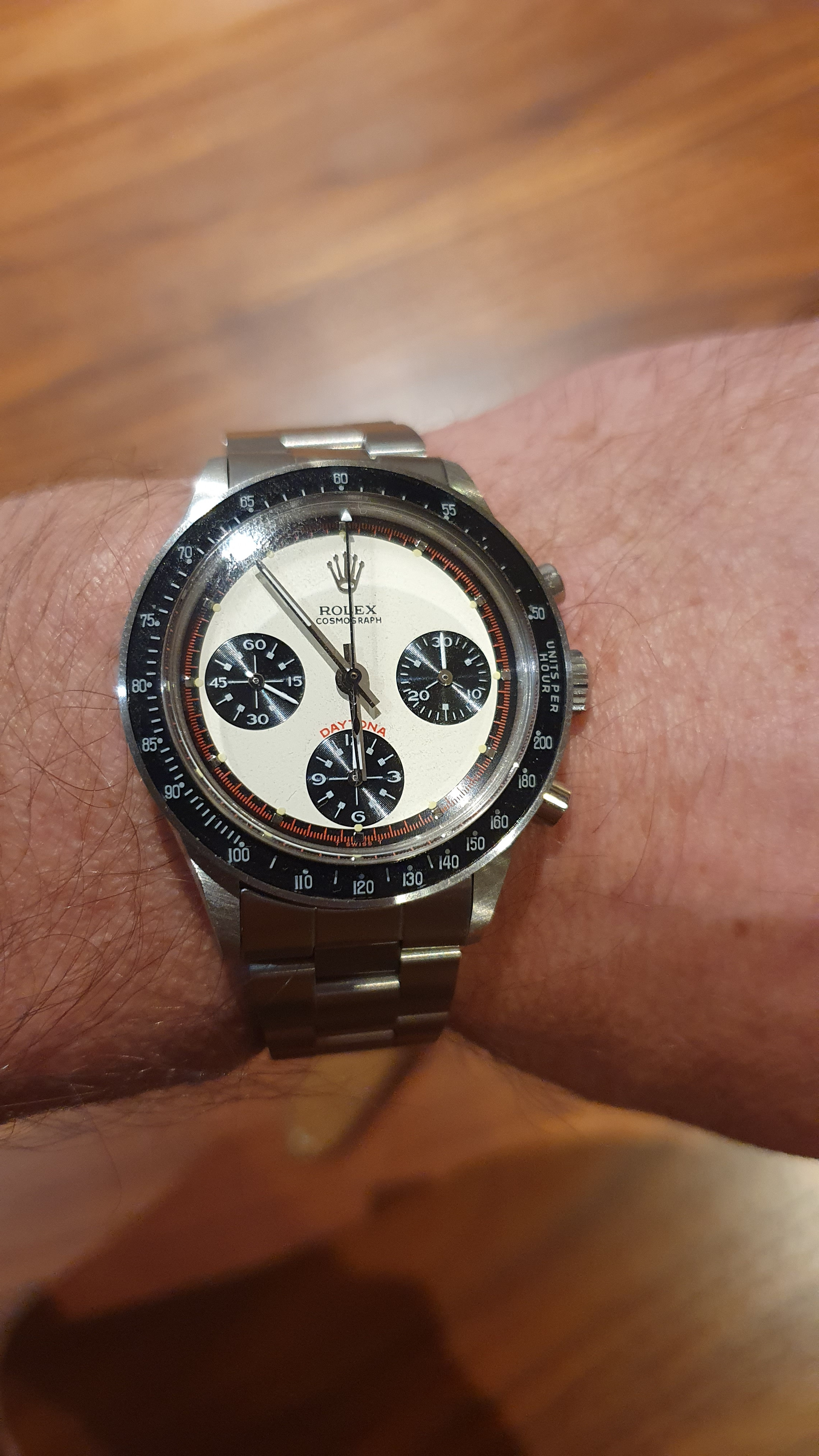

put together mine last night, but with problems. the process started off very smoothly (too smoothly). was expecting to run into problems with the filing and gluing of the 6oclock pinion. had a small code red where the keyless works pinion fell off. but thank god there was a thread in rwg that addressed this. problems started arising when putting it back together. i hadn't worked on a watch for a few years now and had forgotten how much of a pita installing hands were. it's very difficult to line things up on this watch. there are so many contributing factors that will throw off the alignment. this took several trial and error attempts, where the final trial, the coronet had fell off lol ffs. this was a pita level on it's own to align. as you can see on mine, it's not align very well. i double sided taped it, so i can go back and do it properly when i have more time and patience. another problem i had was the reset pusher did not work because it wasn't hitting the mechanism on the movement. that took a few tinkering around to fix. the trick is to push the mechanism with a toothpick when the movement is in the casing. i think it needs to be pushed in a little to accommodate the "L" bracket for the bottom pusher. now the worst part. when i set the time to take this photo, the movement stopped working T_T. will have to buy a new movement. this build seriously....ffs lol.

build specs

- stock cartel everything

- viet dial (looks so effing good)

- alpha subdial hands painted with tamiya acrylic gloss white. only 2 of the 3 hands i received were thin ones *sigh.

extra pic is a tip on how to remove the movement out of the casing. place a toothpick on the non pusher side movement tab/clip hole and use it to lift the movement up on that side. you can then slide/scoop the movement out easily. you need to do this because the "L" bracket on the bottom pusher is in the way preventing you to lift the movement out vertically like you usually would do. reverse the motion to install the movement back in.

and here's the rwg thread for the keyless works.

Hi folks, My usual preface: I am not a watchmaker...but a hack. There are some things I'm going to do that a watchmaker would shudder at. There is also some dust on the pics presented that would make Pugwash, Zig and others puke. The lighting on the pics is terrible...sharpness is bad...compositi...

rwg.cc