- 21/1/25

- 9

- 8

- 3

Hopefully this is.the correct forum for this topic, and plz let me if it would be more appropriate elsewhere, and ill move it...

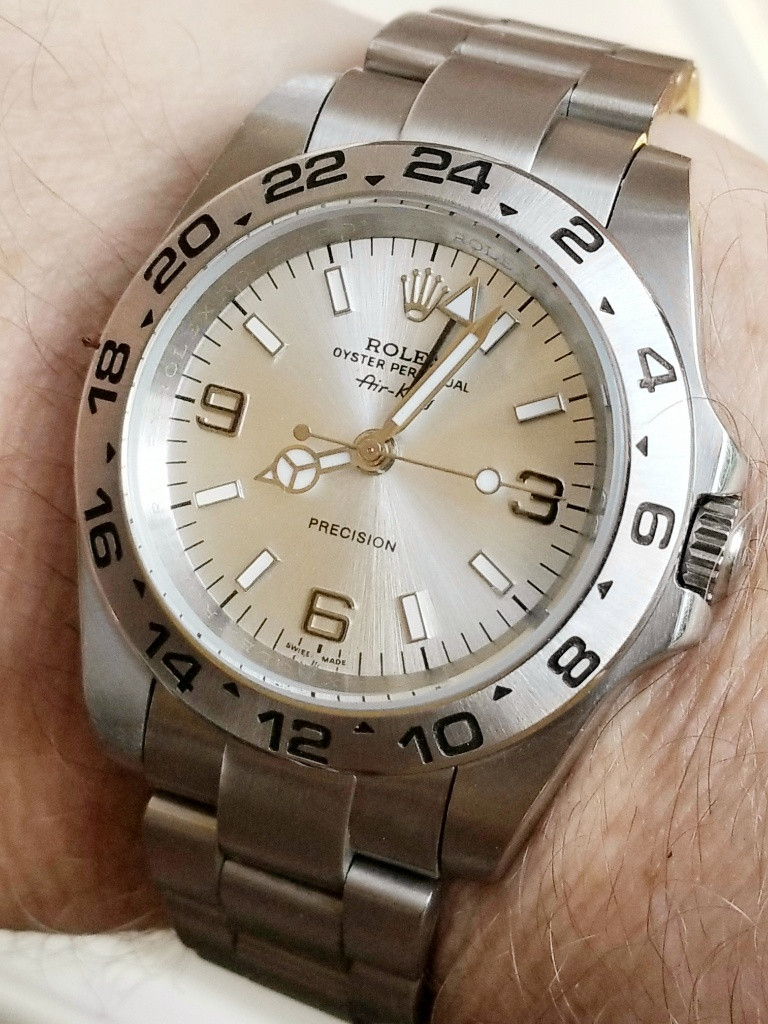

As the title suggests, im.seeking guidance/how-to/tutorials on how to cut those amazing levels on the top (vertically from lug to lug) of vintage Rolex and Tudor Submariner, Sea Dweller, and GMT cases. (Im prob leaving out some ref #s, but that's all I could think of at the moment).

I've seen a myriad of sizes and shapes, some DEEP and WIDE, some delicate and barely visible, and, for the life of me, i cannot visualize any method other than filing by hand to make those cuts, and I know i would have one hell of a time cutting them into some side of the case, and then trying to match the size/shape on the alternate side, mirror image style. It would drive me (and my ocd) crazy, and come out looking like shit.

Does anyone know a method to get the job done with a dremel or other tools? The only answer I've come across so far is to use a "lapping" machine, and when i did a little research into lapping, I can't see how it could be done.

The only watchbuilder/modder that I've been referred to is a gentleman called DBANE, and I've seen pics of some of his case work, and its pure artistry. I haven't been able to locate him (heard he moved on from reps to 100% gens) or any other modders that could help me either find DBANE or another case magician, willing to give it a go, or pass.on the recipe for their secret sauce.

Any ideas?

As the title suggests, im.seeking guidance/how-to/tutorials on how to cut those amazing levels on the top (vertically from lug to lug) of vintage Rolex and Tudor Submariner, Sea Dweller, and GMT cases. (Im prob leaving out some ref #s, but that's all I could think of at the moment).

I've seen a myriad of sizes and shapes, some DEEP and WIDE, some delicate and barely visible, and, for the life of me, i cannot visualize any method other than filing by hand to make those cuts, and I know i would have one hell of a time cutting them into some side of the case, and then trying to match the size/shape on the alternate side, mirror image style. It would drive me (and my ocd) crazy, and come out looking like shit.

Does anyone know a method to get the job done with a dremel or other tools? The only answer I've come across so far is to use a "lapping" machine, and when i did a little research into lapping, I can't see how it could be done.

The only watchbuilder/modder that I've been referred to is a gentleman called DBANE, and I've seen pics of some of his case work, and its pure artistry. I haven't been able to locate him (heard he moved on from reps to 100% gens) or any other modders that could help me either find DBANE or another case magician, willing to give it a go, or pass.on the recipe for their secret sauce.

Any ideas?