TonyMonatana44

Guest

- 3/10/23

- 165

- 103

- 43

What you do via PM is between the 2 of you, but the default advice is for any deal involving money/items changing hands, sales threads are recommended but only certified members can create those.

Gotcha. I will be doing all that when I return from my trip to Europe as I have a few reps and parts to sell and want to be more active on here.

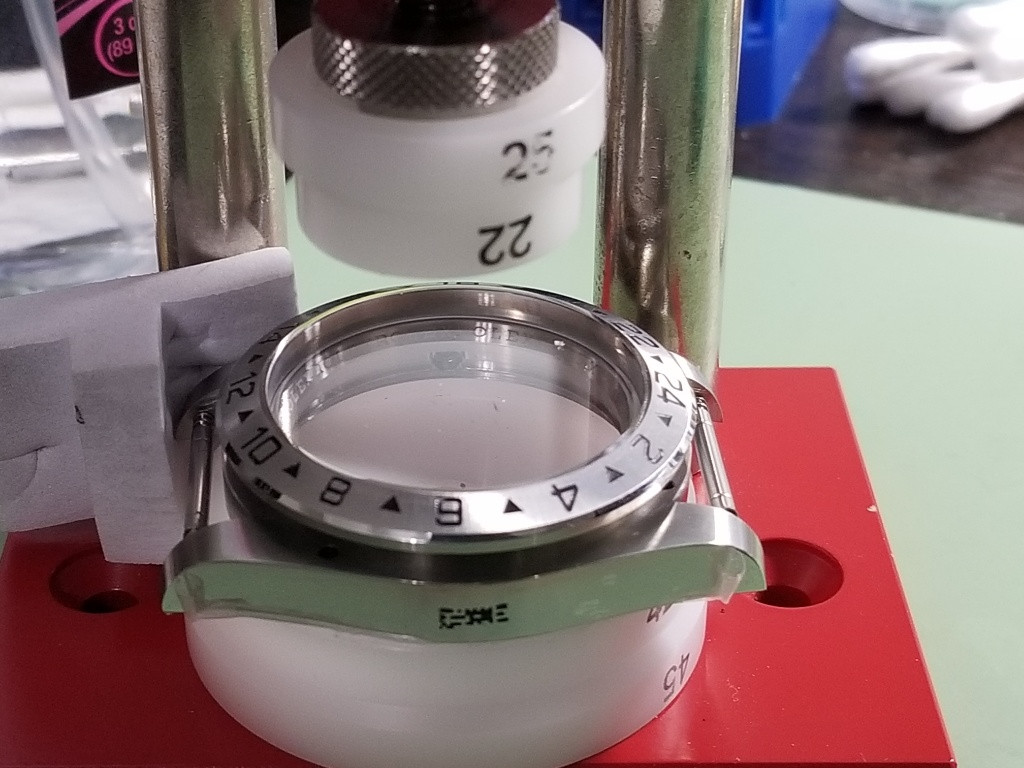

Until then, @freddy333 I have a retaining ring from my junk GMT Batman that I don't need. I'm in the New England area in the US, so if you'd like I can send it to you no problem. I leave in 3 days so let me know before then. Cheers.