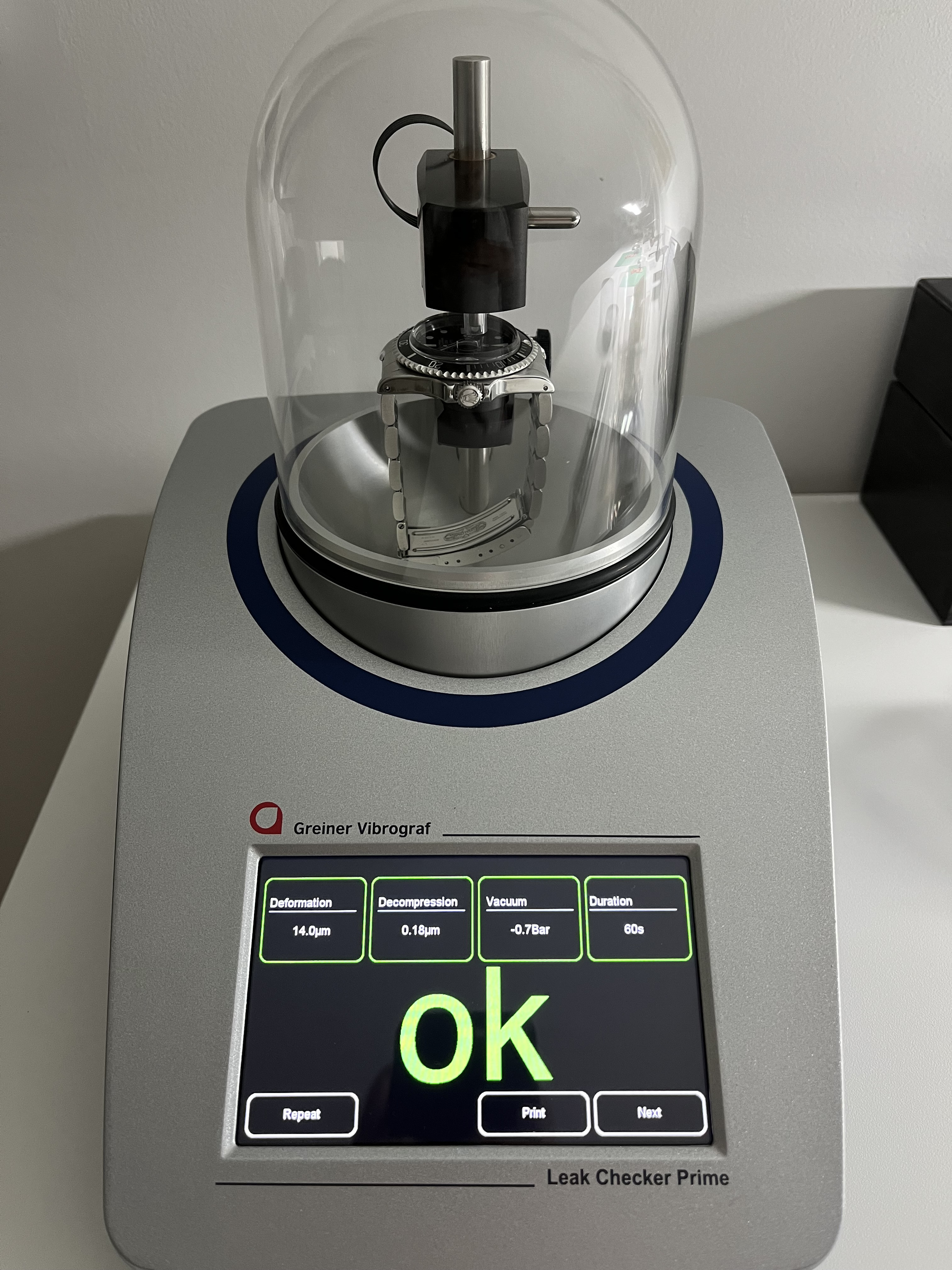

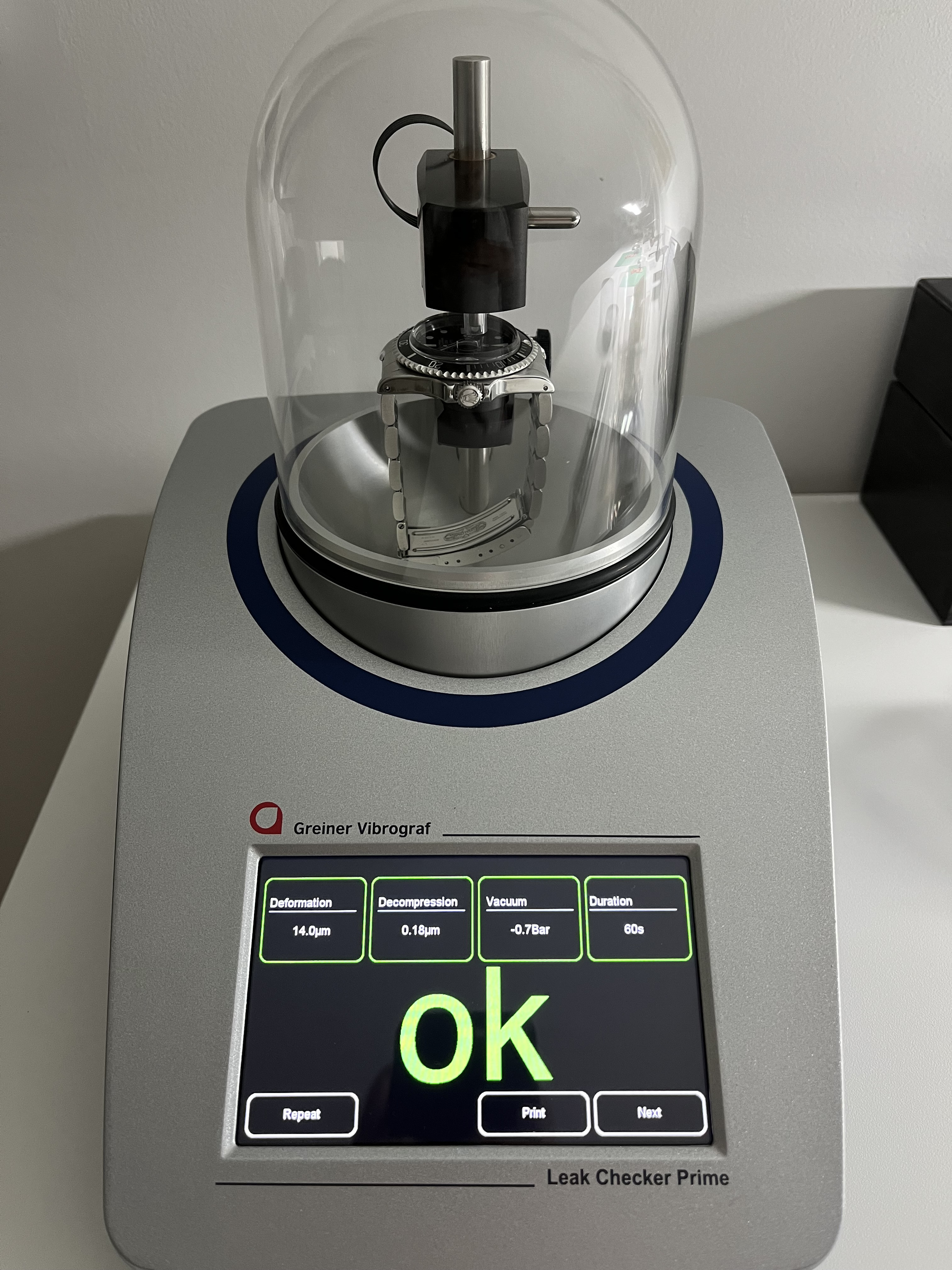

As I got a new toy, I wanted to do a bit of digging into the subject. I will continue wet testing on some of my watches for reference purposes.

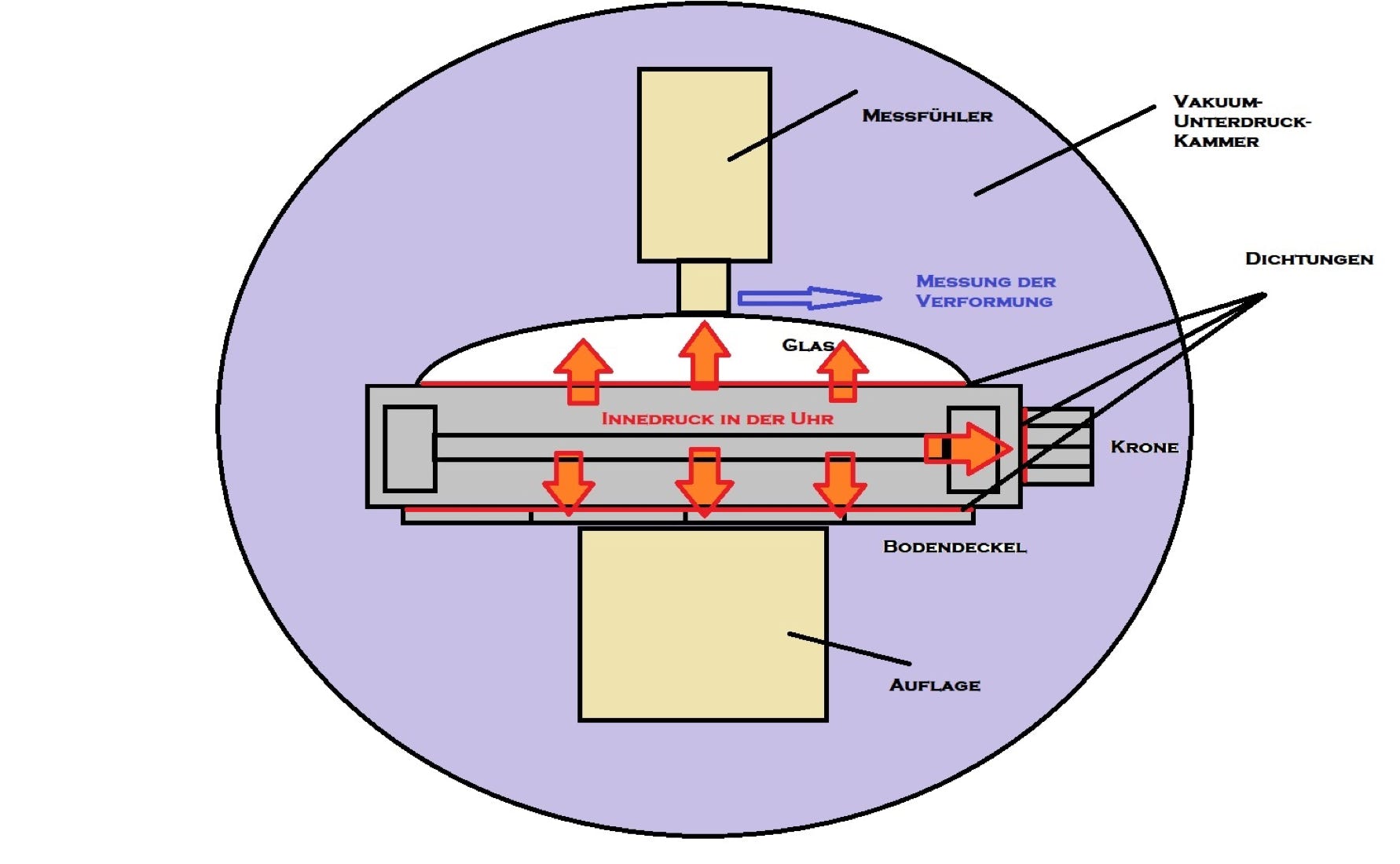

The vacuum-negative pressure method (min 100 mbar - max 700 mbar negative pressure) is a so-called dry pressure test and is therefore carried out without the addition of water in a so-called rough vacuum (1 mbar - 1,013 mbar).

As can be seen in the graphic, the watch is placed on a support in a vacuum chamber. Then the sensor is adjusted. A negative pressure (vacuum) is now generated in the chamber. Due to the watch's own pressure, the case begins to deform in the micrometer range (see orange arrows). Pressure is exerted from the inside outwards on the bottom lid, the glass and the crown.

The weak points are always the seals (shown in red).

If the watch keeps the deformation in the vacuum, the watch is waterproof. If the deformation decreases or the watch does not deform at all, the watch is leaking.

In the process, different negative pressures are always used in ascending order (depending on the deformability of the watch). If the watch deforms too much, the measurement is aborted and repeated with less pressure. This is how the tightness of the watch is determined.

This method is beneficial since the housing is pressed out of the seals at higher internal pressures (the seal opens earlier, which means that a leak can be detected more quickly). In contrast, with the overpressure process, the watch is compressed (pressed into the seals), which in extreme cases can lead to the glass breaking/popping out.

For everyday watches, the vacuum-low pressure method is completely sufficient, since, for example, -0.7 bar low pressure (rough vacuum) measures roughly the same tightness as the 10 bar overpressure test. (Stated, I’m still to check the math).

The vacuum test corresponds to normal stresses on the watch during wearing, showering, swimming and snorkelling.

Special diving watches (more than 10 bar tightness) should be tested in both procedures due to the changing pressure conditions during diving.

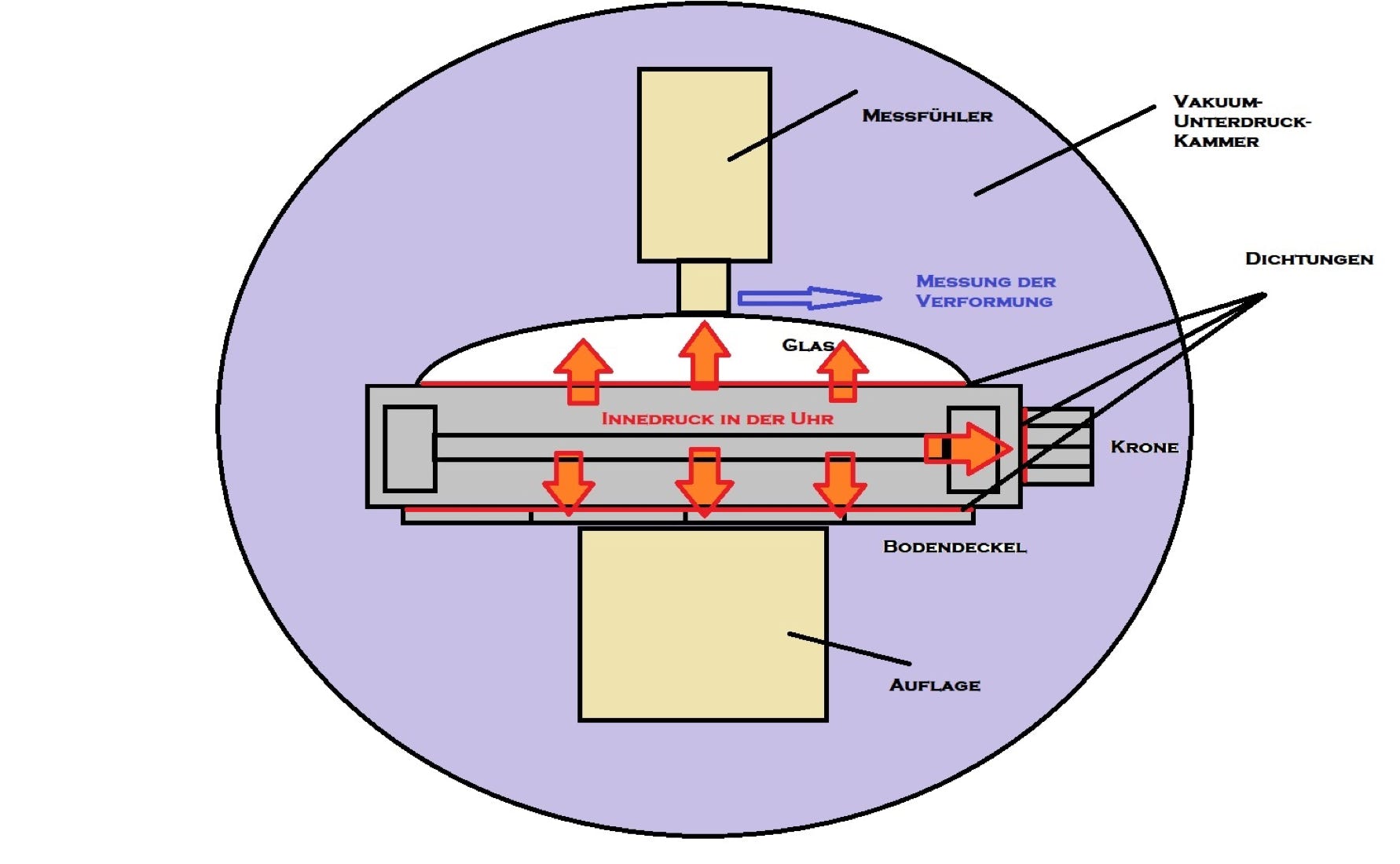

The vacuum-negative pressure method (min 100 mbar - max 700 mbar negative pressure) is a so-called dry pressure test and is therefore carried out without the addition of water in a so-called rough vacuum (1 mbar - 1,013 mbar).

As can be seen in the graphic, the watch is placed on a support in a vacuum chamber. Then the sensor is adjusted. A negative pressure (vacuum) is now generated in the chamber. Due to the watch's own pressure, the case begins to deform in the micrometer range (see orange arrows). Pressure is exerted from the inside outwards on the bottom lid, the glass and the crown.

The weak points are always the seals (shown in red).

If the watch keeps the deformation in the vacuum, the watch is waterproof. If the deformation decreases or the watch does not deform at all, the watch is leaking.

In the process, different negative pressures are always used in ascending order (depending on the deformability of the watch). If the watch deforms too much, the measurement is aborted and repeated with less pressure. This is how the tightness of the watch is determined.

This method is beneficial since the housing is pressed out of the seals at higher internal pressures (the seal opens earlier, which means that a leak can be detected more quickly). In contrast, with the overpressure process, the watch is compressed (pressed into the seals), which in extreme cases can lead to the glass breaking/popping out.

For everyday watches, the vacuum-low pressure method is completely sufficient, since, for example, -0.7 bar low pressure (rough vacuum) measures roughly the same tightness as the 10 bar overpressure test. (Stated, I’m still to check the math).

The vacuum test corresponds to normal stresses on the watch during wearing, showering, swimming and snorkelling.

Special diving watches (more than 10 bar tightness) should be tested in both procedures due to the changing pressure conditions during diving.

Last edited: