Hey

Watchpocketguide42, I'm not having any trouble with moving/aligning the decal, but thanks for your thoughts. It's interesting to hear how other decal dial dudes are dealing with the process.

I apply the decal with the dial fixed to a custom holder I made from a sheet of plastic card with holes for the dial feet (not relevant here as they're clipped, so it's blu-tacked on), with the quarters marked on the card to make accurate alignment easier. I find that the backing paper slips off easily if I put the decal in the water and then spend 30 secs or so applying the glue to the dial. The dial has to be well degreased with isopropyl alcohol or lighter fluid first, otherwise the glue pools unevenly. Removing the decal from the water I place it on the dial, then remove the paper, and then do the fine-tuning of position.

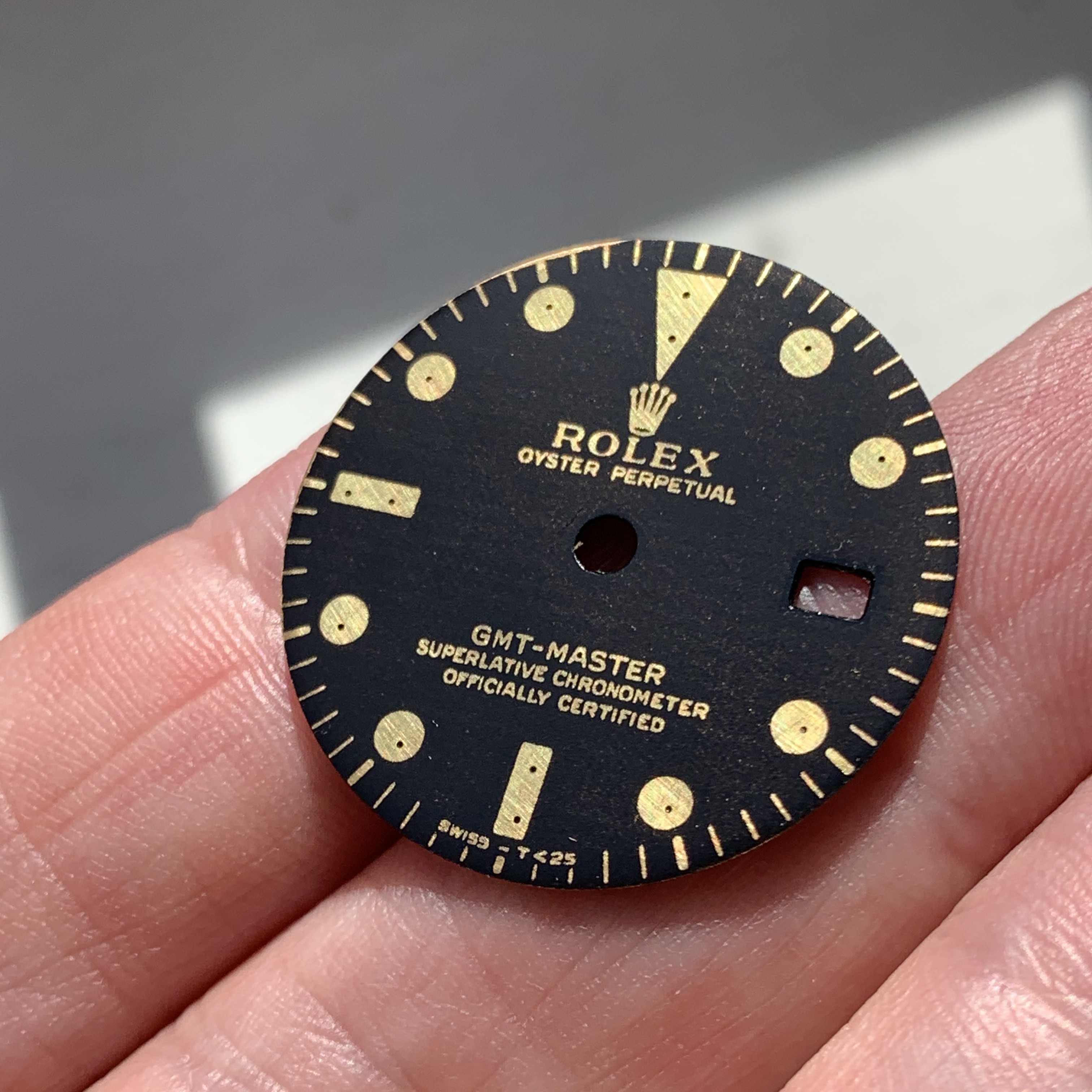

I've tried different borders when I cut round the decal, too much border and it can stick to whatever the dial is resting on and make it harder to position. On the latest I cut the film with about 3mm border all round - but I think I'll increase that as what I found is during the first bake the film curls and can lift the edge of the decal off the dial (you can see this happened at the 11 mark on the dial below).

For baking, I transfer the dial to a small piece of stainless steel sheet, about 4mm thick. I bake the dial in a fan over at about 110 deg for 12 minutes. Then I did the second bake at 220 for 15 mins, to give the decal a really good chance to bake onto the dial.

So, I had a successful session yesterday, but having

almost okayed this one for use, my critical faculties kicked back in and I had to conclude there were too many compromises with the dial.

I've taken this pic from an angle which shows that there's

very faint horizontal inconsistency to the black which to me screams "photocopier"!

This isn't visible from other angles, but it bugs the hell out of me and I know it's not happening on every print I make, so this decal has to come off. But I also might try stacking two decals on top of each other, to completely eradicate this.

Also, and even more importantly, I added a very small stroke to everything on the artwork, in order to bold it up a bit, as some of the fine text was breaking up a little. But this needs further refinement and selective use, as it's caused some of the other elements (like the chapter ticks and crown) to get too fat. So back to the artwork I go...

Something to note: After the first bake, I was alarmed/disappointed to see some micro air bubbles had formed under the decal, which didn't seem to be there before I put it in the oven. However, on the hunch that the ink will go "liquid" while baking onto the dial, I decided to do the second bake anyway and see what happened. And the second bake eradicated them! Which is handy to know.