Hey KJ. I’m assuming the newest DSSDs have an easier bezel (no wire clip) to remove?The discussion about a wire clip bezel was for a 13 year old Noob DSSD

-

Tired of adverts on RWI? - Subscribe by clicking HERE and PMing Trailboss for instructions and they will magically go away!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY GMT Master Crystal Replacement

- Thread starter TonyMonatana44

- Start date

- 12/3/18

- 37,544

- 80,307

- 113

Whenever he goes away (vacation, personal business etc.) his listings disappear. It's different I know - most vendors leave their listings up. But if those other vendors are "away" and you go to put their item in your cart you can't and you get a message "You can't buy this item right now, the seller is away."He had a bunch of gaskets listed on his ebay last night when you sent me that link. He had the 2.5, 2.7 and 2.85 all on his site. It also said he had more than 300 items on his page, now it only says he has 2.

I'll shoot him a message and see what he says.

Don't worry he'll be back and listings will reappear. He isn't always exactly punctual though. Give him a few days.

- 12/3/18

- 37,544

- 80,307

- 113

Yes, and I think you will not find one that can accommodate a 2836.Hey KJ. I’m assuming the newest DSSDs have an easier bezel (no wire clip) to remove?

Unless you make a fantasy model, hehe. Both of these have a 2836. I love the JC dial but not the ankle bracelet DSSD case.

- 12/3/18

- 37,544

- 80,307

- 113

Check out the current threads on what is the best model now. I don't follow that model very closely. Pay close attention to the CGs - ARF makes a great model but their CGs on the top angle back and cover the crown too much. That's a flaw found more commonly on reps that one might imagine and a real pet peeve of mine. You often see mods like "shaved CGs" in sales threads.I think I’m just going to get a current 126660 to put the prof crystal in and keep the BK Swiss noob on ice.

I shaved the CGs on the James "Kermeron" case in the pic above haha.

- 12/3/18

- 37,544

- 80,307

- 113

Check the DSSD threads. Maybe take this discussion there as we have really hijacked this one.I think GMF is the one I’ll be going for. Got trusty on the case

I think there is a better choice than GMF.

- 21/1/20

- 21

- 21

- 8

- 3/10/23

- 366

- 388

- 63

Hey @KJ2020 - I received the crystal gaskets and all parts I need to do the crystal swap. I just had a few questions if you could give your expertise on if and when you have the time:

1 - Should I use UV Glue between the crystal gasket and the crystal to seal it up and make it more water resistant? If so, where do you recommend putting the UV Glue? I believe I read on one of the forums on here that someone experimented with putting a thin bead in the crystal groove and it worked out.

2 - When putting in the new xtal with the new xtal gasket, what parts should go on in order? I understand you can do it a few different ways? Would it be easiest to go -> xtal gasket + xtal -> then retaining ring? I will try putting a thin layer of silicon grease on the gasket after sanding it down to help the retaining ring slide on better per your previous forum comments.

3 - I plan on buying a digital caliper and measuring the thickness of the DEEP Xtal + using the 2.7mm gasket in accordance to your pictures you've posted with the xtal thicknesses and gasket heights. I am assuming the DEEP will be 1.8mm. I plan on going close to gen as possible to make the mag window as gen as possible. My question is, do you know if the xtal on a gen sits flush/sort of flush with the bezel on the new GMT's? I could not find that answer anywhere. I don't want to make the window look like gen then have the xtal too sunken in or higher than the bezel. I'd be okay with compromising a little of the mag window to have the height of the xtal sort of like gen as well.

4 - You mentioned that I can shave off some of the gasket from the bottom end with a fine grit sand paper. Question is - it's okay to shave off the part that has a lip on the bottom of the gasket?

When and if you have time to answer that would be amazing. I understand that you might be busy but these are the questions basically holding me back from doing the job. Any input if any would be awesome. Cheers.

1 - Should I use UV Glue between the crystal gasket and the crystal to seal it up and make it more water resistant? If so, where do you recommend putting the UV Glue? I believe I read on one of the forums on here that someone experimented with putting a thin bead in the crystal groove and it worked out.

2 - When putting in the new xtal with the new xtal gasket, what parts should go on in order? I understand you can do it a few different ways? Would it be easiest to go -> xtal gasket + xtal -> then retaining ring? I will try putting a thin layer of silicon grease on the gasket after sanding it down to help the retaining ring slide on better per your previous forum comments.

3 - I plan on buying a digital caliper and measuring the thickness of the DEEP Xtal + using the 2.7mm gasket in accordance to your pictures you've posted with the xtal thicknesses and gasket heights. I am assuming the DEEP will be 1.8mm. I plan on going close to gen as possible to make the mag window as gen as possible. My question is, do you know if the xtal on a gen sits flush/sort of flush with the bezel on the new GMT's? I could not find that answer anywhere. I don't want to make the window look like gen then have the xtal too sunken in or higher than the bezel. I'd be okay with compromising a little of the mag window to have the height of the xtal sort of like gen as well.

4 - You mentioned that I can shave off some of the gasket from the bottom end with a fine grit sand paper. Question is - it's okay to shave off the part that has a lip on the bottom of the gasket?

When and if you have time to answer that would be amazing. I understand that you might be busy but these are the questions basically holding me back from doing the job. Any input if any would be awesome. Cheers.

If it helps, I did an explorer 2 and a DJ41 today with prof crystals. I reused the original gaskets and didn’t use any grease. Bezels went on ok with a press.

I fitted the gaskets to the crystal first and then on to the watch case. Pressed down by hand then used a press to press down the bezels

I know these watches don’t have retaining rings but some of the info might help.

I’ll be doing a ceramic sub and a gmt2 in the next few days

I fitted the gaskets to the crystal first and then on to the watch case. Pressed down by hand then used a press to press down the bezels

I know these watches don’t have retaining rings but some of the info might help.

I’ll be doing a ceramic sub and a gmt2 in the next few days

- 3/10/23

- 366

- 388

- 63

If it helps, I did an explorer 2 and a DJ41 today with prof crystals. I reused the original gaskets and didn’t use any grease. Bezels went on ok with a press.

I fitted the gaskets to the crystal first and then on to the watch case. Pressed down by hand then used a press to press down the bezels

I know these watches don’t have retaining rings but some of the info might help.

I’ll be doing a ceramic sub and a gmt2 in the next few days

Yeah I'll have to shave the Clark's gasket down width wise to make the retaining ring fit. That's why I plan on buying the measuring calipers to measure the old/Clean gasket to match the clarks gasket that i'll be shaving/sanding down.

What you wrote though Is what I expected. I'll give it a go and see what ends up happening.

Hi KJ, in your opinion then what’s the best DSSD now and why?Check the DSSD threads. Maybe take this discussion there as we have really hijacked this one.

I think there is a better choice than GMF.

- 12/3/18

- 37,544

- 80,307

- 113

Take a look at this thread bro. You can start at the end and work backwards for the most recent discussions.Hi KJ, in your opinion then what’s the best DSSD now and why?

"Official DSSD Club"

Just got this from trusty re the 126660 available The GMT escape text looks off

Funny but I never could work with these, never worked. Always worked with old school butter knife style knife and tapeIf it has a wire clip configuration then no. But those are great tools to have. They are way cheaper on AliExpress though.

Yep the expII and DJ41 I did, the razor blade and small hammer did the job for me.Funny but I never could work with these, never worked. Always worked with old school butter knife style knife and tape

Will break out the 4 blade remover for the ceramics though. It arrived yesterday and is a solid bit of kit for £65

- 12/3/18

- 37,544

- 80,307

- 113

It never hurts to use some glue with a crystal, especially with a rep that may have WP issues. I have glued many crystals for various reasons, always relating to loose fit between parts. I have used GSHypo, E6000, even epoxy. I do a lot of modding and mixing of parts so it's not uncommon for this to be necessary.1 - Should I use UV Glue between the crystal gasket and the crystal to seal it up and make it more water resistant? If so, where do you recommend putting the UV Glue? I believe I read on one of the forums on here that someone experimented with putting a thin bead in the crystal groove and it worked out.

IMO the best place to apply a proper bead of glue is at the outer base of the crystal gasket where it meets the case. The bead needs to overlap both parts at the joint, extending 1 - 2mm to each part. Depending on the job you can let the glue cure before the retaining ring goes on, or press the ring into the glue bed. All glue jobs are reversible with acetone, some can be more challenging than others (epoxy) and sometimes you can lose a gasket in a reversal.

I nearly always fit the crystal to the gasket then set the combo to the case. This is the time to evaluate date mag and correct if necessary. Once that's OK add glue if desired (UV glue is fine) and press the retaining ring. I use a tiny oiler to add about 20 tiny blobs of silicone grease on the mid to upper sides of the outer gasket, then spread it around with a toothpick tip or tiny artist's paintbrush.2 - When putting in the new xtal with the new xtal gasket, what parts should go on in order? I understand you can do it a few different ways? Would it be easiest to go -> xtal gasket + xtal -> then retaining ring? I will try putting a thin layer of silicon grease on the gasket after sanding it down to help the retaining ring slide on better per your previous forum comments.

Deep GMT crystal is 1.8mm. Gen crystal sitting height is not flush, but slightly raised. Here is a pic of a Franken that is about as good as it gets.3 - I plan on buying a digital caliper and measuring the thickness of the DEEP Xtal + using the 2.7mm gasket in accordance to your pictures you've posted with the xtal thicknesses and gasket heights. I am assuming the DEEP will be 1.8mm. I plan on going close to gen as possible to make the mag window as gen as possible. My question is, do you know if the xtal on a gen sits flush/sort of flush with the bezel on the new GMT's? I could not find that answer anywhere. I don't want to make the window look like gen then have the xtal too sunken in or higher than the bezel. I'd be okay with compromising a little of the mag window to have the height of the xtal sort of like gen as well.

There is some more discussion about this in the thread below along with more pics, good and bad.

CLEAN GMT crystal gasket rework

Aside from my previously posted way to determine the top and bottom of a crystal gasket, another way is to fit the crystal both ways. It will always fit tighter to the top and be noticeably harder to force into position and to remove.4 - You mentioned that I can shave off some of the gasket from the bottom end with a fine grit sand paper. Question is - it's okay to shave off the part that has a lip on the bottom of the gasket?

Once the bottom is identified, shave that edge if shaving is warranted. Especially with a CLEAN retaining ring and a gen or aftermarket gasket, there is going to be plenty of bulk there to negate any loss of material at the bottom.

Also when shaving width, don't use the rep gasket width as a goal. Take only enough off that the retaining ring will go on. At that point the proper operation of the bezel becomes the focus and sometimes it can require further thinning of the crystal gasket. Anticipating this, you can thin the crystal gasket a little more initially but be careful as it is easy to thin it too much. Adding glue as discussed is a big plus toward alleviating the consequences of too much crystal gasket thinning.

It's always helpful to dry fit all the parts together and test functionality before a final install. As much of a PITA as it might be, removing the insert can save a major mistake if multiple bezel fittings are needed to achieve proper operation. This is a no brainer if the bezel alignment isn't perfect but even if it is I almost always do it and save the insert re-install as the final step. Also, unless you mark the case with some Sharpie marks inside about 3 of the retaining ring scallops and put the retaining ring back on in the exact original rotational position, your insert alignment will not be the same as it was originally.

Last edited:

- 3/10/23

- 366

- 388

- 63

It never hurts to use some glue with a crystal, especially with a rep that may have WP issues. I have glued many crystals for various reasons, always relating to loose fit between parts. I have used GSHypo, E6000, even epoxy. I do a lot of modding and mixing of parts so it's not uncommon for this to be necessary.

IMO the best place to apply a proper bead of glue is at the outer base of the crystal gasket where it meets the case. The bead needs to overlap both parts at the joint, extending 1 - 2mm to each part. Depending on the job you can let the glue cure before the retaining ring goes on, or press the ring into the glue bed. All glue jobs are reversible with acetone, some can be more challenging than others (epoxy) and sometimes you can lose a gasket in a reversal.

I nearly always fit the crystal to the gasket then set the combo to the case. This is the time to evaluate date mag and correct if necessary. Once that's OK add glue if desired (UV glue is fine) and press the retaining ring. I use a tiny oiler to add about 20 tiny blobs of silicone grease on the mid to upper sides of the outer gasket, then spread it around with a toothpick tip or tiny artist's paintbrush.

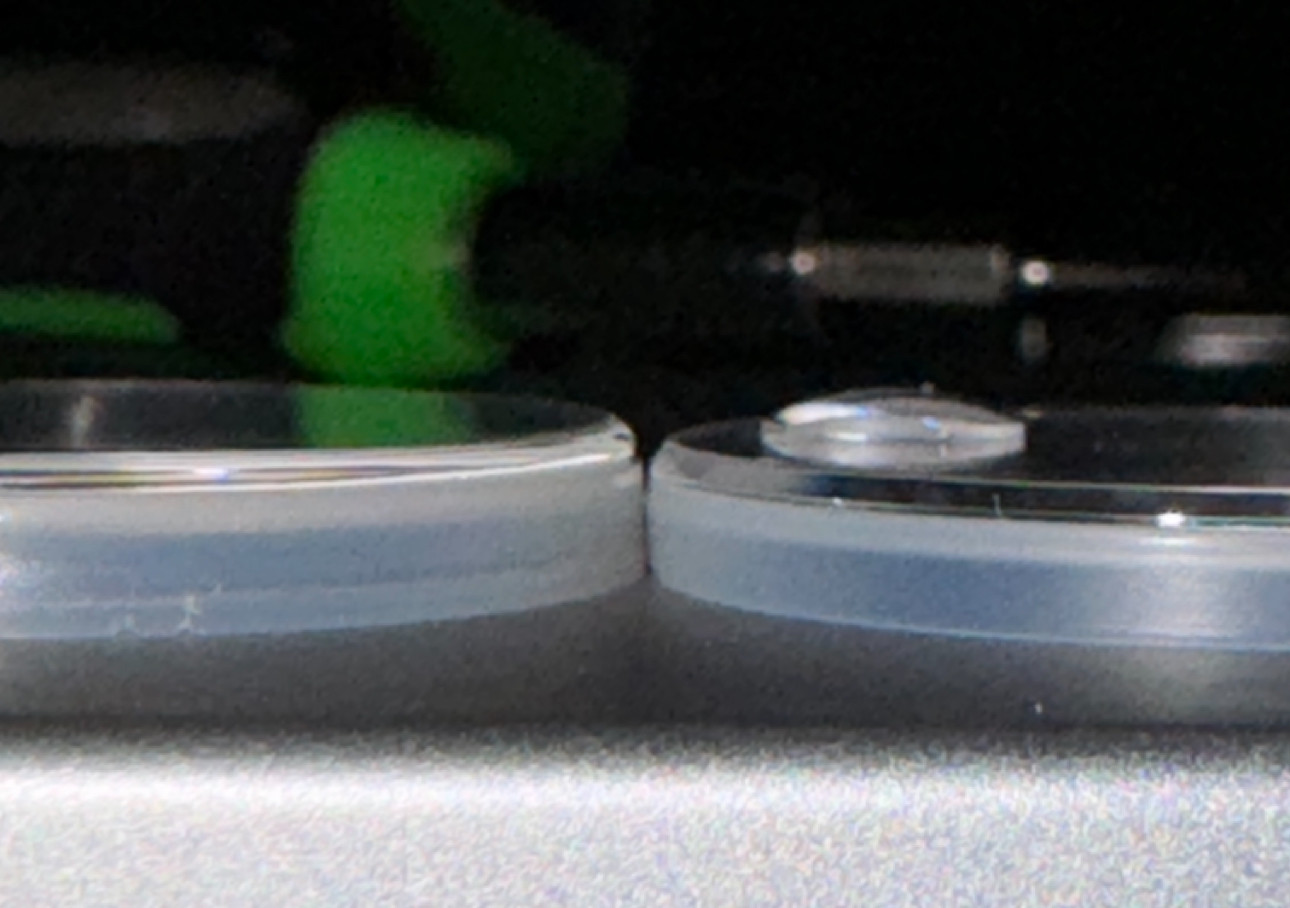

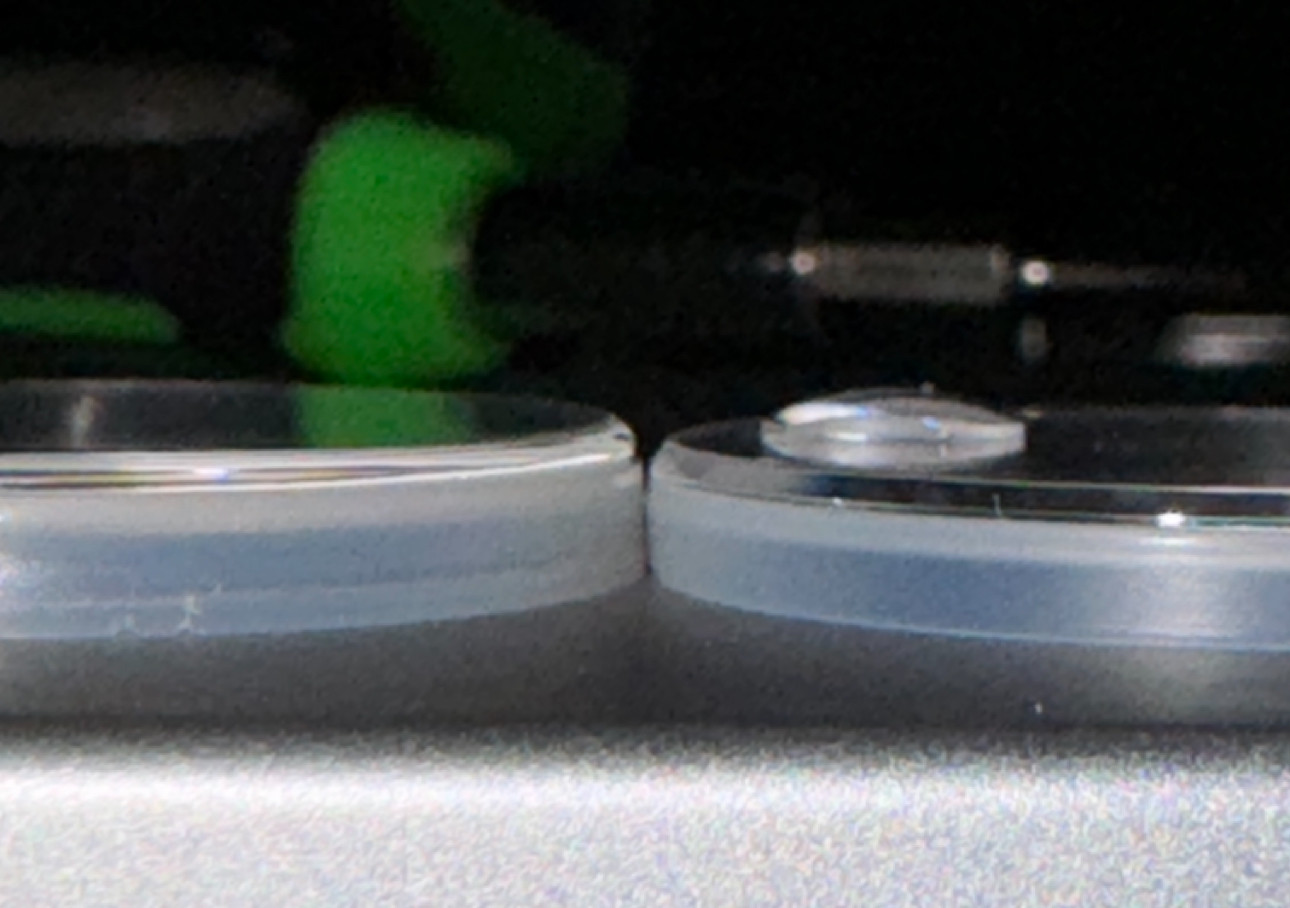

Deep GMT crystal is 1.8mm. Gen crystal sitting height is not flush, but slightly raised. Here is a pic of a Franken that is about as good as it gets.

There is some more discussion about this in the thread below along with more pics, good and bad.

CLEAN GMT crystal gasket rework

Aside from my previously posted way to determine the top and bottom of a crystal gasket, another way is to fit the crystal both ways. It will always fit tighter to the top and be noticeably harder to force into position and to remove.

Once the bottom is identified, shave that edge if shaving is warranted. Especially with a CLEAN retaining ring and a gen or aftermarket gasket, there is going to be plenty of bulk there to negate any loss of material at the bottom.

Also when shaving width, don't use the rep gasket width as a goal. Take only enough off that the retaining ring will go on. At that point the proper operation of the bezel becomes the focus and sometimes it can require further thinning of the crystal gasket. Anticipating this, you can thin the crystal gasket a little more initially but be careful as it is easy to thin it too much. Adding glue as discussed is a big plus toward alleviating the consequences of too much crystal gasket thinning.

It's always helpful to dry fit all the parts together and test functionality before a final install. As much of a PITA as it might be, removing the insert can save a major mistake if multiple bezel fittings are needed to achieve proper operation. This is a no brainer if the bezel alignment isn't perfect but even if it is I almost always do it and save the insert re-install as the final step. Also, unless you mark the case with some Sharpie marks inside about 3 of the retaining ring scallops and put the retaining ring back on in the exact original rotational position, your insert alignment will not be the same as it was originally.

You are my hero. I will attempt to do the job tonight. I will post pictures once I am done.

For the shaving of the gasket I plan on lightly going around the gasket twice and then try fitting the retaining ring. If needed I’ll shave off more and test.

might take some time since I’m going to polish the rehaut with some capecod polishing wipes. Clean the case in my ultra sonic cleaner and regrease all the teeth for the bezel action.

- 3/10/23

- 366

- 388

- 63

Well I finally completed the DEEP Crystal swap with the Clarks Crystal Gasket, polished Rehaut & cleaned the entire watch. I must say with the right tools anything is possible. And with the right RWI community giving you advice and answering questions

When I first opened the CF I was greeted with the 300 lbs of grease the factory uses. Cleaned it all off with a paper towel, removed the movement and crystal and put the case and bracelet into my ultra sonic cleaner.

Here are pics of the date window with the stock CF factory crystal and CF gasket:

I experimented with a 2.5mm, 2.7mm and a 2.85mm gasket. The 2.85 did absolutely nothing because the CF gasket was the same size. The 2.7mm was better but didn't get the "gen" 2.5x magnification i've been looking for. The 2.5 was perfect and looked exactly what the Gen "Batman" Rolex looked like in person when I looked at the Rolex store the other day. Also the height of the Xtal was perfect. Looks like the gen height as well from what I can tell from videos and @KJ2020's picture he posted.

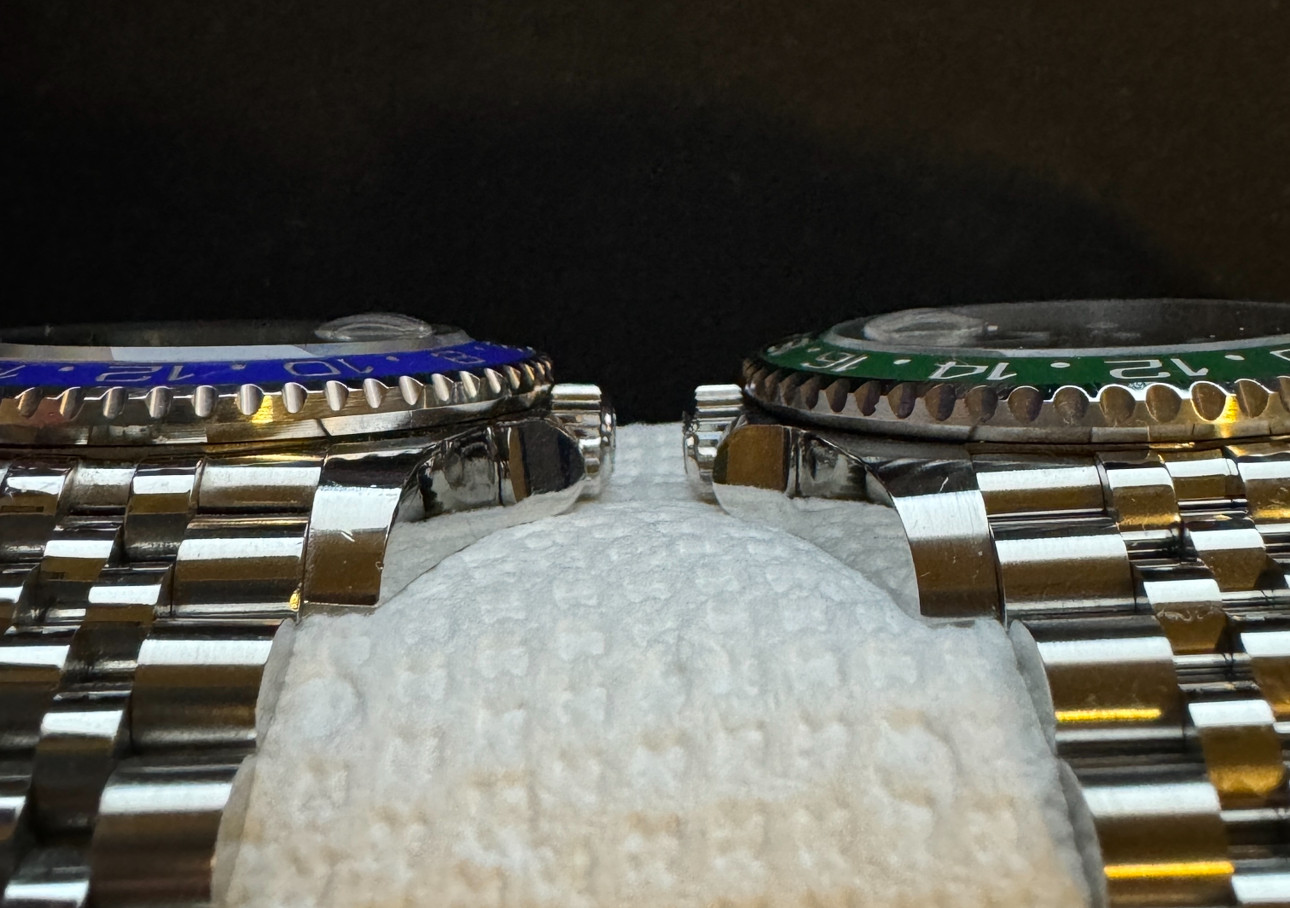

Here is the height difference of the CF Xtal + CF 2.85mm gasket on the left and the DEEP Xtal + Clark's 2.5mm gasket:

Here are pics with the DEEP XTAL with the Clark 2.5mm gasket:

You might not be able to tell a huge difference in pictures because I suck at photography, but looking at the window in person it's literally the same as the gen window size now.

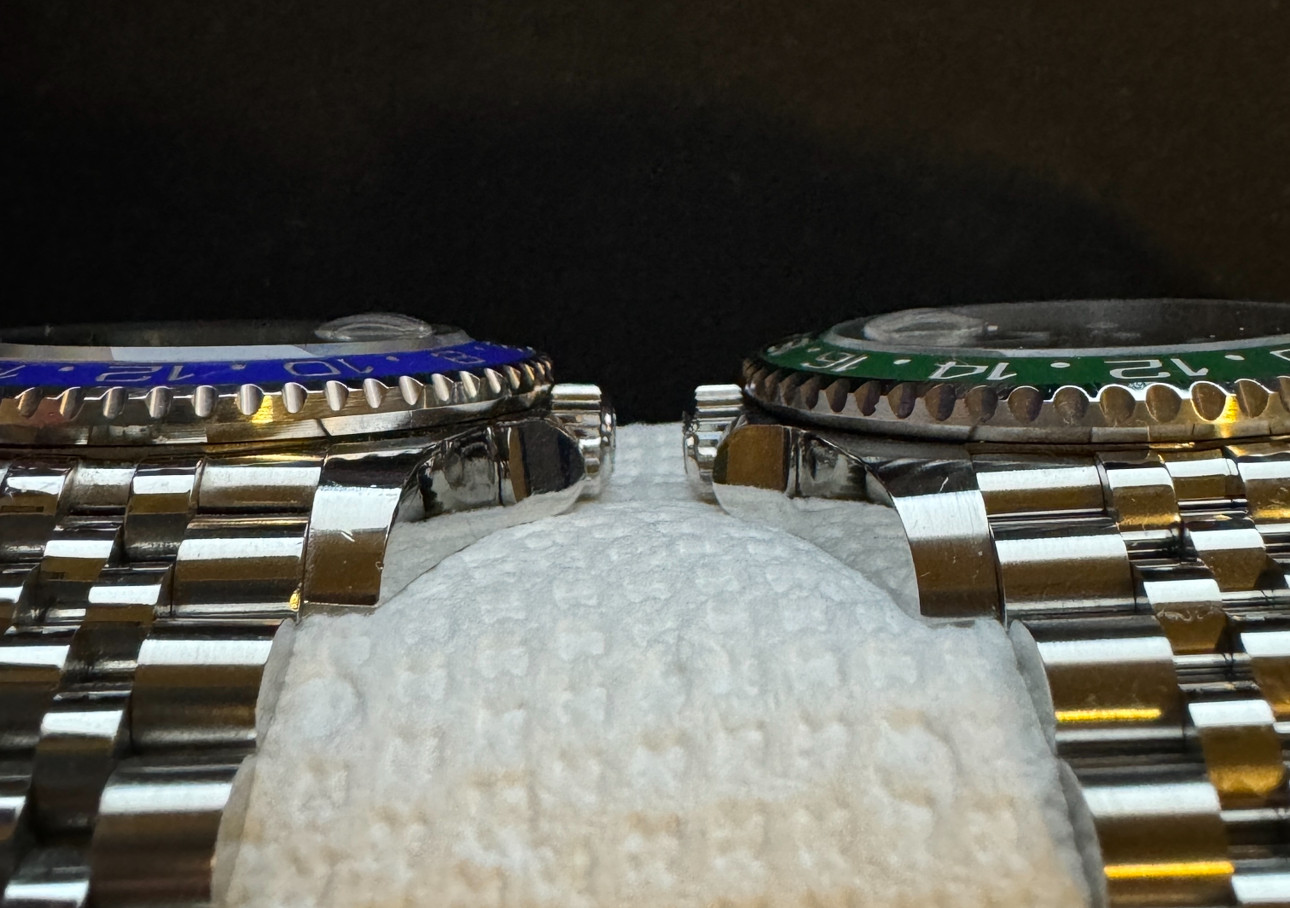

Here are pictures of the crystal height after installation (the batman is a 4 year old rep I bought. I have no idea who even the factory is but it's the same height that the CF had before the swap):

Here are some completed pics with the bracelet on, watched cleaned up, and rehaut polished:

It's currently 5 AM as I'm taking these pictures and posting this, so the lighting is terrible. But the polish of the rehaut plus the Deep Xtal install is a WORLD of difference. It feels and looks much more like the real thing.

I water pressure tested it and it passed a 7 bar test. I used clear UV Glue, changed the o rings and greased them up a little before installing.

Only thing that I could not do for the life of me was fix the bezel play. It still has about 2-4 mm of play left and right. Even after pulling on the spring on the three points multiple times. I guess a Gen spring will be in order.

I will take pictures tomorrow in the sun and post them here. Whoever says DEEP Xtals aren't worth it are wrong. I can tell a huge difference in the "black hole" effect with the DEEP vs the CF Xtal and it's not even in sunlight yet. The DEEP is also days ahead in clarity vs the CF xtal. It's not as cloudy and is super clean. A lot of work to do all of thise but honestly now you cannot tell it apart from a gen other than the stupid CF serial number.

Huge thank you to @KJ2020 once again for helping out with questions. You are the man.

When I first opened the CF I was greeted with the 300 lbs of grease the factory uses. Cleaned it all off with a paper towel, removed the movement and crystal and put the case and bracelet into my ultra sonic cleaner.

Here are pics of the date window with the stock CF factory crystal and CF gasket:

I experimented with a 2.5mm, 2.7mm and a 2.85mm gasket. The 2.85 did absolutely nothing because the CF gasket was the same size. The 2.7mm was better but didn't get the "gen" 2.5x magnification i've been looking for. The 2.5 was perfect and looked exactly what the Gen "Batman" Rolex looked like in person when I looked at the Rolex store the other day. Also the height of the Xtal was perfect. Looks like the gen height as well from what I can tell from videos and @KJ2020's picture he posted.

Here is the height difference of the CF Xtal + CF 2.85mm gasket on the left and the DEEP Xtal + Clark's 2.5mm gasket:

Here are pics with the DEEP XTAL with the Clark 2.5mm gasket:

You might not be able to tell a huge difference in pictures because I suck at photography, but looking at the window in person it's literally the same as the gen window size now.

Here are pictures of the crystal height after installation (the batman is a 4 year old rep I bought. I have no idea who even the factory is but it's the same height that the CF had before the swap):

Here are some completed pics with the bracelet on, watched cleaned up, and rehaut polished:

It's currently 5 AM as I'm taking these pictures and posting this, so the lighting is terrible. But the polish of the rehaut plus the Deep Xtal install is a WORLD of difference. It feels and looks much more like the real thing.

I water pressure tested it and it passed a 7 bar test. I used clear UV Glue, changed the o rings and greased them up a little before installing.

Only thing that I could not do for the life of me was fix the bezel play. It still has about 2-4 mm of play left and right. Even after pulling on the spring on the three points multiple times. I guess a Gen spring will be in order.

I will take pictures tomorrow in the sun and post them here. Whoever says DEEP Xtals aren't worth it are wrong. I can tell a huge difference in the "black hole" effect with the DEEP vs the CF Xtal and it's not even in sunlight yet. The DEEP is also days ahead in clarity vs the CF xtal. It's not as cloudy and is super clean. A lot of work to do all of thise but honestly now you cannot tell it apart from a gen other than the stupid CF serial number.

Huge thank you to @KJ2020 once again for helping out with questions. You are the man.

- 12/3/18

- 37,544

- 80,307

- 113

Here are pics with the DEEP XTAL with the Clark 2.5mm gasket:

Really nice work bro, congrats. Solid hit on both date mag and sitting height.

You didn't mention crystal gasket shaving. Did you thin it? Also I would try something different with the hytrel ring before buying a gen click ring. A slightly thicker hytrel ring (or fishline) will tighten up the bezel.

I was going to mention it before - I may have forgotten. Regarding rehaut polishing, once it's done to your satisfaction finishing it with some 600 or 800 grit sandpaper or a piece of Scotchbrite puts the horizontal grooves back nicely. It can take a little practice to make them even and level but it's the ultimate in making it gen-like. I've made a rehaut or two more smooth than it should be before using this final step.

Last edited:

Great work Tony.

Think I’m going to remove the movements on mine before attempting this.

Assume just a couple of movement holder screws that get “tightened” and spin the movement to remove yes?

Also did you remove the stem in winding or time set position? I don’t want to upset the keyless

Think I’m going to remove the movements on mine before attempting this.

Assume just a couple of movement holder screws that get “tightened” and spin the movement to remove yes?

Also did you remove the stem in winding or time set position? I don’t want to upset the keyless