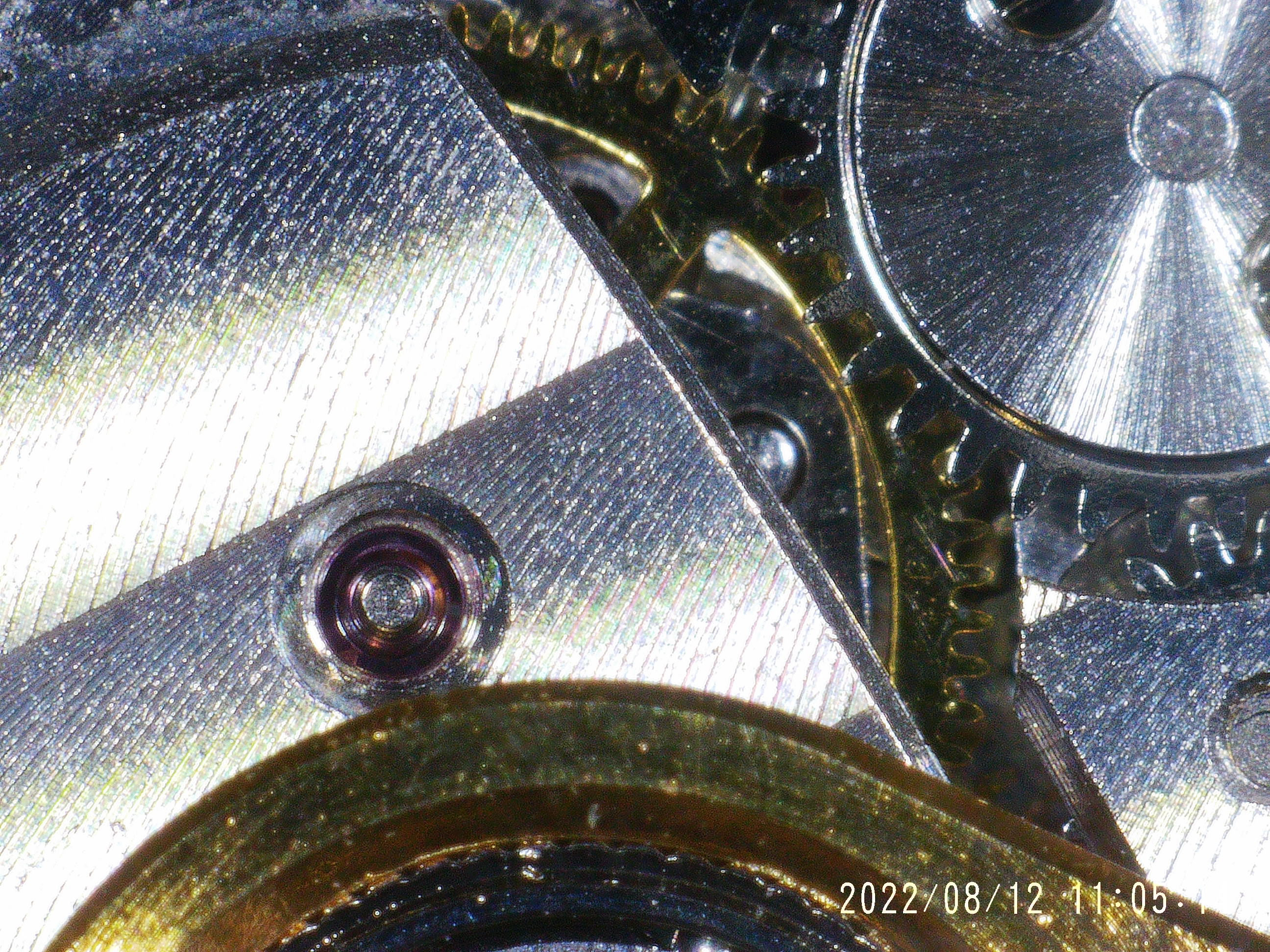

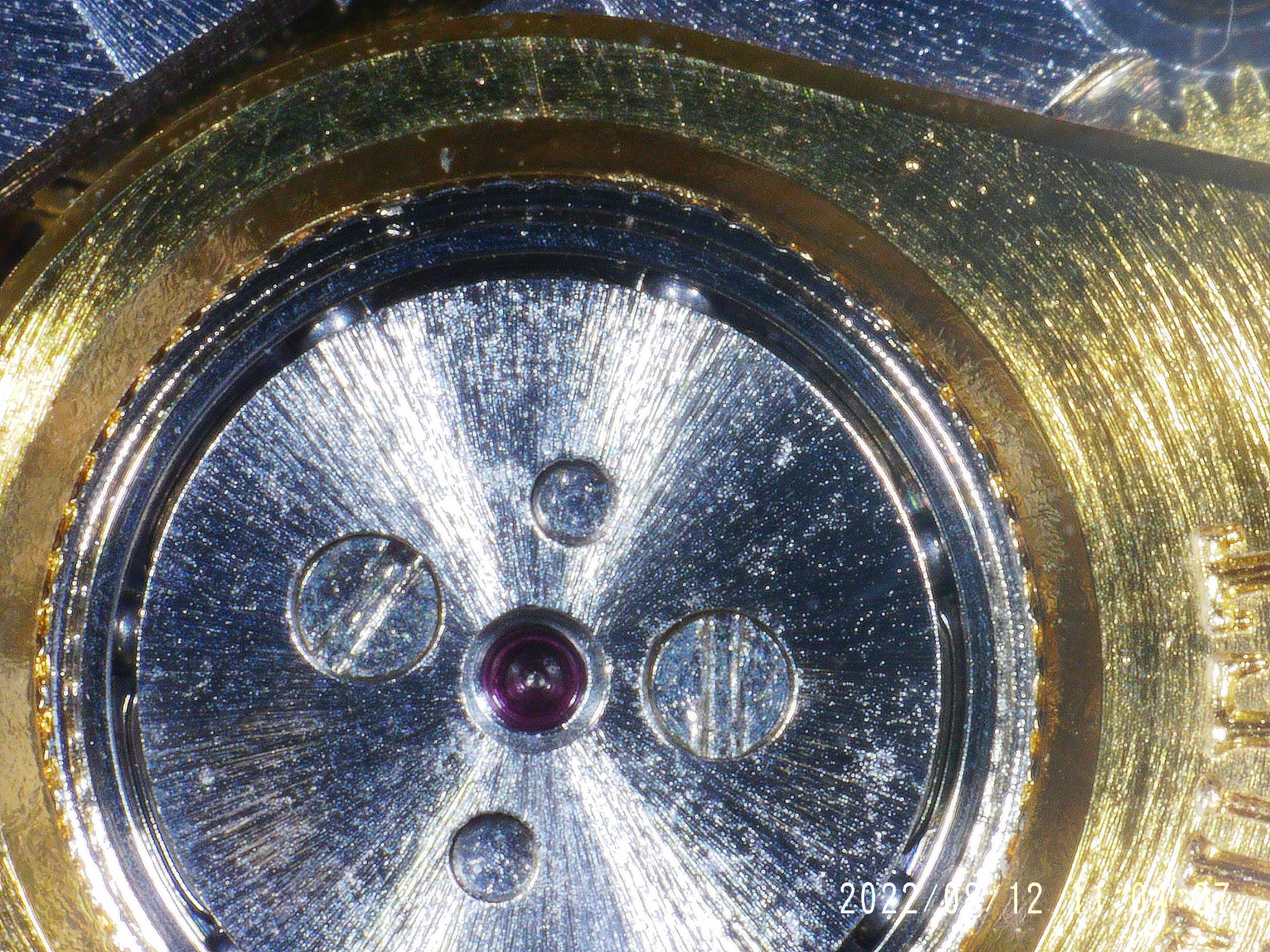

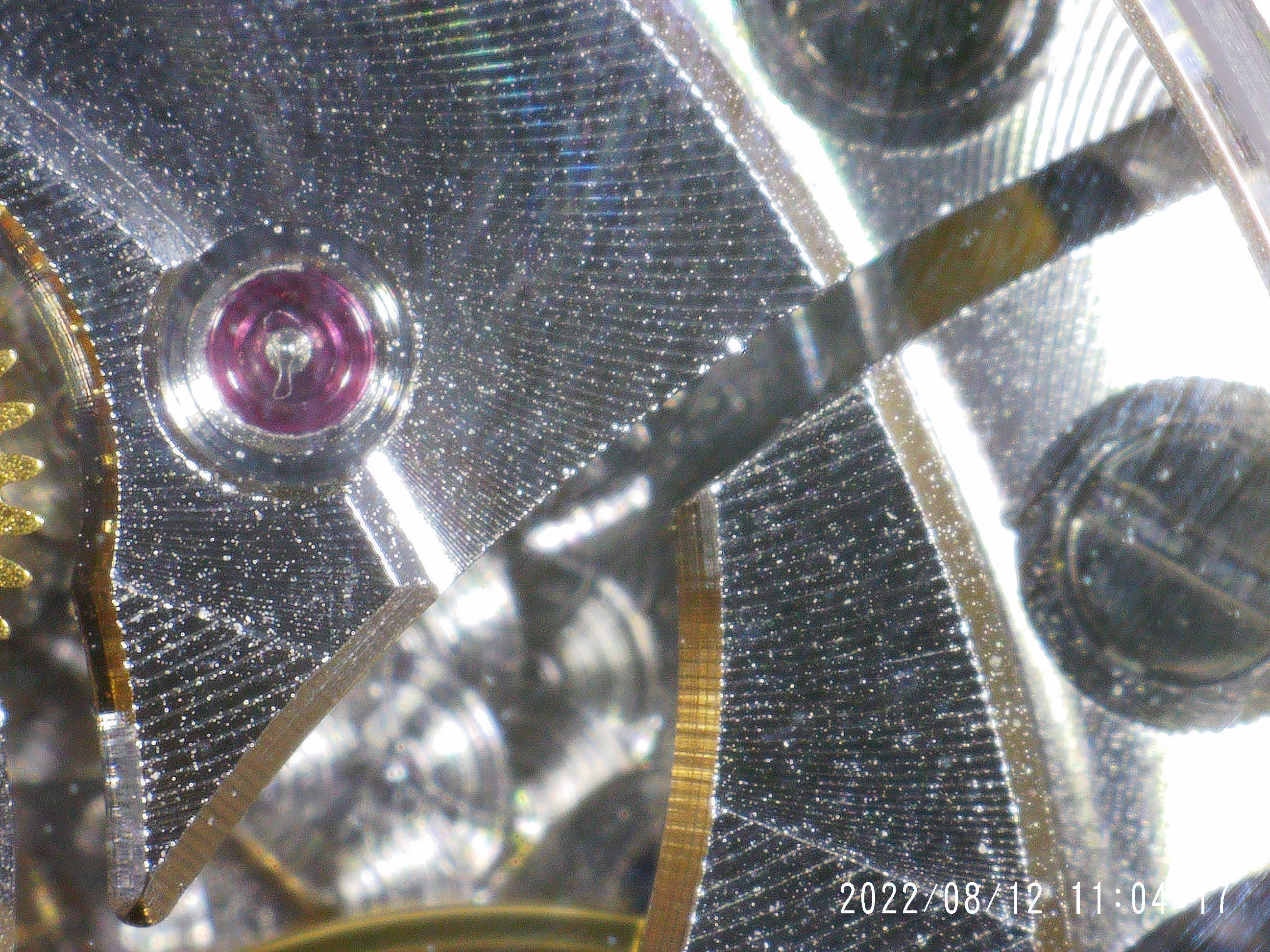

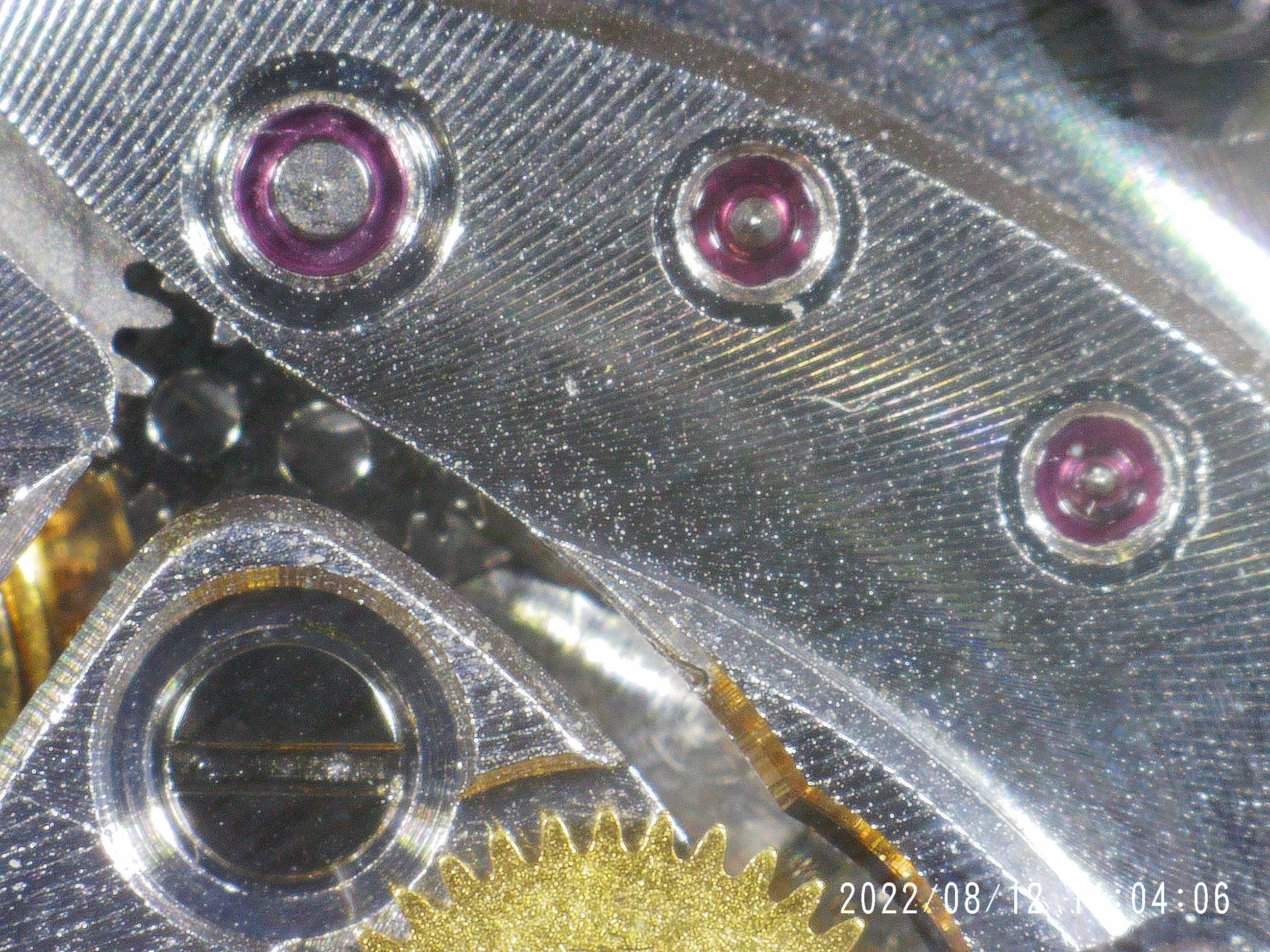

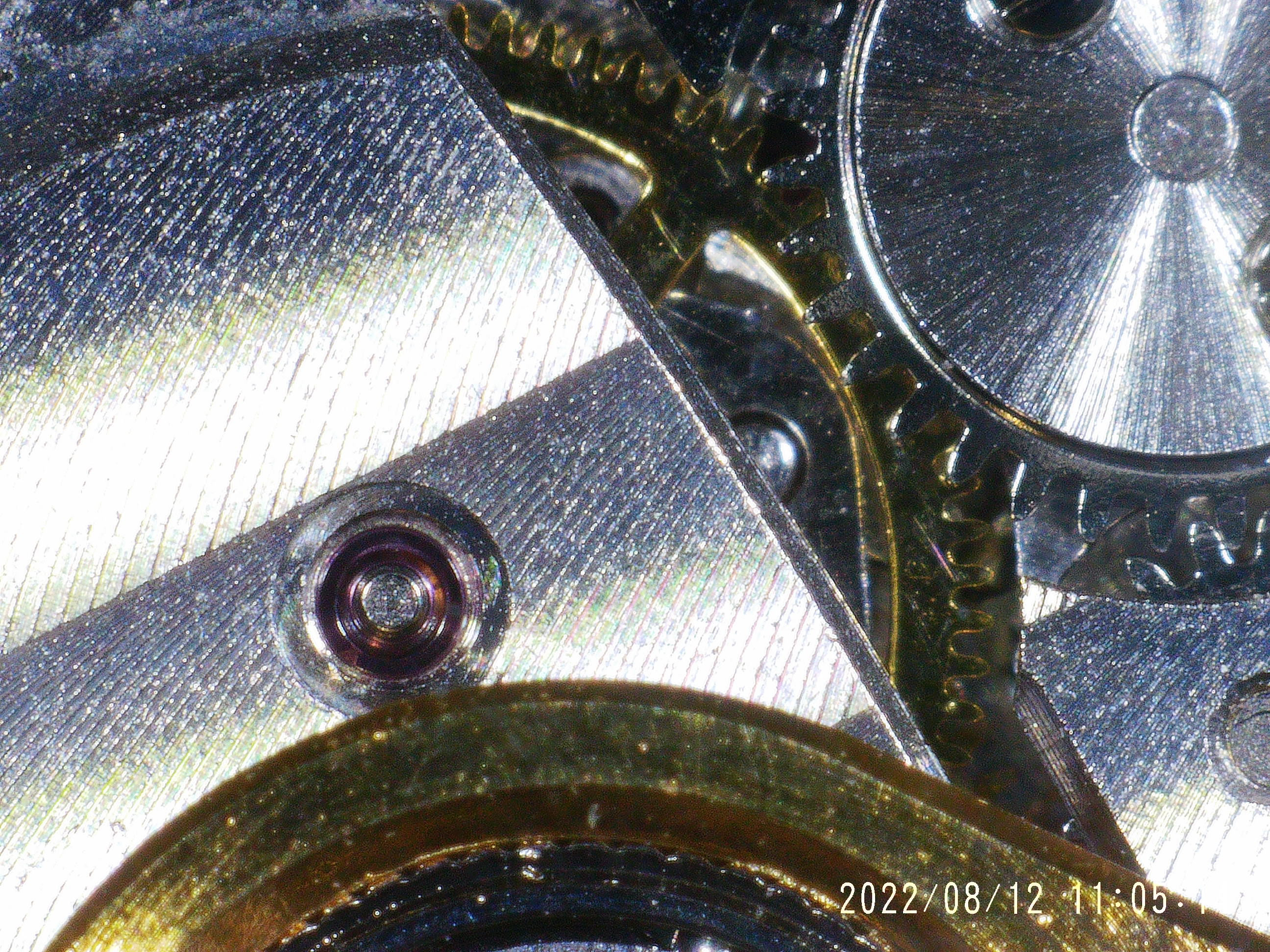

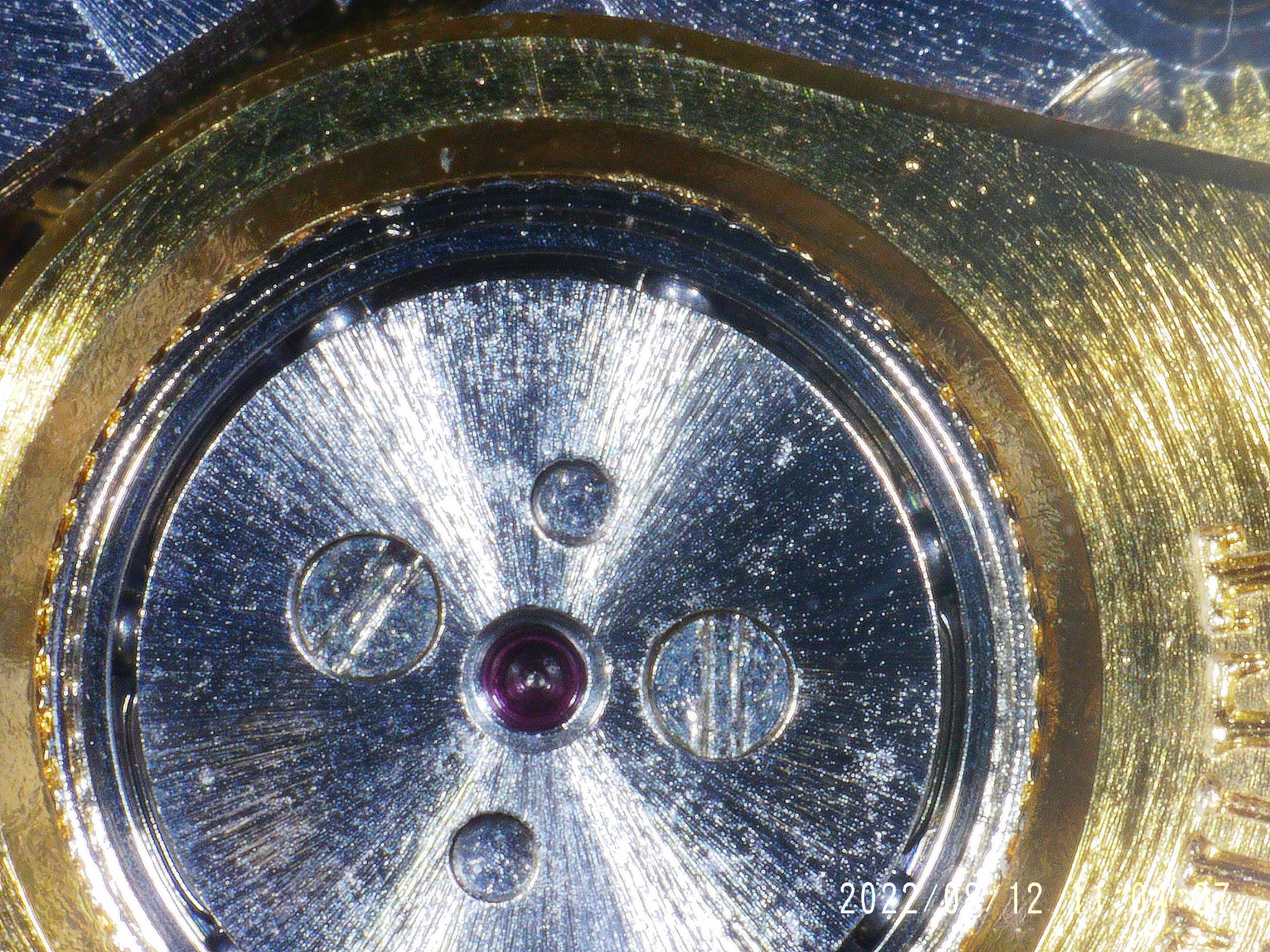

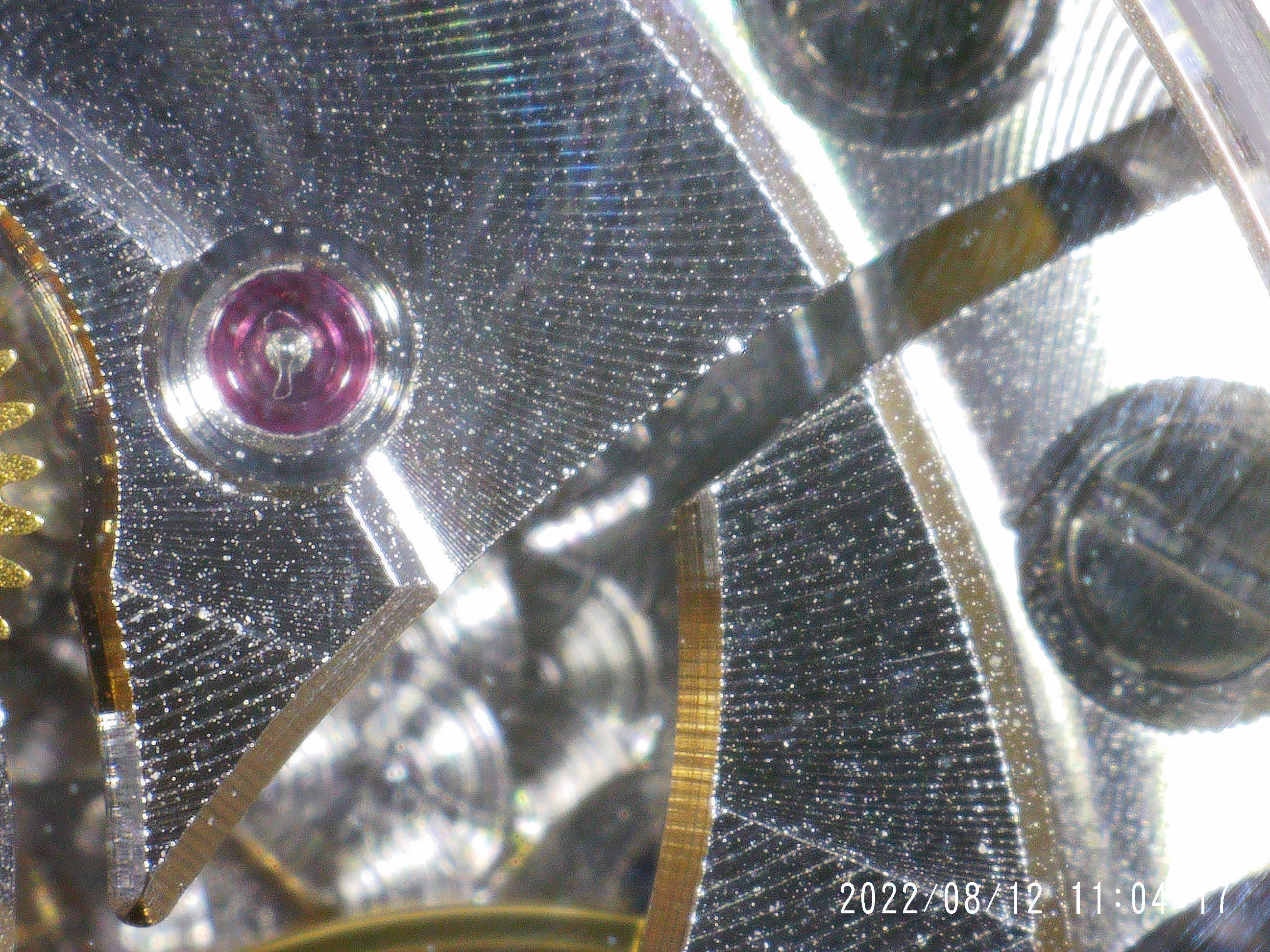

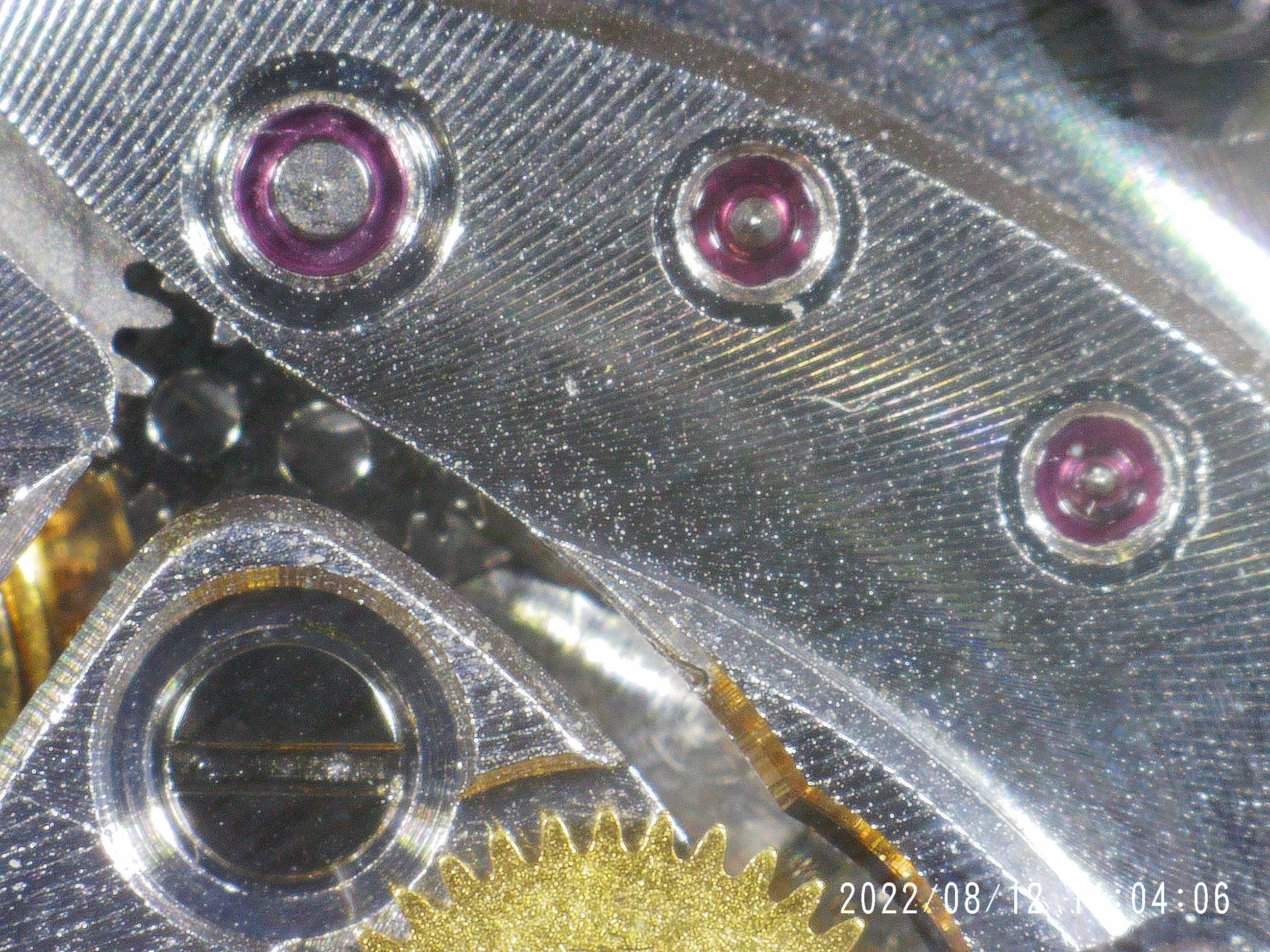

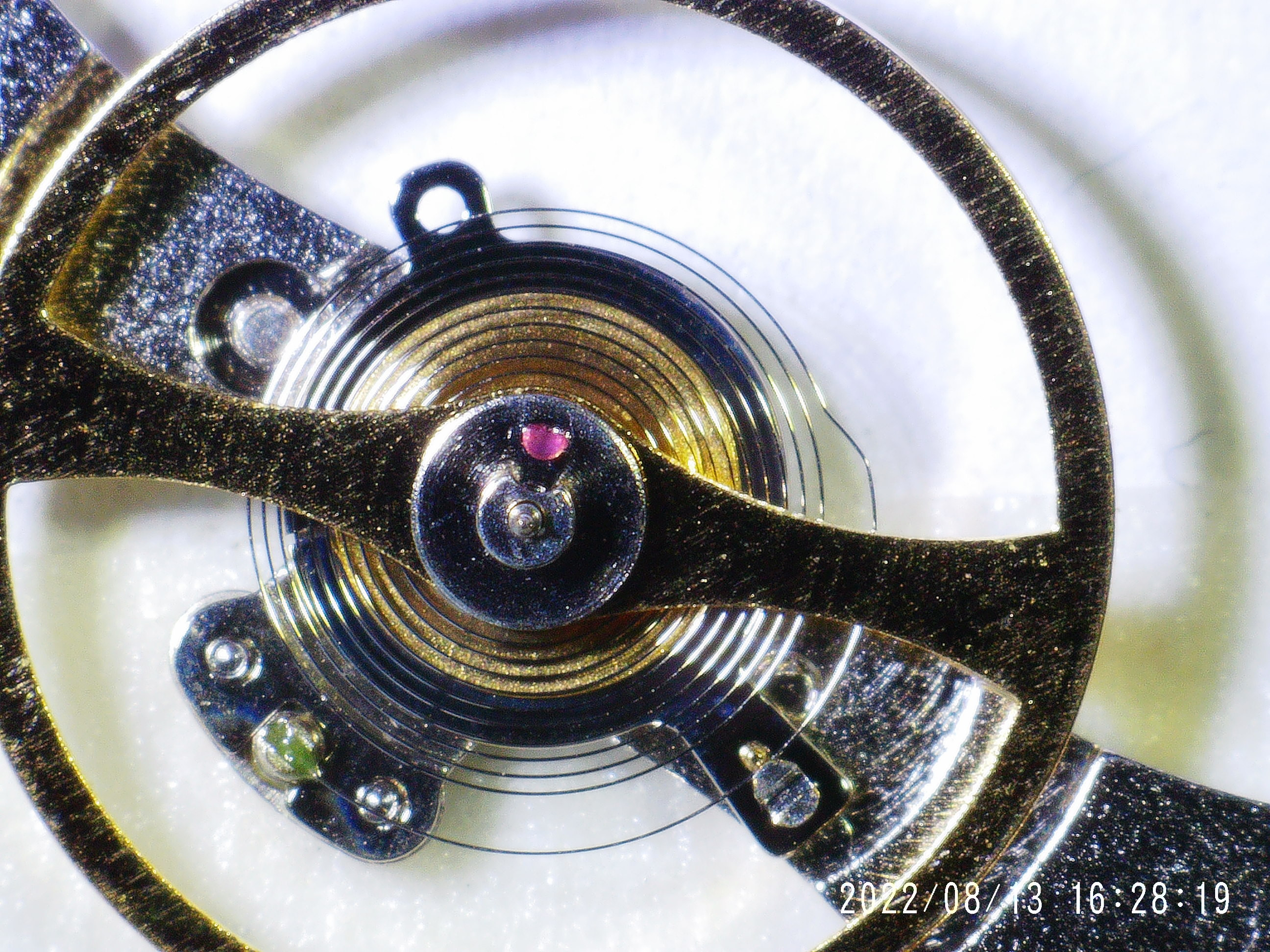

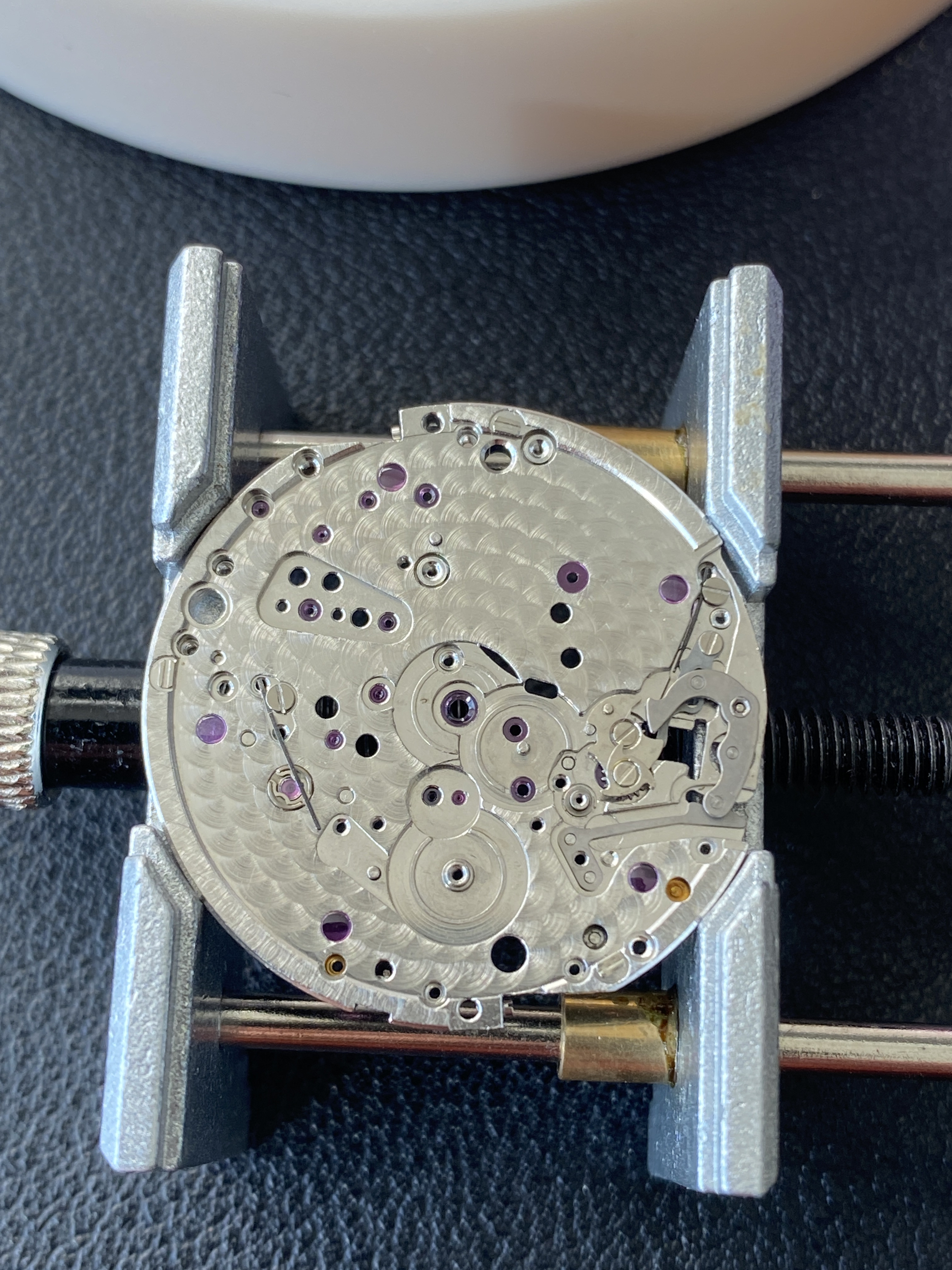

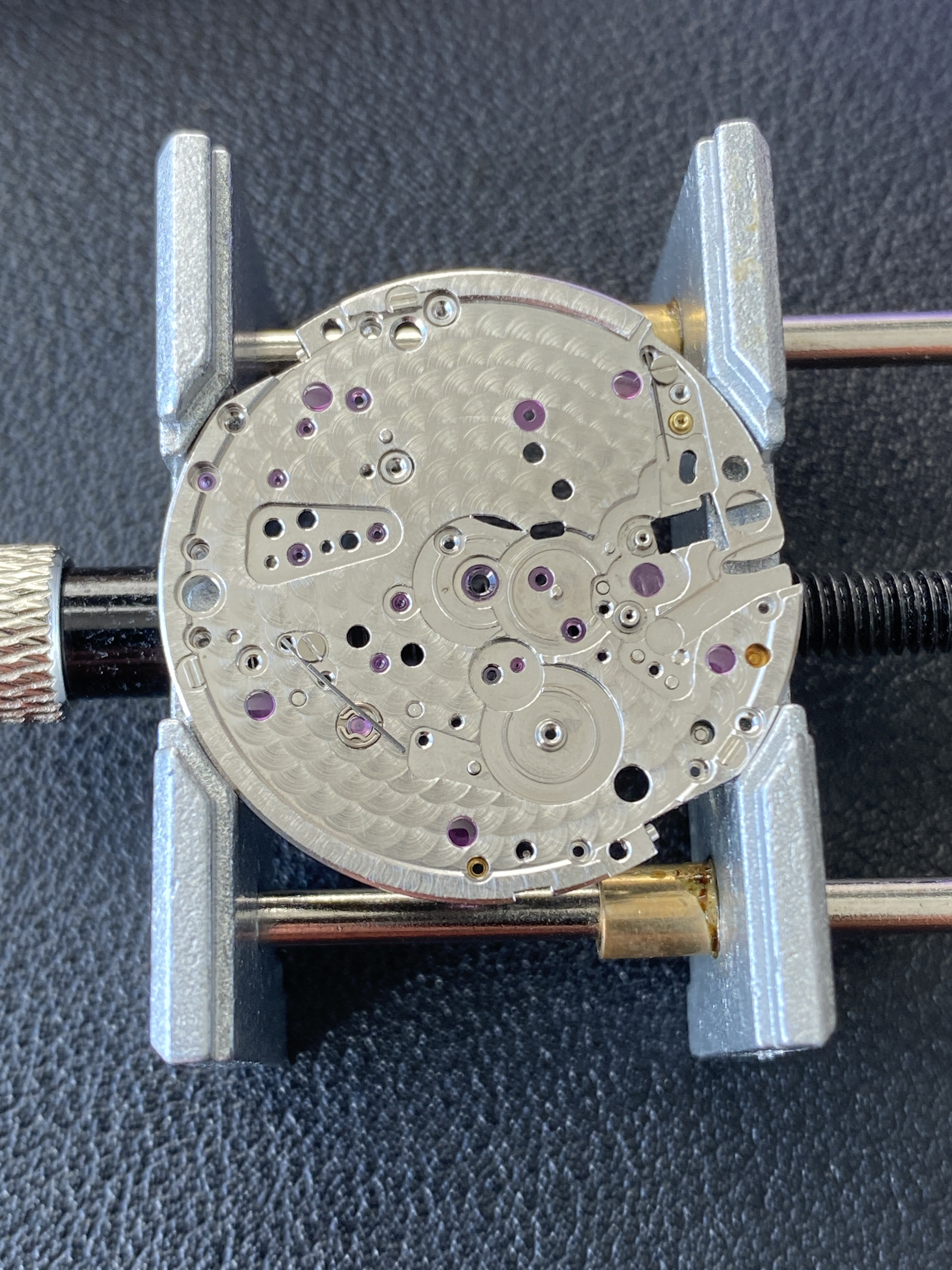

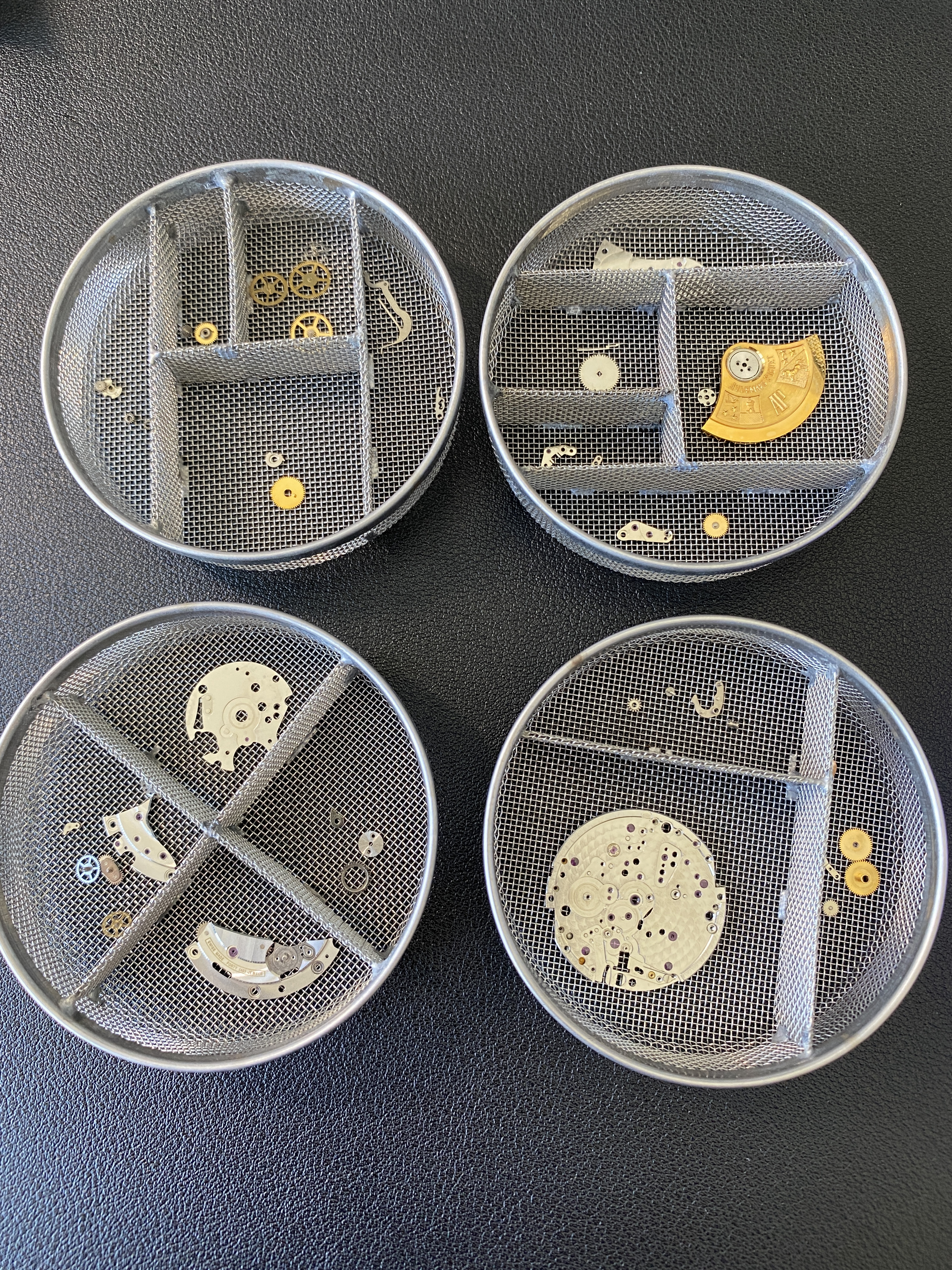

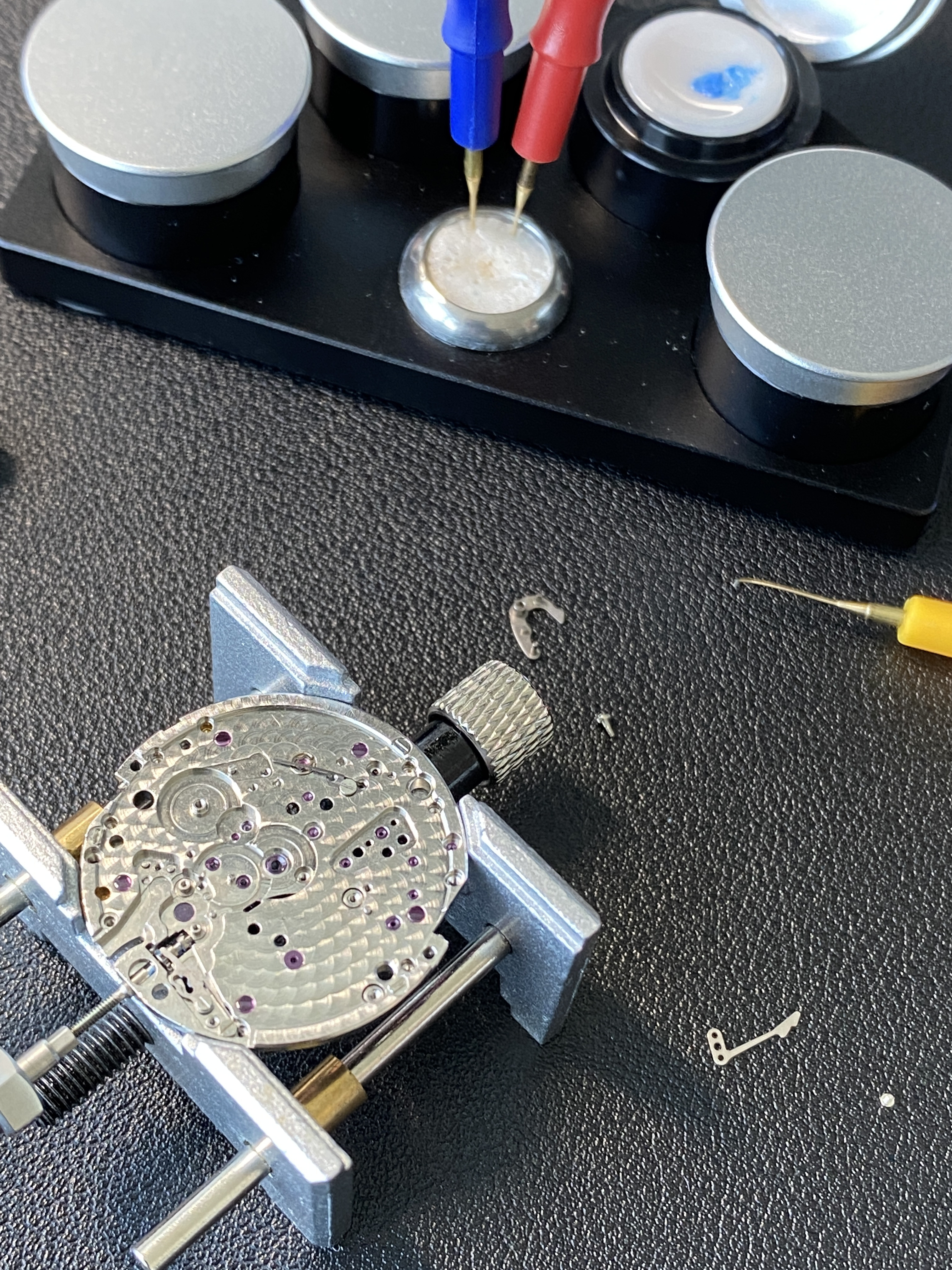

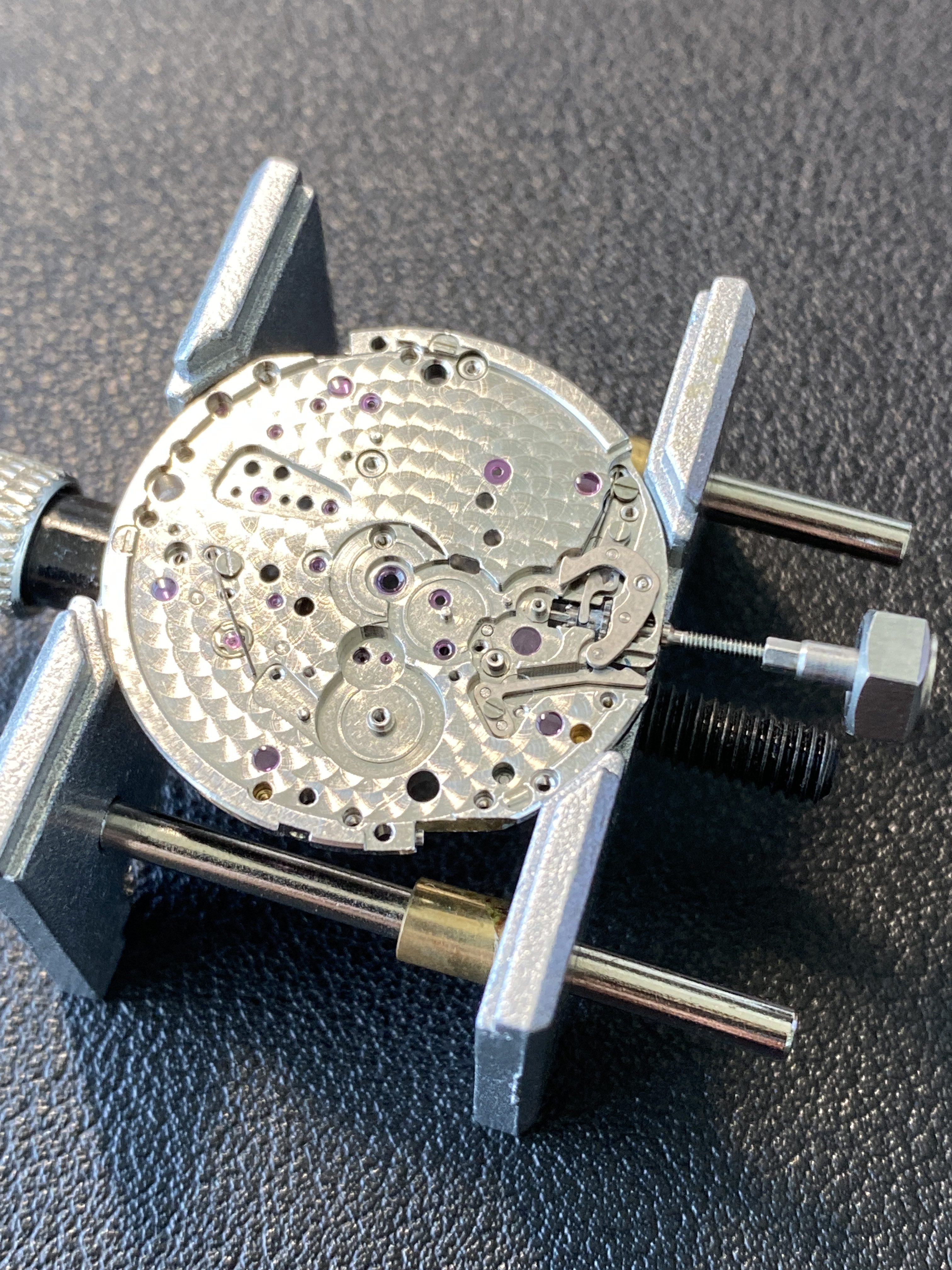

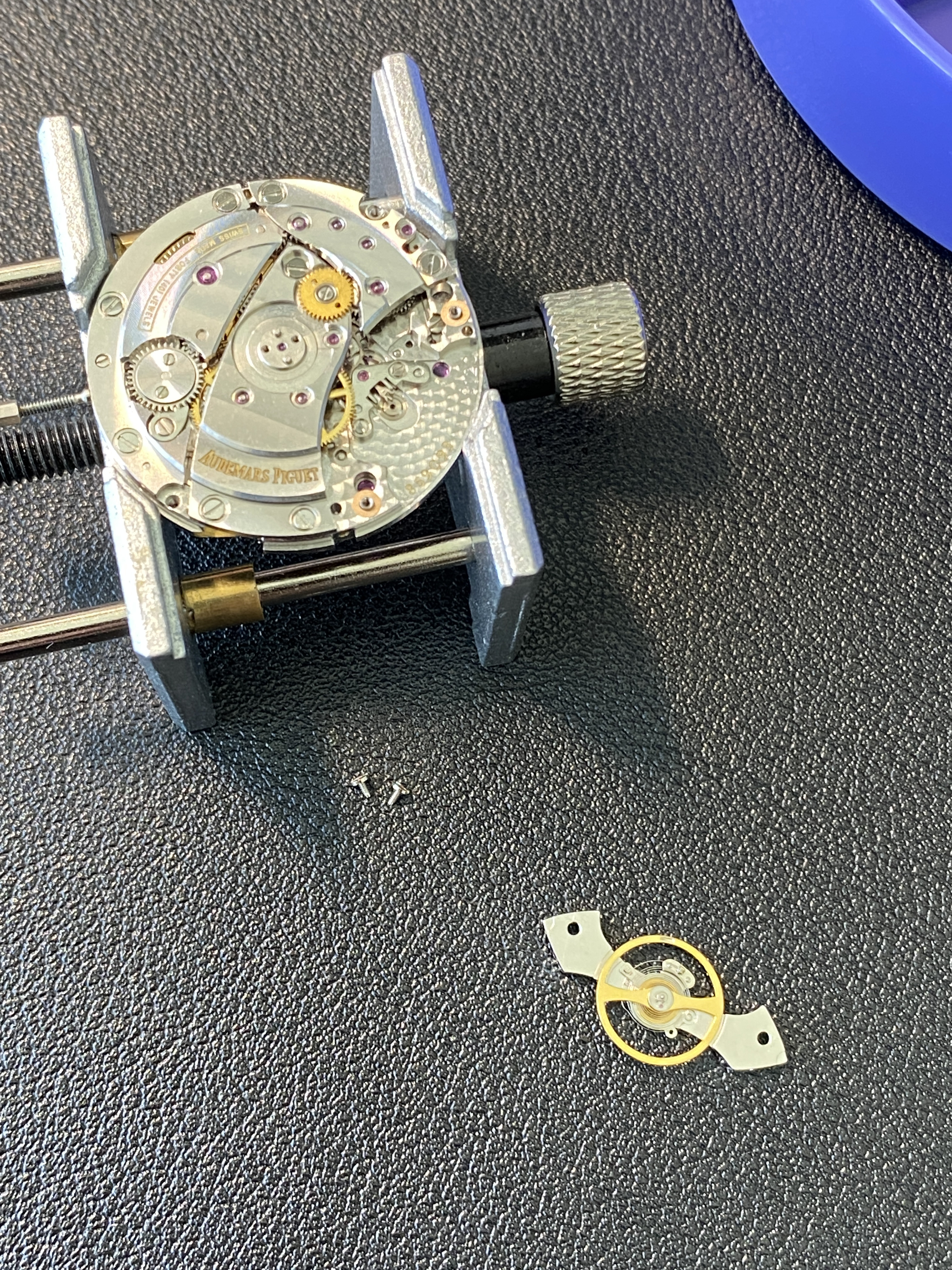

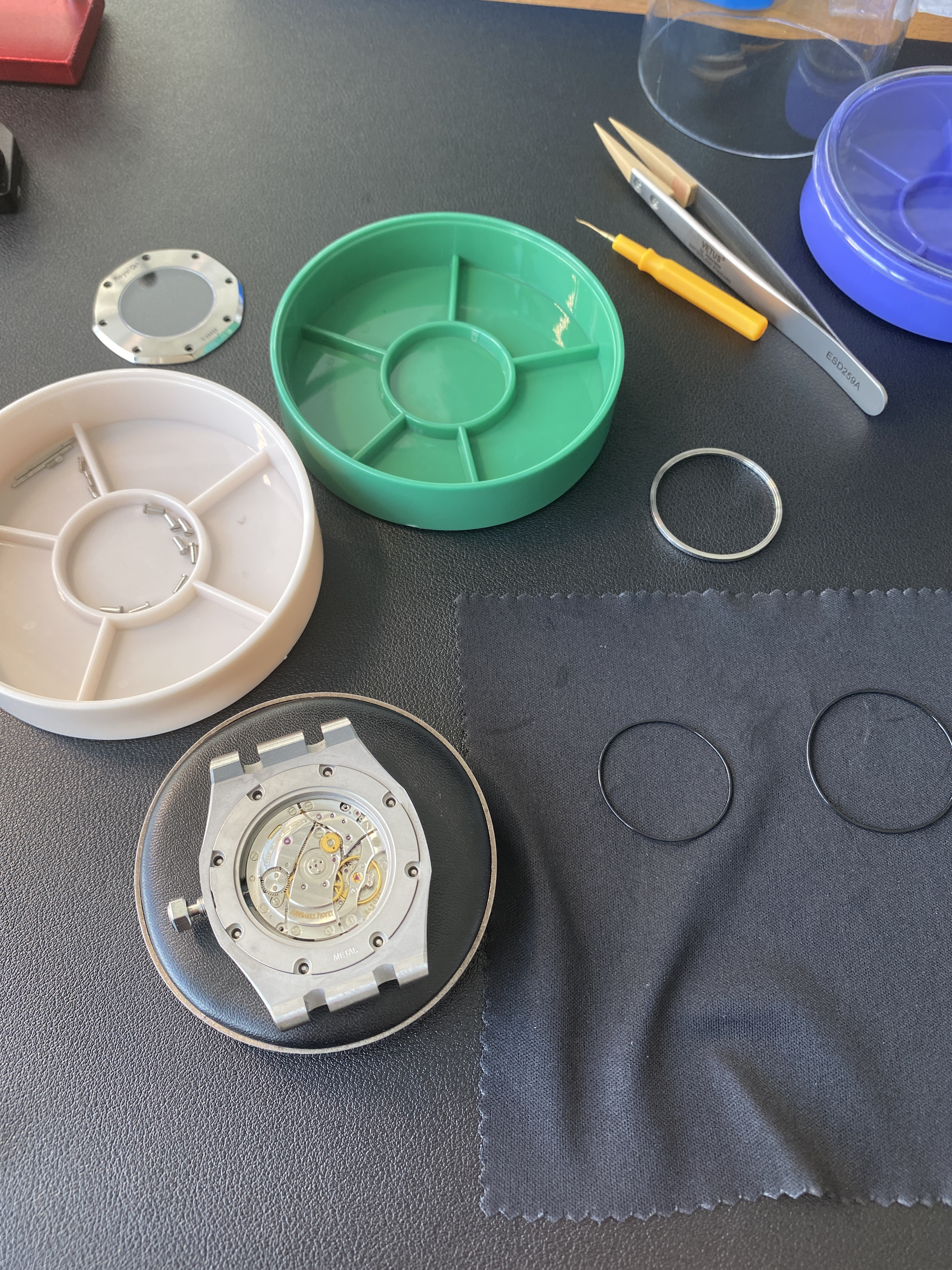

Update: After letting the parts dry under the saran wrap dust cover for an hour, I got to work on the re-assembly. This started with the two sock settings (mercifully there's no shock setting for the escape wheel like there is on the N4130). The two sock settings were much easier to work with than the ones on the N4130 or the VR3235 (or maybe I'm getting better at assembling these tiny bastards). Regardless, I managed to get the two shock settings assembled. I did the balance bridge one first, and I used the mainplate as a jig to hold the balance in place. I figured it would be easier to assemble the setting if if wasn't under tension, so by doing the bridge side first, the balance staff would hang down into the empty setting on the mainplate and allow me to work without upward pressure on the cap jewel. After this was complete, I removed the balance, and worked on the setting in the main plate.

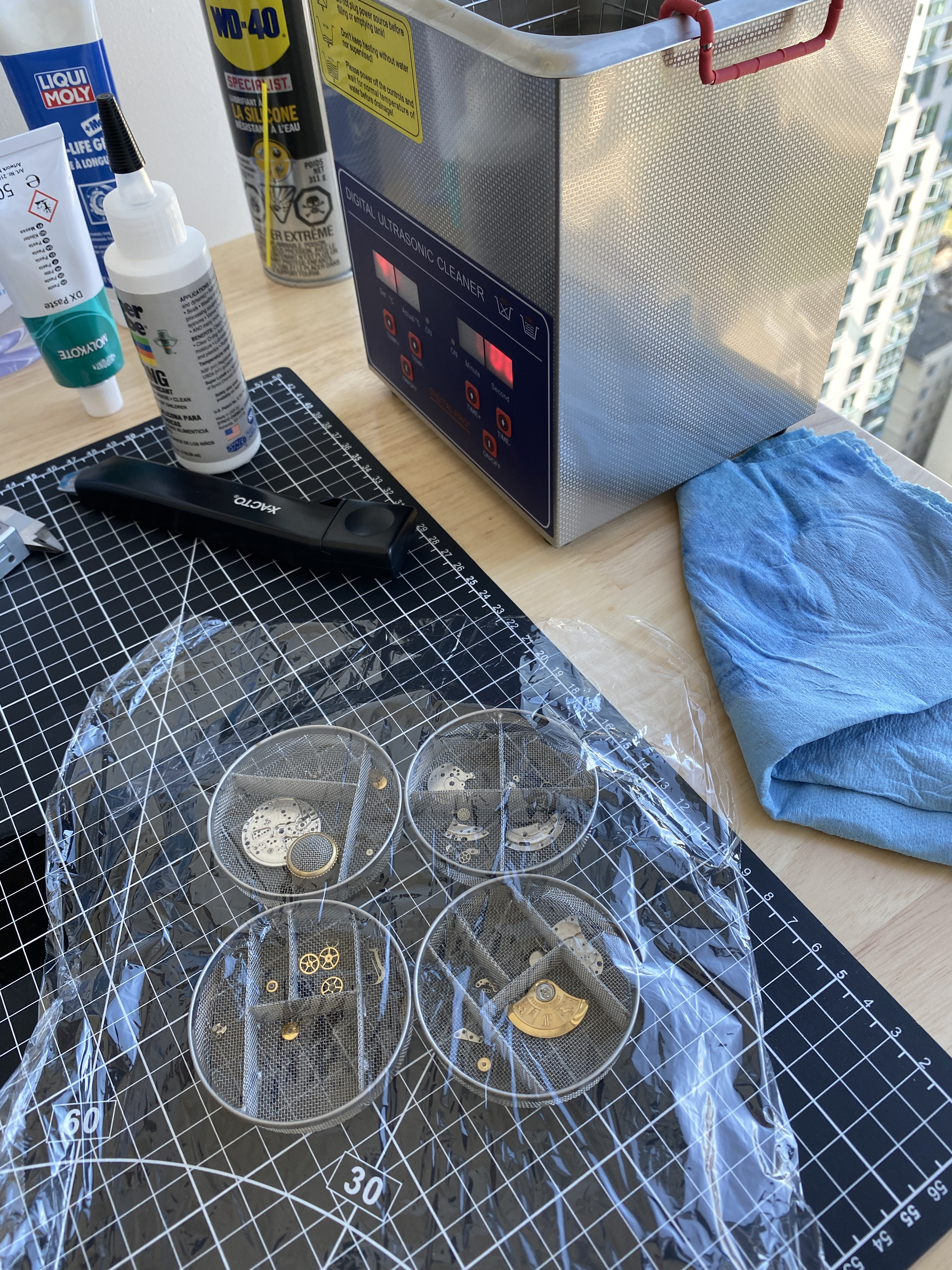

Next was doing an epilame treatment for the keyless works and the automatic module parts. I'm not sure if this is required or recommended, but I'm just kind of cribbing my way along based on what is says to do in the Rolex 3135 movement service manual. This is also the logic I'm using for which lubricants to use in which places as I re-assemble.

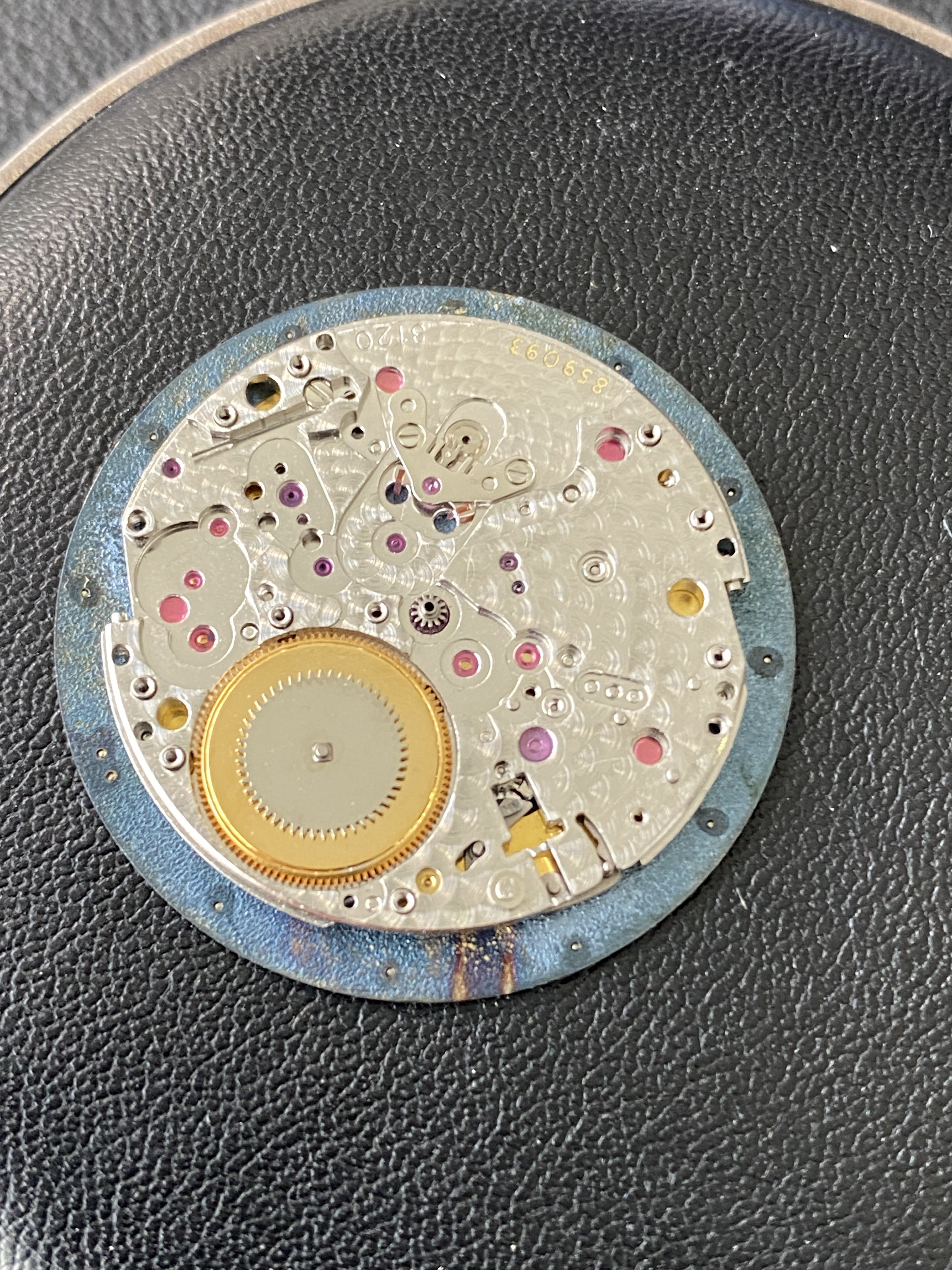

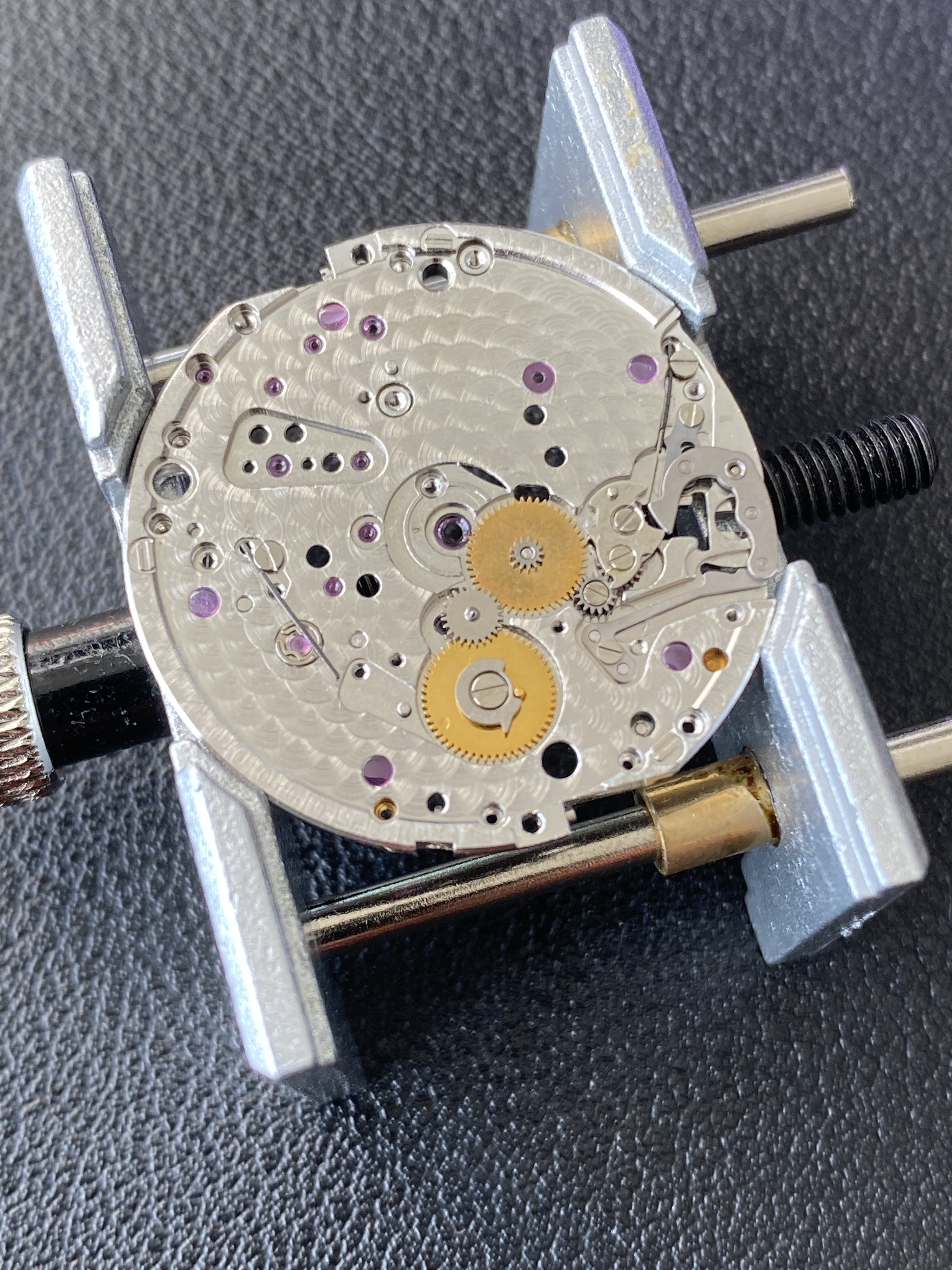

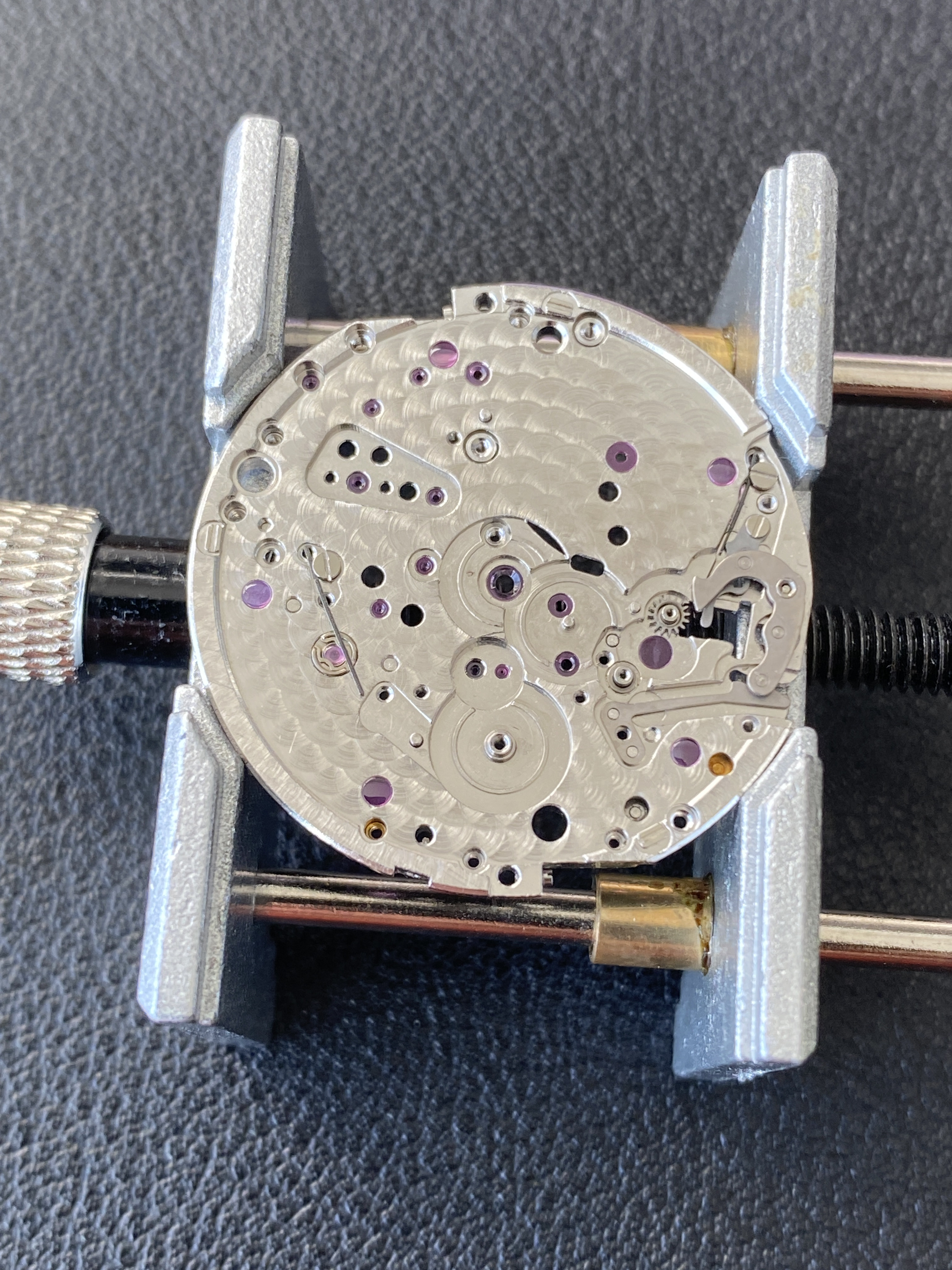

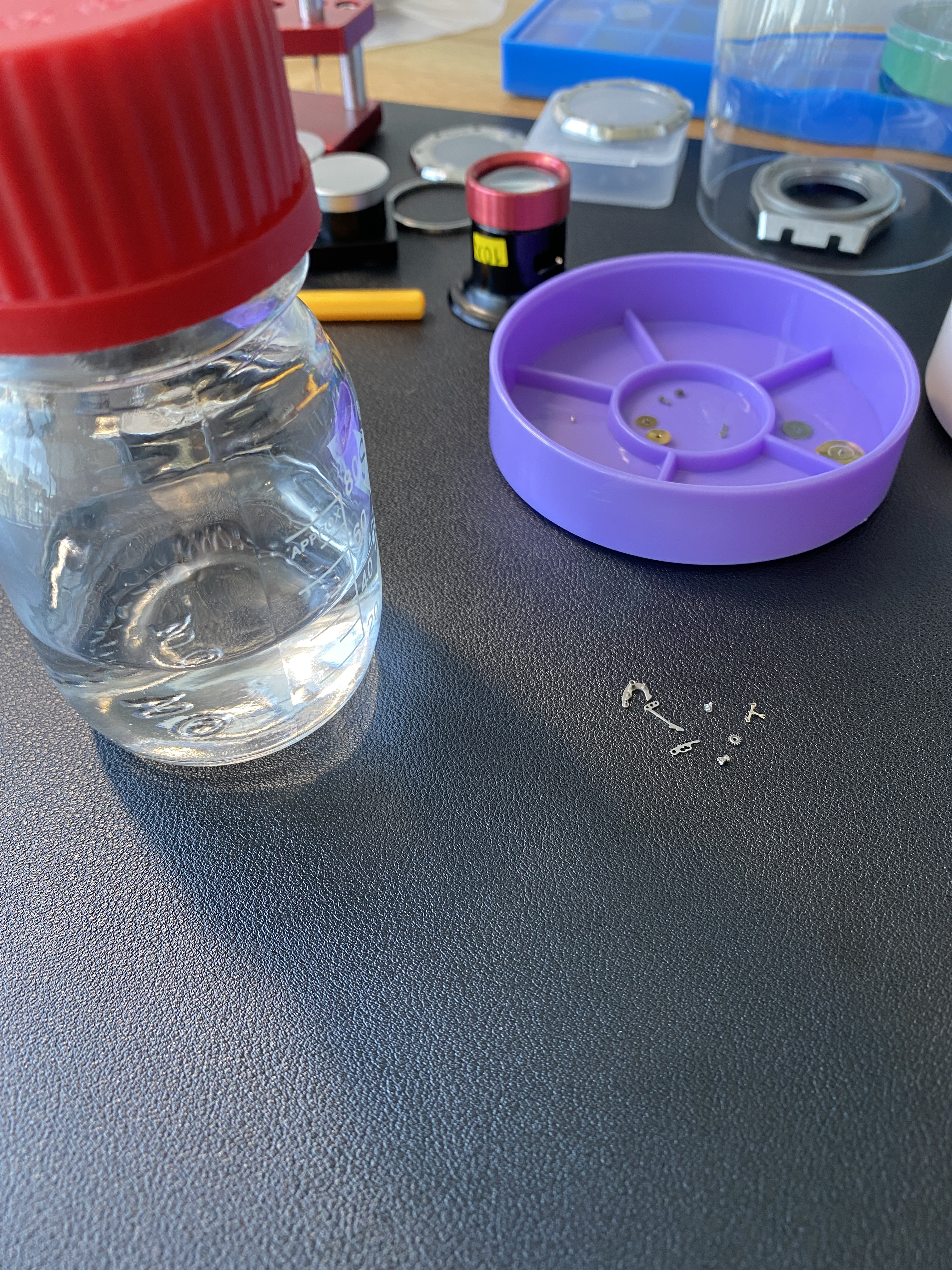

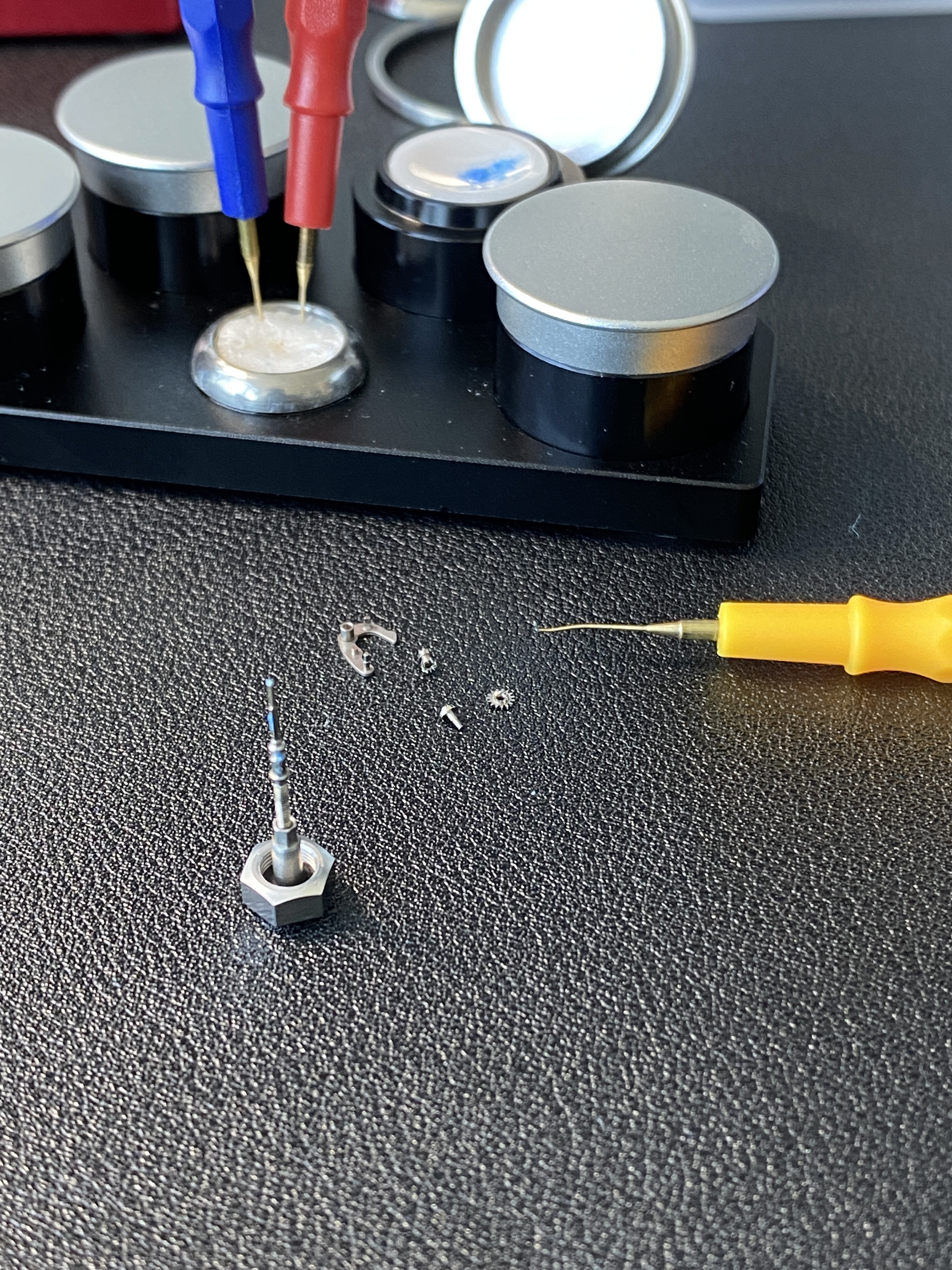

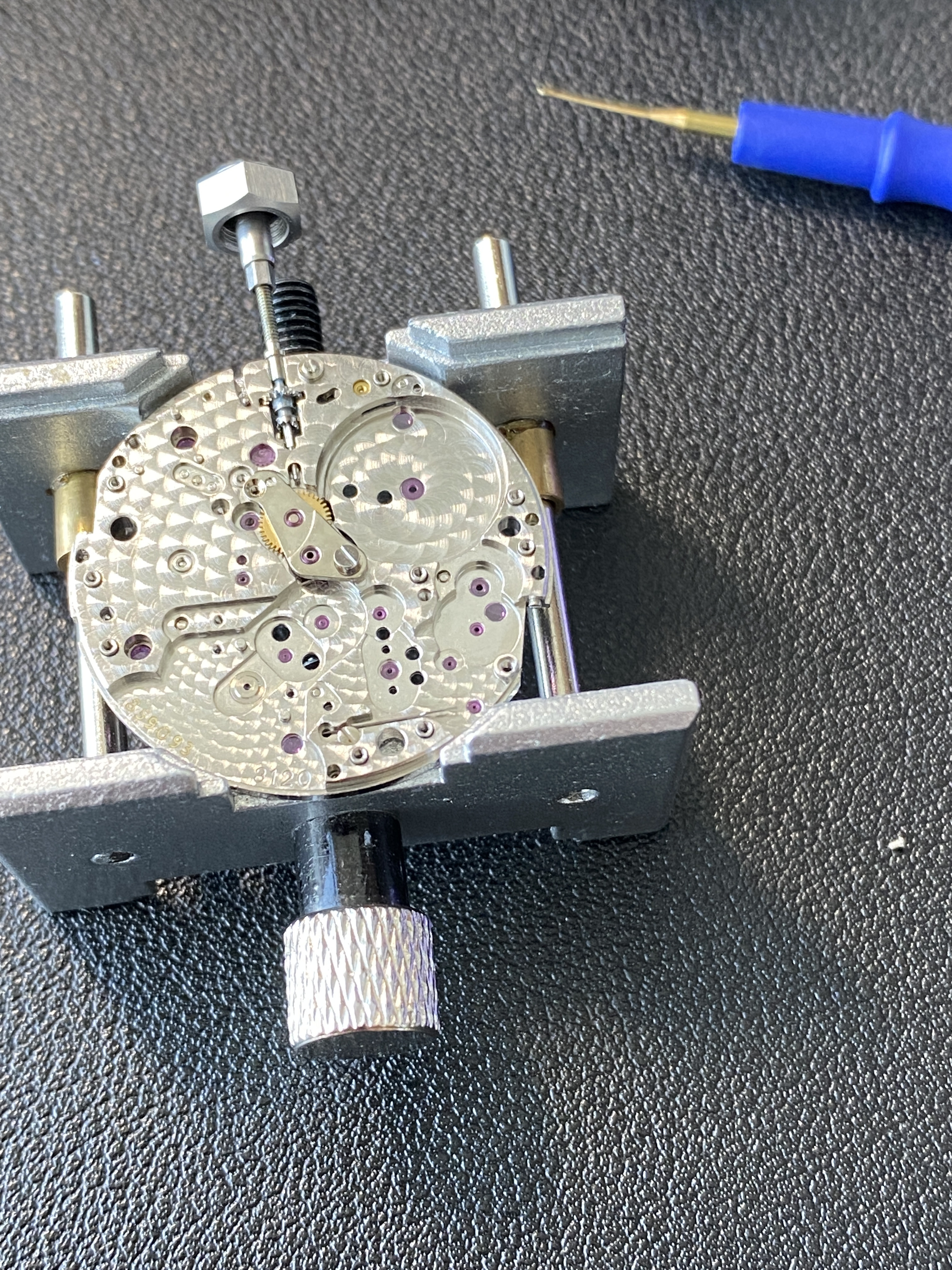

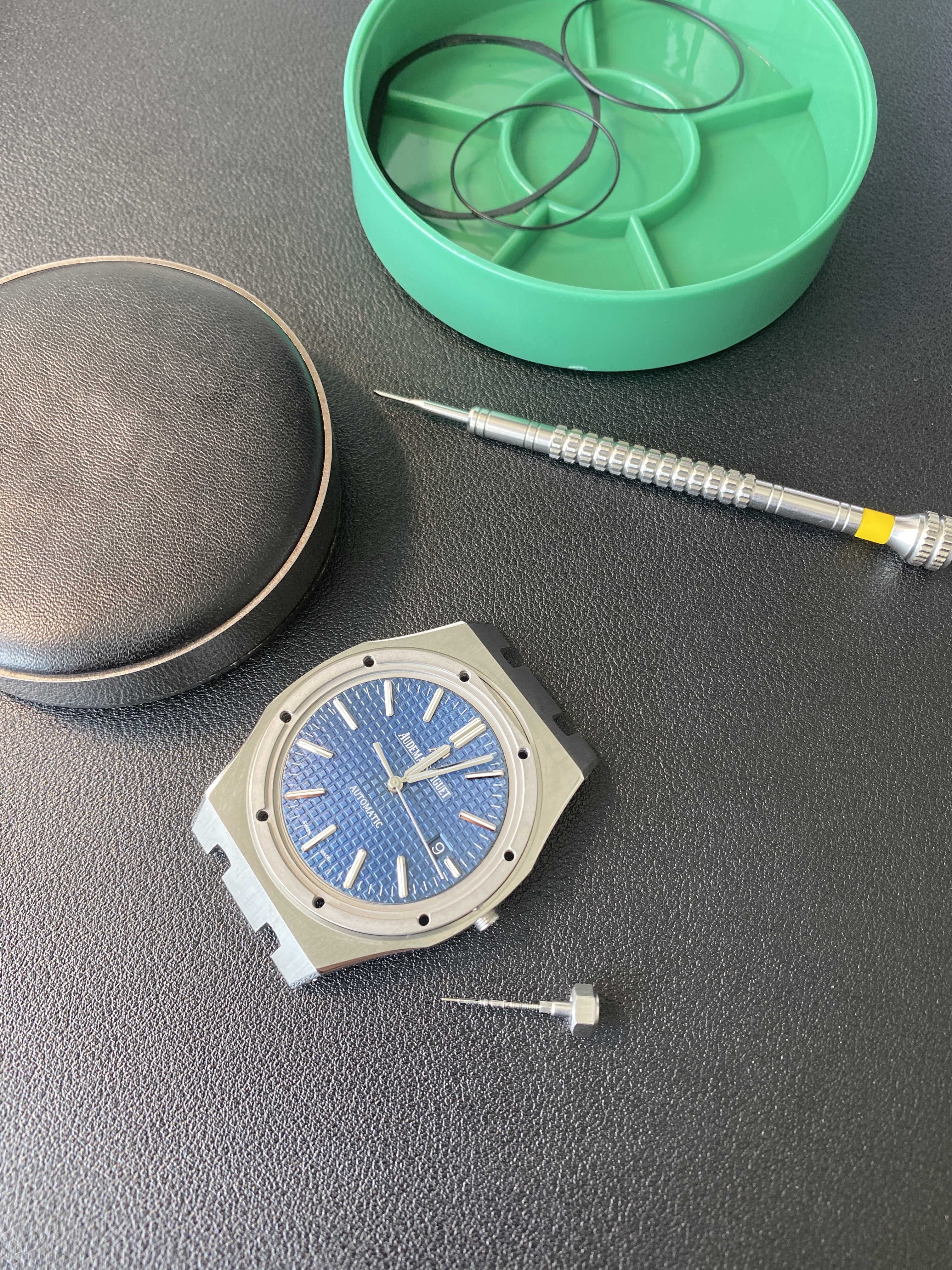

After the epilame was done, I stared re-assembling the keyless works. I started with the yoke and the screw to secure it. I lubricated here with moebius 9415 grease (this grease has a blue dye so it's sometimes visible in the pics). Then I flipped the movement over and installed the stem, winding pinion and sliding pinion. These were also all lubricated with 9415. The 3120 movement has a nice design for this part of the assembly, the mainplate has a slot cut into it, so you can skewer the two pinions on the stem and then place it into the movement and then slide the stem further into its slot. On the rolex caliblers I've worked on, you have to kinda hold the pinion in place on the mainplate and skewer it in place which is more delicate a procedure.

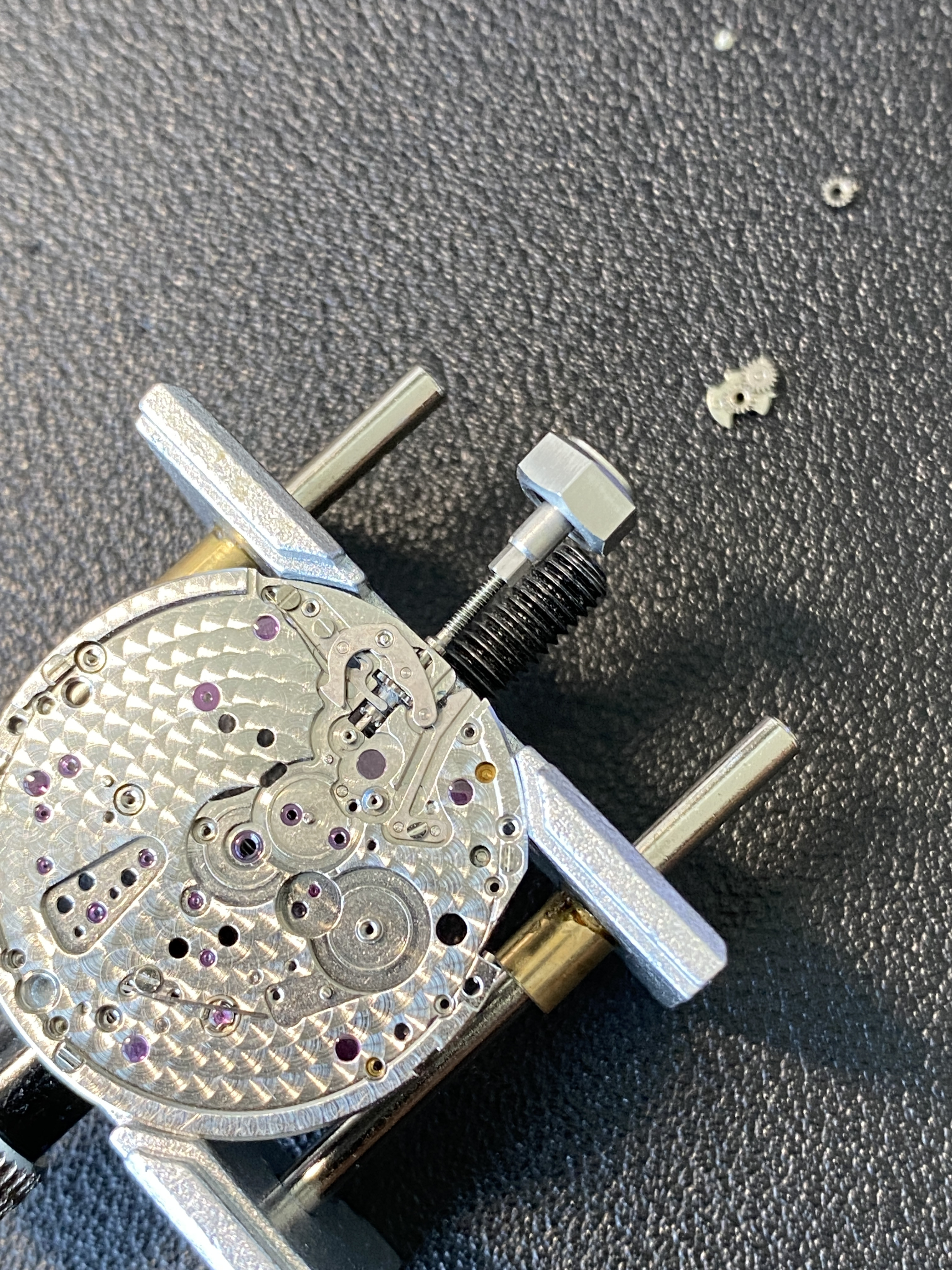

With the yoke, stem, and pinions in place, I flipped the movement again, and installed the setting lever spring. This was a really easy procedure compared to the explosive U-shaped springs found on rolex calibers. All the metal to metal slider surfaces and gently lubricated with 9415.

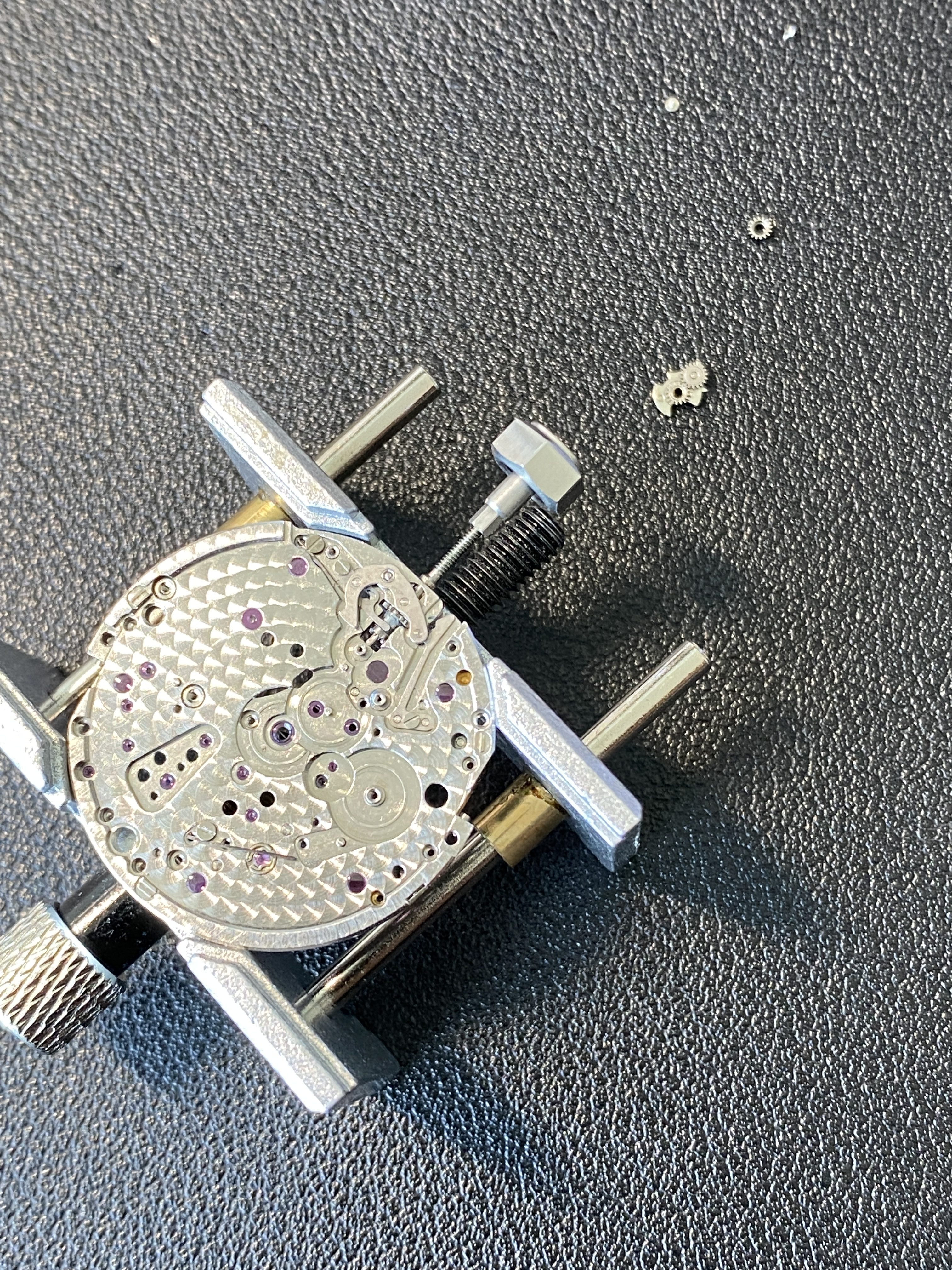

Then it was on to the setting lever. I was worried that this would be tricky since it's held in place by a screw that threads in from the other side of the movement. But it turns out, that the setting lever, once in place, is held nicely against its pivot by the setting level spring and yoke spring. So there's no danger of it falling away when you flip the movement to secure the setting lever screw from the other side.

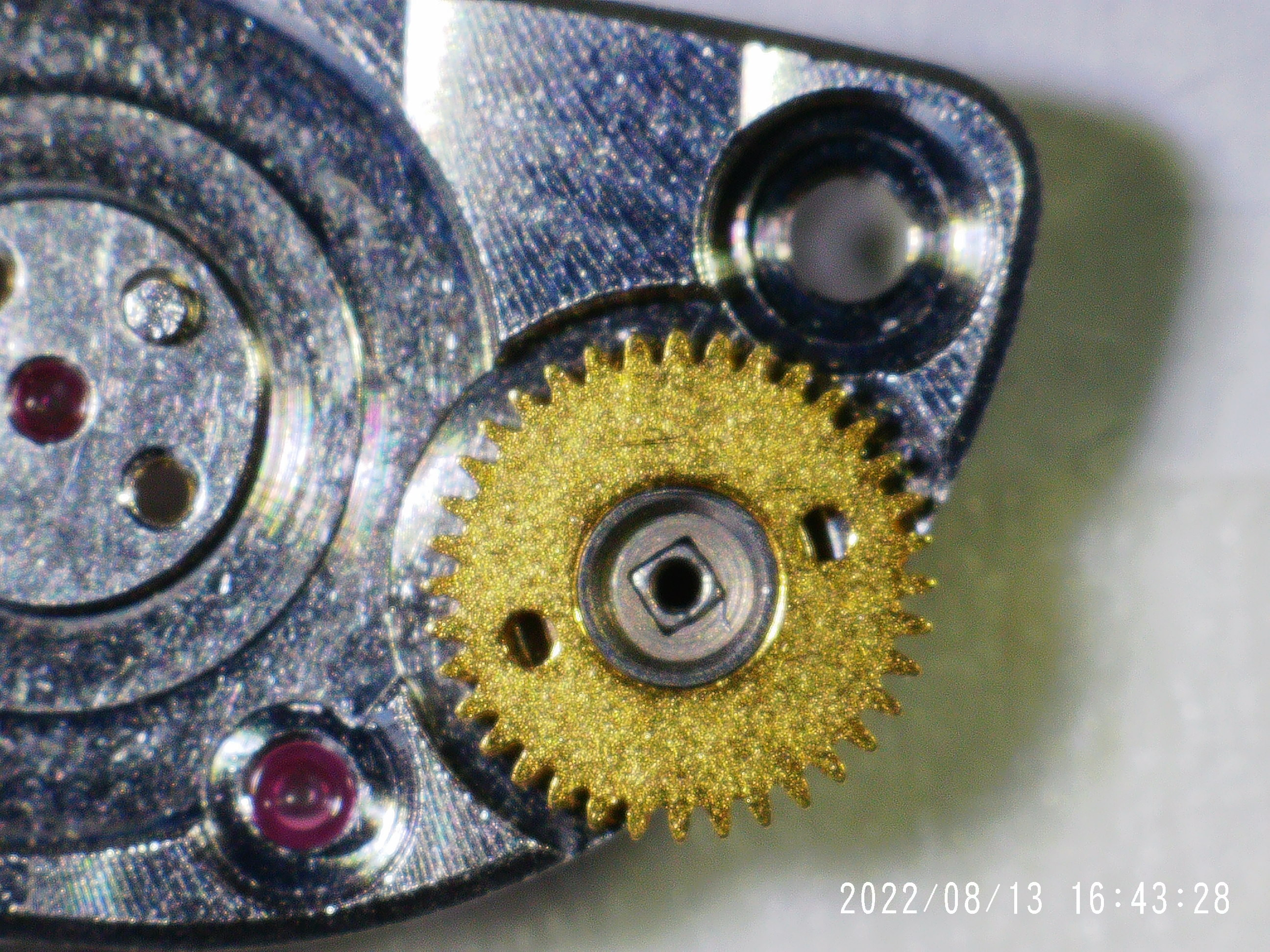

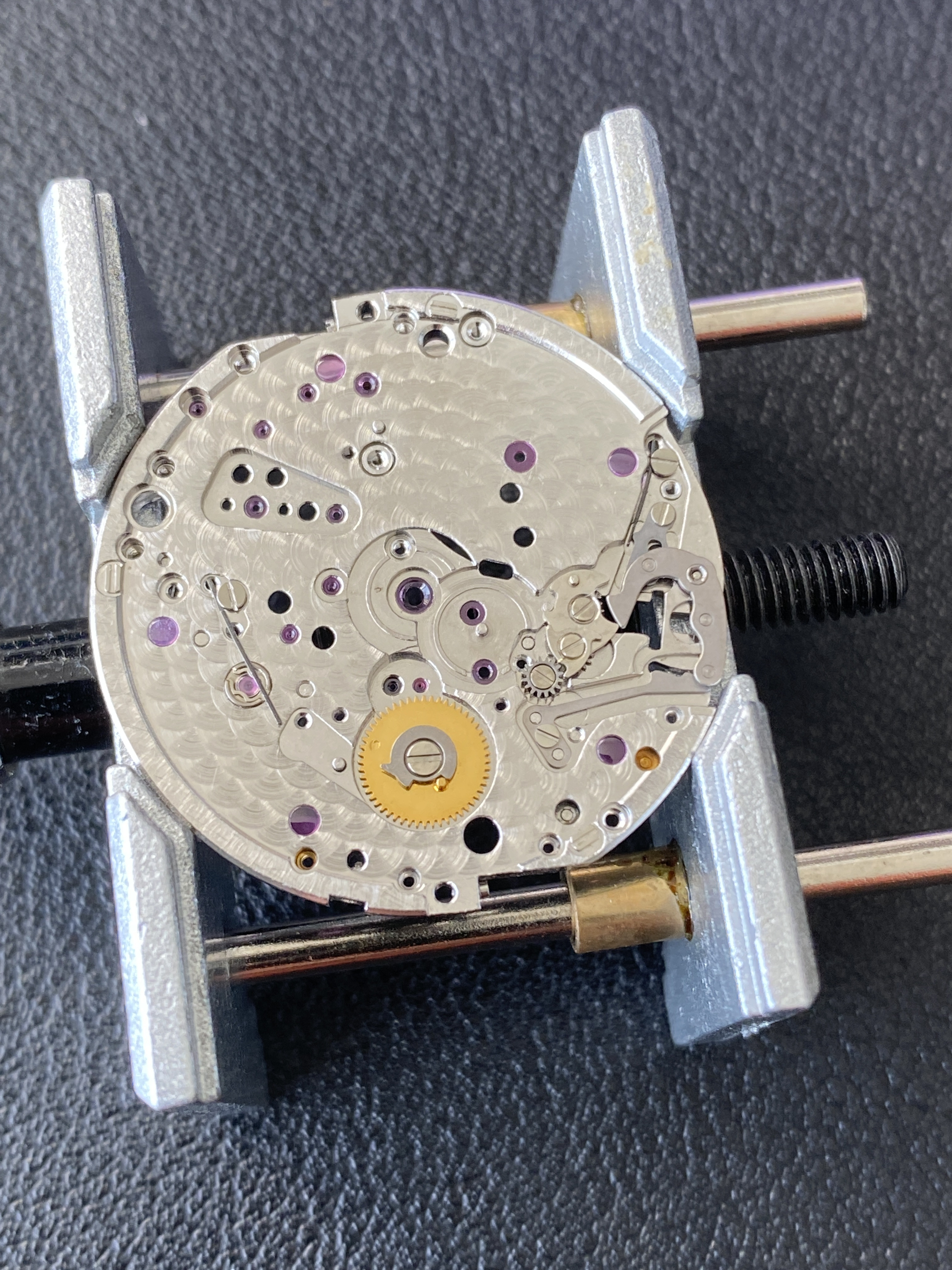

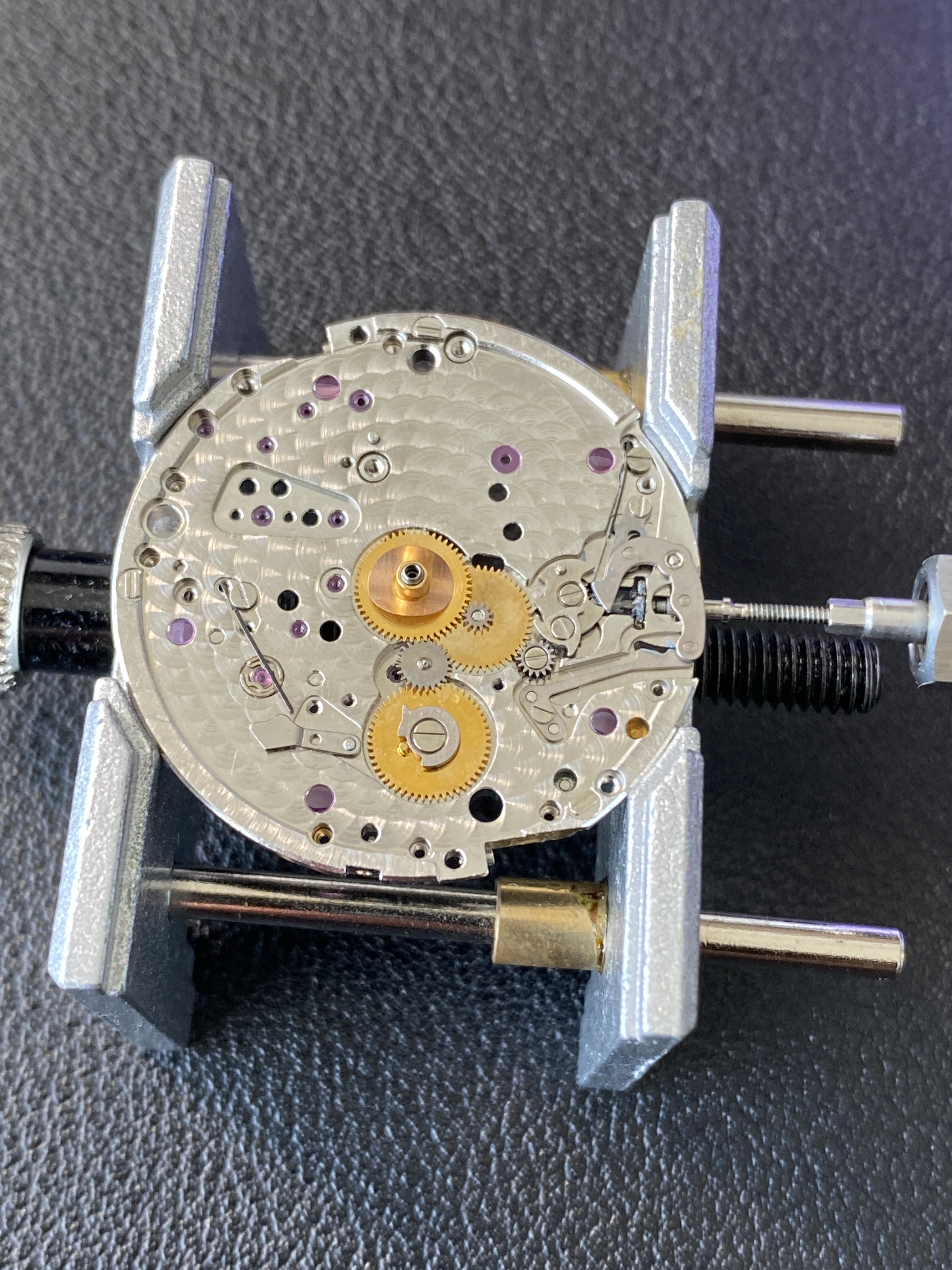

Next was getting all the setting wheels and date quick set wheels back into place. This was pretty straight forward, and made sure to lubricate any columns with 9415 if they had pinions that spun on them. But I used D-5 to lubricate the riveted gear pivots. I'm not sure if this was the correct method, but I figured I wanted an oil to get into the bushing on these parts since I couldn't access them directly with grease.

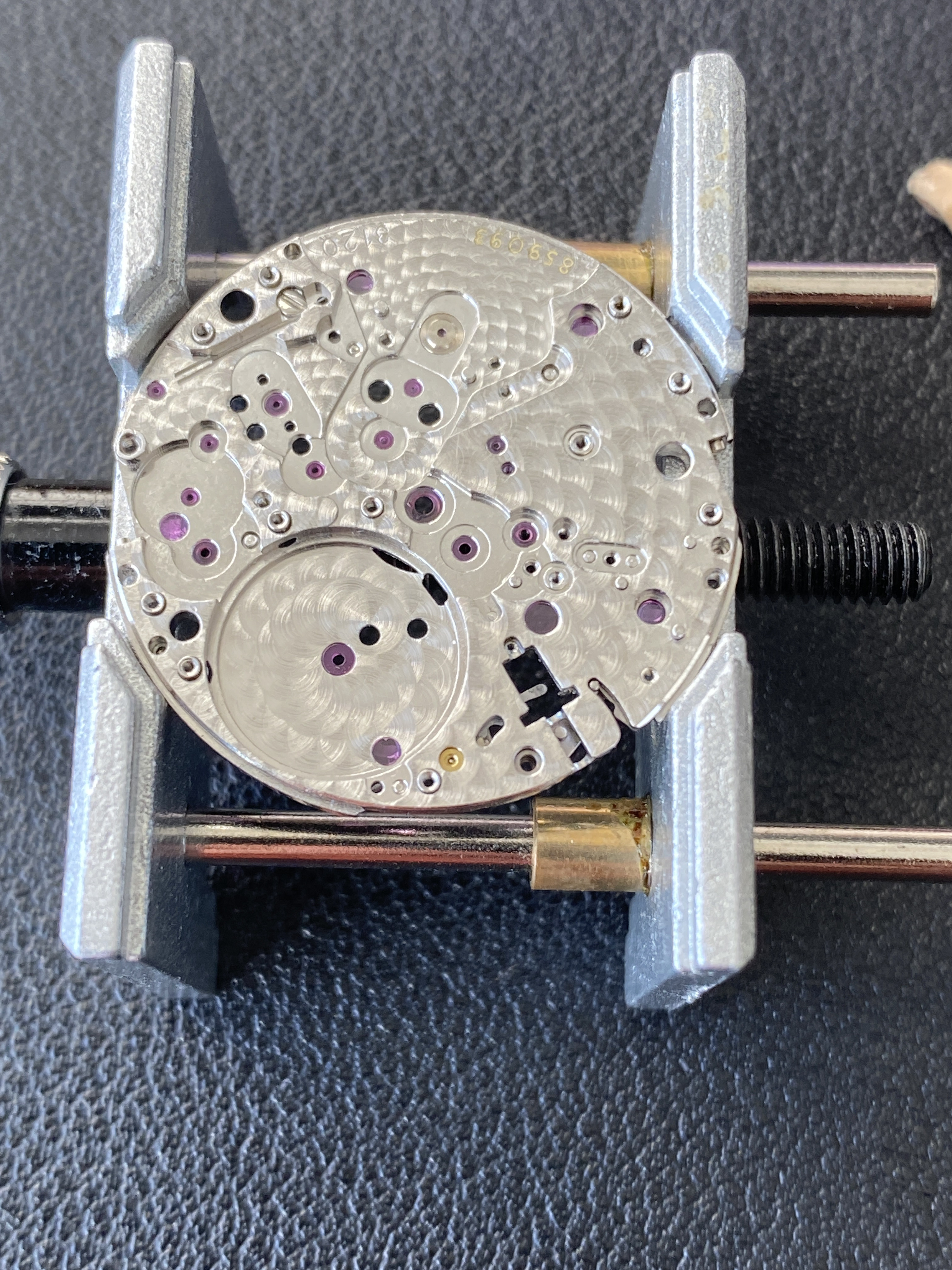

The it was on to the date change mechanism. Here is used D-5 since I figured there is some fast motion when the date jumps at midnight (well technically it jumps half way because it starts changing at 11pm and gets half way before jumping at 12 midnight). I figured an oil would be better for this type of movement.

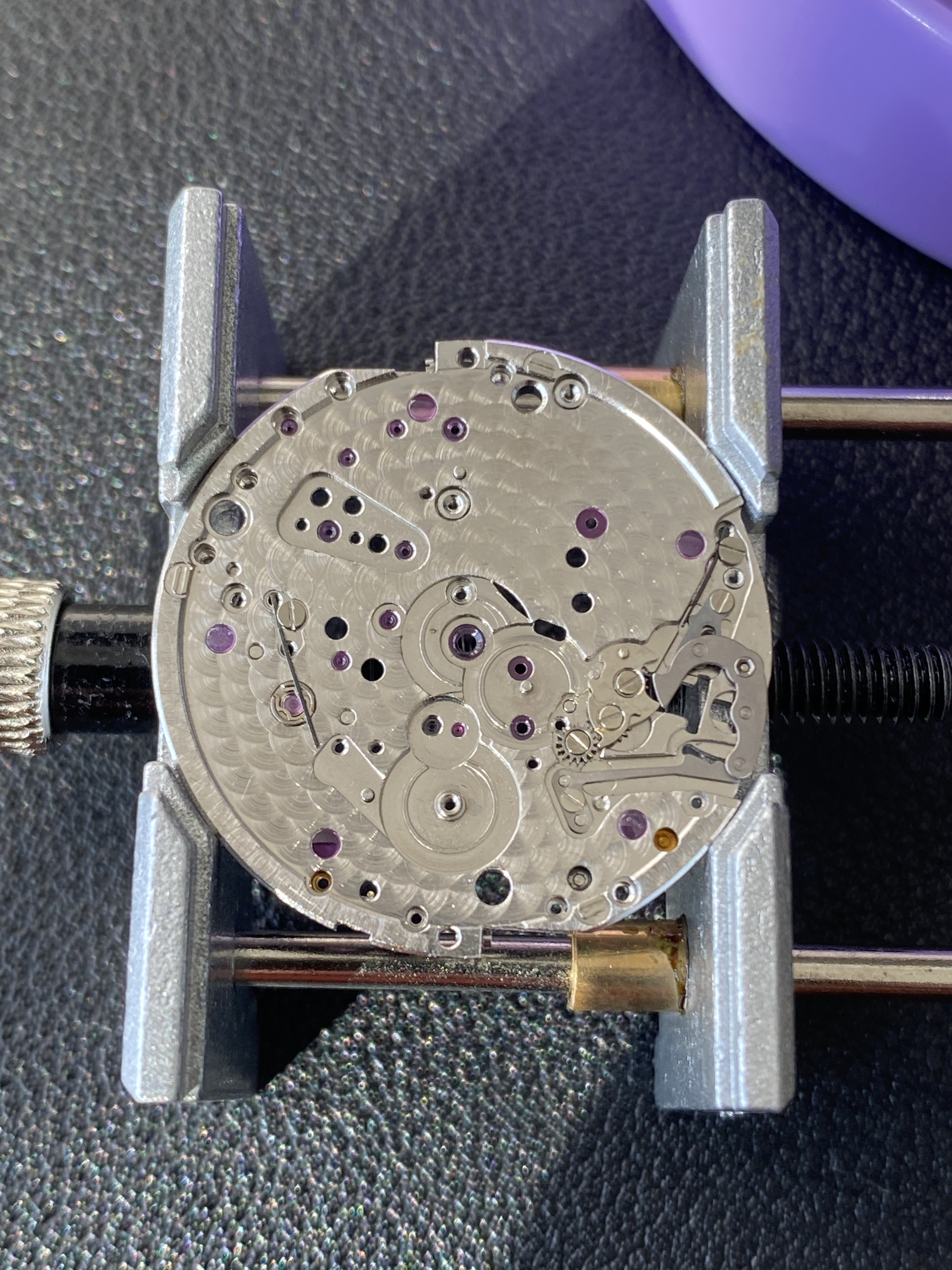

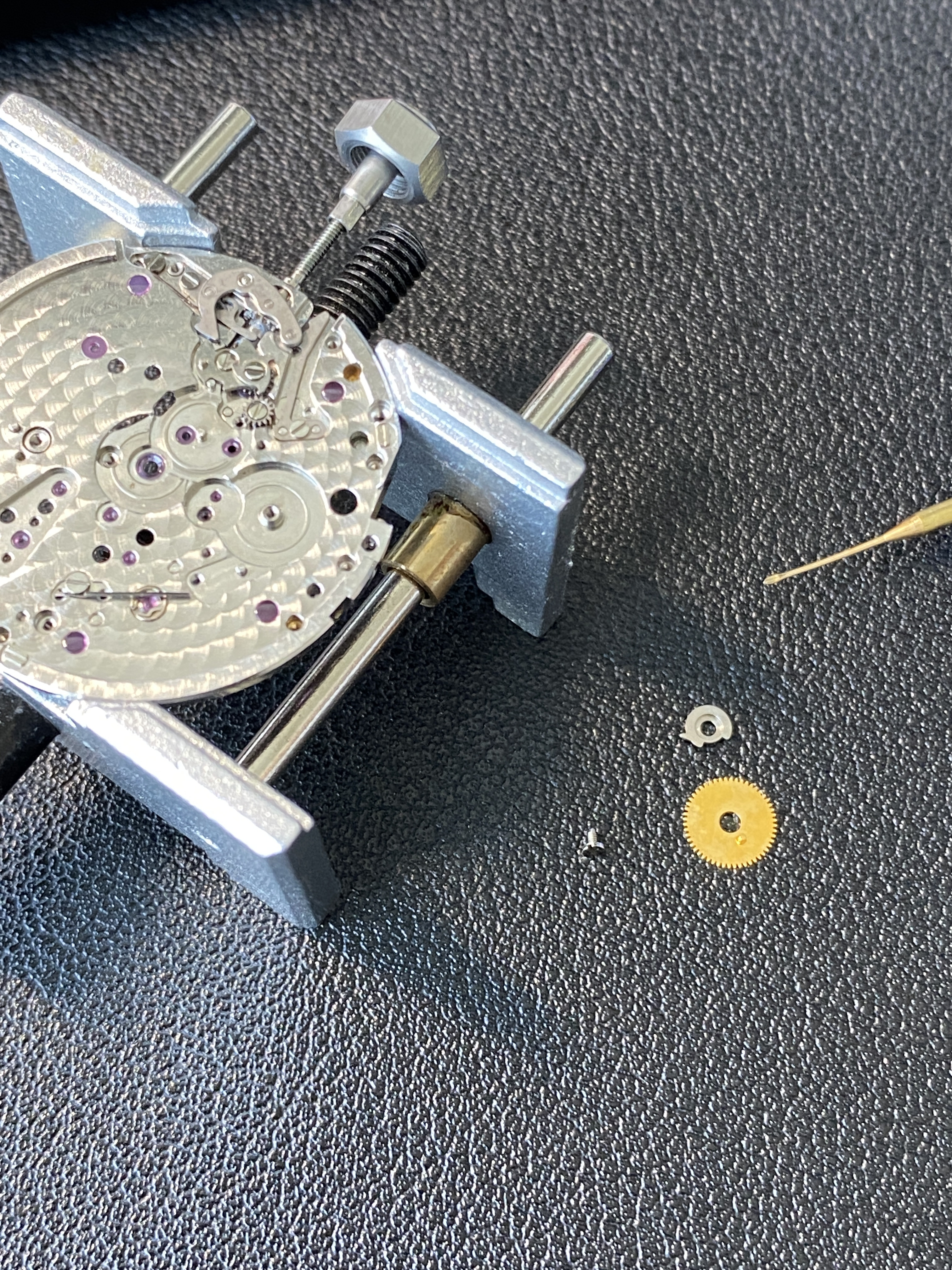

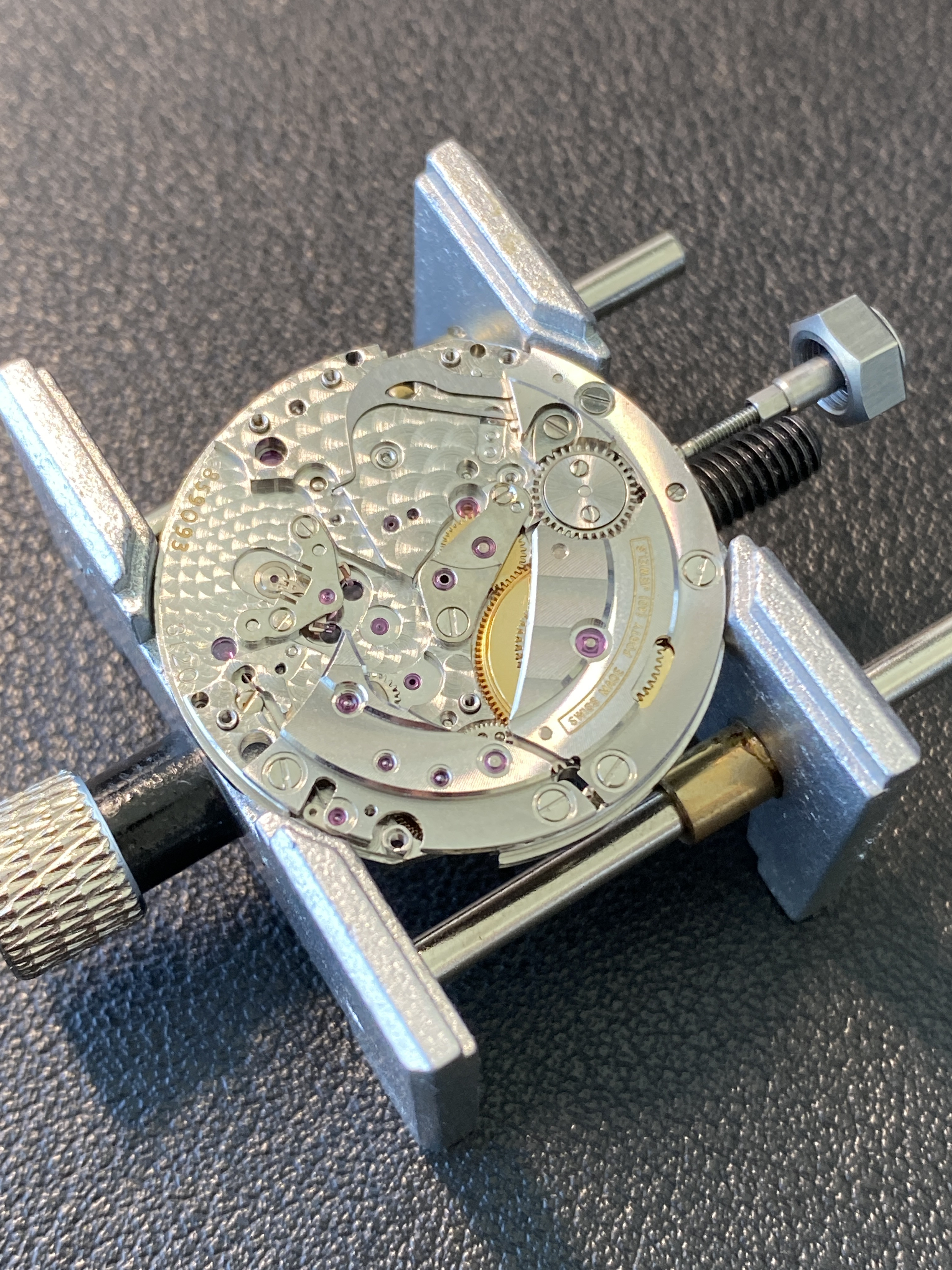

Then I flipped the movement over and installed the minute pinion and the minute pinion bridge. This is where I messed up the order on the disassembly because I removed these parts before removing the cannon pinion / motion works. I lubricated these parts as though they were the parts of a rolex 3135 movement. I'm not sure this was correct, but the design looks very similar in principal, so I'm hoping that D5 in the places I'd put it on a 3135 will work here.

Next I flipped the movement back over to the dial side, and installed the setting intermediate wheel, the hour wheel, and the date intermediate wheel. Here I lubricated with D-5.

And now my back is a little sore, so I think I'll take a walk outside and get some fresh air. Once again, thanks for following along.