- 28/2/17

- 2,401

- 1,977

- 113

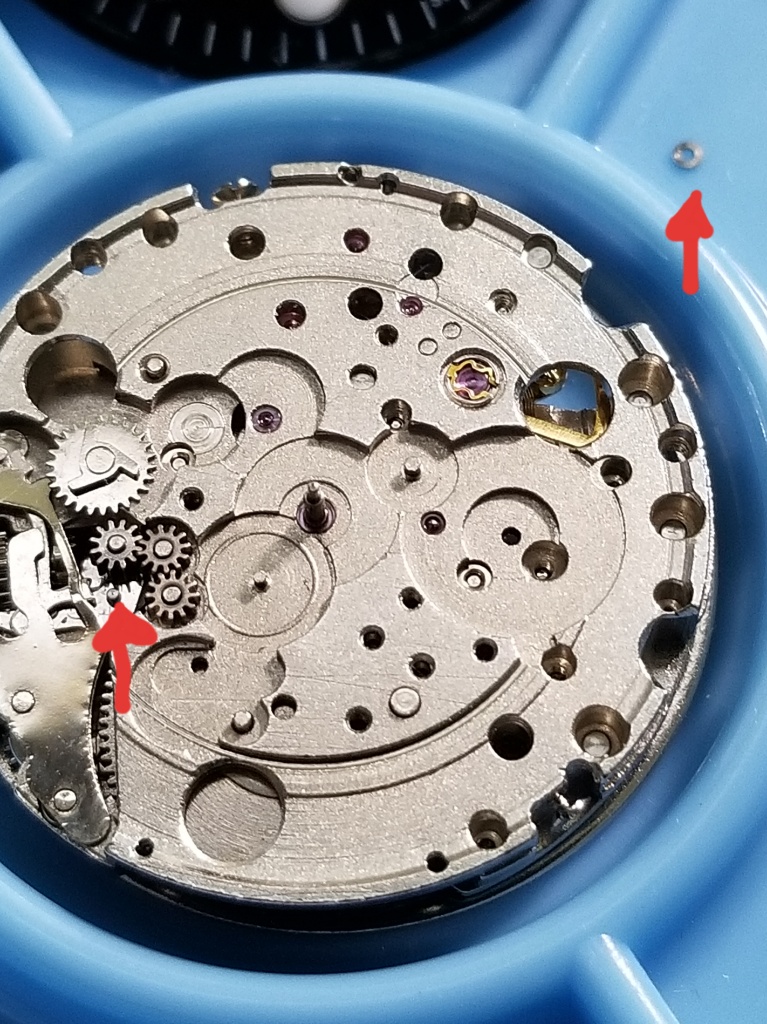

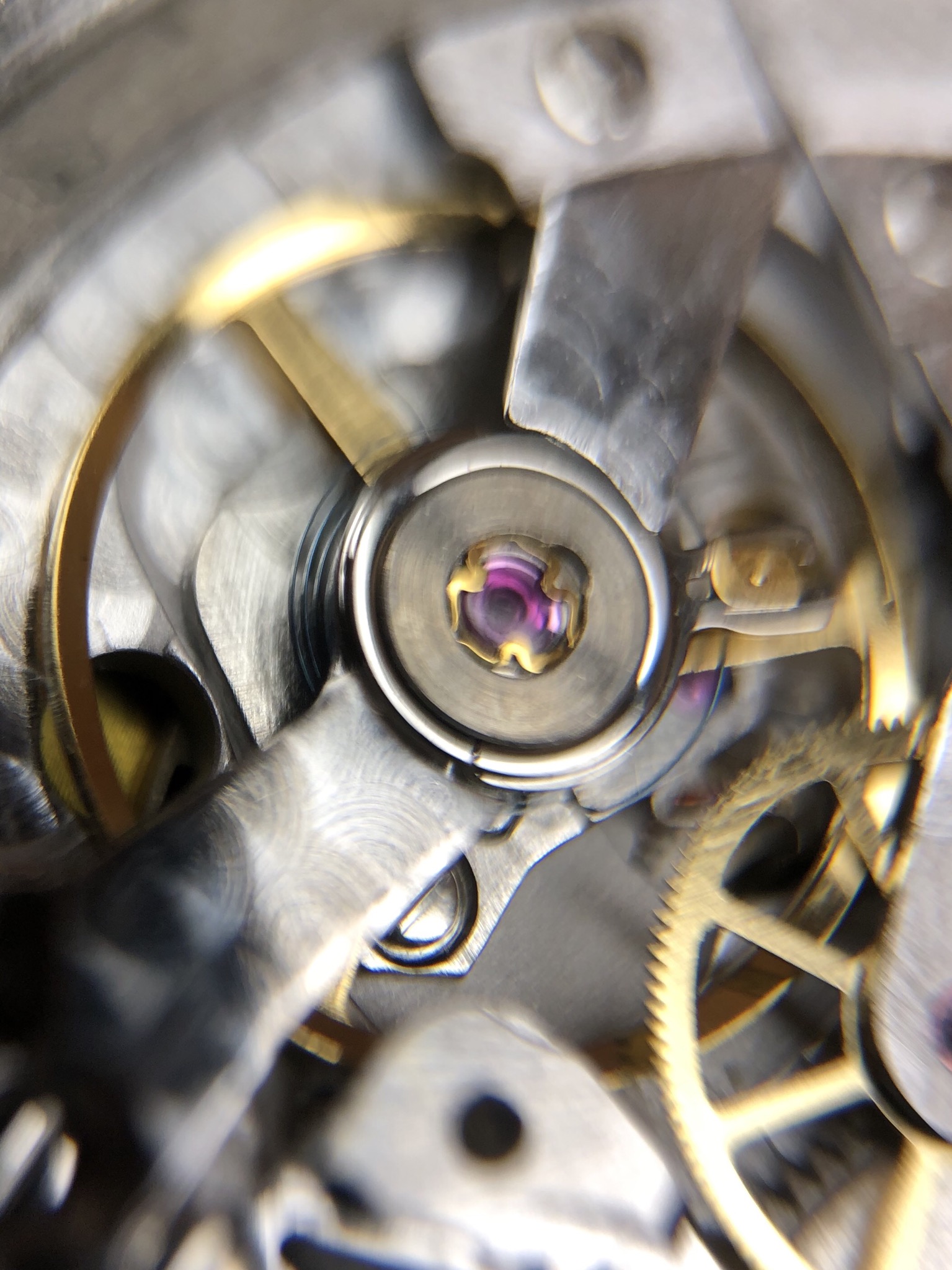

Well we see where they got the idea from. Could always break that spindle off the 2824 movement and drill a little hole in the plate, haha.

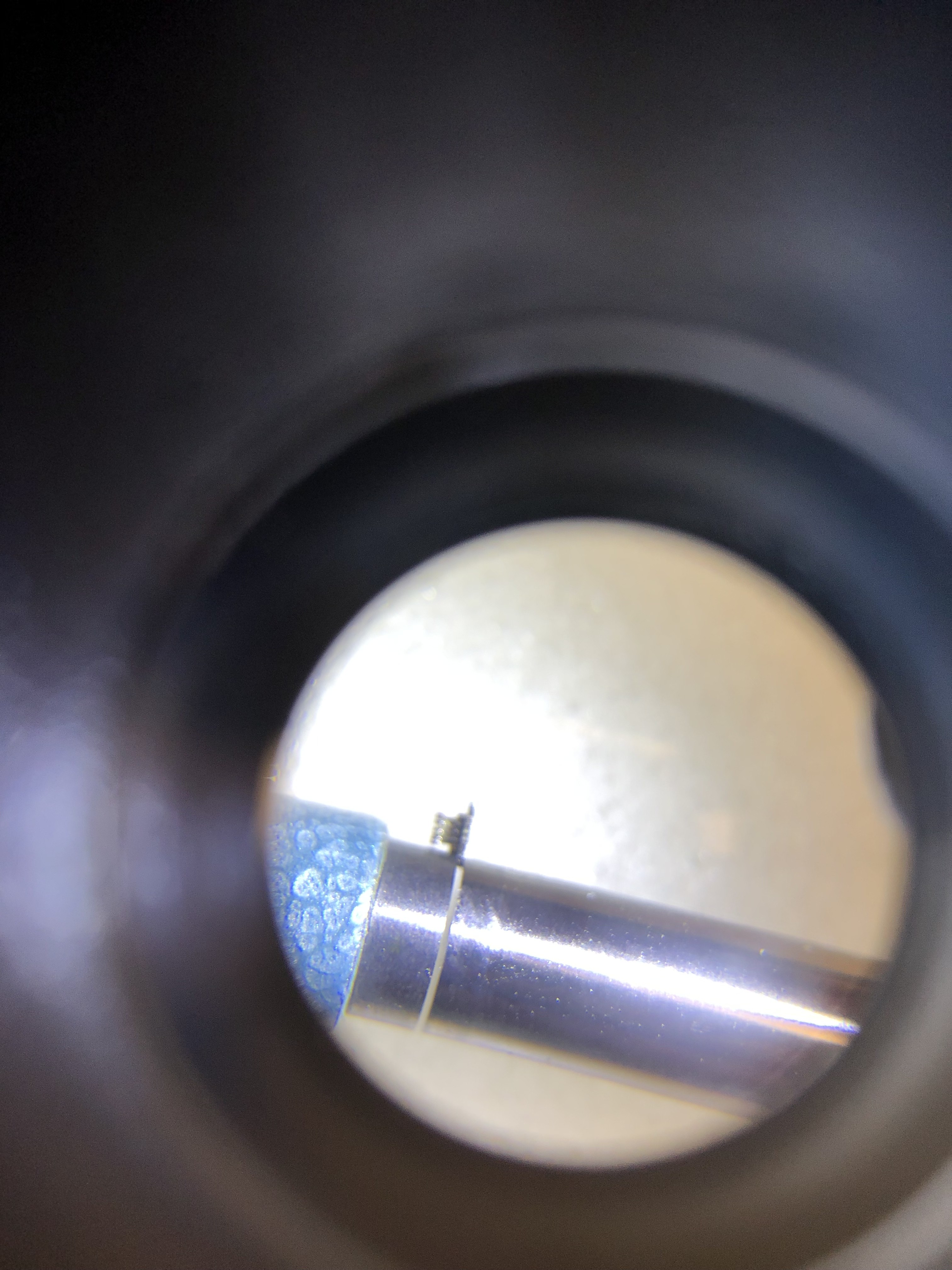

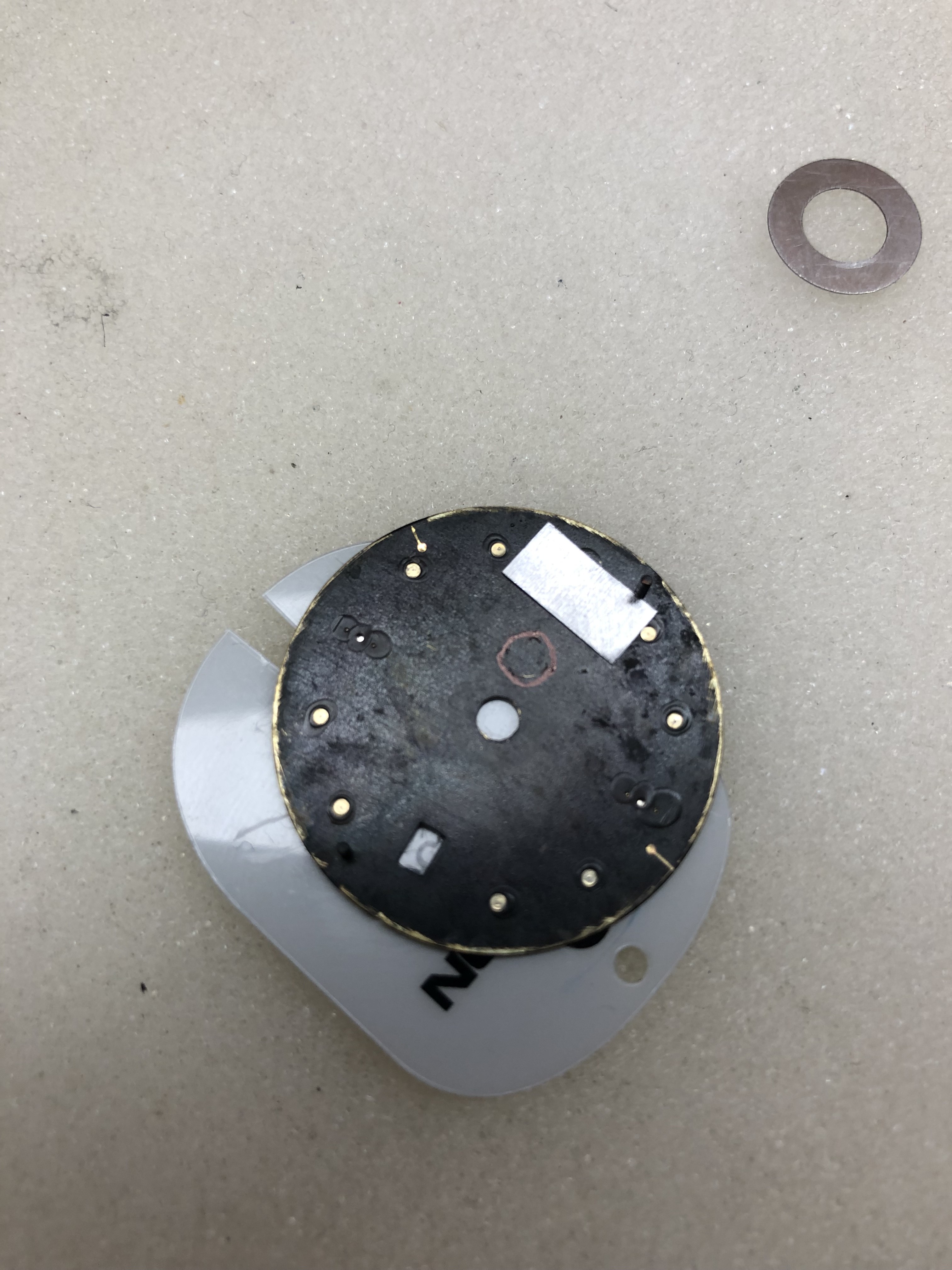

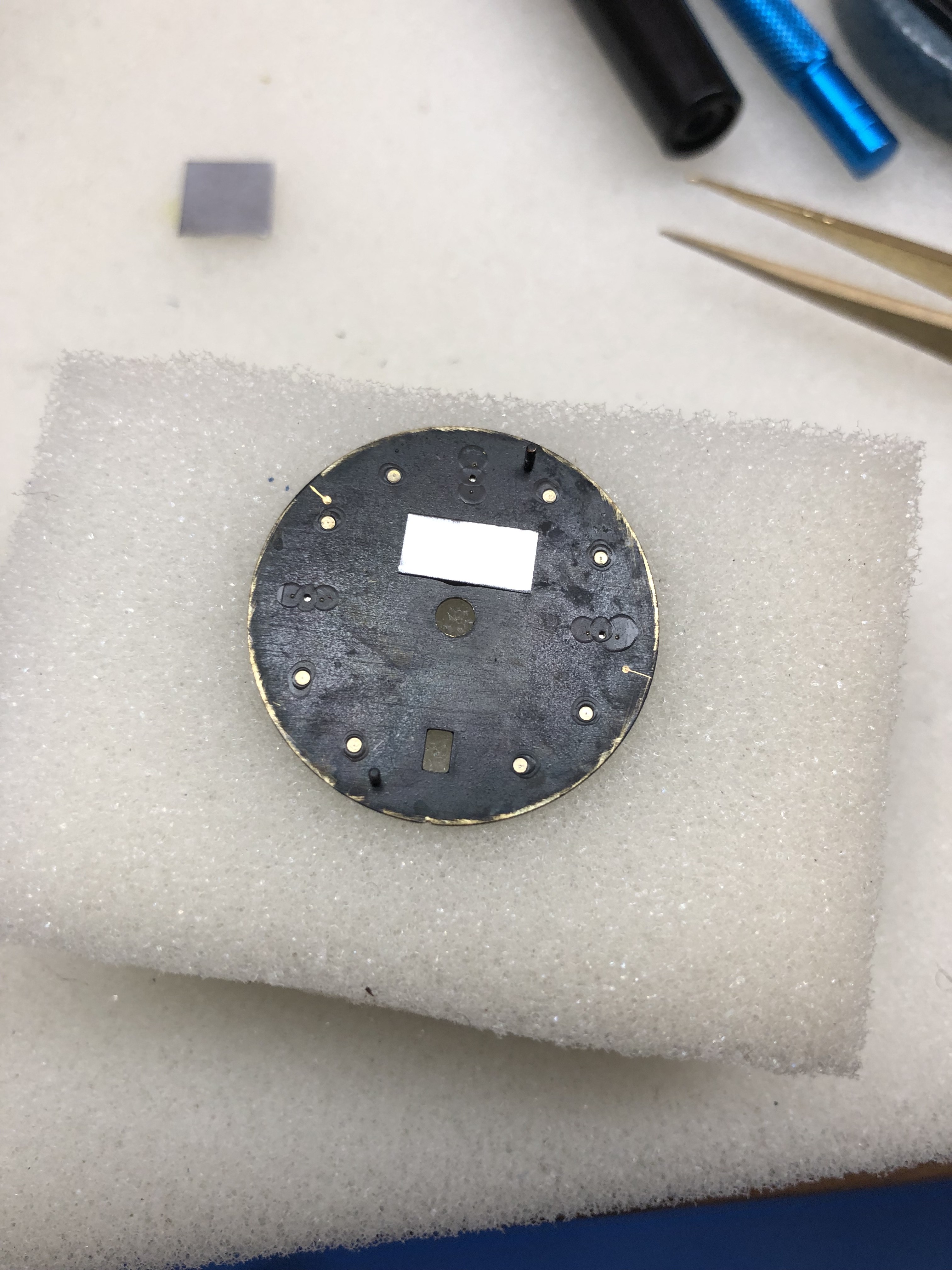

Haha i like the idea but id rather buy a whole new bloody watch and sell the bits i dont need for that kind of money! On a side note im 99% sure the issue with my movement is that the intermediate date wheel is rising up. As before gmt and minute hands have kept time, the hour stopped at 7 last night and still hasnt moved, and neither has the date. Going to try and work out the distance from the underside of the dial and shim the hell out of it.