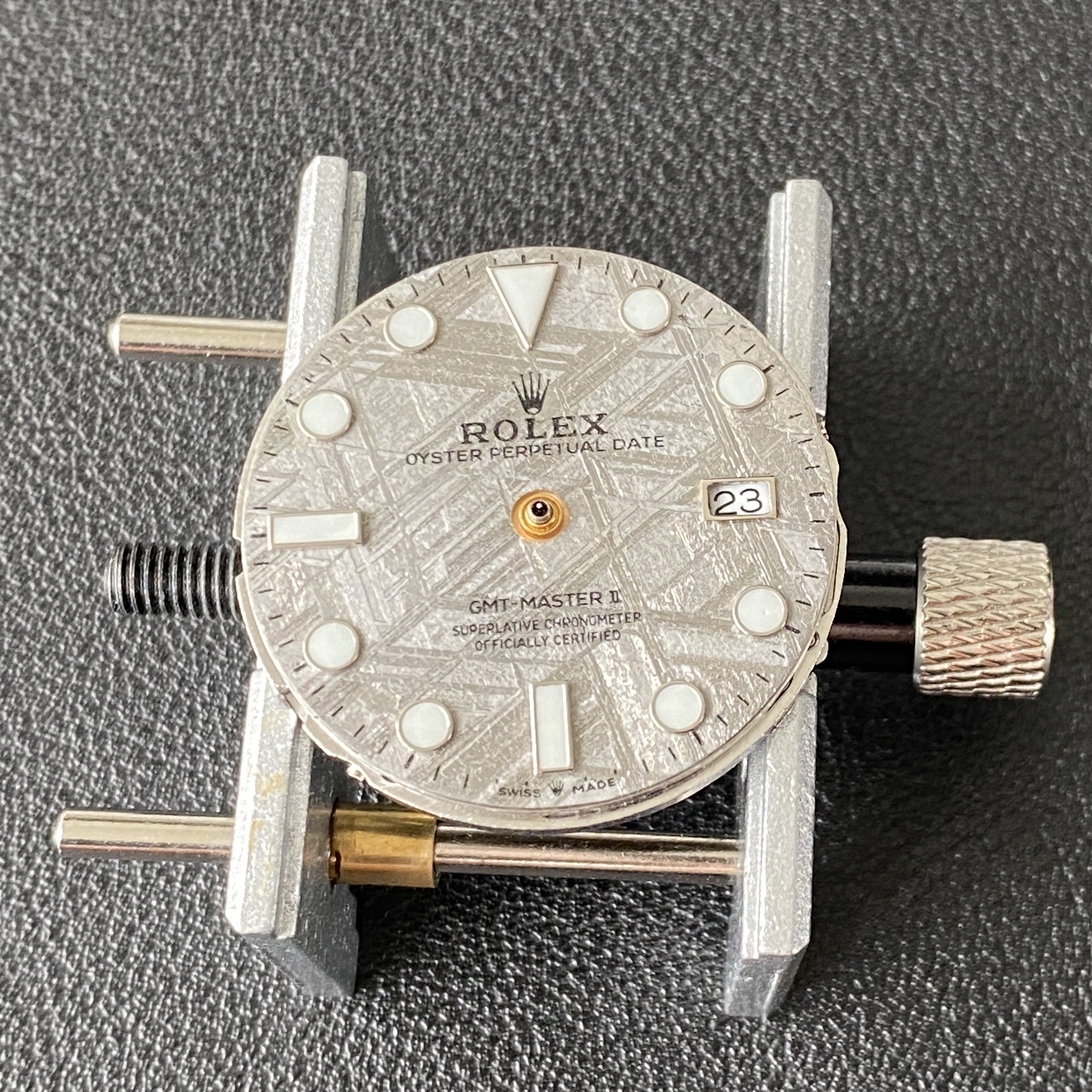

So, back in January I tried my hand at swapping the white gasket on my Noob v4 Daytona, and it wasn't an altogether terrible experience. A month after that, I thought I'd give servicing a movement a try... and well, that turned out ok, but not after a lot of "learning moments" along the way. Fast forward a few weeks, and I managed to snag one of the beautiful real meteorite dials that oascom makes. Just look at how beautiful this thing is:

I figured, I've swapped a gasket AND I've "serviced" a movement, how hard could a simple dial swap be... Famous last words.

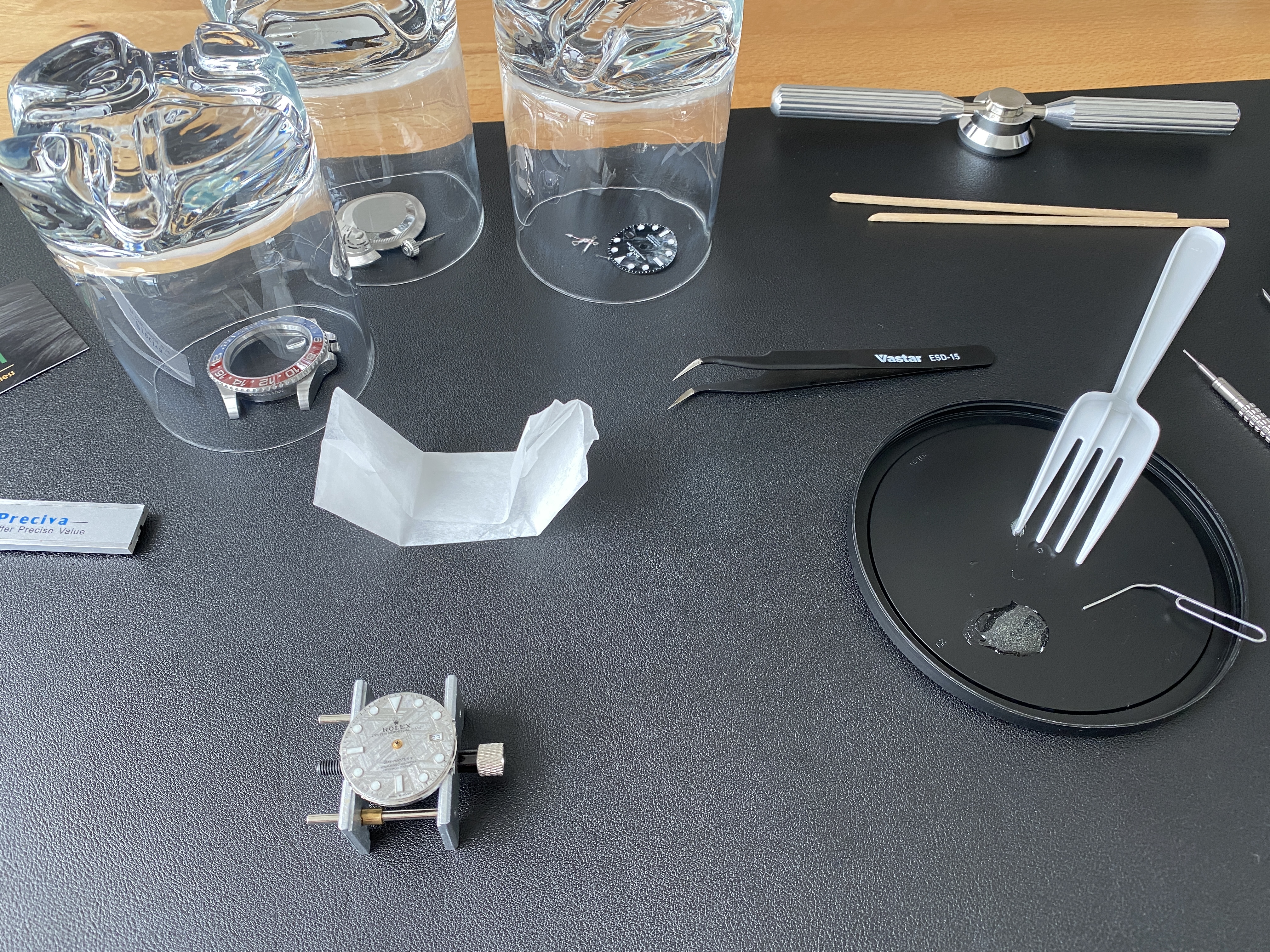

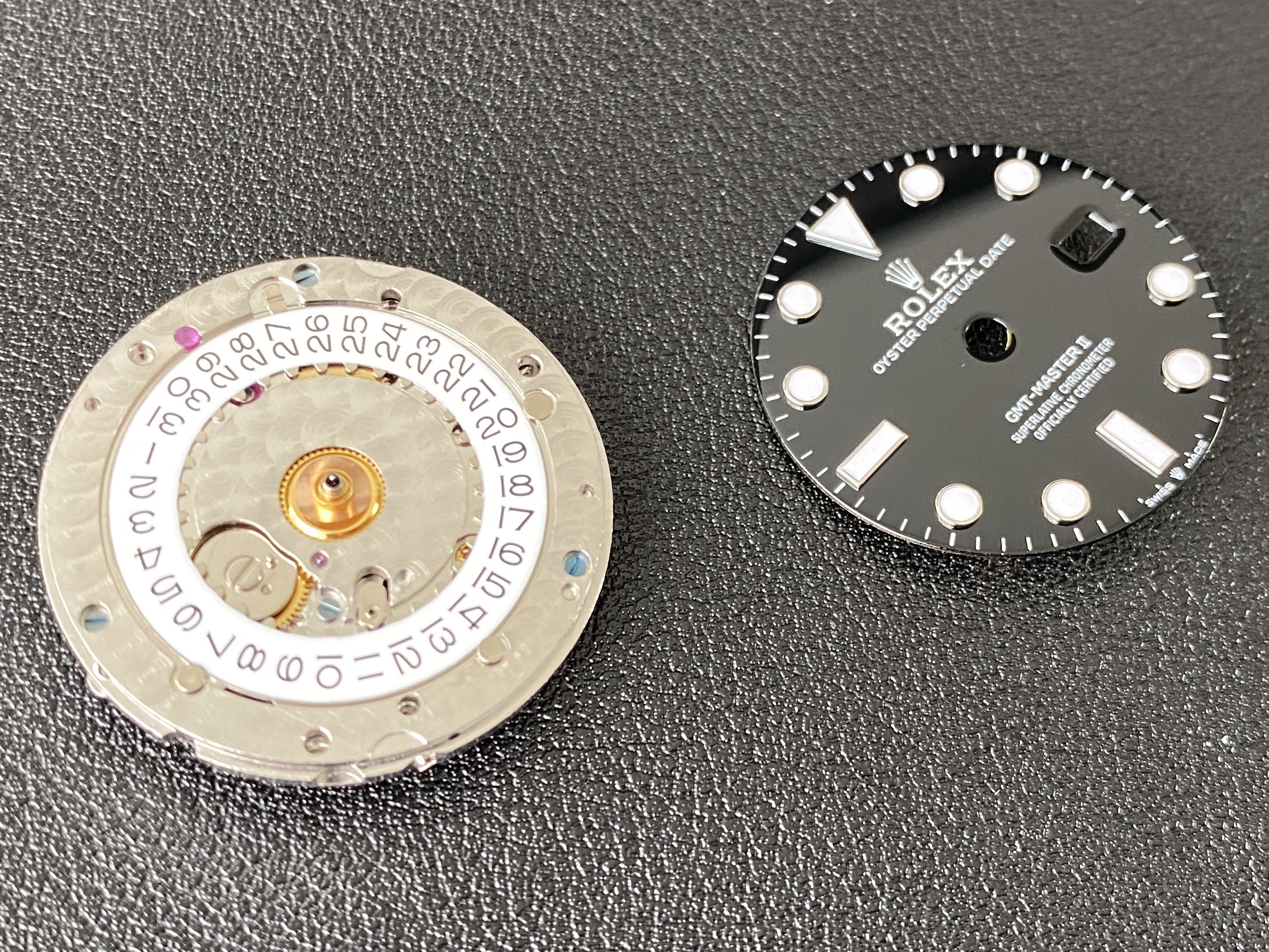

Here's where I started... a nice Clean Factory GMT Master II. Looks pretty. That's probably not going to last.

I started by removing the bracelet. That was easy.

Then I removed the rotor by sliding the little release thingy. I had to move the little release thingy farther than I thought, and it seemed pretty loose when I had it all the way slid outwards, but the rotor released and I was able to remove it.

Next was removing the stem -- easy breezy, pull the stem out to the outer most position, then push the little button, and it just comes free. Fortunately, when the stem is in this outermost position, the movement is "hacked" and stops moving. This is great since it makes removing the hands (the next step) easier. Strangely, the watch had almost no wind on it when I was doing this work, but I struggled to release the mainspring tension by holding back the click. I'm not sure I understand exactly how the click on this movement works, maybe I was pushing it in the wrong direction.

The next step was to remove the hands. For this I used saran wrap (cling wrap) over the dial and used two screw drivers to gently lift each hand off of the stack one at a time. I have a hand puller, but since I'd been stupid and not set the hands to all be aligned at midnight before I removed the stem, I didn't feel comfortable using the presto hand puller and opted for the screw driver method since it would allow me to remove one hand at a time.

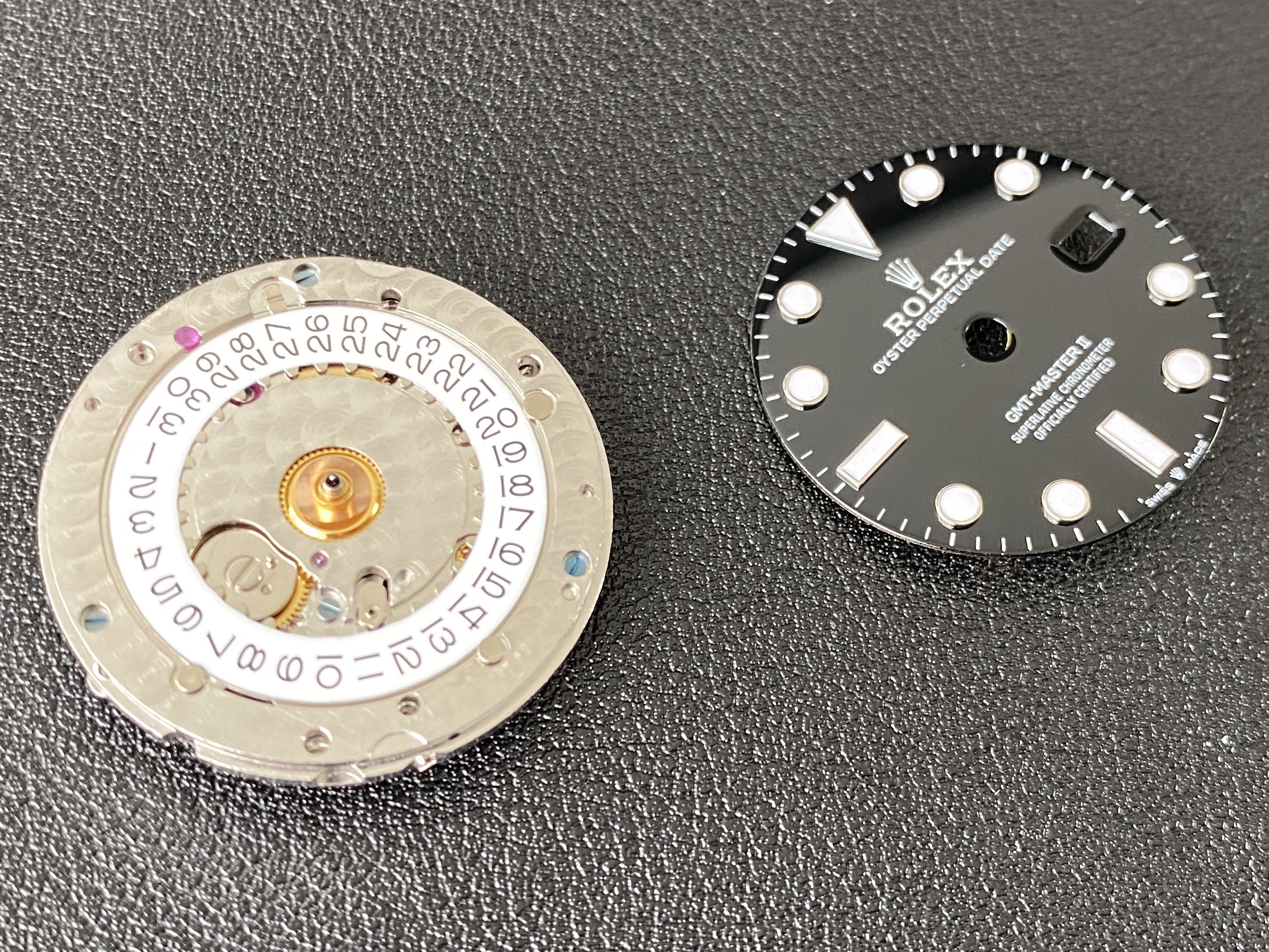

Next was removing the dial... another easy task. The VR3186 movement has two dial feet screws. This should have been a warning bell for me since the beautiful meteorite dial I'd received in the mail didn't have dial feet. But I plowed forward regardless. I slightly unscrewed the dial feet screws on the movement and used a thin screw driver in the two slots between the movement and the dial to gently lift the dial free. The dial came up no problem (much more easily than my Clean Factory DJ41 dial separated from the VR3235 movement I "serviced" a few weeks ago).

But it was at this moment, that I realized that I'd fucked up. The stock CF dial had dial feet. My fabulous meteorite dial didn't. This feels like it's going to be a problem.

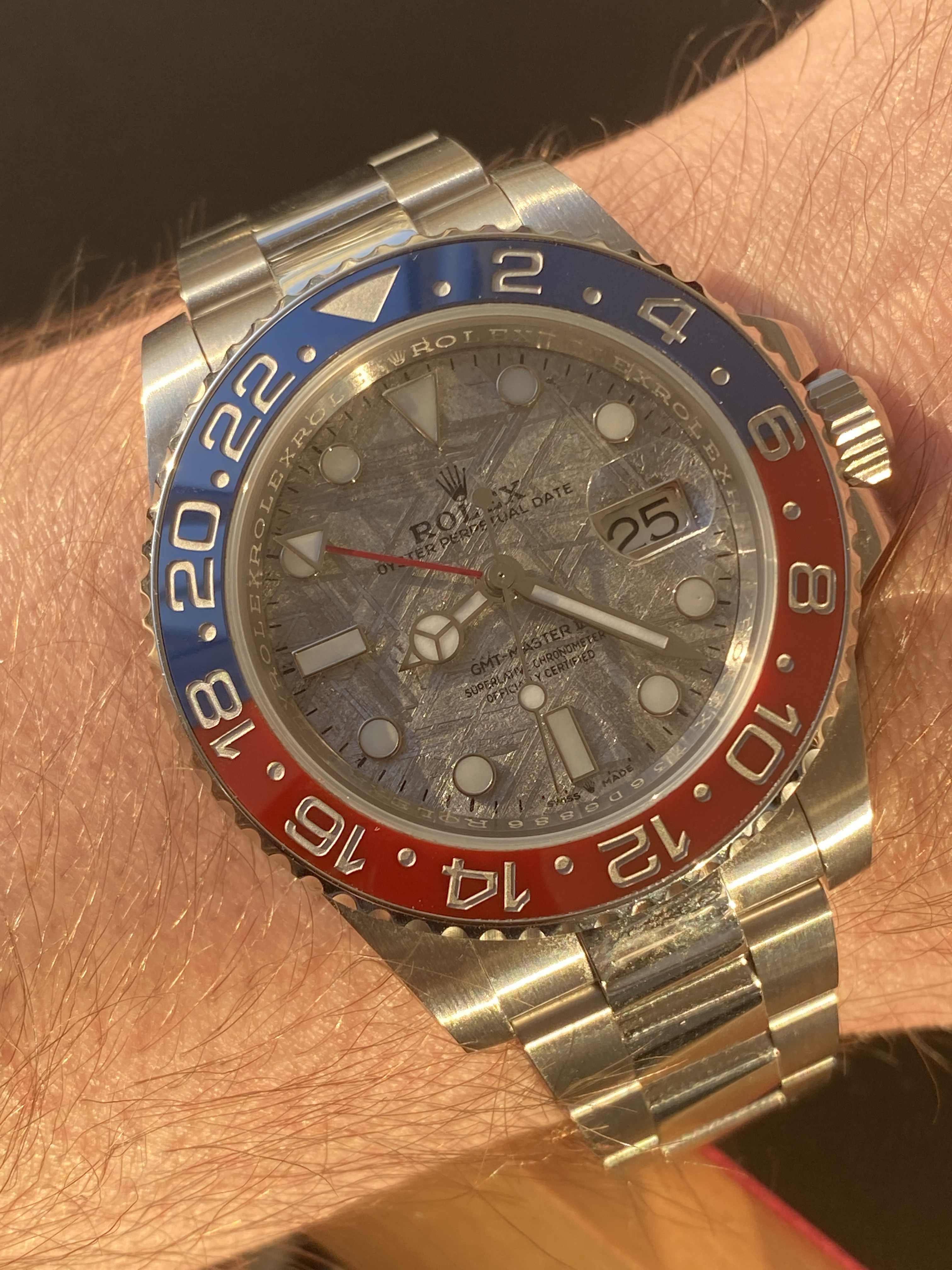

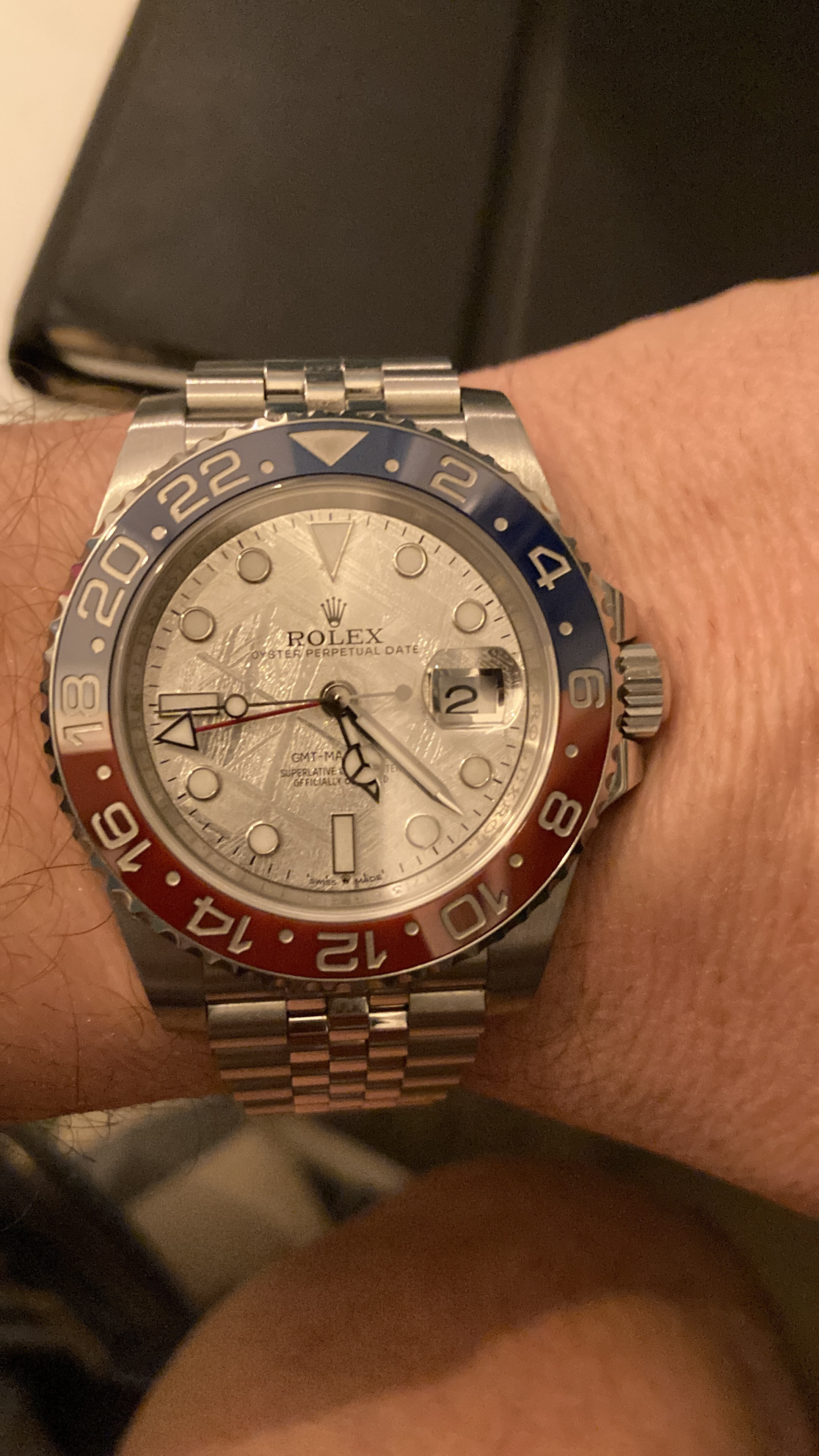

How does one attach a dial to a movement if the movement expects it to have feet, but the dial doesn't have feet? Do I need to make feet (out of wire?) and then glue them into the correct positions? Or is it possible to just place the dial on the movement and have it stay in place by being sandwiched between the movement and the case?

I figured, I've swapped a gasket AND I've "serviced" a movement, how hard could a simple dial swap be... Famous last words.

Here's where I started... a nice Clean Factory GMT Master II. Looks pretty. That's probably not going to last.

I started by removing the bracelet. That was easy.

Then I removed the rotor by sliding the little release thingy. I had to move the little release thingy farther than I thought, and it seemed pretty loose when I had it all the way slid outwards, but the rotor released and I was able to remove it.

Next was removing the stem -- easy breezy, pull the stem out to the outer most position, then push the little button, and it just comes free. Fortunately, when the stem is in this outermost position, the movement is "hacked" and stops moving. This is great since it makes removing the hands (the next step) easier. Strangely, the watch had almost no wind on it when I was doing this work, but I struggled to release the mainspring tension by holding back the click. I'm not sure I understand exactly how the click on this movement works, maybe I was pushing it in the wrong direction.

The next step was to remove the hands. For this I used saran wrap (cling wrap) over the dial and used two screw drivers to gently lift each hand off of the stack one at a time. I have a hand puller, but since I'd been stupid and not set the hands to all be aligned at midnight before I removed the stem, I didn't feel comfortable using the presto hand puller and opted for the screw driver method since it would allow me to remove one hand at a time.

Next was removing the dial... another easy task. The VR3186 movement has two dial feet screws. This should have been a warning bell for me since the beautiful meteorite dial I'd received in the mail didn't have dial feet. But I plowed forward regardless. I slightly unscrewed the dial feet screws on the movement and used a thin screw driver in the two slots between the movement and the dial to gently lift the dial free. The dial came up no problem (much more easily than my Clean Factory DJ41 dial separated from the VR3235 movement I "serviced" a few weeks ago).

But it was at this moment, that I realized that I'd fucked up. The stock CF dial had dial feet. My fabulous meteorite dial didn't. This feels like it's going to be a problem.

How does one attach a dial to a movement if the movement expects it to have feet, but the dial doesn't have feet? Do I need to make feet (out of wire?) and then glue them into the correct positions? Or is it possible to just place the dial on the movement and have it stay in place by being sandwiched between the movement and the case?