Edit: I redid the pearl pip using UV light curing resin. Though I loved the first result. Would not last swimming or getting impact hit on the bezel.

Let's Resin = brand. Same viscosity as varnish. Once complete shine UV light for 2-4 min and it turns to hard resin.....

Bezel Pip Lume Change:

Is this the correct area to post this? I am not sure but it is the VSF Pam1074.

I did it myself and changed the bezel pip to hopefully match the dial. I will post pictures down below and of course might include extra info that can annoy some and help others.

1st is a picture of tools used listed below with other not pictured info.

- C3 TriTec Lume & A60 TriTex Varnish. Was going to use clear epoxy but went TriTec route.

- Paint is Revell acrylic orange (aqua color). *Did not stir. I wanted the thin watery coat on top. Thick paint settles down to bottom of container.

- Scale. 1:1 ratio on weight. 0.15 grams of Lume and A60 varnish (changed to UV cure resin) was plenty.

- Metal Pick for for taking out old lume. Not in these photos. Patiently kept dipping back of a toothpick in acetone then scratching with pick. Once halfway I pressed pick in and pried it out. Then used pick for cleaning excess lume thinly covering the inside.

- Oiler I used for mixing lume & varnish (resin) then paint.

- Syringe. I used for applying the lume inside.

- Painters tape with hole punch (2mm). This was an idea I had to keep from getting bezel messy. Glad I did it.

- Powder spoons and mixing tray that came in a kit. Good for getting correct weight of lume powder.

- Table mounted magnifying lens with a ring/halo light attached.

Taped the bezel (below)

First paint mixture seen below. I barely dipped my oiler in the Revell orange paint and mixed in circular motions. End up dipping twice to get this color. Pic looks like blue emission, but trust me it is green. Light from magnifying lens made for a bad photo.

Seeing I did not fill the bezel pip enough, I thought I could go one shade darker. Below is pic of a third very small dip of the oiler in the Revell paint. I used the syringe and added the slightly darker shaded lume into the bezel pip/pearl. Under a magnifying lens I can slightly see I have some orange acrylic paints specs in the center. I cannot see this orange without a magnifying lens.

Below is the finished watched after drying/curing over night. Will let cure a couple days and not in a rush to wear it. Below this pic I will link a youtube video that used the same paint for same color... And any other info or tips that might help.

Helpful youtube video that gave me confidence to do this.

Extras:

- Practice beforehand helps.

- Don't rush. The varnish is easier to work with when it dries a bit (10 to 30min depending on how much lume/varnish you made). You will see it's consistency on your oiler, needle, syringe that you are using.

- Had some cleanup. About 1/5th of the pip top edge got a bit of lume residue. I used the back of a toothpick to scrape off. A plastic flat surface can be used too. The tape helped make sure I did not get an accidental drop spill.

- Varnish first --> then add powder.

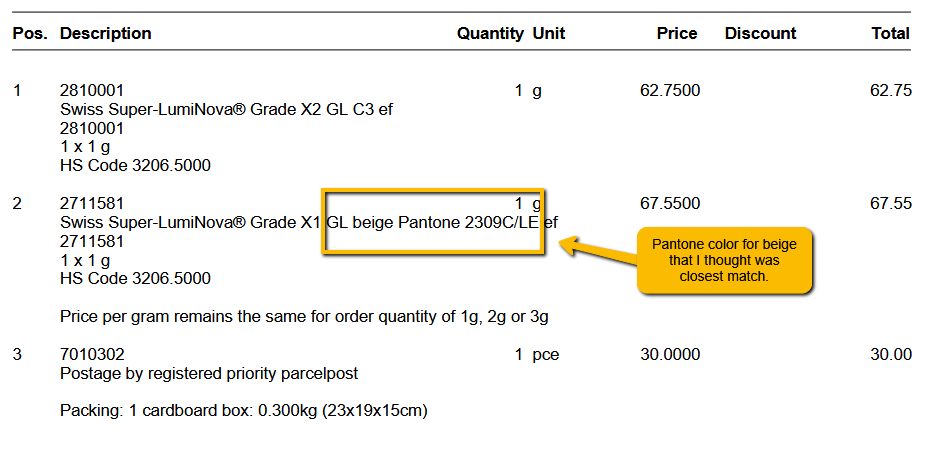

- I bought the C3 Lume, A60 ( & A61 dilutor) on ebay. Think it might be Standard Grade or Grade A. Below is a screenshot if you choose to buy direct from TriTec with beige color. Not sure of end result of this color since I have not used. Just looked very close to accurate on my computer screen. I am also not sure if you need to buy both listed or just the Grade X1 "GL Beige Pantone 2309/LE". Of course they will not tell me color used on Pam1074. If anyone knows please share and it can help someone else get brighter lume. Adding even the smallest, super small amount of paint takes away from lume glow brightness.

- Don't buy cheap lume or already made lume in syringe. I practiced with this type mixing different paint colors. Lume brightness is very short and it will not last on exterior of watch. Not sure what type of binder they use.

Question to anyone skilled at this. Will the varnish hold up on the exterior of the watch? I have seen some people use clear epoxy as a binder or mix in with varnish.

I think A60 = Acryl 60 used to make concrete more waterproof such as swimming pools. If this is Acryl 60 TriTex is selling then they are making a large profit margin. 4 Liters costs $22. I could be completely wrong.

That is it. Long post.