-

Tired of adverts on RWI? - Subscribe by clicking HERE and PMing Trailboss for instructions and they will magically go away!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

VSF 126610 Submariner with VS3235 Latest Movement 72 Hours Power Reserve

- Thread starter trustytime

- Start date

I joined this forum 5 years ago with a view to buying a submariner replica. The different versions, dealers and credit card issues all put me off at the time, but I started looking again before Christmas.

I had decided to go for a 3235, but now I’m confused and I’m thinking a 3135 is more reliable? is this the case?

I have not decided which TD to buy from yet. This isn’t easy, but I guess that’s part of the fun.

I had decided to go for a 3235, but now I’m confused and I’m thinking a 3135 is more reliable? is this the case?

I have not decided which TD to buy from yet. This isn’t easy, but I guess that’s part of the fun.

I joined this forum 5 years ago with a view to buying a submariner replica. The different versions, dealers and credit card issues all put me off at the time, but I started looking again before Christmas.

I had decided to go for a 3235, but now I’m confused and I’m thinking a 3135 is more reliable? is this the case?

I have not decided which TD to buy from yet. This isn’t easy, but I guess that’s part of the fun.

My 126610 LN (with 3235) is very reliable. Today I also placed order for LV.

in my opinion 126610 (41mm) is way cooler than boxy 116610. Since I got 41mm sub I can’t force myself to wear 116610.

- 12/3/18

- 37,000

- 77,344

- 113

Hope you find a good fitting one bro, unfortunately chinese movements often lack in the spring parts, too strong, too soft or whatever.. One other reason i could imagine for the wheel not going back in position 1 could be oil or grease on the washer sticking it to the bridge or the crown wheel just enough to take its needed strength, or was it the same after a cleaning ?

This all began after cleaning. I just ran the train bridge and the crown wheel through the cleaner again, and put a little extra oil on the crown wheel shaft. I also put two slight creases in the rep curved washer just outside the shaft and along the long axis. This gave it some shape back. It worked a few times after that and now its failing again. So, currently looking for some suitable workaround parts.

So I'm going to have to find some kind of replacement curved spring washer for the cheap rep part. Or maybe a thinner spacer would work so the rep part doesn't have to provide for as much return travel distance to lower the crown wheel back down.

KJ2020 The ultimate solution should be getting the gen. replacement of this particular part. Any chances at all?

Where did you get all these gen. full balance setup? Care to share your source? And how about their cost?Second balance install went perfectly. These movements run soooooo good with the gen balance and bridge.

With the gen. balance you measure the amplitude with a lift angle of 59°?

This all began after cleaning. I just ran the train bridge and the crown wheel through the cleaner again, and put a little extra oil on the crown wheel shaft. I also put two slight creases in the rep curved washer just outside the shaft and along the long axis. This gave it some shape back. It worked a few times after that and now its failing again. So, currently looking for some suitable workaround parts.

okay, curious to see your solution then bro and thanks again for sharing !!

- 30/12/20

- 517

- 332

- 0

My 126610 LN (with 3235) is very reliable. Today I also placed order for LV.

in my opinion 126610 (41mm) is way cooler than boxy 116610. Since I got 41mm sub I can’t force myself to wear 116610.

I think I’m going to order one from trusty time today. None of the EU/U.K. dealers seem to have any.

Is this the best submariner rep?

Mille M

I'm Pretty Popular

- 24/7/18

- 1,254

- 2,759

- 113

NWBIG! Amazing!

Mine has had nothing but problems, the movement went silent twice. Took it to a watchmaker who 'fixed' the first problem (loose screw and crooked balance or something). After two days, the watch again stopped working, no power reserve, silent movement again. So the second time the watchmaker (for free) had to do some work on the movement in order to get it running again. apparently the wheels got stuck, or something got stuck. The movement, according to him was very fragile. My v2s ran buttery smooth, VR seems better? Maybe I have bad luck. Let's see how long it'll run now. It has lost 25 seconds in the first 24 hours.. But still: what a great looking watch!!

Last edited:

- 13/12/16

- 1,986

- 976

- 113

I was waiting the end of the holidays for place an order, but these movement problems are changing my mind

Inviato dal mio iPhone utilizzando Tapatalk

Inviato dal mio iPhone utilizzando Tapatalk

muiramas

Aristocrat

- 18/1/17

- 6,055

- 7,979

- 113

I was waiting the end of the holidays for place an order, but these movement problems are changing my mind

Inviato dal mio iPhone utilizzando Tapatalk

Most people haven’t had any issues with this movement.

Mille M

I'm Pretty Popular

- 24/7/18

- 1,254

- 2,759

- 113

Mine's on the winder and on rotation almost every week, for over a month now - super accurate and reliable movement.

So far so good!

So far so good!

- 12/3/18

- 37,000

- 77,344

- 113

okay, curious to see your solution then bro and thanks again for sharing !!

I'm sure the gen part (crown wheel and staff) would fix this winding issue but I'm going to try some other things.

Inspired by your suggestion, my latest notion is to add another thin curved spring washer on top of the rep one, oriented in the opposite way. It could just be laid there. Once the crown wheel staff goes through its middle hole and the train bridge is replaced it can't go anywhere.

- 12/3/18

- 37,000

- 77,344

- 113

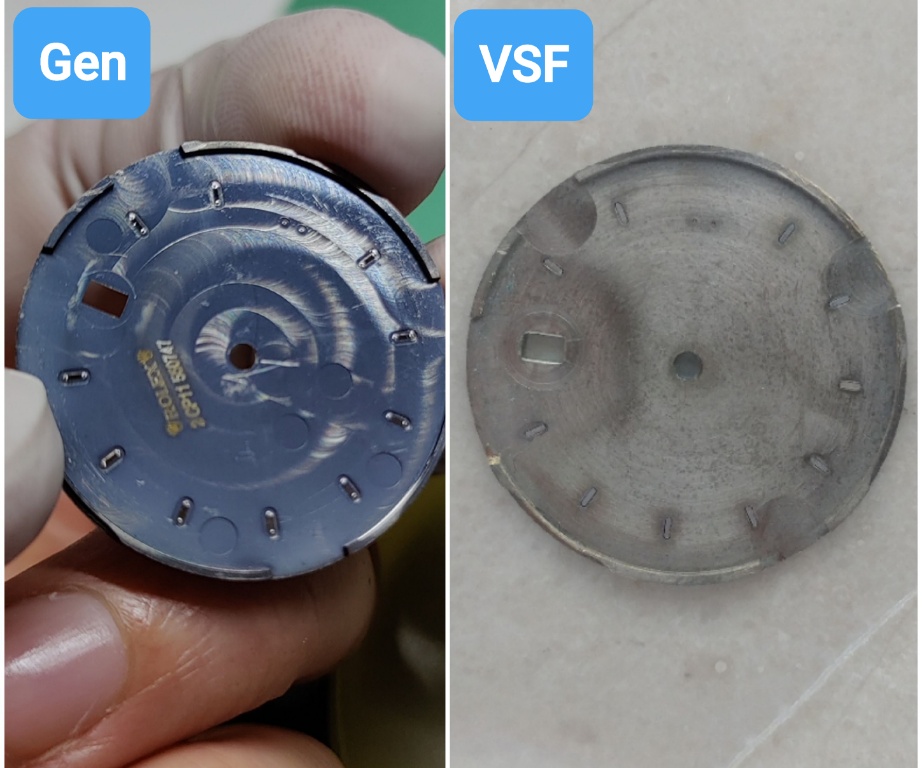

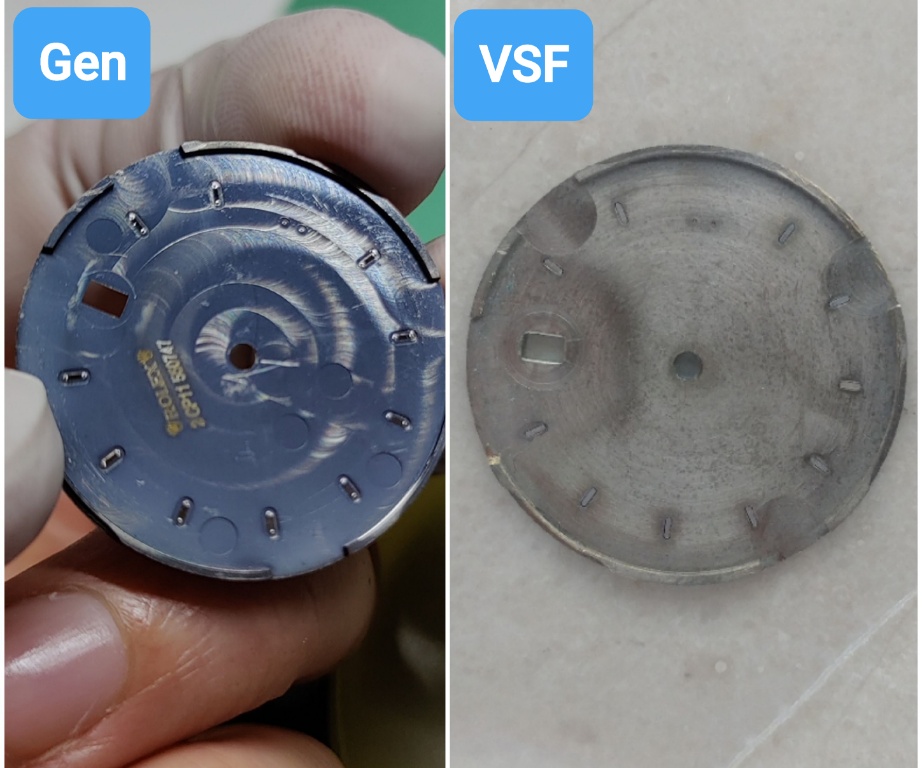

A question came up in the VSF DJ41 thread about replacing the rep dial with one from an earlier generation model. My reply there is relevant here as well so I'm reposting it below.

"The rep VSF DJ41 dials are like the gen DJ41 dials in that there are no dial feet, but there is a non-continious rim on the underside at the edge. This rim hugs the movement with a friction fit and tabs protruding from the movement prevent the dial from rotating in either direction.

Pics are borrowed from other threads

So to use a previous generation dial on the VS3235, you could use dial dots. I've always hated those things, dials can shift laterally which risks paint scraping on the dial edges against the rehaut. This could occur while pulling or pushing the stem. Dial dots are also a PITA when you need to remove the dial for whatever reason as they are super sticky.

The other option would be to drill two holes in the date plate to accommodate the dial feet of the replacement dial. It's possible the dial feet on the replacement dial can't go on the VS3235 in the same place due to other parts of the VSF movement being in the way. So two holes could be drilled anywhere it's clear, and the replacement dial feet clipped and moved (new feet glued on).

However, here comes the real potential rub. I can't speak firsthand about the rep DJ41 dial face, but the rep VSF 126610 dials have a stairstep edge to them (probably like the gen), and the case is cut with a stairstep dial seat to fit the exact dial contour. I had never seen a dial like this before, with the stairstep face edge, and the non-continuous rim underneath, it's a much more elaborate construction than a flat plate dial.

So, if planning to use a flat plate dial, two things have to work:

1. The replacement dial has to fit completely within the very narrow bottom step of the case's stairstep dial seat or there would be a gap between the dial and the rehaut

2. The dial can't have more extra space outside the minute tics than the very narrow width of that bottom step of the stairstep dial seat or you will have displaced (floating) minute tics.

Basically for the Sub, a replacement dial would need to be the same size, and have the same minute tic placement as what's on the upper flat level only of the Sub dial pictured above. A dial could be shaved to those specs but there is precious little room for error.

I had toyed around with the notion of making a 126610 Hulk until I saw the 3235 Sub dial construction and the case grooves. Combined with the dial mounting issues to the movement, it's just not worth it IMO."

Edit: Note that there certainly are folks here capable of this type of precision work. I like to do my own work and can shave a dial but I don't have a lathe and I don't want to ruin my BP Miyota Hulk dial I've been saving for a special build. I guess it's going in the ZZF afterall. The ZZF markers will get swapped over.

"The rep VSF DJ41 dials are like the gen DJ41 dials in that there are no dial feet, but there is a non-continious rim on the underside at the edge. This rim hugs the movement with a friction fit and tabs protruding from the movement prevent the dial from rotating in either direction.

Pics are borrowed from other threads

So to use a previous generation dial on the VS3235, you could use dial dots. I've always hated those things, dials can shift laterally which risks paint scraping on the dial edges against the rehaut. This could occur while pulling or pushing the stem. Dial dots are also a PITA when you need to remove the dial for whatever reason as they are super sticky.

The other option would be to drill two holes in the date plate to accommodate the dial feet of the replacement dial. It's possible the dial feet on the replacement dial can't go on the VS3235 in the same place due to other parts of the VSF movement being in the way. So two holes could be drilled anywhere it's clear, and the replacement dial feet clipped and moved (new feet glued on).

However, here comes the real potential rub. I can't speak firsthand about the rep DJ41 dial face, but the rep VSF 126610 dials have a stairstep edge to them (probably like the gen), and the case is cut with a stairstep dial seat to fit the exact dial contour. I had never seen a dial like this before, with the stairstep face edge, and the non-continuous rim underneath, it's a much more elaborate construction than a flat plate dial.

So, if planning to use a flat plate dial, two things have to work:

1. The replacement dial has to fit completely within the very narrow bottom step of the case's stairstep dial seat or there would be a gap between the dial and the rehaut

2. The dial can't have more extra space outside the minute tics than the very narrow width of that bottom step of the stairstep dial seat or you will have displaced (floating) minute tics.

Basically for the Sub, a replacement dial would need to be the same size, and have the same minute tic placement as what's on the upper flat level only of the Sub dial pictured above. A dial could be shaved to those specs but there is precious little room for error.

I had toyed around with the notion of making a 126610 Hulk until I saw the 3235 Sub dial construction and the case grooves. Combined with the dial mounting issues to the movement, it's just not worth it IMO."

Edit: Note that there certainly are folks here capable of this type of precision work. I like to do my own work and can shave a dial but I don't have a lathe and I don't want to ruin my BP Miyota Hulk dial I've been saving for a special build. I guess it's going in the ZZF afterall. The ZZF markers will get swapped over.

Last edited:

FadeToBlack

Getting To Know The Place

- 25/7/20

- 38

- 31

- 18

I have recently purchased a gen 41mm Sub no date and have done a comparison.

Comparing it to my VSF it is astonishingly close although I have no cyclops to compare that area of the watch.

The few differences i do notice are that the crystal is not quite as clear, the rehaut not slightly less defined, a very slight different hue in the steel,

and the bezel has slightly lighter tension.

Other than these few minor differences the watch is amazingly close esthetically. Over best replica I have personally ever handled.

Comparing it to my VSF it is astonishingly close although I have no cyclops to compare that area of the watch.

The few differences i do notice are that the crystal is not quite as clear, the rehaut not slightly less defined, a very slight different hue in the steel,

and the bezel has slightly lighter tension.

Other than these few minor differences the watch is amazingly close esthetically. Over best replica I have personally ever handled.

- 25/3/17

- 4,414

- 3,922

- 113

.....a very slight different hue in the steel,

Why? Rep SS is it different?

FadeToBlack

Getting To Know The Place

- 25/7/20

- 38

- 31

- 18

Why? Rep SS is it different?

Chances are they are not using exact same 904 steel as Rolex. To be honest i can only tell the ever so slight difference with the gen side by side.