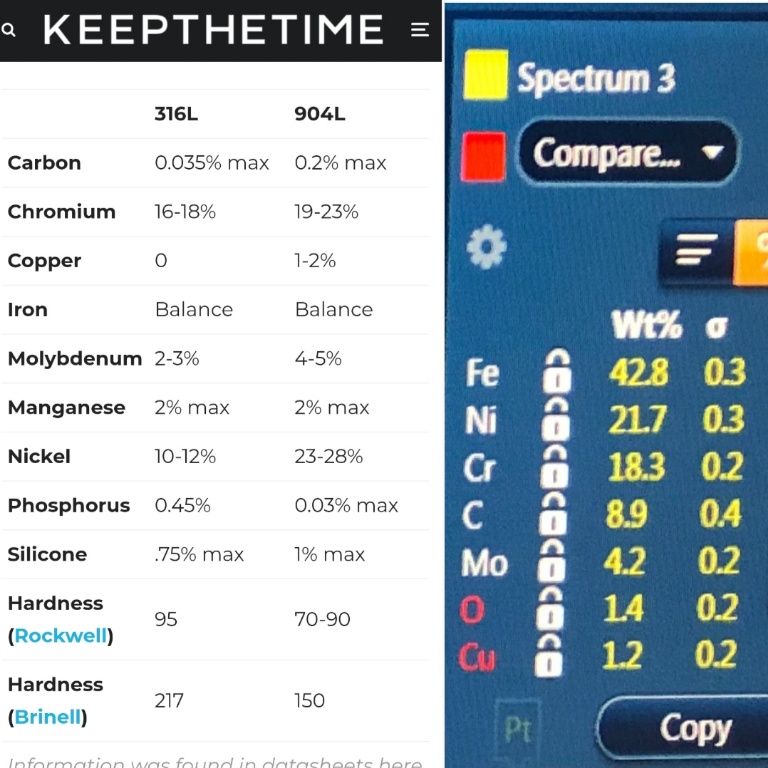

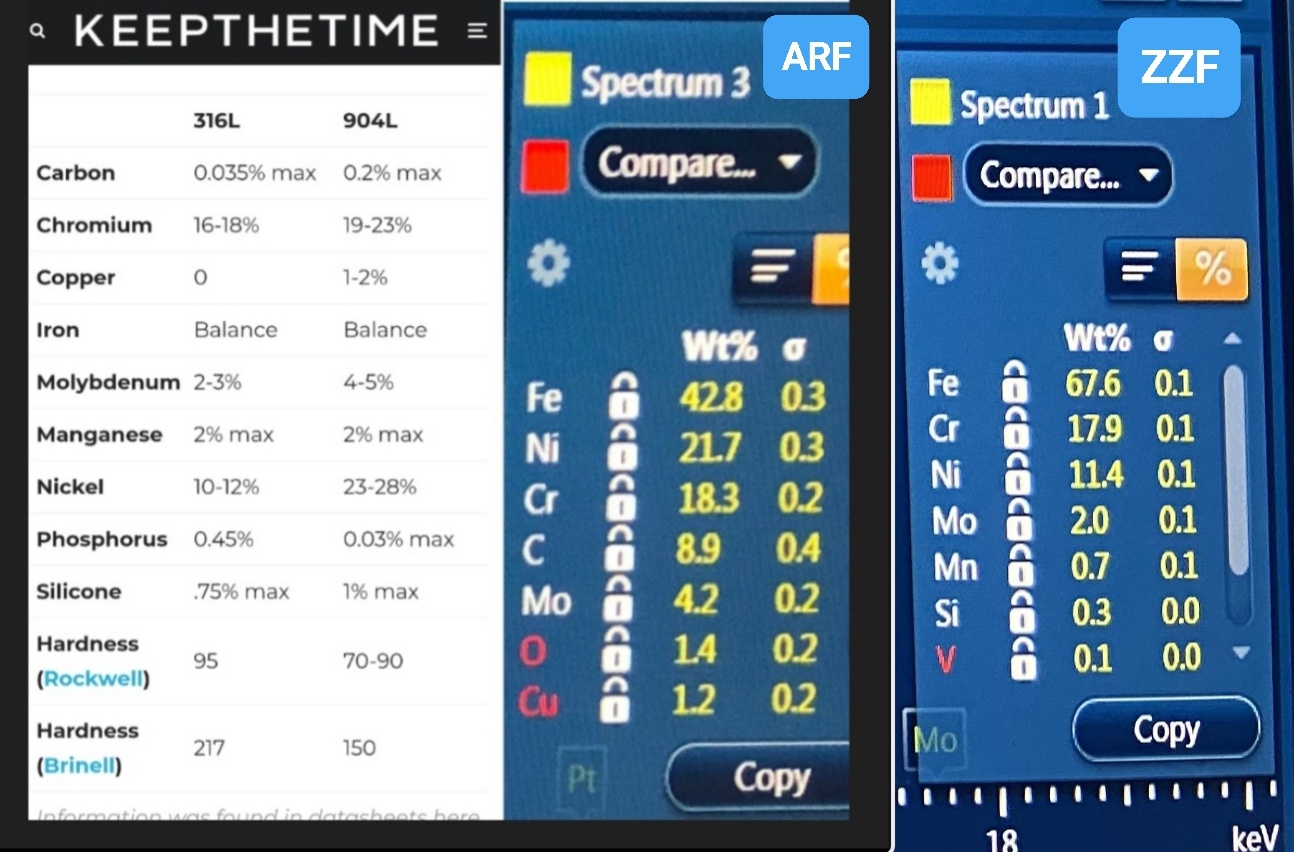

316L use in real Swiss brands are actually 1.4404, you can say 316L = 1.4404. But in watch industry, 1.4404 means Swiss SS 1.4404, the chemical composition is in exact %, that means no min or max %. If you know material technology you will know cost more to have exact %. That's why Swiss brands in 316L(1.4404) cost higher than others.

Same situation in 904L, Rolex is not using 904L they are using 1.4539 in exact %.

The reason why Rolex use 1.4539 is the higher hardness and corrosion resistant. Higher hardness can have a more well defined flat surface, sharp edges, less wrinkle/buffing marks. Higher corrosion resistant can prevent pitting on brushed surface when doing artificial sweat test, ISO 23160. 316L do have pit marks found on brushed surface in South America, in Asia, especiall India, no offense, that's is the hot chili and curry. Customer won't take off their watch when cooking.

Yes, 316L and 904L have different color. But after polishing, the 904L may looks worst if they use wrong craftmanship, wrong wax, wrong speed, wrong cleaning. Same, 316L can look as good as 904L if they do it right.

Reason why replica first introduced 904L bracelet instead of case. Bracelet link blank produced by hot extrusion. The extrusion process is same in both 316L and 904L. Factory just order extrusion rods and all they need to do is cutting, drilling and polishing. But in case making, a 300t hydraulic press is good enough to produce 316L case. But a 500t hydraulic press works hard and 800t is better for 904L. This will make case making cost much more higher. Replicas' need to earn enough money from 316L to produce 904L.

Ti case making have more then 25 years history. Most use is Grade 2 Ti. High end brands will use Grade 5 Ti. Grade 5 Ti can have sharp, polished surface like SS.

Please remember, watch making is not only about case, bracelet. They also involved dial, crystal, hands, assembly, sales and marketing. Sometimes a piece of China made genuine Swiss brand dial cost more than a G-shock complete watch. A China made genuine Swiss brand sapphire crystal can cost even more. The complete watch cost in Switzerland is more than 10 times higher then in China. Together wil sales and marketing expense, to run a service center, to keep 30 years service component inventory. Then you may find it is worth to own an entry price genuin Swiss brand.

Sorry to my poor writing. Hope these info can let you guys feels better when wearing genuine.

A insider of low end watch making.