-

Tired of adverts on RWI? - Subscribe by clicking HERE and PMing Trailboss for instructions and they will magically go away!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How to make a true gilt dial on the cheap - Tropical or Black

- Thread starter chrome72

- Start date

Throwing this out there too…here are some alternative oxidation solutions to get browns and blacks.

-liver of sulfur (can get some various shades of browns. Check out this website https://www.brackendesigns.com/blog/my-first-experiments-patina and look at the last image for ideas of mixing liver of sulfur and other easily found ingredients)

-vinegar and ammonia fumes (got good chestnut browns when doing this)

-freshly made hard boiled egg crushed with the dial in a baggie (got a brown similar to an aged penny)

-ferric nitrate or ferric nitrate/ferric chloride (can be applied hot or cold, I have some and will be trying it soon. Should be able to get some reddish browns)

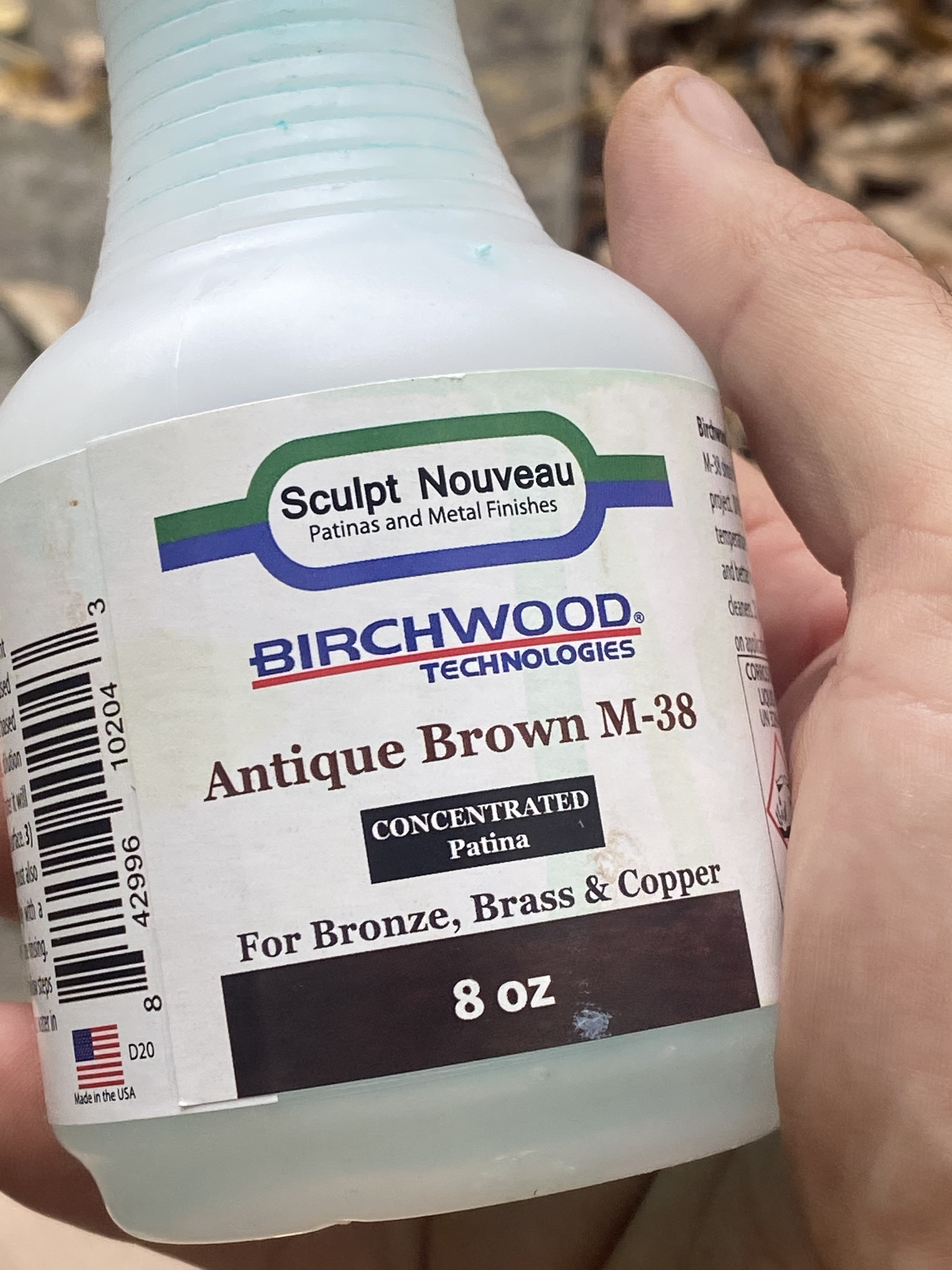

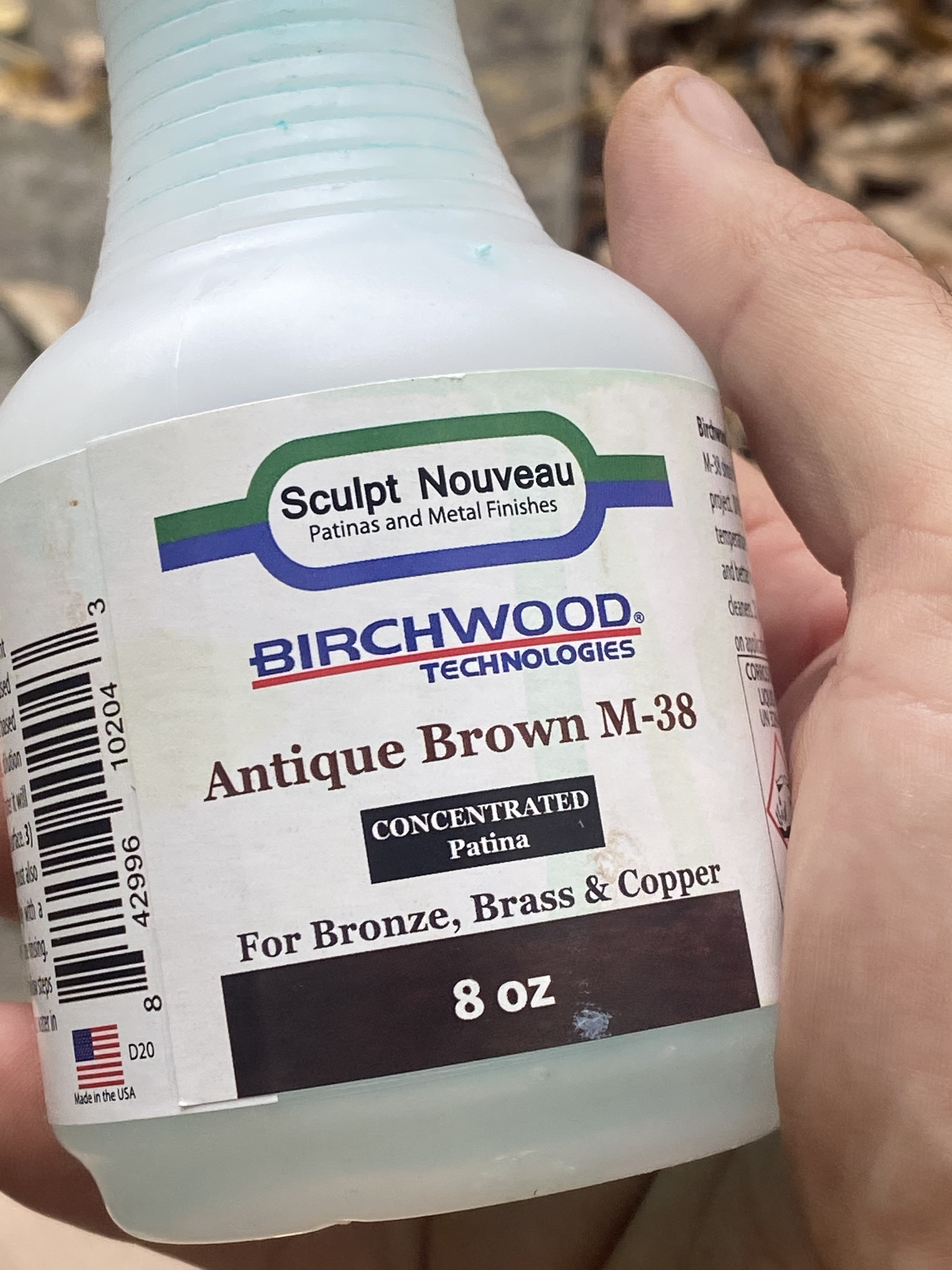

-proprietary mixtures: in the USA, Sur Fin chemical has some good mixtures (BC,CB2, and NR11), Sculpt Neavou (check out their brown patinas…M38 is what I am using). There are a few European places that have brown patinas. Just search for something like “brass brown patina” and find a local distributor.

I have quite a few ideas on how to achieve various tropical dial styles (ie dark around the edges but brown on the inside, brown speckles, gradients or brown) and will get around to posting those one day.

-

-liver of sulfur (can get some various shades of browns. Check out this website https://www.brackendesigns.com/blog/my-first-experiments-patina and look at the last image for ideas of mixing liver of sulfur and other easily found ingredients)

-vinegar and ammonia fumes (got good chestnut browns when doing this)

-freshly made hard boiled egg crushed with the dial in a baggie (got a brown similar to an aged penny)

-ferric nitrate or ferric nitrate/ferric chloride (can be applied hot or cold, I have some and will be trying it soon. Should be able to get some reddish browns)

-proprietary mixtures: in the USA, Sur Fin chemical has some good mixtures (BC,CB2, and NR11), Sculpt Neavou (check out their brown patinas…M38 is what I am using). There are a few European places that have brown patinas. Just search for something like “brass brown patina” and find a local distributor.

I have quite a few ideas on how to achieve various tropical dial styles (ie dark around the edges but brown on the inside, brown speckles, gradients or brown) and will get around to posting those one day.

-

I used white vinegar and deionised water for mine and then I have some zinc electrodes that hang on wires in my tank, I also threw a few bits of zinc in the tank to dissolve, that helps enrich the electrolyte a bit. Be aware though this process is a bit stinky due to the white vinegar.Looks like a diy zinc solution is super simple to make. I’ll try it very soon then plate black nickel over it.

Zinc Plating on the Cheap – Christian Moist

www.cmoist.com

I have fish tank heaters which are supposed to help and air pumps as well to agitate the electrolyte which gives a more even plating.

Nice, that LOS looks pretty quick and easy to try so I think I’ll give that a go first.Throwing this out there too…here are some alternative oxidation solutions to get browns and blacks.

On the flip side if anyone is interested in getting a deeper black you can put your dial back into the acid etch (pre plating solution) with the current reversed and it will deepen the black apparently, I’ve not tried this but the company who I buy my kit from recommends this method.

Should also have mentioned brass black. I posted photos of my very black brass dial on my original threadNice, that LOS looks pretty quick and easy to try so I think I’ll give that a go first.

On the flip side if anyone is interested in getting a deeper black you can put your dial back into the acid etch (pre plating solution) with the current reversed and it will deepen the black apparently, I’ve not tried this but the company who I buy my kit from recommends this method.

Making a gilt dial (not decal)

Sold an ebike I made, have lots of play money. I have made some gilt decal dials but want to try to go one step further. I recently had a 6538 template printed by a UV printer (see image below), it looks a bit grainy though from the preview photo. The printer says its just the way the light it...

It’s post #16 and #93. Don’t know how to link to a specific post. It’s cold bluing and is super easy and easy to get your hands on.

Tried a colder application of the oxidation on a dial that probably wasn’t super clean and got a speckled pattern on the dial along with a worn pattern around the pinion hole. Text is great. Figured out need to have new dunking solution each time because it looks like bits of oxidation flakes from previous attempts contaminated my mixture. Little bits of oxidation flakes settled on my last dial and prevent the oxidization from happening in that spot leading to a small brass fleck on the end product.

Got some browns and blacks. The longer it stays in the solution the darker it gets.

Got 20 brass blanks which I’ll turn into dials and will post more as I can make them

Got some browns and blacks. The longer it stays in the solution the darker it gets.

Got 20 brass blanks which I’ll turn into dials and will post more as I can make them

Had 10 minutes to cranked one out. Trying spraying on my oxidizing agent. It was a cold application. Should have heated the meta a bit. Took about 4 minutes of waiting, dunking in water, spraying, dunking in water.

Got some really nice tropical browns. I left the photo out on the first post but here is my oxidizing agent.

This dial was made from brass blanks from Etsy. They cost me less than a $1. Will make a tutorial on how to make brass blank dials easily and pretty cheap.

Got some really nice tropical browns. I left the photo out on the first post but here is my oxidizing agent.

This dial was made from brass blanks from Etsy. They cost me less than a $1. Will make a tutorial on how to make brass blank dials easily and pretty cheap.

Have a more simple rubric for heat/time for heating up the metal and paper for those that don’t have a thermometer.

I found the best results where the toner transfers completely and crisp is this:

Put your piece of metal or pan on the stove. Put your paper artwork facing up and align your dial with your centering hole. Turn on your stove to MEDIUM HIGH and let heat up for 1 MINUTE. Turn off the stove. Flip the dial/paper over and burnish all over the artwork (which you should be able to kind of see through the paper).

I have abandoned temperature checking since this setting/time works great.

Remember. You don’t need fancy transfer paper. Glossy magazine paper works just as well. So if you have a laser printer and a magazine lying around you have 2/3 of the materials needed to get artwork on your dial. The other 1/3 is a donor dial.

I found the best results where the toner transfers completely and crisp is this:

Put your piece of metal or pan on the stove. Put your paper artwork facing up and align your dial with your centering hole. Turn on your stove to MEDIUM HIGH and let heat up for 1 MINUTE. Turn off the stove. Flip the dial/paper over and burnish all over the artwork (which you should be able to kind of see through the paper).

I have abandoned temperature checking since this setting/time works great.

Remember. You don’t need fancy transfer paper. Glossy magazine paper works just as well. So if you have a laser printer and a magazine lying around you have 2/3 of the materials needed to get artwork on your dial. The other 1/3 is a donor dial.

Etsy. Search for 26mm .016” thick or 27 gauge for the 26mm diameter dials. Just have to drill a center hole. I have to make my own 29mm ones out of brass sheet.Where are you getting your blanks from? I’ve had a look around and can’t find any, their either the wrong diameter or wrong thickness.

I’ve just realised (I’m an idiot), we’ve got a 2KW fibre laser at work so I can cut my own. It’s just cost me £16 for an A3 size sheet of brass at .4mm thick, I’ll get a shed load out of that even if their only good enough for practice.Etsy. Search for 26mm .016” thick or 27 gauge for the 26mm diameter dials. Just have to drill a center hole. I have to make my own 29mm ones out of brass sheet.

I can cut them and stick them in the vibration tumble to tidy them up a bit, that’s if they don‘t float on top of the media of course due to being too light.

Happy days.

@jamiex here is where I get mine https://www.supplydiva.com/products...supplies-20-pieces?_pos=2&_sid=0cc2b1994&_ss=

Rock n roll!I’ve just realised (I’m an idiot), we’ve got a 2KW fibre laser at work so I can cut my own. It’s just cost me £16 for an A3 size sheet of brass at .4mm thick, I’ll get a shed load out of that even if their only good enough for practice.

I can cut them and stick them in the vibration tumble to tidy them up a bit, that’s if they don‘t float on top of the media of course due to being too light.

Happy days.

Fantastic results thus far. I can understand using the blanks now sans feet so you dont have to be super precise on dial / print placement otherwise that will ad another level of complexity in positioning it. I am absolutely loving the tropical look on these. This definatly seems to be the way. I assume the finish is quite durable since its a chemical reaction to the metal plate.

Look fwd to seeing one completed.

The line up for the pre sales starts behind me.

_______________________________________________________________

Look fwd to seeing one completed.

The line up for the pre sales starts behind me.

_______________________________________________________________

@369mafia the finish is very durable as it is a chemical reaction. I have 20 26mm dials to make soon. Got some new oxidizers to play with too. Talked to a few product managers of chemical companies of best product/method to achieve various looks. Will be butchering my too thick dials on testing those methods.

There are patinas out there for that. Unless you happen to have various chemicals lying around or can buy just a few ounces of the chemical, it’s more cost efficient to just buy a premade patina. That’s my experience learning various formulas for colors and made one on my own.Do you know the formula to make this with a turquoise/copper finish? Btw your dial looks amazing

Here is a start for you.

Patina Formulas for Brass, Bronze and Copper

The Science Company has collected chemical patina recipes from a variety of sources and presents them in an organized list by metal type and color effects.

Thanks, I see that they got most of the product on there too. Probably going to buy a few and experiment myself .

Do you know the specifics technic and what formula for this exact finish?

This one is natural by leaving it in the ocean for quite a while but I'm sure there's a way to do it faster and more permanent as this one will buff out quite easily.

Do you know the specifics technic and what formula for this exact finish?

This one is natural by leaving it in the ocean for quite a while but I'm sure there's a way to do it faster and more permanent as this one will buff out quite easily.

@jewelz i don’t know exactly but have seen it before. I remembering searching Google for something like brass patina watch and there is a thread out there of people sharing their brass watch patina experiments. Just search and browse images on the Google image results. Maybe include “turquoise” or “speckled”.