@HulkyGalore

Well done! Excellent job taking your time to clearly present each step with personal tips in your commentary. Each step supported with very nice photos allowed the readers to be a part of the build with you.

Thank you for sharing yout build tutorial with the community.

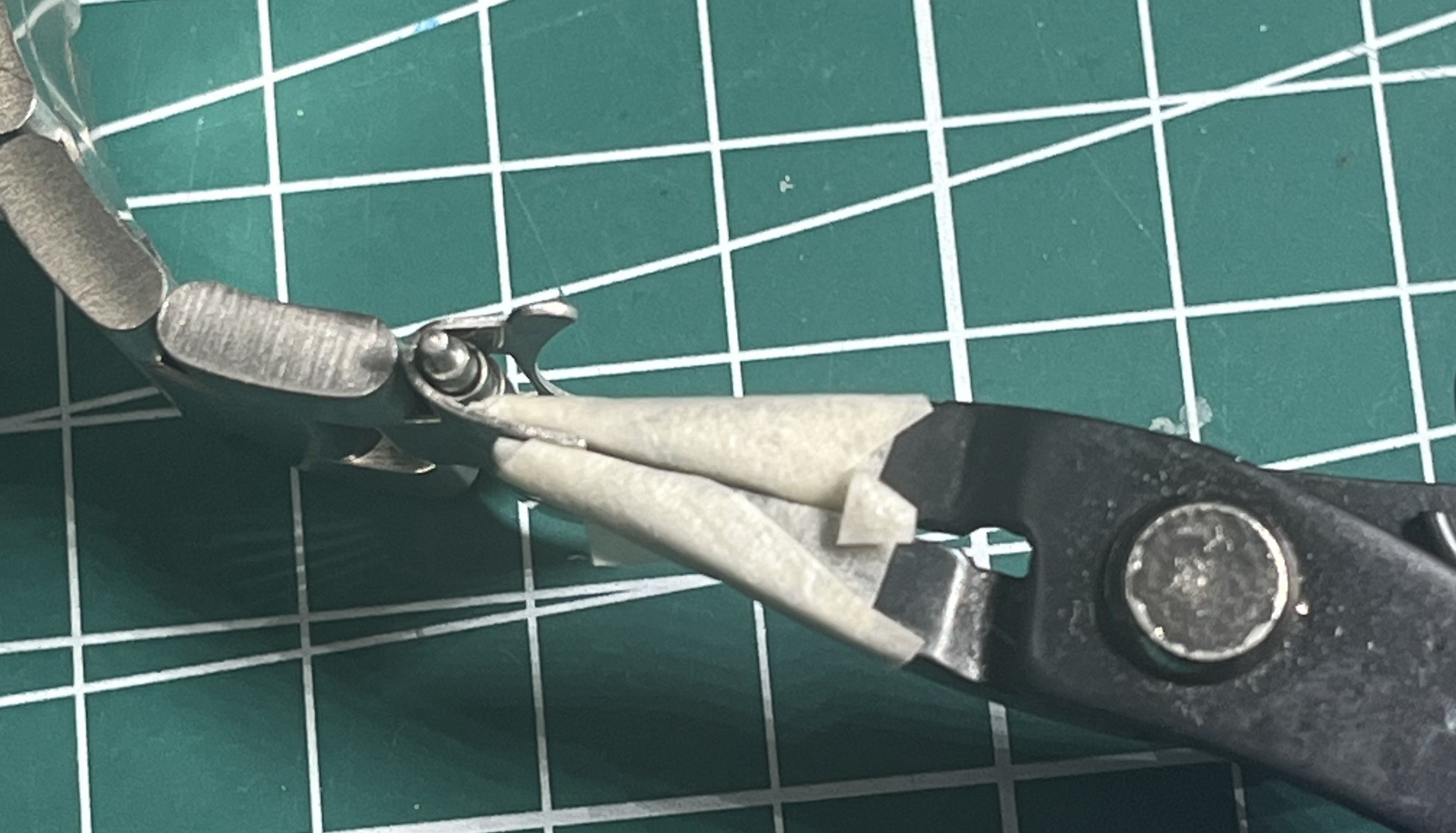

Thanks for this comment. I have learned so much on this forum from people doing builds, restorations, even sales threads. From low to high budgets, reading around you can learn a lot. Although a lot of my experience was learned through mistakes, others posting their journeys and learning got me started. So I thought, why not share a few pictures and explanations. I get so much satisfaction from wearing a self built watch, hopefully others may try it too!

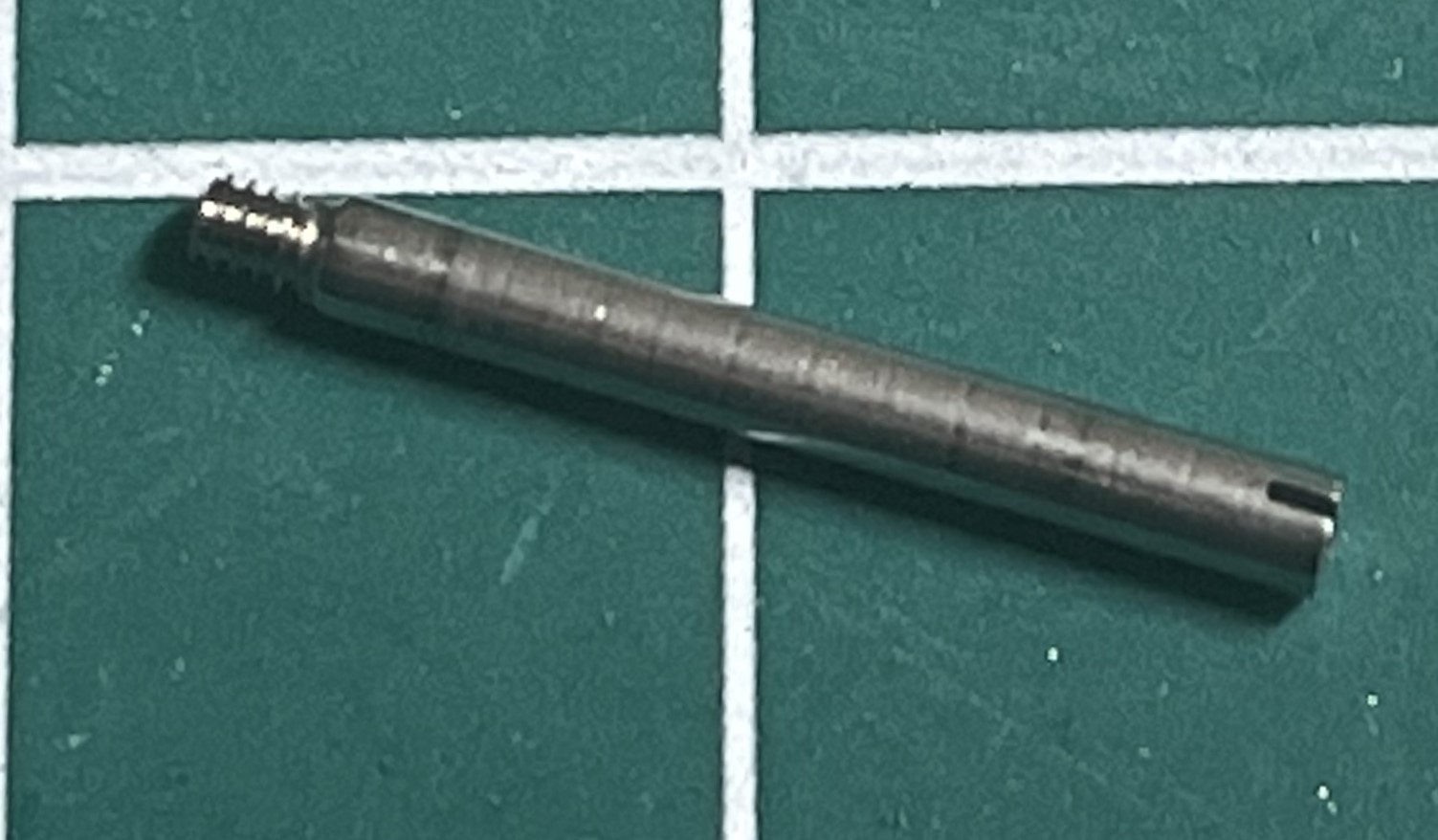

The other tip is to get a cheap watch or parts to experiment on. This can take the stress out of damaging expensive parts, and by the time you get to using those, you have a basic skill level.

My thanks go out to all the builders, modders, hobbyists and fellow members who helped me build my dream watch. The sharing attitude and helpfulness across different regions and cultures is great, it is an amazing community.

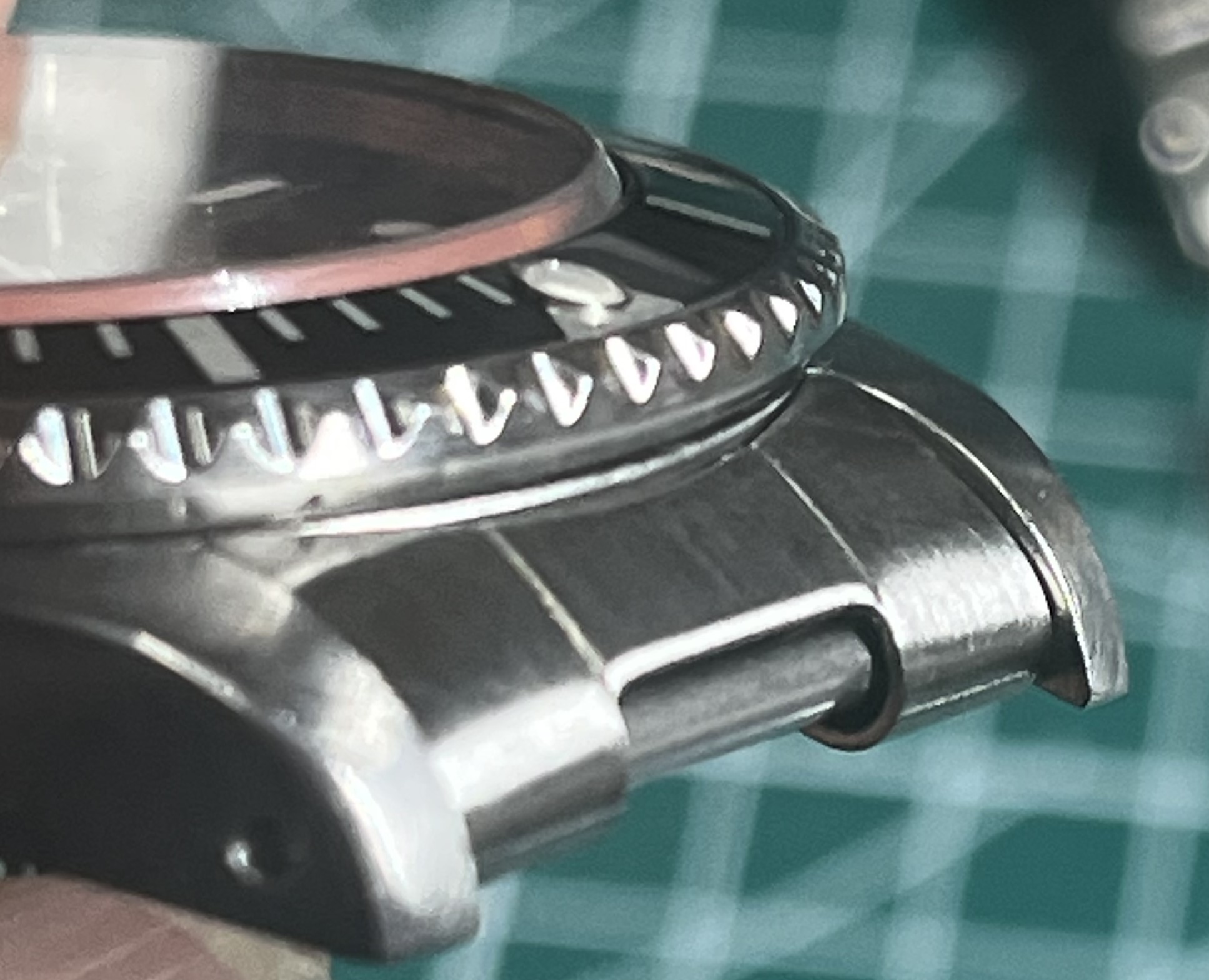

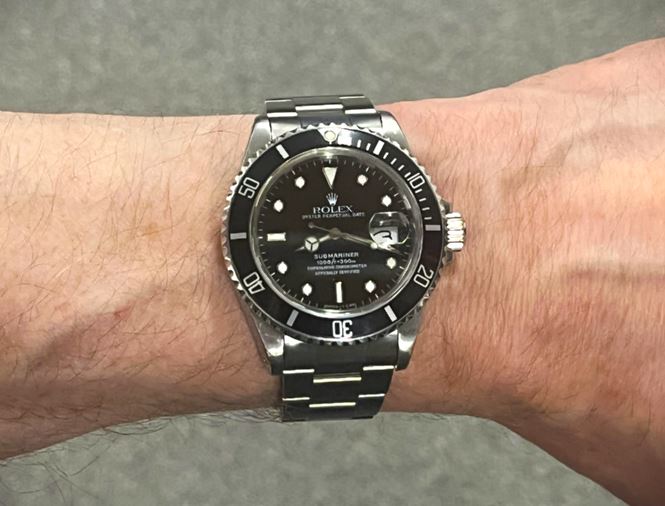

It is not finished yet, I have a few steps left but in the meantime, here is the watch that got me started appreciating these types of subs many years ago. It is interesting that the parts on this franken were probably made at around the same time as the legendary Datejust Submariner - which as you can see has seen some action, I even dived with it and it survived (only to about 10m though).