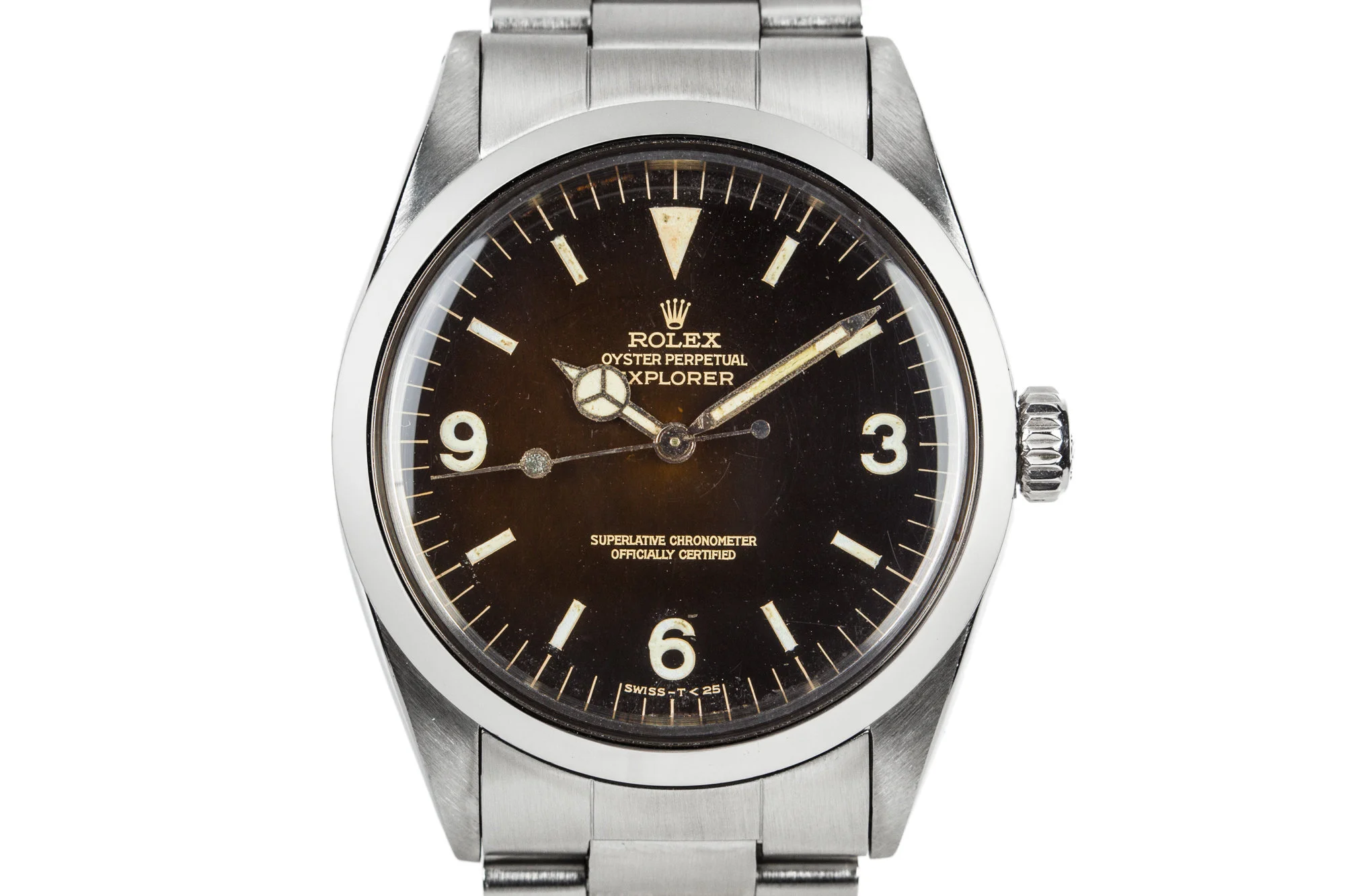

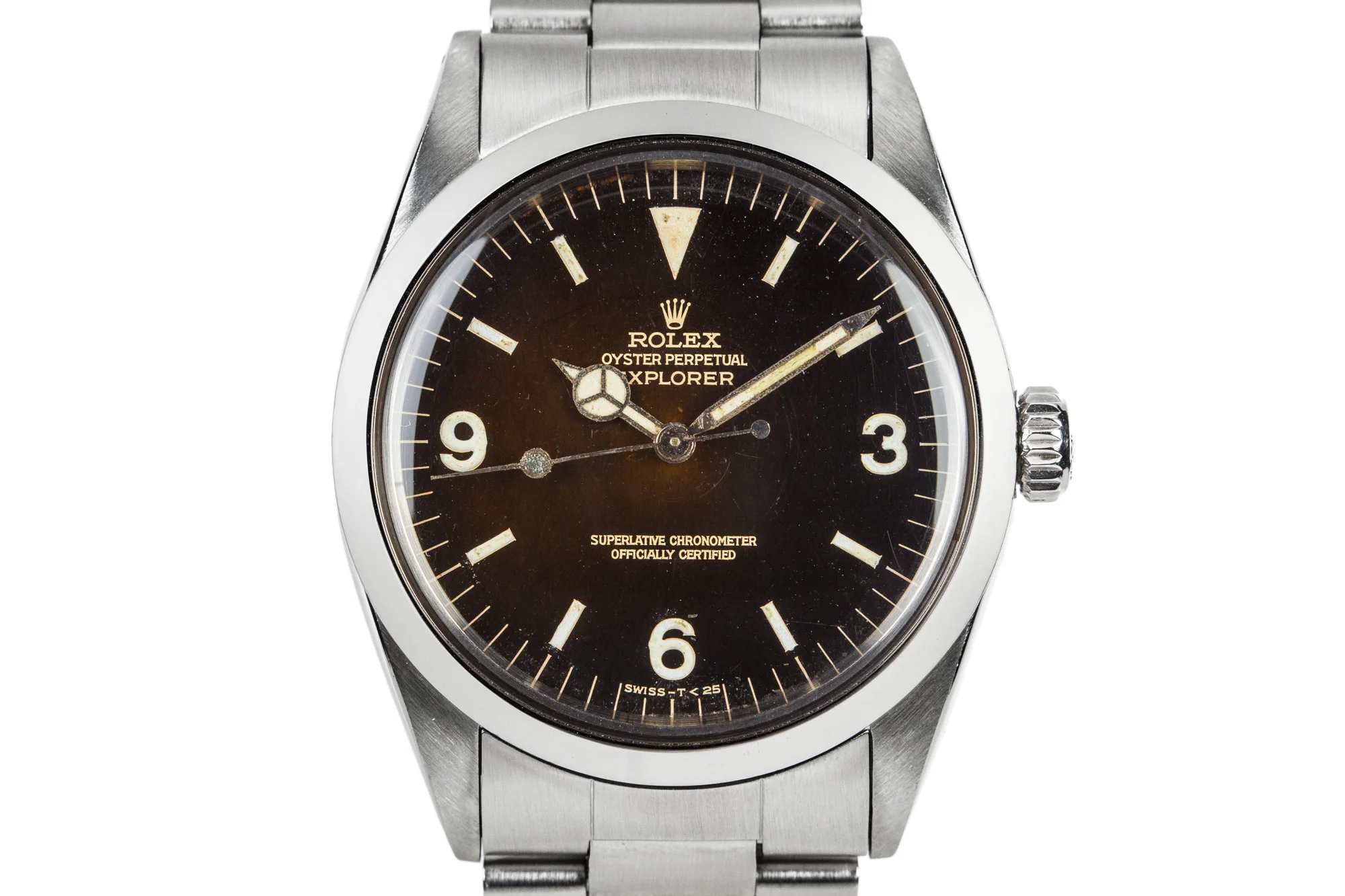

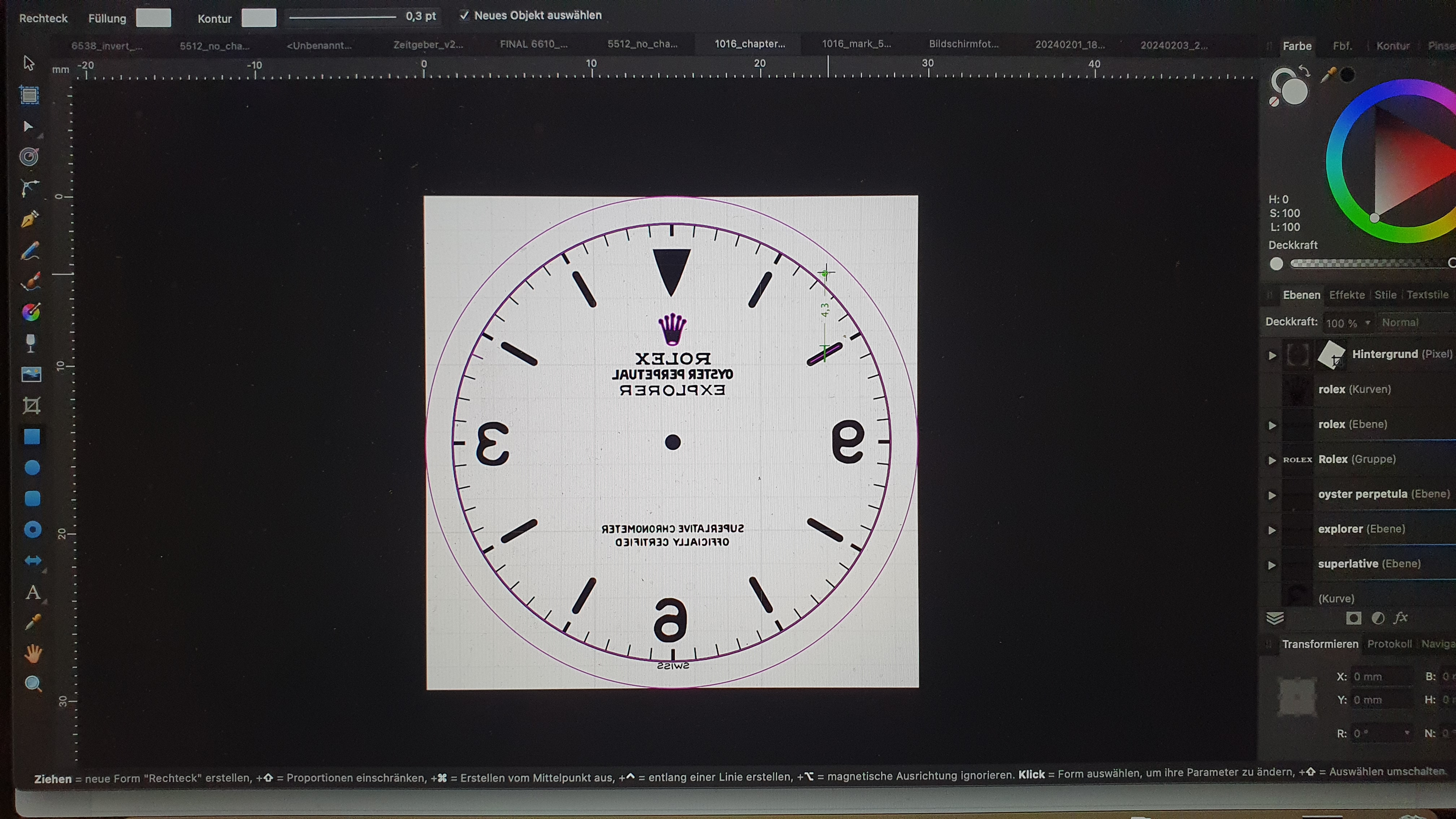

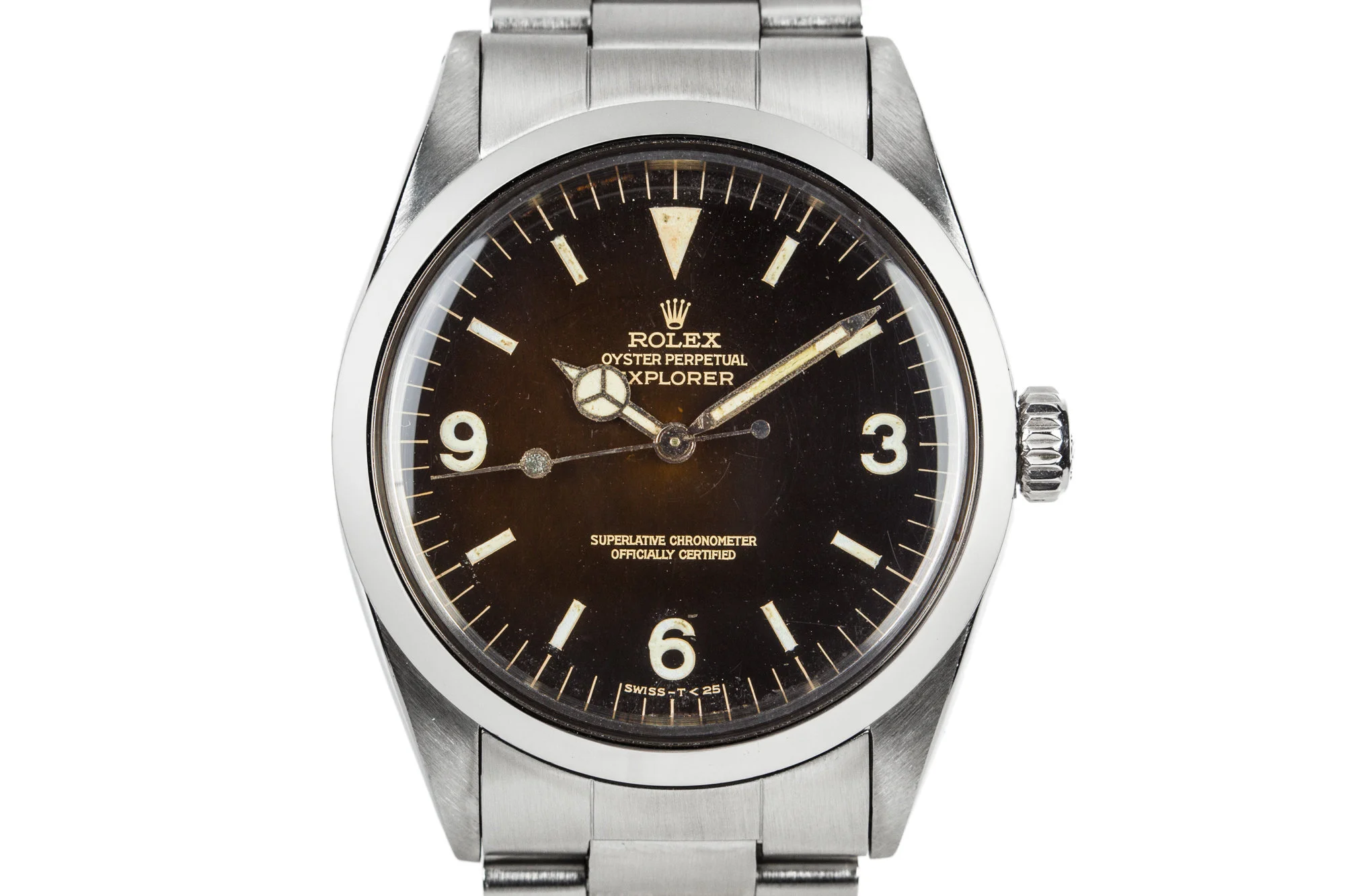

This will be a thread about the creation of a Rolex Explorer reference 1016 watch with real gilt dial. Inspired by many posts and nice builds I am motivated to start a new project and rebuild the small Explorer watch with custom gilt dial. Firstly, a big thank you to all those who share their experience in their work.

Historically, the reference 6610 is the successor to the 6010, both watches have a diameter of 36mm. The 6610 had a brief existence, lasting only for a few years in the late 1950s. It runs with the 1030 caliber. In 1959 Rolex released the new 15xx calibre movement line—models 5512, 1675, and 1016, respectively. Afterward, Rolex settled down with these references and focused on making small tweaks over the next 20-30 years. These models became the reliable mainstays of the sports line and are highly sought after by collectors due to their excellent design and construction.

Referenz 6610

The term "gilt" or "gilt/gloss" describes dials made using a galvanic coating process and was used on the 1016 until around 1967. Galvanization is a process of coating metals with another substance through a chemical reaction. Later dials were called matt dials.

If you are interested to more details and history, I can recogment you the following site: https://explorer1016.com

Historically, the reference 6610 is the successor to the 6010, both watches have a diameter of 36mm. The 6610 had a brief existence, lasting only for a few years in the late 1950s. It runs with the 1030 caliber. In 1959 Rolex released the new 15xx calibre movement line—models 5512, 1675, and 1016, respectively. Afterward, Rolex settled down with these references and focused on making small tweaks over the next 20-30 years. These models became the reliable mainstays of the sports line and are highly sought after by collectors due to their excellent design and construction.

Referenz 6610

The term "gilt" or "gilt/gloss" describes dials made using a galvanic coating process and was used on the 1016 until around 1967. Galvanization is a process of coating metals with another substance through a chemical reaction. Later dials were called matt dials.

If you are interested to more details and history, I can recogment you the following site: https://explorer1016.com