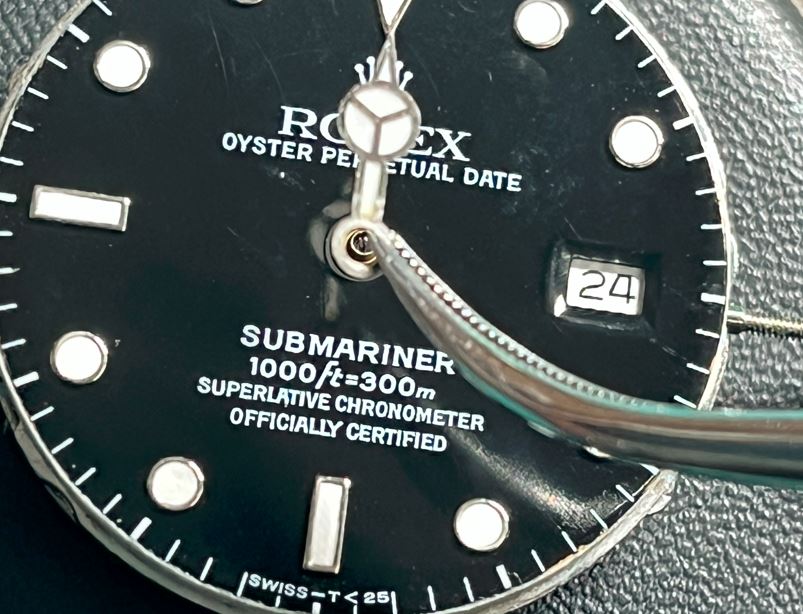

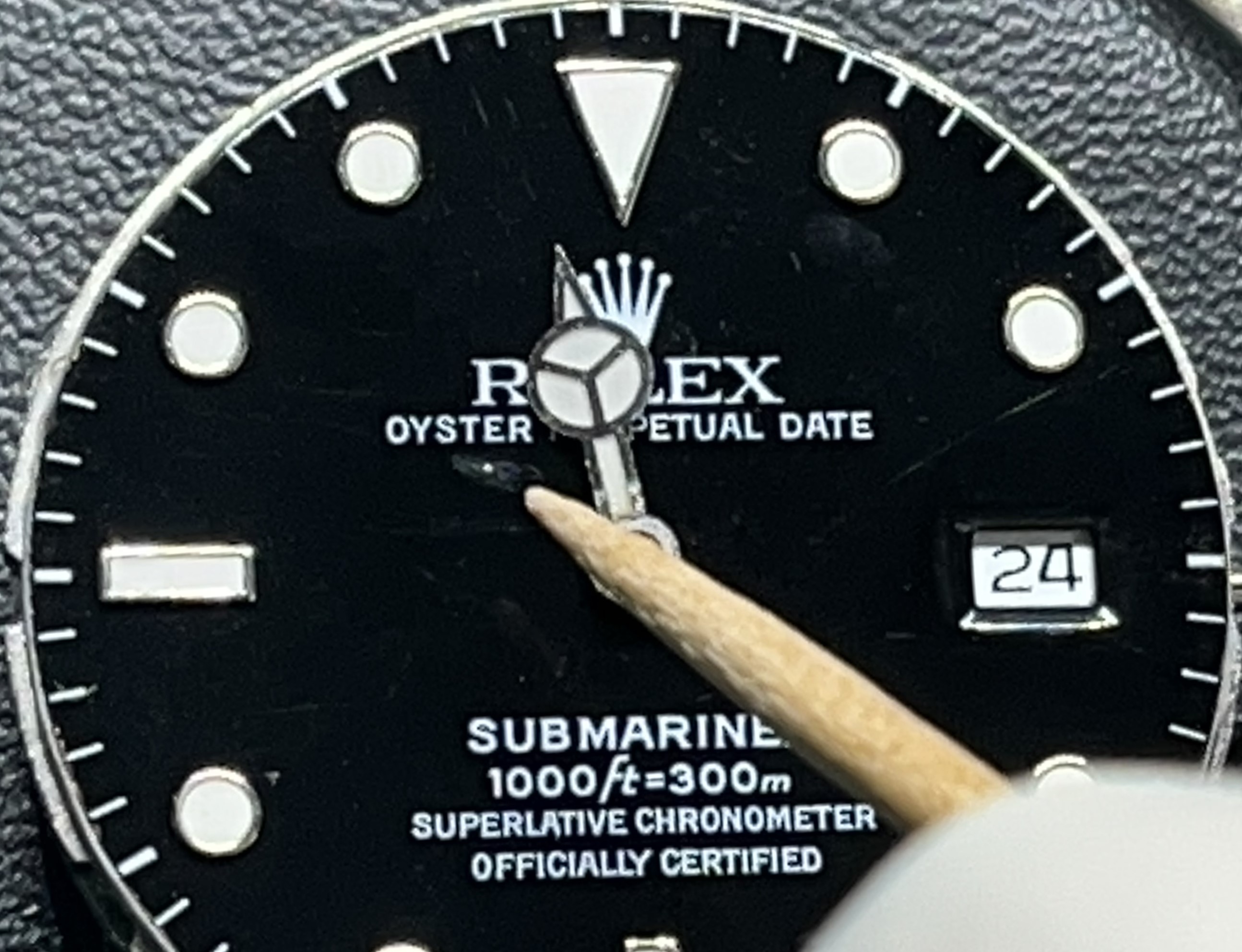

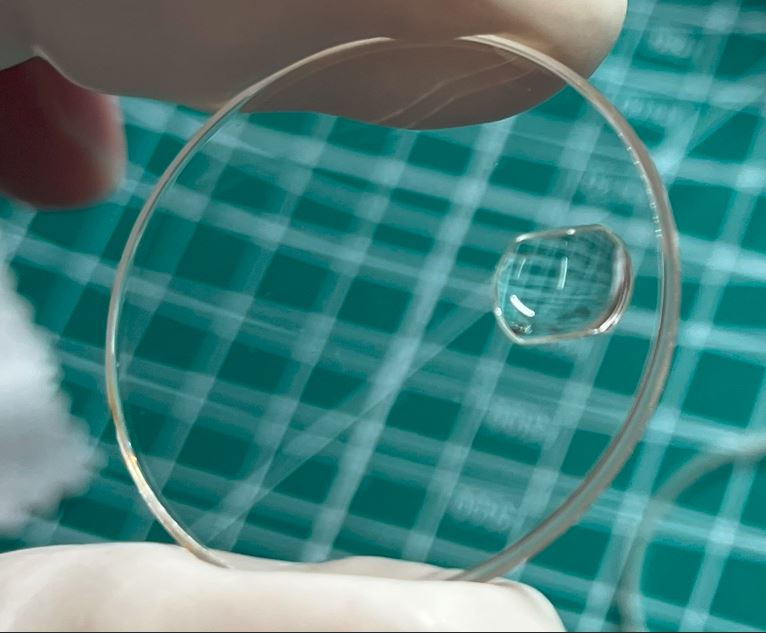

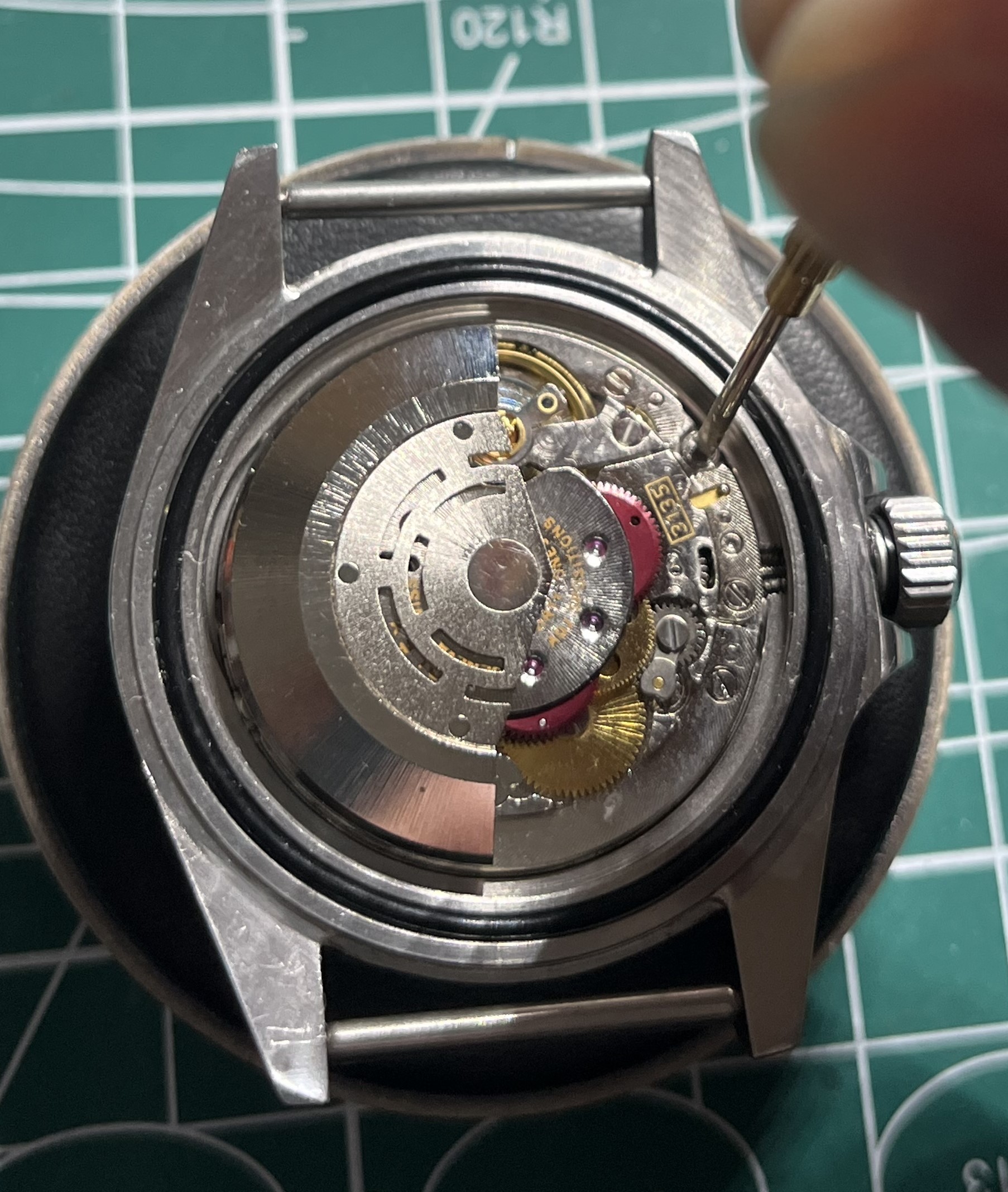

Its not all bad news, fortunately. The cracked sapphire was an ARF one, the case had been reworked by

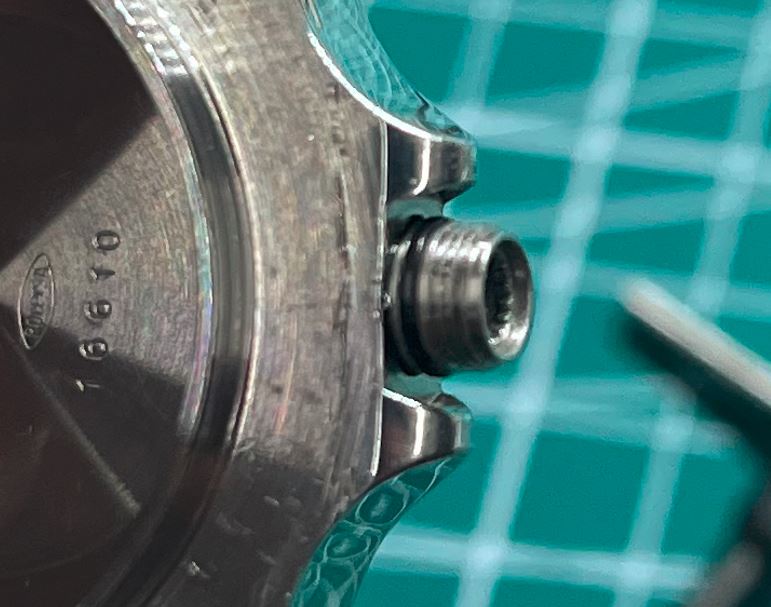

@tripdog (a lower cost alternative, not far off the viet case). He had modified the lugs, drilled holes in them, modified the rehaut slightly, the crown gaurds and the bezel shape. Watch out for a future build with it. I replaced the crystal with one from a TC which actually, was better! (edge shape, especially). And fortunately the experience prevented me from doing it again.

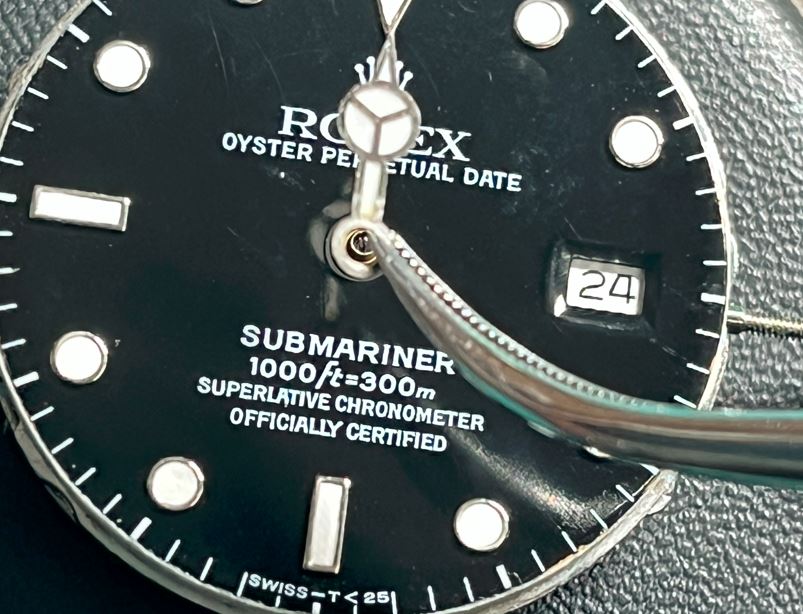

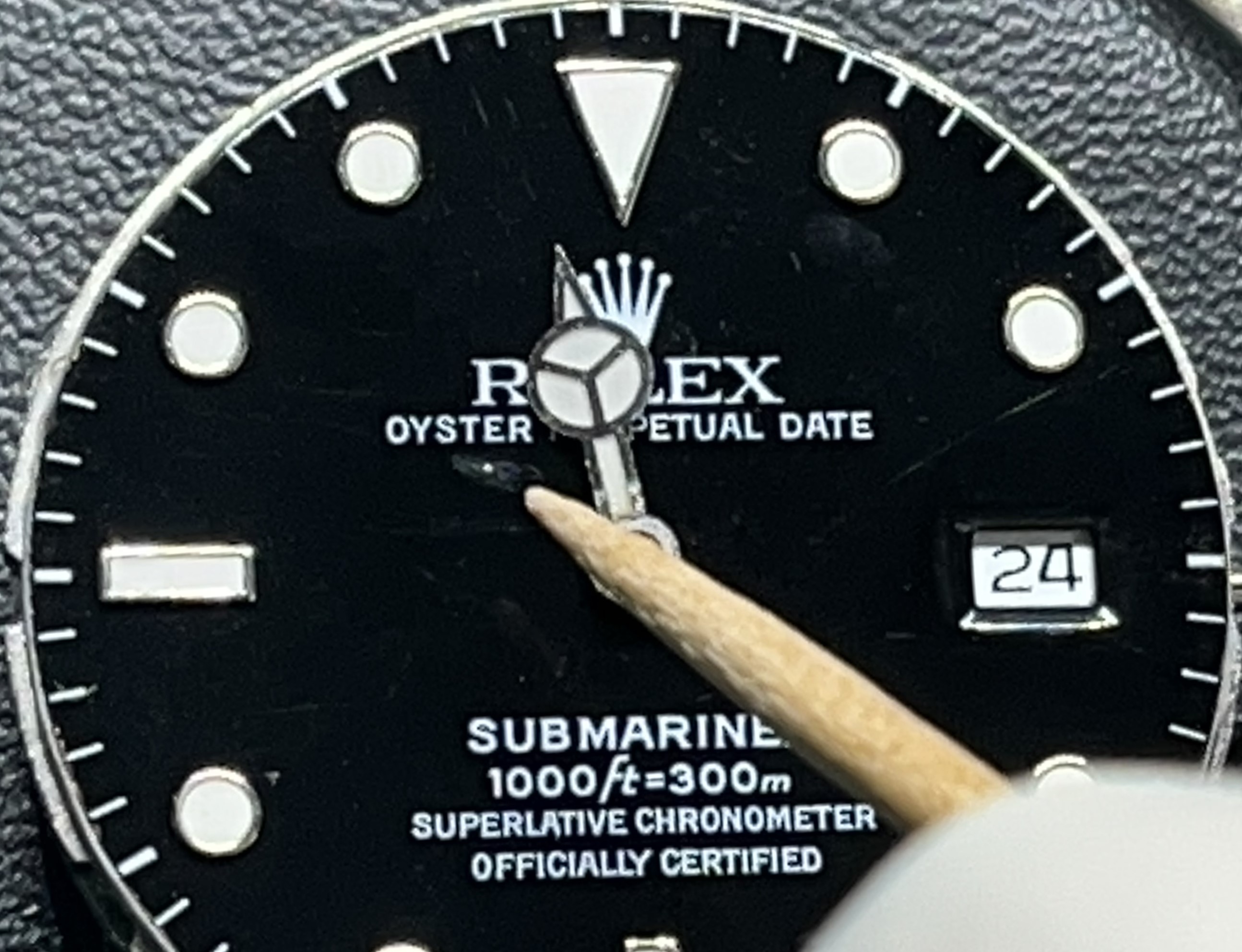

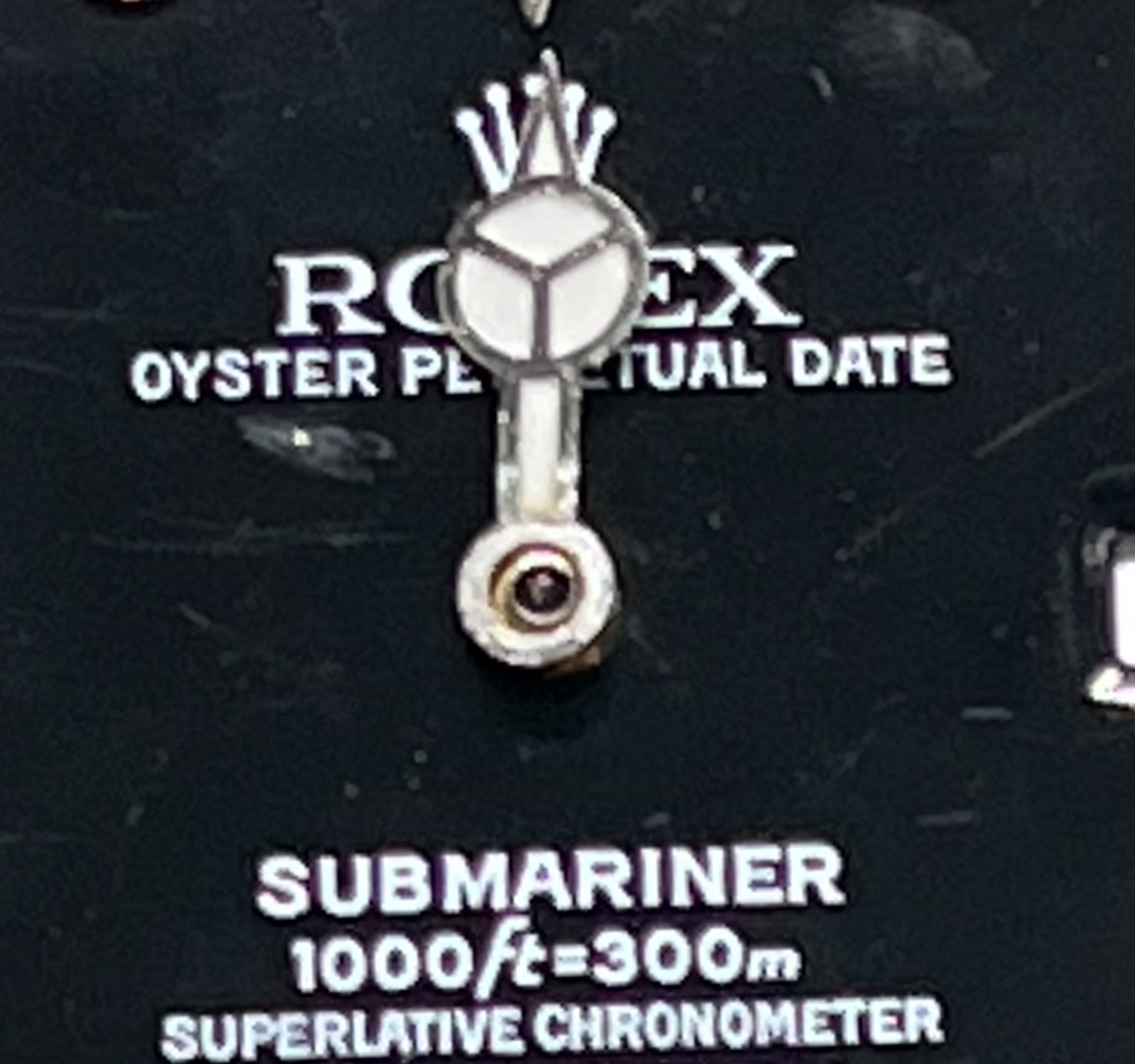

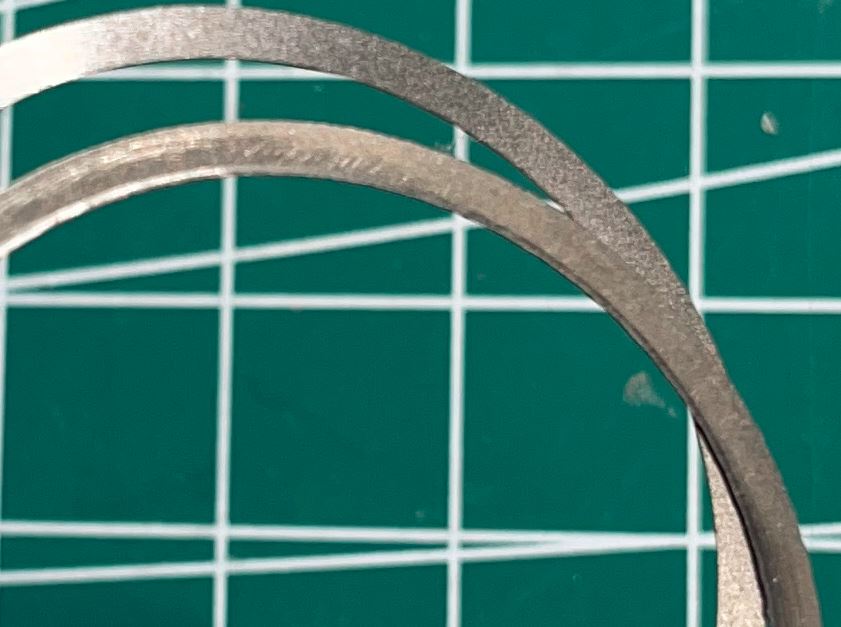

So back to this build - I put the bezel on and it felt rough turning it. I then changed the spring washer as I had anticipated this issue and got new springs as well as gaskets. Check out the quality of the spring washers. The new one is much smoother and very slightly thinner I think, although I didn't measure it.

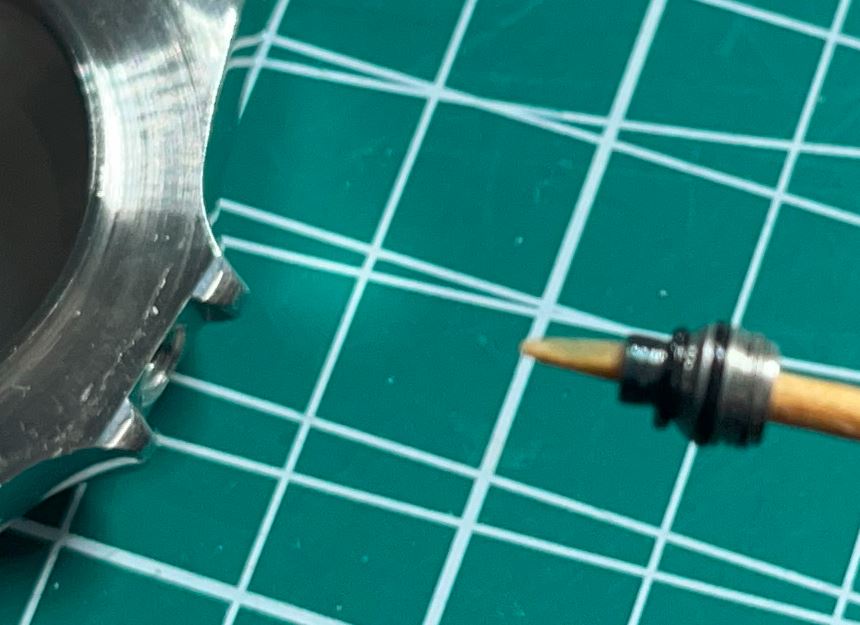

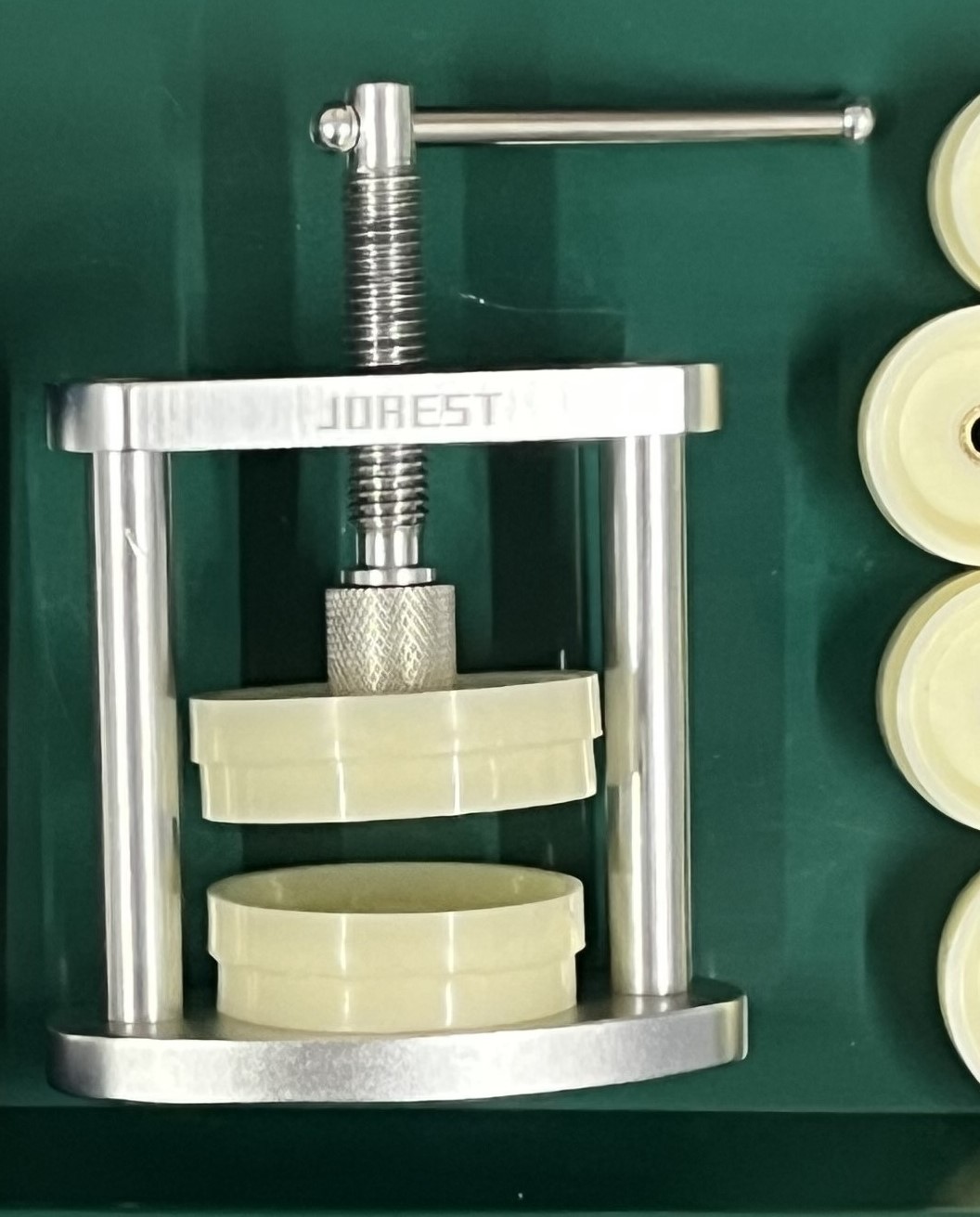

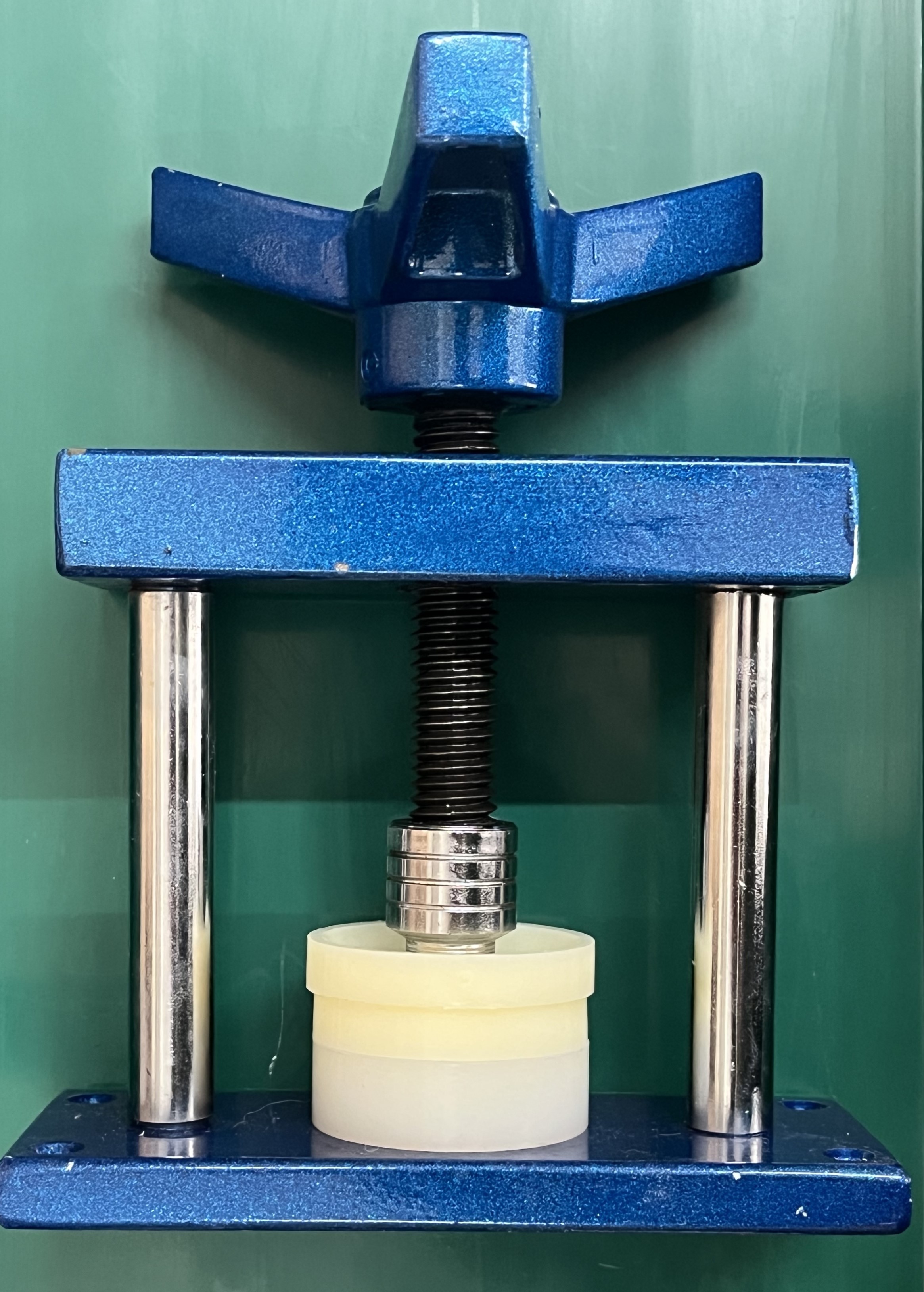

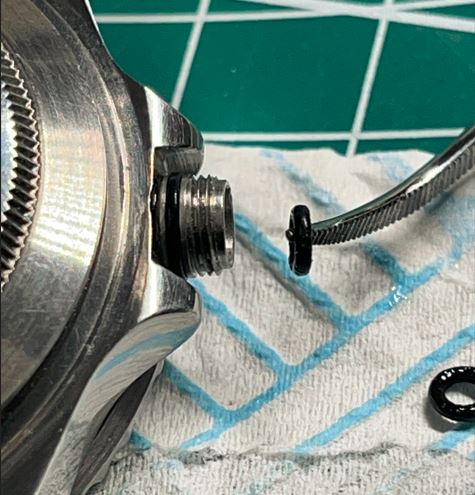

To get the bezel off, a knife edge or similar tool can be put under it, is very easy to get on and off. I put masking tape on the knife to avoid taping the case every time (to avoid scratching it). To get it back on, just press it in place after fitting the click spring, above the spring washer, starting at that side and pushing the opposite side until a satisfying "click" is heard. Have spare click springs because they can go flying sometimes...