-

Tired of adverts on RWI? - Subscribe by clicking HERE and PMing Trailboss for instructions and they will magically go away!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

PsychoTee's Repair & Servicing Journey

- Thread starter PsychoTee16

- Start date

This thread is the absolute bollocks!!

Amazing work, you started pretty much where I am now, I am so impressed with what you've done.

Well done mate, I'll be following this intently

Hey there!

Thanks for the kind words! It’s been a journey for sure and definitely not a hobby anymore hah!

I have a Instagram too that I share more frequently on as well. Check it out if interested.

mightynimrod

Active Member

Will do Trevor, look out for Steve PatrickHey there!

Thanks for the kind words! It’s been a journey for sure and definitely not a hobby anymore hah!

I have a Instagram too that I share more frequently on as well. Check it out if interested.

Evening all!

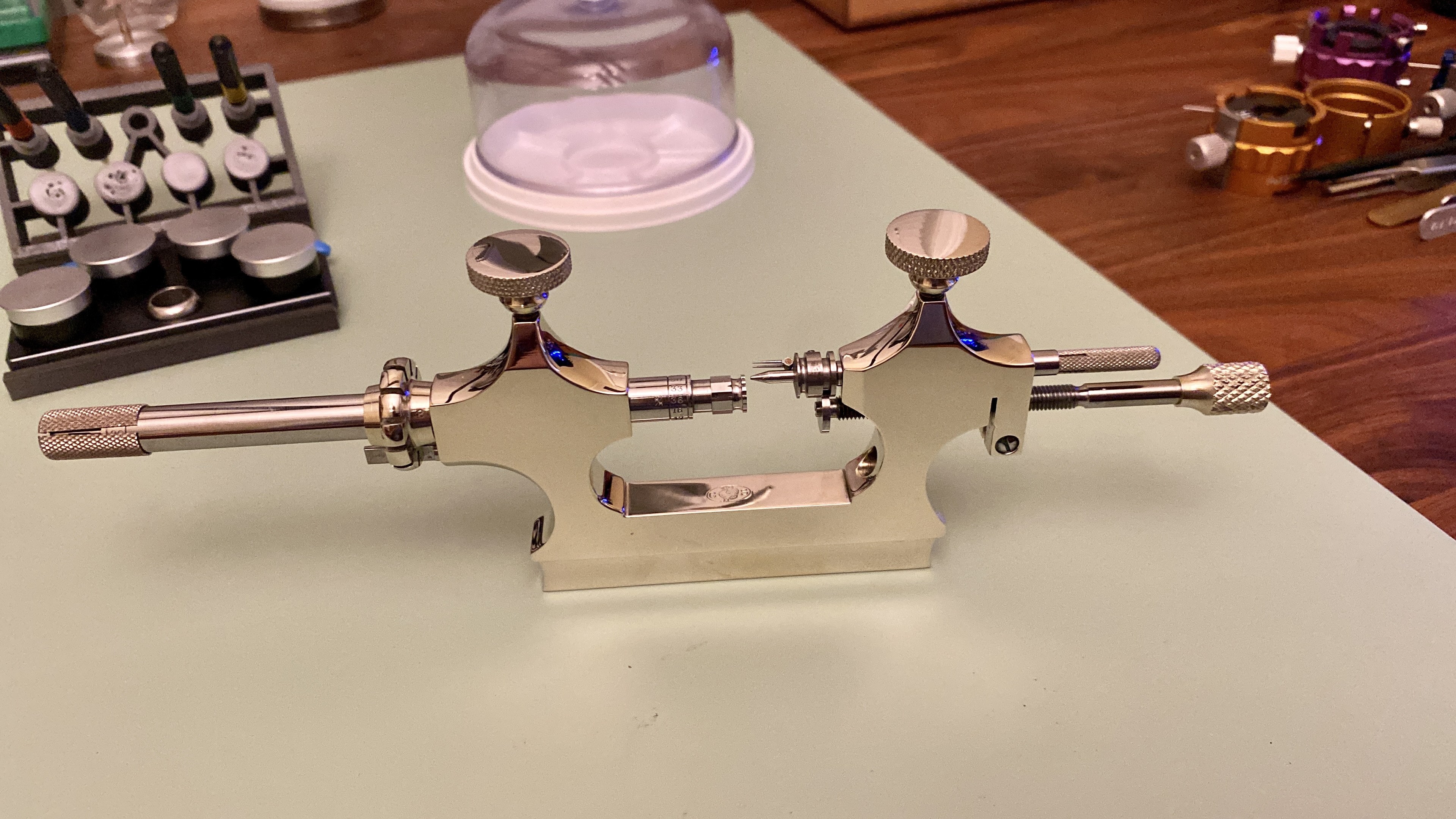

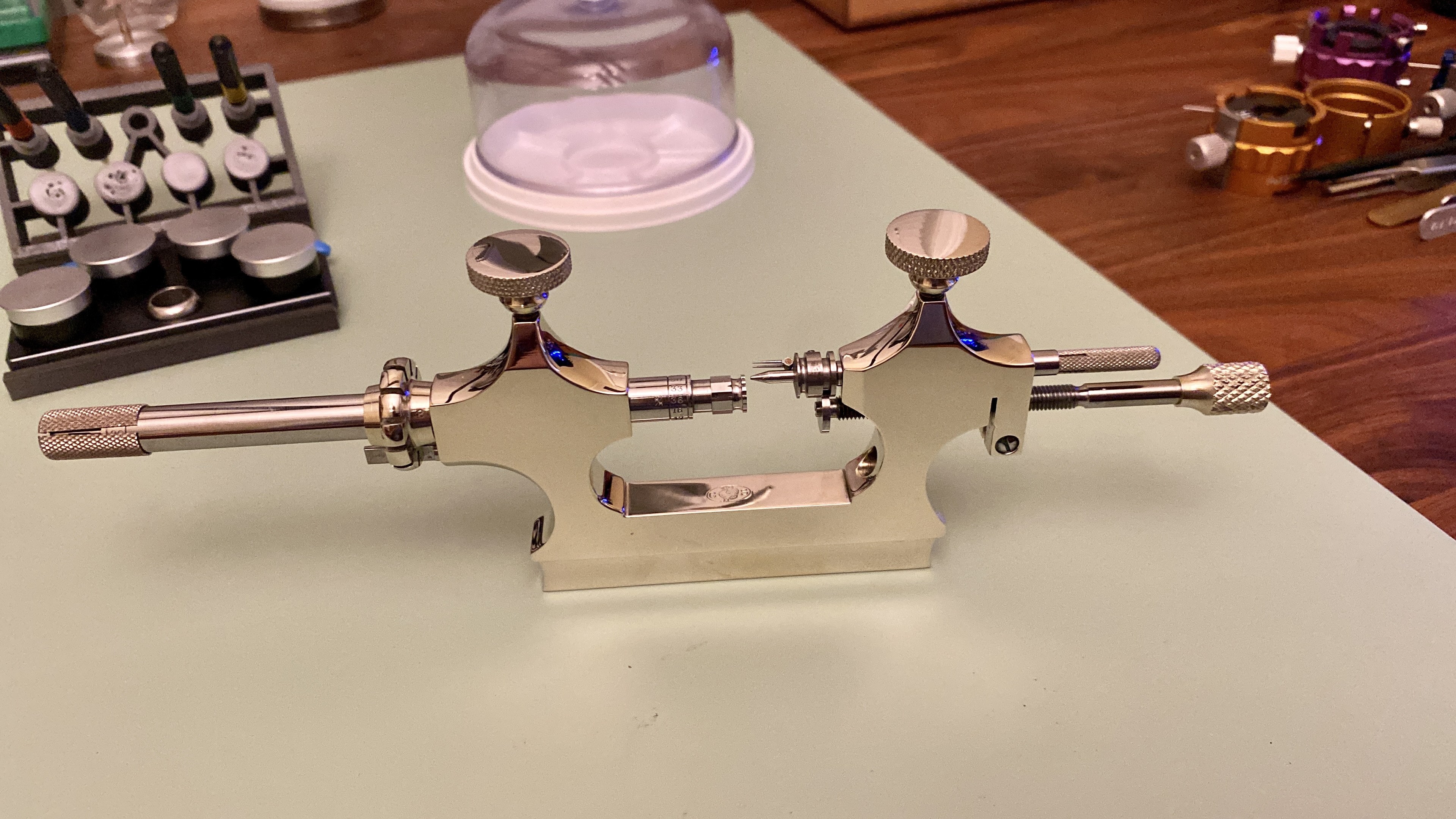

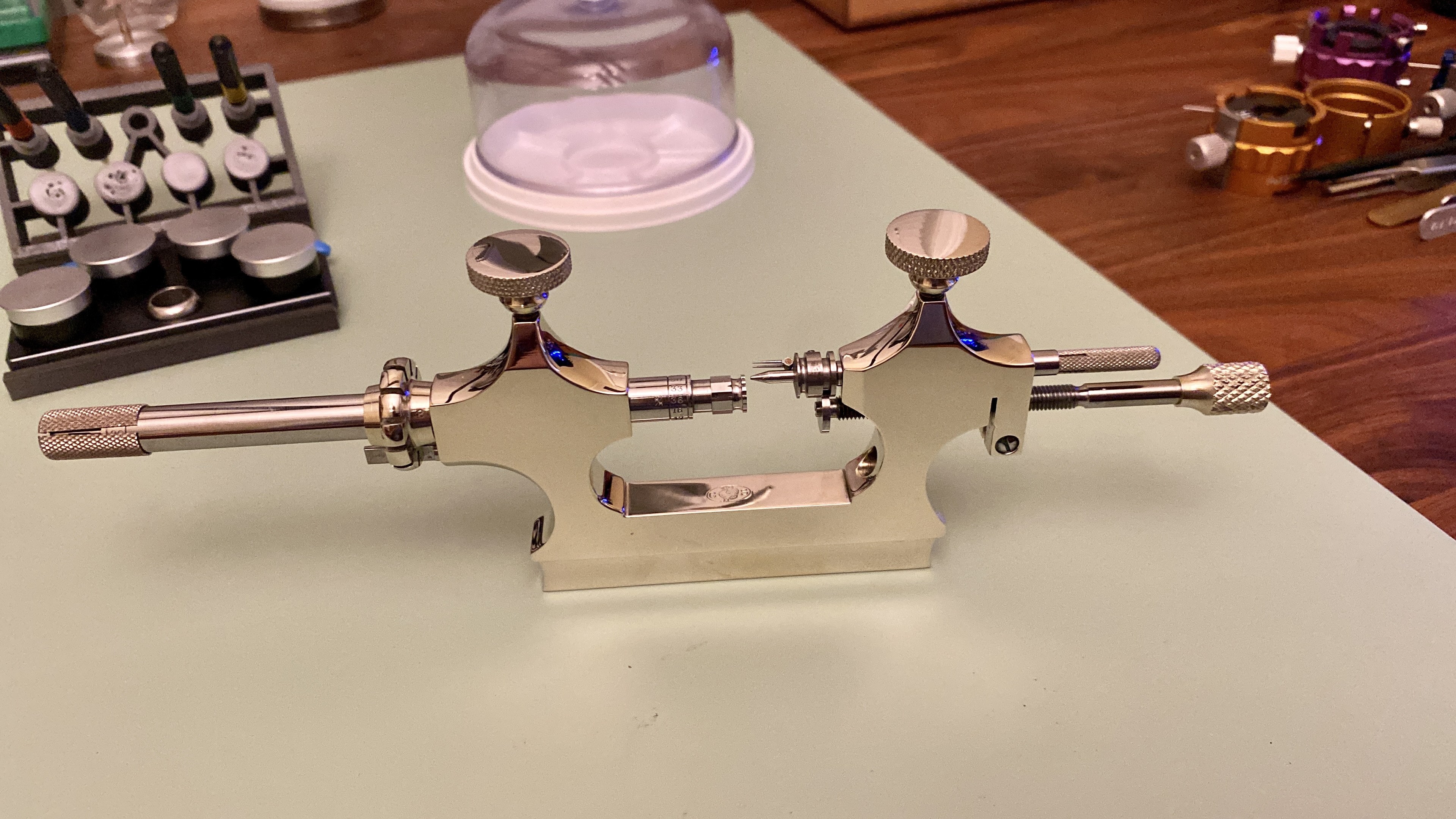

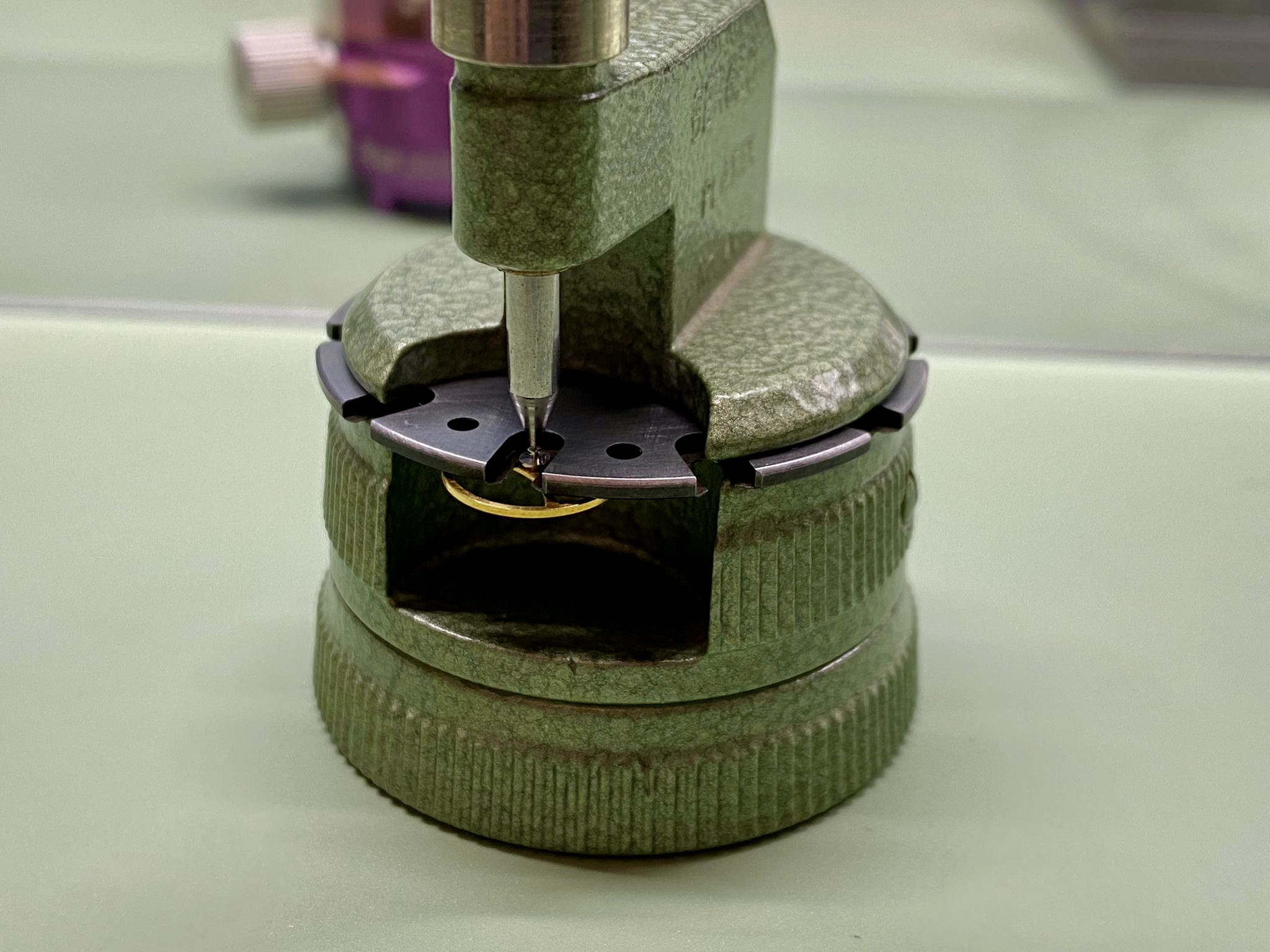

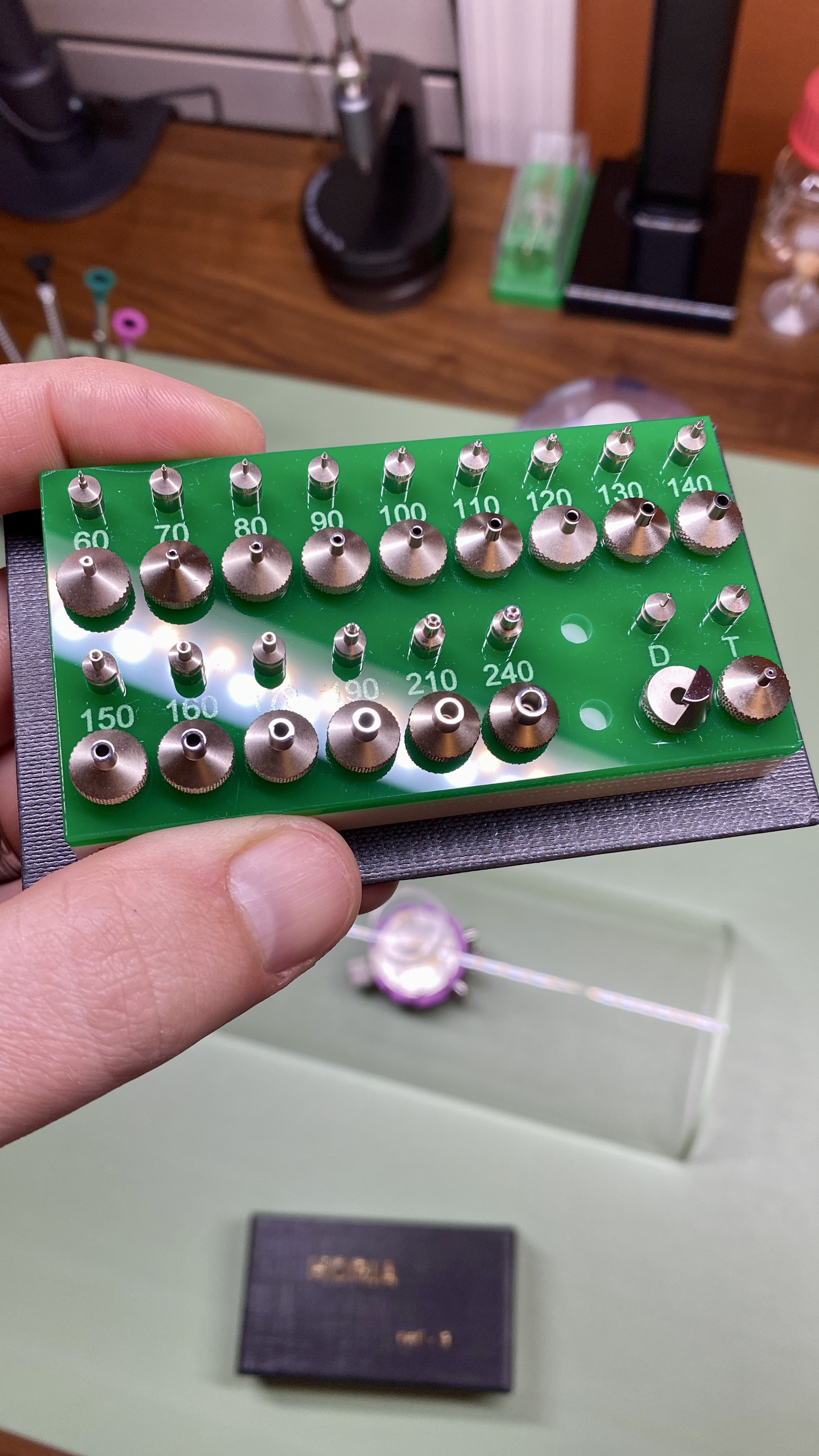

Today was another tool day!! I was able to secure a practically new Jacot Tool priced very well. These are very hard to find priced well, clean, and with all the parts. And this one only has a couple bumps in it, that could probably be polished out.

For those not familair with the purpose of this tool, we can use it to file down pivots or burnish/polish them. Think of it as a manual lathe. This helps a bit with friction as these rotate in their jewels.

These are probably more used on vintage movements, but it could come in handy on more recent watches and reps that have rough pivots.

There are tools called “pivofix” that are more of an automatic tool compared to this and don’t require too much skill. But are typically 5x as expensive…

I’m looking forward to practicing this quite a bit and seeing results! I’ll be sure to share progress as I start to learn this skill.

Today was another tool day!! I was able to secure a practically new Jacot Tool priced very well. These are very hard to find priced well, clean, and with all the parts. And this one only has a couple bumps in it, that could probably be polished out.

For those not familair with the purpose of this tool, we can use it to file down pivots or burnish/polish them. Think of it as a manual lathe. This helps a bit with friction as these rotate in their jewels.

These are probably more used on vintage movements, but it could come in handy on more recent watches and reps that have rough pivots.

There are tools called “pivofix” that are more of an automatic tool compared to this and don’t require too much skill. But are typically 5x as expensive…

I’m looking forward to practicing this quite a bit and seeing results! I’ll be sure to share progress as I start to learn this skill.

Last edited:

Hey all!

Figured I’d share a interesting, although not too surprising finding on a recent watch.

I had a customer send in a Daytona he bought off of a Reddit BST sub. Mentioned the chronograph hadn’t worked since he bought, and he also wanted me to check out the hands. The seller claimed they were gen, and also listed them for $950 under his sales thread.

Hands as on watch received:

Can you all tell yet?

Gen hands for reference:

These were clearly rep hands and not gen. Finishing was terrible and even the lume is different.

His chrono was also busted, and after opening it up the issue was clear. I was able to fix the issue without tearing down the watch completely.

Seller also claimed the movement was serviced, however it was not and was very dirty.

Lesson learned, don’t buy off of Reddit BSTs. Those subs are full of scammers, and the mods will likely do nothing to help you.

Edit ; The mods there on reddit have done absolutely nothing to help this buyer....

Figured I’d share a interesting, although not too surprising finding on a recent watch.

I had a customer send in a Daytona he bought off of a Reddit BST sub. Mentioned the chronograph hadn’t worked since he bought, and he also wanted me to check out the hands. The seller claimed they were gen, and also listed them for $950 under his sales thread.

Hands as on watch received:

Can you all tell yet?

Gen hands for reference:

These were clearly rep hands and not gen. Finishing was terrible and even the lume is different.

His chrono was also busted, and after opening it up the issue was clear. I was able to fix the issue without tearing down the watch completely.

Seller also claimed the movement was serviced, however it was not and was very dirty.

Lesson learned, don’t buy off of Reddit BSTs. Those subs are full of scammers, and the mods will likely do nothing to help you.

Edit ; The mods there on reddit have done absolutely nothing to help this buyer....

Last edited:

Evening all!

Today was another tool day!! I was able to secure a practically new Jacot Tool priced very well. These are very hard to find priced well, clean, and with all the parts. And this one only has a couple bumps in it, that could probably be polished out.

For those not familair with the purpose of this tool, we can use it to file down pivots or burnish/polish them. Think of it as a manual lathe. This helps a bit with friction as these rotate in their jewels.

These are probably more used on vintage movements, but it could come in handy on more recent watches and reps that have rough pivots.

There are tools called “pivofix” that are more of an automatic tool compared to this and don’t require too much skill. But are typically 5x as expensive…

I’m looking forward to practicing this quite a bit and seeing results! I’ll be sure to share progress as I start to learn this skill.

Looks in very good condition, and is commonly known as a Jacot tool, I can't see the "bow" in your picture?, If you dont have one, you will need one. A very useful piece of equipment, especially on Rep's. Learning to handle this correctly is a skill in itself and can bring very surprising results.

It is s tool very seldom used these days in our world of exchange parts, However they are a very very handy tool and kudos to you

for looking further ahead to progress your watchmaking skills.

Looks in very good condition, and is commonly known as a Jacot tool, I can't see the "bow" in your picture?, If you dont have one, you will need one. A very useful piece of equipment, especially on Rep's. Learning to handle this correctly is a skill in itself and can bring very surprising results.

It is s tool very seldom used these days in our world of exchange parts, However they are a very very handy tool and kudos to you

for looking further ahead to progress your watchmaking skills.

Thanks!

It did not come with a bow. I’ll either make my own or I saw that some people use a retractable lanyard as well.

Will hardly be used yes, but always want to keep learning!

Afternoon all!

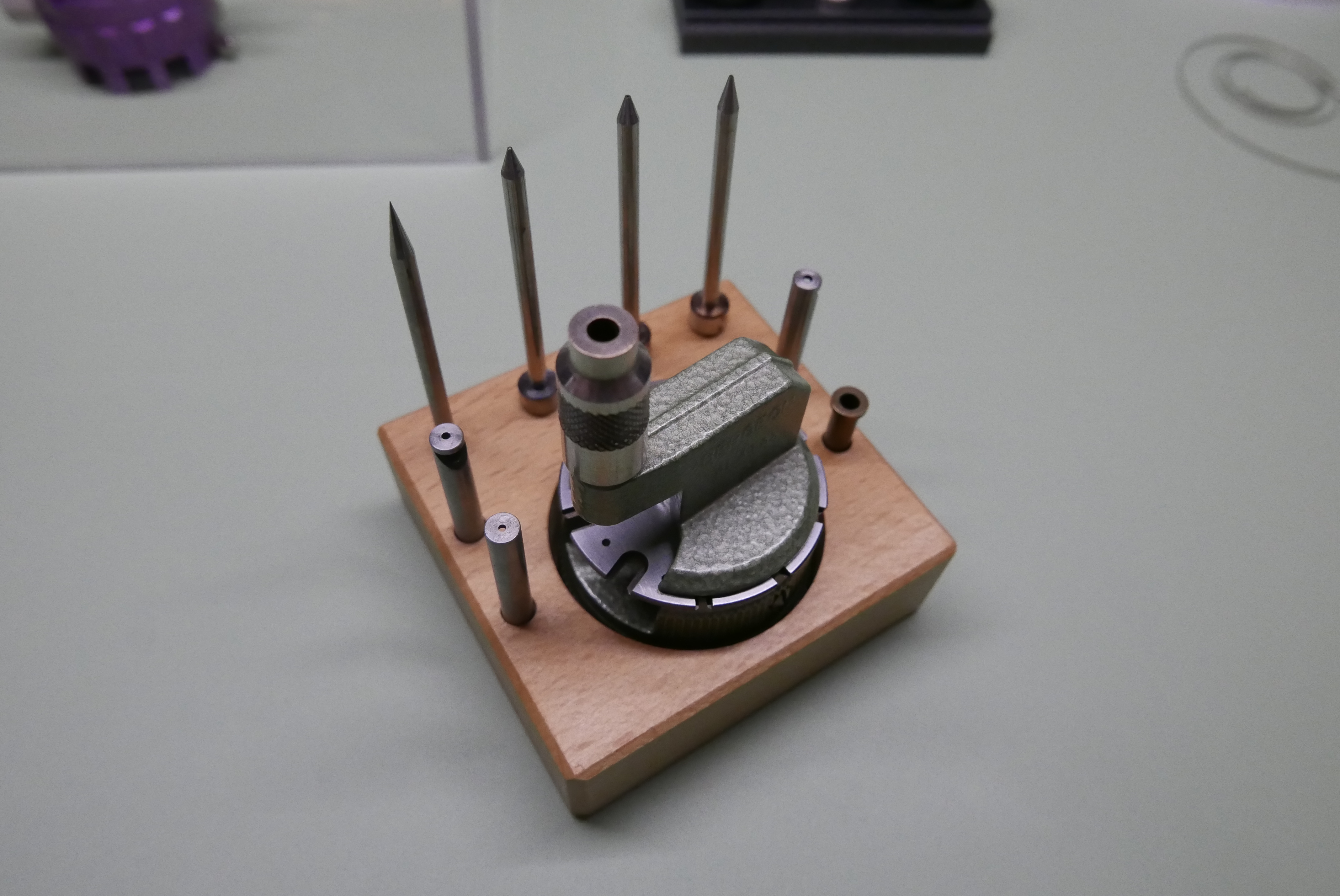

I haven't posted in awhile...been very busy with life, the upcoming move, and of course knocking out watches!

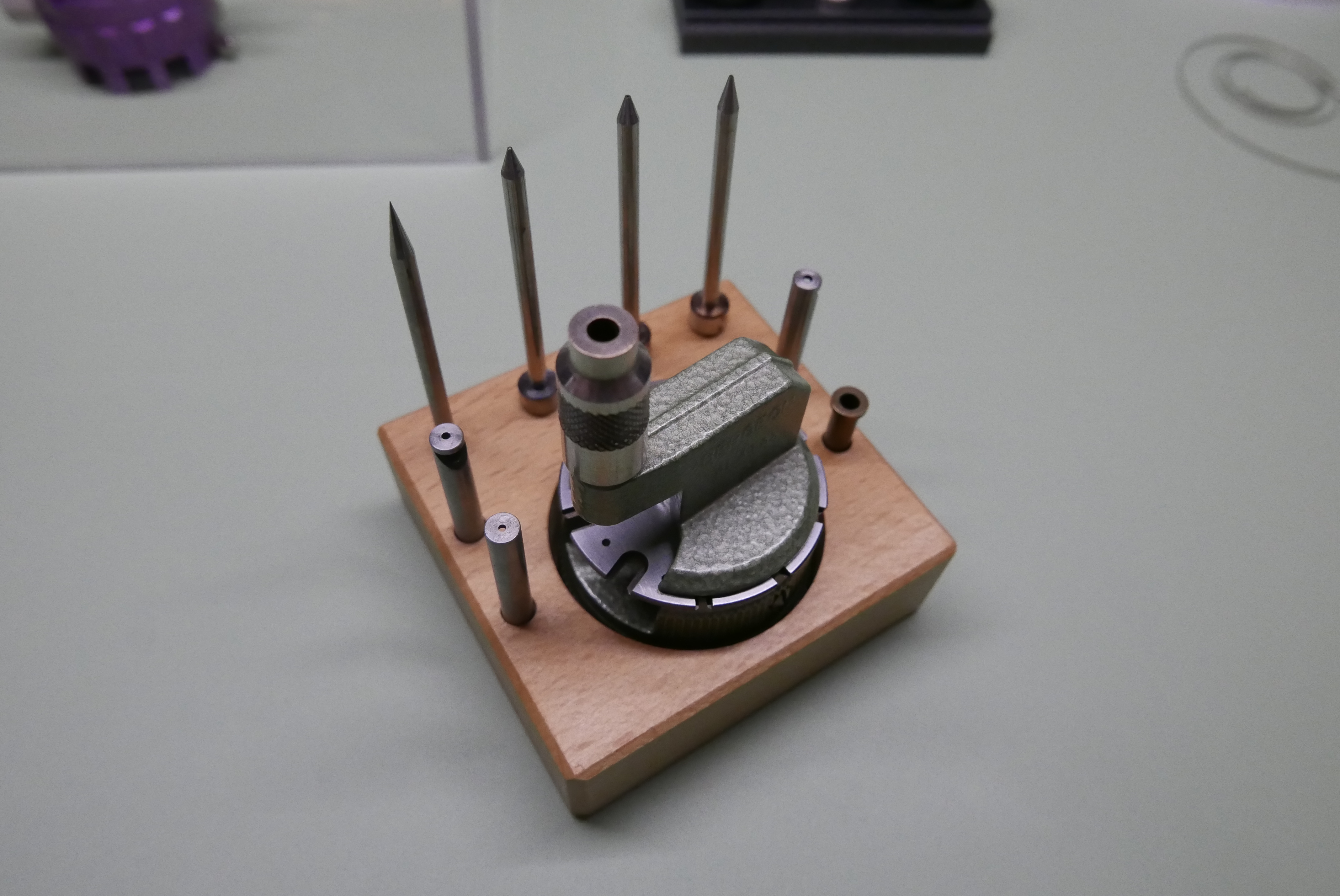

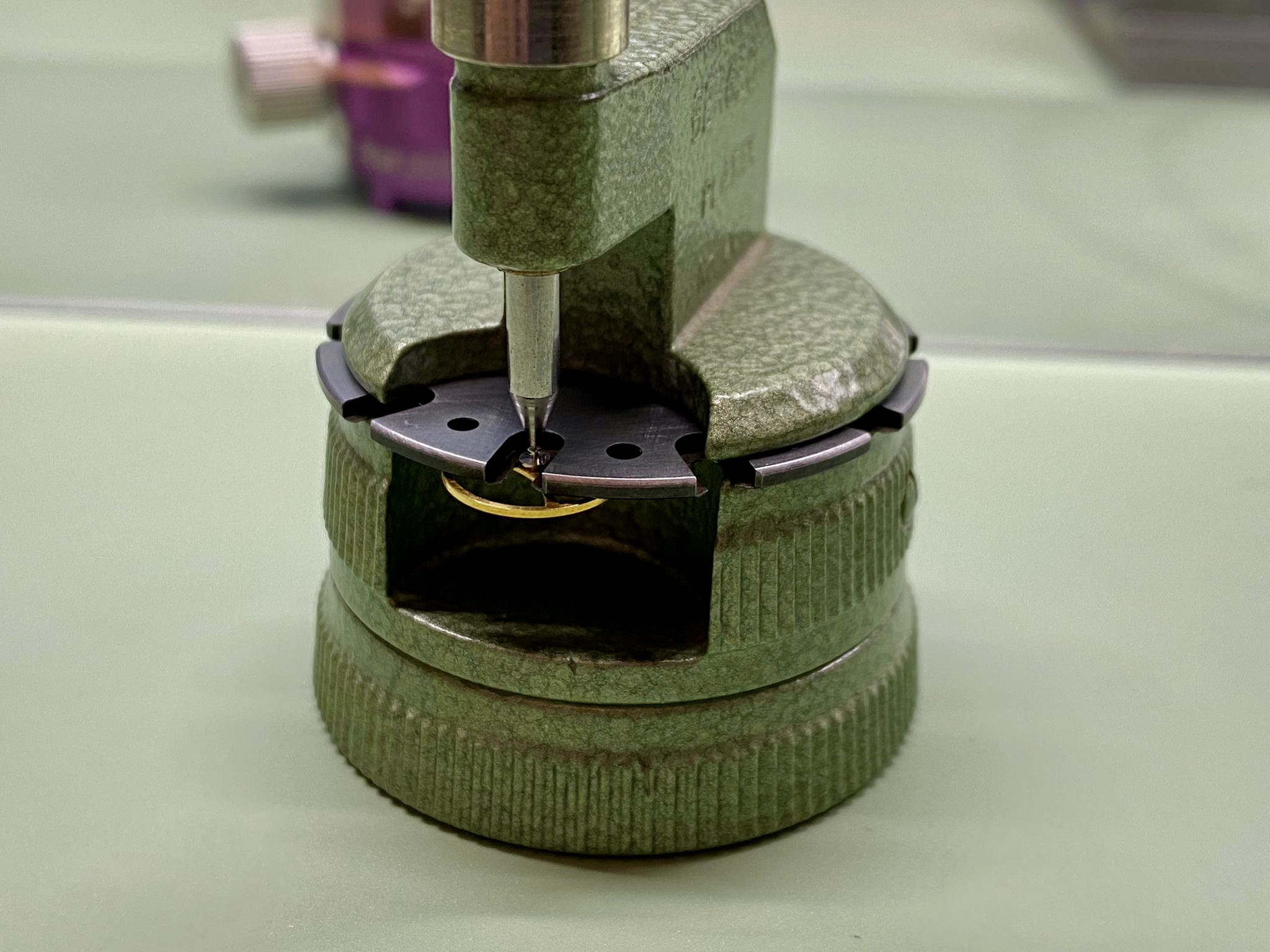

I did have a chance to grab a Platax Tool off of eBay, so I figured I would share that. This tool is a popular choice among watchmakers for removing roller tables and balance staffs from the balance wheels. This tool is no longer made by Bergeon, so it now fetches a premium when sold online. And finding ones in good condition are hard...so I am pumped with what I found!

Mine did come with a few busted staked, but a fellow watchmaker was nice enough to make some new ones! And it all works perfectly. Not sure how much I will use it, but was a solid addition to the tool set.

Also finished up a beautiful 126610LN with gen bezel and insert, as well as a bunch of other goodies. I have to say that insert removal and install is still the most nerve-racking part of watchmaking for me. But with proper tools it makes it a little more bearable....

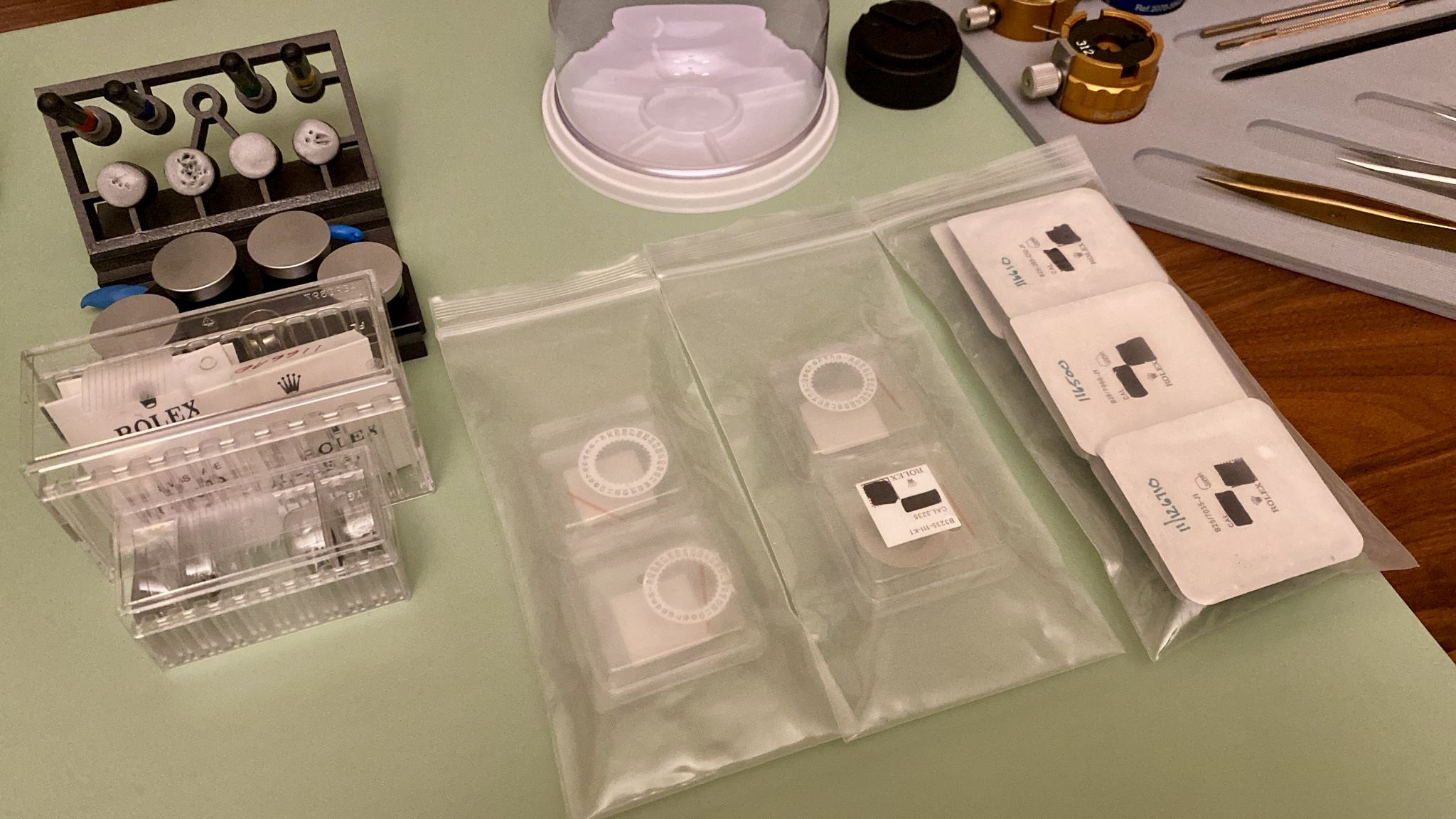

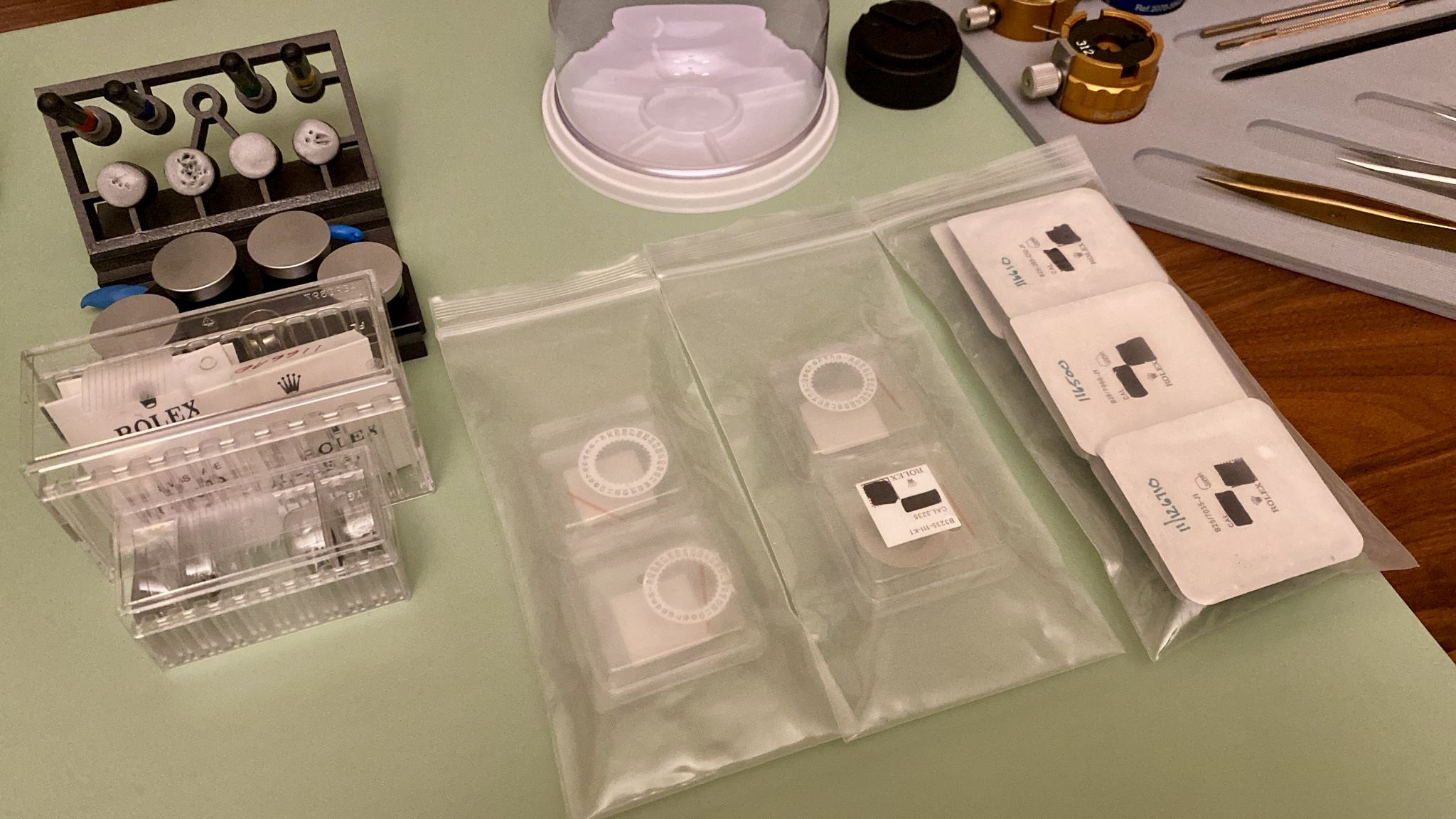

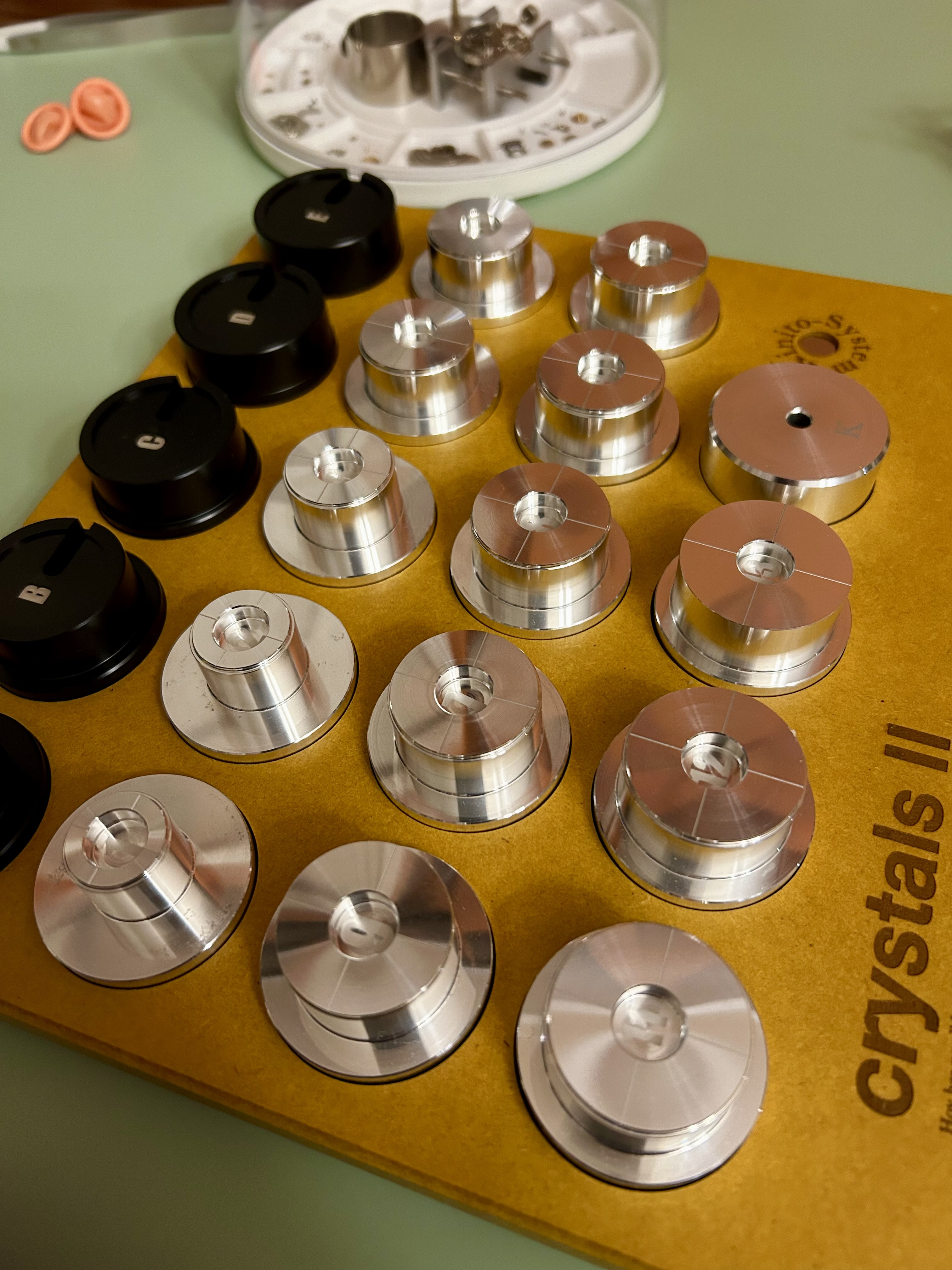

Also made the business decision to start stocking some of the more popular "parts" . I'll have these available for paying customers, as I don't want to become a parts vendor. So stay tuned for that!! Sneak peak below.

. I'll have these available for paying customers, as I don't want to become a parts vendor. So stay tuned for that!! Sneak peak below.

Shameless plug for my instagram again! Go follow!

instagram.com

instagram.com

I haven't posted in awhile...been very busy with life, the upcoming move, and of course knocking out watches!

I did have a chance to grab a Platax Tool off of eBay, so I figured I would share that. This tool is a popular choice among watchmakers for removing roller tables and balance staffs from the balance wheels. This tool is no longer made by Bergeon, so it now fetches a premium when sold online. And finding ones in good condition are hard...so I am pumped with what I found!

Mine did come with a few busted staked, but a fellow watchmaker was nice enough to make some new ones! And it all works perfectly. Not sure how much I will use it, but was a solid addition to the tool set.

Also finished up a beautiful 126610LN with gen bezel and insert, as well as a bunch of other goodies. I have to say that insert removal and install is still the most nerve-racking part of watchmaking for me. But with proper tools it makes it a little more bearable....

Also made the business decision to start stocking some of the more popular "parts"

Shameless plug for my instagram again! Go follow!

Login • Instagram

Welcome back to Instagram. Sign in to check out what your friends, family & interests have been capturing & sharing around the world.

instagram.com

instagram.com

Last edited:

Morning All!

I'm happy to say that I'm all moved in and settled at my new location! We finally have the full room back to Watchmaking activities, and I'm thrilled with how it looks!

I did fall a little behind with the move and Holidays, so I will be working to catch back up over the next several weeks!

Look forward to getting back to work!

I acquired a couple new tools too....Gen 126610 Bezel Insert Removal Die (Has the 42mm yatchmaster on one side too), and the 116710 Insert Removal Die. Can't beat the gen stuff!! I feel like I'm now pretty set on my die collection.

Also as mentioned above, I will now be stocking certain gen Rolex parts. What I have in stock thus far is as follows:

- 2 x 7035 Crystal (GMTs and 36MM DateJust)

- 2 x 7000 Crystal (Daytona)

- 2 x 395-C12 Crystal (116610 Sub)

- 1 x Daytona Hands

- 1 x GMT BLNR Hands

- 1 x 116610 Hands

- 1 x 126610 Hands

- 2 x 3135 Datewheels

- 2 x 3235 DateJust Datewheels

- 2 x 704 Crowns

- 2 x 604 Tubes

I have more I am waiting on to complete my stocking, but some things available as of right now! Again, these will be reserved for customers, as I don't want to become a parts vendor. This stuff isn't readily available, and takes some time to come in.

Thanks!

I'm happy to say that I'm all moved in and settled at my new location! We finally have the full room back to Watchmaking activities, and I'm thrilled with how it looks!

I did fall a little behind with the move and Holidays, so I will be working to catch back up over the next several weeks!

Look forward to getting back to work!

I acquired a couple new tools too....Gen 126610 Bezel Insert Removal Die (Has the 42mm yatchmaster on one side too), and the 116710 Insert Removal Die. Can't beat the gen stuff!! I feel like I'm now pretty set on my die collection.

Also as mentioned above, I will now be stocking certain gen Rolex parts. What I have in stock thus far is as follows:

- 2 x 7035 Crystal (GMTs and 36MM DateJust)

- 2 x 7000 Crystal (Daytona)

- 2 x 395-C12 Crystal (116610 Sub)

- 1 x Daytona Hands

- 1 x GMT BLNR Hands

- 1 x 116610 Hands

- 1 x 126610 Hands

- 2 x 3135 Datewheels

- 2 x 3235 DateJust Datewheels

- 2 x 704 Crowns

- 2 x 604 Tubes

I have more I am waiting on to complete my stocking, but some things available as of right now! Again, these will be reserved for customers, as I don't want to become a parts vendor. This stuff isn't readily available, and takes some time to come in.

Thanks!

Morning All!

Haven't posted in awhile, but figured I'd share a quick update.

We had another tool day!

I finally got a Horia Tool. As previously mentioned, I really enjoyed the Seitz tool I have, and absolutely loathed the chines clone of the Horia I have. So figured it was time to upgrade. And I can say this, I may never use that Seitz tool again!

I also got some other odds and ends including a truing caliper, riveting block, bench vise, and a new Elma Ultrasonic Cleaner!

And a new pic of the bench area. Really happy with how it looks right now!

I have also been posting more content on Instagram, so head on over there to take a peek. I've started posting videos of the servicing I perform as well.

Haven't posted in awhile, but figured I'd share a quick update.

We had another tool day!

I finally got a Horia Tool. As previously mentioned, I really enjoyed the Seitz tool I have, and absolutely loathed the chines clone of the Horia I have. So figured it was time to upgrade. And I can say this, I may never use that Seitz tool again!

I also got some other odds and ends including a truing caliper, riveting block, bench vise, and a new Elma Ultrasonic Cleaner!

And a new pic of the bench area. Really happy with how it looks right now!

I have also been posting more content on Instagram, so head on over there to take a peek. I've started posting videos of the servicing I perform as well.

Hey all!

More tools came in!!

Super pumped to have these. These are for the automatic modules on the 3135, 4130, and 3235. Some may know that working on automatic modules is sometime awkward, so those help with proper support.

I had made some printed versions, but as always, nothing beats the Gen versions.

More tools coming soon

More tools came in!!

Super pumped to have these. These are for the automatic modules on the 3135, 4130, and 3235. Some may know that working on automatic modules is sometime awkward, so those help with proper support.

I had made some printed versions, but as always, nothing beats the Gen versions.

More tools coming soon

Hey all!!

Been awhile since I posted!

Made some small (big to me) upgrades to the bench storage over the weekend.

My drawers had become a bit of a mess, and I figured what better to organize it than custom foam inserts. That way everything has its own spot and stays in place no matter.

I must say they turned out so good! And even some room for additional tools! A clean bench is a productive bench!

Been awhile since I posted!

Made some small (big to me) upgrades to the bench storage over the weekend.

My drawers had become a bit of a mess, and I figured what better to organize it than custom foam inserts. That way everything has its own spot and stays in place no matter.

I must say they turned out so good! And even some room for additional tools! A clean bench is a productive bench!

- 11/7/16

- 2,439

- 2,395

- 113

Looks great! Good idea with the custom inserts. There are so many pieces of equipment with this that I am always running low on storage.

Thanks Major!Looks great! Good idea with the custom inserts. There are so many pieces of equipment with this that I am always running low on storage.

I found it was a good time to toss stuff I never use as well....LOL

Do you worry at all about corrosion of parts? I’ve started storing my parts in air tight containers with desiccant packets. Maybe not such an issue for you guys down south, but in the pacific north west it’s basically always at or near the dew point. I haven’t had any issues but I didn’t want to risk building a deep rep parts drawer only to have parts rust on me.

Do you worry at all about corrosion of parts? I’ve started storing my parts in air tight containers with desiccant packets. Maybe not such an issue for you guys down south, but in the pacific north west it’s basically always at or near the dew point. I haven’t had any issues but I didn’t want to risk building a deep rep parts drawer only to have parts rust on me.

I'll just say this.

I haven't noticed any sort of corrosion or rust on any of the spare parts I have....yet.

- 11/7/16

- 2,439

- 2,395

- 113

In winter time I notice it more on my scissors/blades, as my office is in a 'second zone' of my HVAC system, so it runs less when I'm not in the office. But yes all parts are in air-tight containers, dessicant packs are a great idea.Do you worry at all about corrosion of parts? I’ve started storing my parts in air tight containers with desiccant packets. Maybe not such an issue for you guys down south, but in the pacific north west it’s basically always at or near the dew point. I haven’t had any issues but I didn’t want to risk building a deep rep parts drawer only to have parts rust on me.

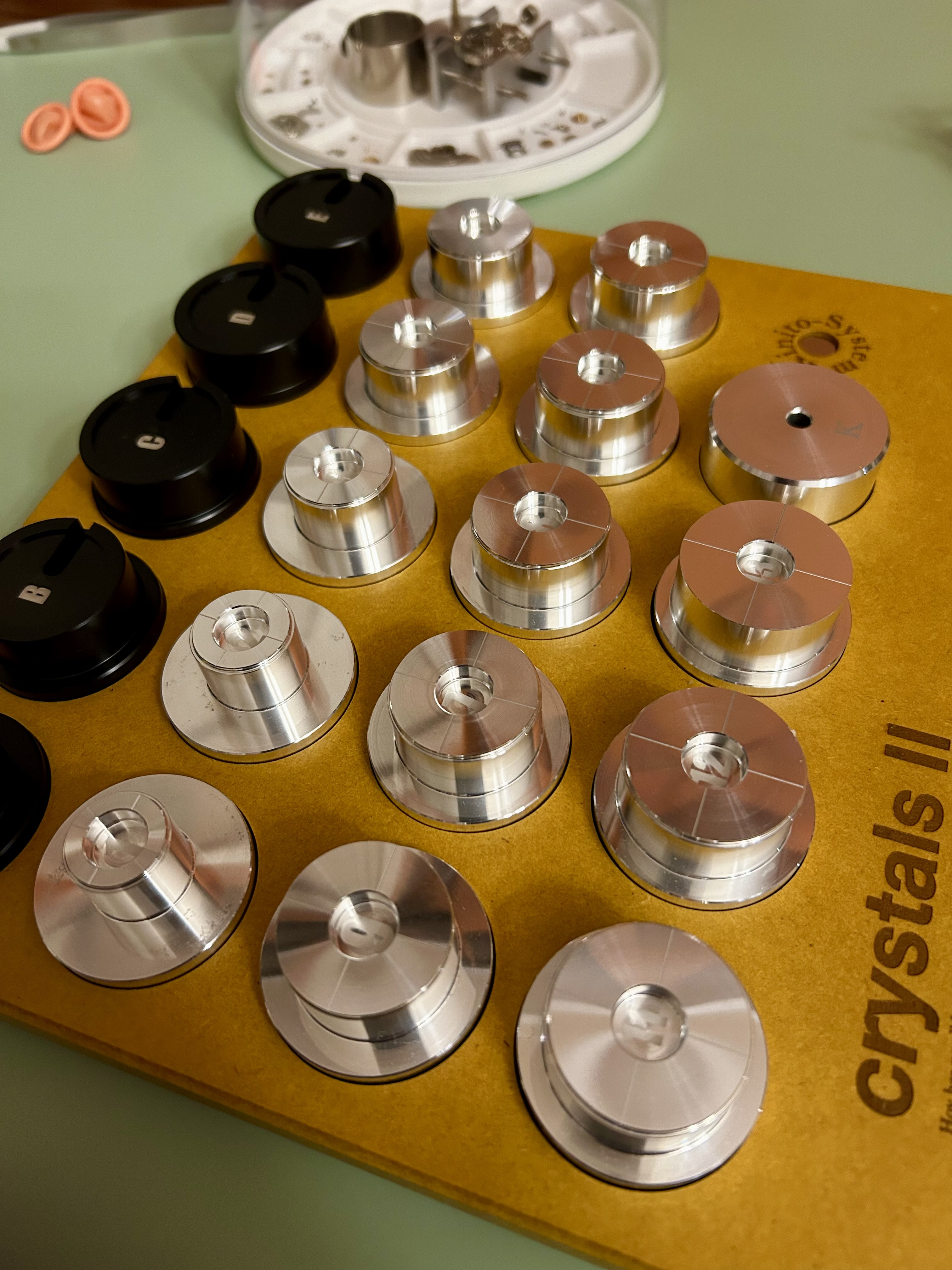

Hey all!!

Got some new tools in recently!

I’ve recently been looking to increase the amount of dies I have, specifically for Rolex watches. And I really wish I would have found these a lot earlier.

I’ve spent a pretty penny on Gen Rolex dies, and these sets are practically the same. CNC aluminum and Derlin!

First set is for crystal installation. Essentially there are dies that aid with holding the case properly and helping line up the xtal. They also have a magnetic system to install the xtal on the case, but I don’t see that being too useful.

Second set is for ceramic insert work. Priceless if you ask me. Submariner and gmt bezel dies as well as for retaining ring installation.

Third set is just adapter for my Bergeon press.

The individual also makes many more sets. I’ll still be getting two more once they get stock.

If you’re looking for a great set of Rolex specific dies, this is for you. And way better than any 3D printed stuff you see on the market. The tolerances on these seem great.

I may have to sell these Gen dies I have

Got some new tools in recently!

I’ve recently been looking to increase the amount of dies I have, specifically for Rolex watches. And I really wish I would have found these a lot earlier.

I’ve spent a pretty penny on Gen Rolex dies, and these sets are practically the same. CNC aluminum and Derlin!

First set is for crystal installation. Essentially there are dies that aid with holding the case properly and helping line up the xtal. They also have a magnetic system to install the xtal on the case, but I don’t see that being too useful.

Second set is for ceramic insert work. Priceless if you ask me. Submariner and gmt bezel dies as well as for retaining ring installation.

Third set is just adapter for my Bergeon press.

The individual also makes many more sets. I’ll still be getting two more once they get stock.

If you’re looking for a great set of Rolex specific dies, this is for you. And way better than any 3D printed stuff you see on the market. The tolerances on these seem great.

I may have to sell these Gen dies I have

congrats on the beautiful set. They look very well made and finished.

Maybe if you arnt in a rush to sell the Rolex dies I can buy it off you

Maybe if you arnt in a rush to sell the Rolex dies I can buy it off you